Escolar Documentos

Profissional Documentos

Cultura Documentos

M.tech. Chemical Engineering Syllabus

Enviado por

vkpaithankarDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

M.tech. Chemical Engineering Syllabus

Enviado por

vkpaithankarDireitos autorais:

Formatos disponíveis

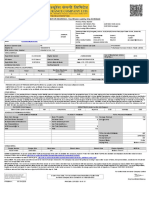

DEPARTMENT OF CHEMICAL TECHNOLOGY NORTH MAHARASHTRA UNIVERSITY, JALGAON SYLLABUS FOR M. TECH.

(CHEMICAL ENGINEERING)

First Semester Sub. No. Paper Teaching Scheme Hrs/ Week Examination Scheme Marks Internal CH: 1.1 CH: 1.2 CT: 1.1 CH: 1.4 CH: 1.5 Chemical Engineering Modeling and Optimization Heat, Mass and Momentum Transfer Modern Methods Instrumental Analysis Instrumental Analysis Engineering Lab. ( PR ) of 03 & 06 03 Total : 18 40 40 200 60 60 300 100 100 500 3 3 15 40 60 100 3 External Total Credit

03

40

60

100

03

40

60

100

Process Dynamics and Control

Second Semester Sub no. Teaching Scheme Hrs/week 03 03 03 03 03 03 03 03 03 15 Examination Scheme Marks Total Internal CH: 2.1 CH: 2.2 CH: 2.3 CH: 2.4 CH: 2.5 CH: 2.6 CH: 2.7 PT: 2.3 NT: 2.2 Mass Transfer with Multiphase System Reaction Engineering and Nano Catalysis Chemical Equipment Design Pollution Control in Chemical Industries Membrane separation operations Modern Methods of Extraction Biochemical Engineering Polymer Reaction Engineering Science & Technology of nano-medicines Total : 40 40 40 40 40 40 40 40 40 200 External 60 60 60 60 60 60 60 60 60 300 100 100 100 100 100 100 100 100 100 500 3 3 3 3 3 3 3 3 3 15 Credit

Paper

Note:- CH-2.1, CH-2.2, CH-2.3 are compulsory. Select any two papers out of CH-2.4, CH-2.5, CH-2.6, CH- 2.7, PT- 2.3 and NT- 2.2 Third Semester Examination Scheme Internal 100 80 External 100 120 200 Grand Total 300 5 10 15 Total Marks Credit

Sub. No.

Paper

Teaching Scheme Hrs/week 10 20

CH:3.1 CH:3.2

Seminar Project

Fourth Semester

Sub. No.

Paper

Teaching Scheme Hrs/week 30

Examination Scheme Internal External

Total Marks

Credit

CH: 4.1

Project

120

180 300 Grand Total 300

15 15

UNIVERSITY DEPARTMENT OF CHEMICAL TECHNOLOGY NORTH MAHARASHTRA UNIVERSITY, JALGAON M.Tech. Chemical Engineering Admission Candidates holding B.Tech./ B.E. degree in Chemical Engineering or Chemical Technology with 55 % marks or any equivalent degree recognized by North Maharashtra University, Jalgaon shall be eligible for admission to M. Tech. (Chemical Engineering). Relaxation for the reservation candidates shall be as per norms. Preference will be given to candidates holding valid gate score. Notes:1. The students of M. Tech. Course will have to attend 80% of lectures, practical and any other term work as may be prescribed by the university. The conduct and behavior of the student must satisfy the Head of the Department. 2. The Head of the Department will certify that the student has attended the course as prescribed and has conducted himself satisfactorily. In absence of such certificate, the student shall not be permitted to the University Examination. 3. The University examinations for all the terms shall be conducted at the end of the term. 4. The student shall have to appear personally to all parts of the examination. 5. The credit structure is based on M. Tech. credit guidelines sanctioned by University Academic Council

FIRST SEMESTER

CH-1.1

Chemical Engineering, Modeling and Optimization

3 hrs/week Credit = 3

Basic Modeling: Introduction to Modeling: Application & scope of coverage, Modeling Fundamentals, Chemical Engg. Modeling, Several Aspects of Modeling approach, General Modeling procedure, simulation tools, ISIM. Formulation of dynamic Models: Mass balance equation, balancing procedure, case studies, CSTR, Tubular reactor, Coffee percolator. Total mass balances: case studies, tank drainage etc. Component balance case studies, waste holding tank, Extraction from solid by solvent. Energy balance: Continuous heat mean agitated tank, heating in a filling tank, parallel reaction in semi, continuous reactor with large temperature differences. Momentum balances: Dimensionless model equation, CSTR, Gas-Liquid mass transfer in a continuous tank reactor. Chemical Kinetics: General modeling scheme, Liquid phase CSTR, Radical kinetics, Heterogeneous kinetics. Modeling of stage wise processes: Introduction, Stirred tank reactors, Configuration, Generalised model description, Heat transfer to and from reactors, Steam heating in jackets, Dynamics of the metal jacket wall, Batch reactor: Constant volume, semi batch. CSTR: Constant volume CSTR, CSTR cascade, Dynamic modeling: Plug flow reactor, Plug flow reactor contactors, Liquid-Liquid extraction column dynamics, Heat Exchanger dynamics. Optimization: Salient features of Optimization, Classification, Process optimization using different techniques such as linear programming and dynamic programming, optimization of multistage process. Reference Books: 1. C. L. Smith, R. N. Pike & P. W. Murill, Formulation optimization of Mathematical International text, Pensylvania (1970) 2. W. L. Luyben, Process Modeling Simulation and Controls for Chemical Engineers, Mc. Graw Hill Book Co. 3. John Inghan, Irving J, Dunnl Elmar, Henizle Jiri, E. Pernosil: Chemical Engineering Dynamics, VCH Publisher Intenatioal Inc. New York USA. 4. Klaus Hartmann, Klaus Kaplick: Analysis & Synthesis of Chemical Process Systems, Elsevier Science Publisher International New York, USA. 5. Roger G. E. Franks : Modeling & Simlation in Chemical Engineering, Wiley Interscience, New York USA . 6. Himmelblau D.M. Bischoff K. :Process system analysis and simulation. 7. Beveridge G.S.G.Schechter R.S.:Optimization theory and practice. 8. Aoki M. Macmillon : Introduction to optimization technique.

CH: 1.2

Heat Mass and Momentum Transfer

3 hrs/week Credit = 3

Equation in change in Isothermal, Non-isothermal and Multi component system. Mechanism of momentum, heat and mass transfer. Mass transfer and Heat transfer Boundary layer flow in laminar and turbulent flow. Numerical based on it. Relation between Hydrodynamic boundary layer and Concentration boundary layer, thermal boundary layer, Numerical based on it. Mass transfer and Heat transfer fully developed flow for different profile. Analogy based on mass, heat and momentum transfer Numerical based on it. Diffusional mass transfer Condensation and Boiling, Numerical based on it Inerphase mass transfer in binary and multistage system. Macroscopic balances for isothermal and Non isothermal Systems. Reference Books: 1) Transport Phenomena by R. Byron Bird, Warren E. Stewart Edwin N. Light foot 2) Transport process and Unit Operation by Christie J. Geankoplis 3) Heat mass and Momentum transfer by Bennet C.O. Mayers J.E. CT-1.1 Modern Methods of Insturmental Analysis 3 hrs/week Credit = 3

Detail study of following sophisticated instruments with reference to construction, operation principle, applications and merits and demerits: Gas Liquid Chromatography High Performance Liquid Chromatography Infra Red & FTIR Spectroscopy NMR Spectroscopy UV Visible Spectroscopy Mass Spectroscopy Differential Scanning Calorimeter Thermo gravimetric Analysis Scanning Electron Microscope Transform Electron Microscope & Atomic Force Microscopy XRD crystalline phase analysis Surface area determination by BET- method, Particle size by light scattering method, Zeta potential Color matching spectrophotometer and lavibond tintometer

CH-1.4 Instrumental Analysis & Engineering Lab. [Pr]

6 hrs/week Credit = 3

Minimum 8 experiments based on Instruments Studied in Modern Methods of Instrumental Analysis. Minimum eight experiments based on heat, mass, process control, modeling and simulation (CHEMCAD, MATLAB, AUTOCAD, ASPEN)

CH: 1.5

Process Dynamics and Control

3 hrs/week Credit = 3

Analogue simulation open and closed loop systems, concept of stability, stability criteria, root locus analysis, frequency response method, controller system design by frequency response. Advanced control strategies, Optimum control settings, Control valves, valve characteristics. Theoretical analysis of complex control systems such as steam jacketed kettle, gas absorber, mass transfer and chemical reactor systems, overall process control. Non linear process control methods, phase plane analysis, describing function technique. Analog and digital computers. Microprocessor based controllers and distributed control. Reference Books: 1. Coughanowr Donald R.: Process system Analysis and Control, McGraw Hill 2. Luben W. L., : Process modeling ,simulation and control for Chemical engineers, McGraw Hill 3. George Stephanopoulos : Chemical Process Control , Person Education Indian Branch.

SECOND SEMESTER

CH-2.1

Mass Transfer with Multiphase System

3 hrs/week Credit = 3

Diffusional mass transfer: Diffusional coefficient for a binary gas mixture, Diffusion of a Component through a stagnant medium and Varying Cross Sectional area. Diffusion in Biological Solution Numerical based on it. Dimensionless Correlation for convective mass transfer, Mass transfer with reaction in Fluid-Fluid- Solid system Selection of Contractors Determination of minimum reflux ratio by different methods and Problem based on multicomponent system. Design parameter for fractionating column, Simultaneous absorption and Desorption with reaction. Mass transfer accompanied by General order irreversible and reversible reaction in gas liquid and liquid- Liquid System. Design parameter of Simson Walker Crystaliser Calculation of Number of Plate by Triangle Point Method in case of Extraction. Reference Books: 1) Gas liquid relation by Danckwerts P.V.. 2) Heterogeneous Relation Analysis example and Relation design Vol: 2 John Wiley and Sons by Doraiswamy L.K. and M.M. Sharma 3) Principle of mass and heat transfer by S.D Dawande Central Technical Publication

CH -2.2

Reaction Engineering and Nanocatalysis

3 hrs/week Credit = 3

Review of techniques of interpretation of kinetic data, material and energy balance across reactors with reference to their design, Detail coverage of design of fixed, fluidized, trickle, moving bed reactors. Nanocatalysis: Role of transition metals & metal oxides in homogeneous and heterogeneous catalysis and their mechanism of catalysis, manufacture of these catalysts in nano-form and their characterization.

Silica, alumina, carbon as high temperature carriers for catalysts. Use of nanocatalysts in automobile pollution control, photocatalysis of toxics in effluents, gas sensors. Reactor design for manufacture of nanocatalysts and nanosupports: Design of flame aerosol reactors, diffusion and premixed flame reactors, co precipitation reactors, hot wall flow reactors; their mechanical features, modeling and simulations. Catalytic vapour liquid- solid growth mechanism for understanding particle formation and growth during chemical vapour deposition, particle dynamics and CFD simulations of flame process based on fundamental equations for flow, heat and mass transfer, aerosol dynamics in flames. Reference Books: 1. Levenspiel O.: Chemical Reaction Engineering; Wiley Eastern. 2. Davidson J.F., Harrison D.: Fluidization: Academic Press. 3. Carberry J.J.: Chemical and Catalytic Reaction Engineering: Mc Graw Hill. 4. Satterfield C.N.: Mass Transfer in Heterogeneous Catalysis: M.I.T. Press.

CH- 2.3 Chemical Equipment Design

3 hrs/week Credit = 3

Design of Heat transfer equipments in detail such as Shell and Tube heat exchangers: correction factor for Log mean temperature difference, Vibrations in shell & tube heat exchanger, Effectiveness. Plate type Heat Exchanger: thermal Design considerations. Heat regenerators, cooling tower design considerations. Evaporators: selection criterion, Optimum no. of effects in multiple effect systems. Design of Separation Process Equipments: Gas liquid separators, Liquid-liquid separators, Gravity separation, Cyclone separators, Electrostatic precipitators. Distillation: Comparisons of Plate column or packed column, Design of sieve plate column and Bubble cap column in detail. Design of continuous dryers: Rotary dryer, fluidized bed dryer. Reference Books: 1. Richardson, J.M., Coulson J.F. and Sinnot R. K.: Chemical Engineering Vol . 6. 2. Dawande S.D. Process Design of Equipment Vol 2.,Central Techno Publications. 3. Kern D.Q. : Process Heat Transfer. 4. Kunni D., Levenspial D. : Fluidization Engineering. Wiley Ny. . CH-2.4 Pollution control in Chemical Industries 3 hrs/week Credit = 3

Identification, Segregation and Control of solid / liquid/ gases Pollutants from following Chemical Industries: Petrochemical and Petroleum refinery Vanaspati Edible oil Refinery and Oleochemical industry Fermentation Beverage Dairy and Suger Industries Plastic Processing Industry Polymer and Resin Industry Control of Volatile Organic Emissions in Paint Industry Pharmaceutical and Fine Chemicals

CH: 2.5

Modern Methods of Extraction

3 hrs/week Credit = 3

Theory & principle of extraction, types of extraction Liquid-Liquid extraction: Method of Liquid-Liquid extraction, Theory & practice batch & continuous process, Calculation of no. of stages in co-current and counter-current extraction by different methods, design of extraction column : number of stages, efficiencies, NTU, HTU, Height of packing, Mass transfer coefficient, etc,. Selection criterion for solvent, Modern practices / plant for extraction of different raw material. Solid-Liquid extraction: Method of Solid-Liquid extraction, Theory & practice batch & continuous process, Calculation of no. of stages in co-current and counter-current extraction by different methods, design of extraction column : number of stages, efficiencies, Mass transfer coefficient, Characterization of alpha & alpha n selection criterion of solvent, Modern practices / plant for extraction of different raw material. Super critical fluid extraction: Theory principle and application, Extraction of essential oils, spices oleoresins and other valuable products, Comparative study of above processes with respect to solvent losses, Recovery of solvents and energy conservation, Safety Hazards and Toxicity. Reference Books: 1. Chemical Engg., J. M. Coulson & J. F. Richardson Vol-2. 2. Mass Transfer by Trybal 3. Baileys Industrial Oils & Fats Products edited by Hui, Jhon Wiley vol-3.

CH: 2.6

Membrane Seperation operations

3 hrs/week Credit = 3

Solute Transport Parameters for membrane performance prediction in RO / UF system involving aqueous and non-aqueous solutions. Physio-chemical, polar and nonpolar criterion govering RO separation, Membrane transport mechanism, Membrane fouling and compactations, TFC Membrane development. RO/ UF/ ED process design and module analysis RO/ UF/ ED and DD in acid and enzyme recovery from sacchinified hydrolyzates. Membrane techniques in reclaimation of water and chemicals along with pollution control from industrial effluents, Cost benefit analysis in resources recycling and environmetal quality improvement by MT., Industrial processing with membrane-membrane reactor, concept in biotechnology industries and in downstream processing, Per-vaporization techniques in alcohol concentration, Gas separation by RO. Reference Books: 1.S. Sourjan, T. Matsura, ( Ed ), RO/UF Principles & Applications, NRCC Publications, Ottawa-Canada, 1986. 2. Munir Cheryan, UF Application Handbook, Technomic Publishing Co., Lancaster USA, 1986.

CH 2.7

Bio-Chemical Engineering

3 hrs/week Credit = 3

Enzymes kinetics, immobilized enzymes and their application. Recombinant DNA and its applications. Bioconversion of renewable sources to organic chemicals. Bio Technology of food and food bio energy. Kinetics of growth, bio mass production, substrate utilization and product yield. Batch, plug flow and chemostat cultures, mixed cultures. Aeration and agitation. Oxygen and demand supply. Surface and submerged fermentation. Bio reactors, their design and operation, sterilization. Process control instruments, product recovery. Recent advances in production of microbial proteins, antibiotics, vaccines, organic acids, steroid transformations etc. Industrial effluent and their treatments, environmental pollution and its control. Reference books : 1. Aiba, s. ,Humphrey , A. E. , Mills , N. F. , : Biochemical Engneering: Academic Press. 2. Bailey, J. E. ,Biochemical Engineering Fundamentals. : McGraw Hill. 3. Atkinson, B. , :Biochemical Reactors : Pion Ltd. London.

PT: 2.3

Polymer Reaction Engineering

3 hrs/week Credit = 3

Classification of polymerization reactions. addition polymerization reaction mechanisms and rate equations; Dead end radical polymerization; molecular weight distribution in batch and continuous reactors; avg. molecular weight and experimental determination based on viscosity, osmotic pressure etc. semi-batch reactor operation; Design of batch and continuous reactors. Heat removal from polymerization reaction. Heterogeneous polyaddition reactions; Suspension and emulsion polymerization; SmithEwarts theory and Stock Mayers equation; continuous emulsion polymerization; Anionic and Cationic poly addition; Co-polymerization; Mayos equation and reactivity ratio; Alfred- Price equation; Rate of co polymerization and y factor; Skiests equation. Polycondensation reactions; Florys equation and molecular weight distribution; Molecular weight regulations. Typical case studies of polymers like PE, PP and PS . Reference books: 1. G. M. Burnett, Mechanism of polymer Reactions, Interscience, 1954. 2. F. M. Bovey, A. K. Medalia, I. M. Kolthoff, Emulsion Polymerisation, Interscience, 1955. 3. G. E. Harn, Co polymerization, Intersicence, 1969. 4. F. W. Billemeyer, (Ed.) Encyclopaedia of Polymer science and Technology, Interscience, 1969.

NT 2.2

Science & Technology of Nano Medicines

3 hrs/week Credit = 3

Present status of pharmaceuticals and fine chemicals, outline of biochemistry of cells of living organisms. Concepts of nano medicines, physical properties of molecules and supermolecular complexes within cells. Molecular machinery and manufacturing with due stress on programmable medical micromachines, tiny supercomputers through molecular computing, concept of nano robots / molecular robotics smaller than a cell and their role in elimination of cancer, infection, clogged articles etc., retardation of aging phenomenon. Role of nano technology in bio technology, engineered enzymes, coated colloids in cosmetics in pharmaceuticals, encapsulated drugs for sustained release, sunscreen and UV protective cosmetics, bio medical tagging and bio magnetic separation, diagnostic content agent, bio medical implants.

Third Semester

CH-3.1

Seminar

10 hrs/week Credit = 5

Presentation on selected topics with due emphasis on latest developments

CH 3.2

Project

20 hrs/week Credit = 10

Finalization of particular research problem thorough literature review, preliminary experimental work, Presentation of Project report and viva - voce based on project work.

Semester IV CH-4.1 Project 30 hrs/week Credit = 15

The entire semester will be devoted for detail experimental work on a research problem selected in III semester. The student will present his findings in the form of neatly typed and bound thesis within one month after approval of his synopsis. He will have to appear before panel of experts for defending his Thesis.

Você também pode gostar

- MSC Syllabus 2010-11-1-Islam May Mju MMRDocumento14 páginasMSC Syllabus 2010-11-1-Islam May Mju MMREngr Saikat100% (1)

- Hydrothermal Analysis in Engineering Using Control Volume Finite Element MethodNo EverandHydrothermal Analysis in Engineering Using Control Volume Finite Element MethodAinda não há avaliações

- Proposed Syllabus FOR Credit Based Curriculum ON Thermal Power Engineering (2011-12)Documento15 páginasProposed Syllabus FOR Credit Based Curriculum ON Thermal Power Engineering (2011-12)hotniliAinda não há avaliações

- Journal of Process Control: Volume 8, Issues 5-6Documento12 páginasJournal of Process Control: Volume 8, Issues 5-6Sarvesh GantalaAinda não há avaliações

- Modelling of Nuclear Reactor Multi-physics: From Local Balance Equations to Macroscopic Models in Neutronics and Thermal-HydraulicsNo EverandModelling of Nuclear Reactor Multi-physics: From Local Balance Equations to Macroscopic Models in Neutronics and Thermal-HydraulicsAinda não há avaliações

- SyllabusDocumento22 páginasSyllabusSohael AftabAinda não há avaliações

- Rate Constant Calculation for Thermal Reactions: Methods and ApplicationsNo EverandRate Constant Calculation for Thermal Reactions: Methods and ApplicationsHerbert DaCostaAinda não há avaliações

- Syllabus PDFDocumento26 páginasSyllabus PDFMahfuzur Rahman SiddikyAinda não há avaliações

- V Sem Scheme - Syllabus081117030234Documento13 páginasV Sem Scheme - Syllabus081117030234Aditya GuptaAinda não há avaliações

- Ucsi University B.Eng (Hons) in Chemical Engineering Course OutlineDocumento2 páginasUcsi University B.Eng (Hons) in Chemical Engineering Course OutlinetkjingAinda não há avaliações

- M.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014Documento40 páginasM.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014hmasif456Ainda não há avaliações

- ChE SyllabusDocumento30 páginasChE SyllabusRavindra Kumar NiranjanAinda não há avaliações

- ChE SyllabusDocumento30 páginasChE SyllabusSubodh DwivediAinda não há avaliações

- Computer Applications in Process IndustriesDocumento10 páginasComputer Applications in Process IndustriesNikhil Kumar ChennuriAinda não há avaliações

- Chemical Engineering Syllabus VTU BEDocumento65 páginasChemical Engineering Syllabus VTU BESunil ShamanurAinda não há avaliações

- Chemical and Biomolecular Engineering (EG) (CBE) : Page 1 of 10Documento10 páginasChemical and Biomolecular Engineering (EG) (CBE) : Page 1 of 10Philip ZhangAinda não há avaliações

- Syllabus For Fixed Term Associates-1Documento7 páginasSyllabus For Fixed Term Associates-1Khan KhursheedAinda não há avaliações

- Optimization ProblemsDocumento6 páginasOptimization Problemsneft0% (1)

- Chemical Engineering SyllabusDocumento25 páginasChemical Engineering Syllabusविनय कुमार शर्माAinda não há avaliações

- AMIE Section-B ChemicalDocumento13 páginasAMIE Section-B ChemicalmintuboruahAinda não há avaliações

- Pdpu/Sot/5 Sem.B. Tech. Chemical EngineeringDocumento11 páginasPdpu/Sot/5 Sem.B. Tech. Chemical EngineeringMeetAinda não há avaliações

- Chain KilnsDocumento287 páginasChain KilnsNael100% (1)

- Chemical Engineering of IIT RoorkeeDocumento53 páginasChemical Engineering of IIT RoorkeeSandeep KumarAinda não há avaliações

- Chemistry Gate 2018Documento17 páginasChemistry Gate 2018mona171Ainda não há avaliações

- Measurement of Condensed-Phase Reaction Kinetics in The Aerosol Phase Using Single Particle Mass SpectrometryDocumento10 páginasMeasurement of Condensed-Phase Reaction Kinetics in The Aerosol Phase Using Single Particle Mass SpectrometryJanine MolinaAinda não há avaliações

- B.tech 6th Sem ChE Final 1Documento11 páginasB.tech 6th Sem ChE Final 1Last BencherAinda não há avaliações

- M.E.Mech. HEAT POWERDocumento37 páginasM.E.Mech. HEAT POWERKapil KotangaleAinda não há avaliações

- Chemical Engineerin1Documento5 páginasChemical Engineerin1ajayfake01012001Ainda não há avaliações

- ChE+3116 Syllabus+Fuid+MechanicsDocumento2 páginasChE+3116 Syllabus+Fuid+MechanicsEric MartinezAinda não há avaliações

- 10100Documento42 páginas10100احمد الدلالAinda não há avaliações

- TE Chemical LeachingDocumento25 páginasTE Chemical LeachingevemillyAinda não há avaliações

- 3.1 FLUID Flow: RationaleDocumento16 páginas3.1 FLUID Flow: RationaleAli übeyitoğullarıAinda não há avaliações

- UCH802Documento2 páginasUCH802JoseAinda não há avaliações

- JKLDocumento9 páginasJKLanon_314301380Ainda não há avaliações

- University of Mumbai: Examination SchemeDocumento20 páginasUniversity of Mumbai: Examination SchemeAkash BhatAinda não há avaliações

- Syllabus (New) Gujarat University B E Chemical Engineering All SemesterDocumento57 páginasSyllabus (New) Gujarat University B E Chemical Engineering All Semestertarunbnsl100% (1)

- Final B Cud ReportDocumento37 páginasFinal B Cud ReportsubburajsAinda não há avaliações

- 5 Sem ChemicalDocumento16 páginas5 Sem Chemicalabhijit gogoiAinda não há avaliações

- MmechanicalDocumento11 páginasMmechanicalpank1987_inAinda não há avaliações

- Chen L D 2017Documento145 páginasChen L D 2017gabin demsAinda não há avaliações

- GATE 2021: (Syllabus)Documento2 páginasGATE 2021: (Syllabus)chemical todiAinda não há avaliações

- Chemical Process Modeling and SimulationDocumento3 páginasChemical Process Modeling and SimulationscribedoctorAinda não há avaliações

- Chemical Reaction Engineering-IIDocumento3 páginasChemical Reaction Engineering-II2020001873.gcetAinda não há avaliações

- Te Autonbomous SyllabusDocumento36 páginasTe Autonbomous SyllabusRama Manikanta DondapatiAinda não há avaliações

- 2008 Minh AICHE PDFDocumento9 páginas2008 Minh AICHE PDFinf2014Ainda não há avaliações

- Mech Sem6Documento17 páginasMech Sem6Nidhi GandhiAinda não há avaliações

- Literature Review FluidizationDocumento8 páginasLiterature Review Fluidizationea4hasyw100% (1)

- GATE Chemical EngineeringDocumento2 páginasGATE Chemical EngineeringWater ResearcherAinda não há avaliações

- Verification, Validation and Testing of Kinetic Mechanisms of Hydrogen Combustion in Fluid Dynamic ComputationsDocumento37 páginasVerification, Validation and Testing of Kinetic Mechanisms of Hydrogen Combustion in Fluid Dynamic Computationscata_alex_muntAinda não há avaliações

- Multiscale Modelling in Computational Heterogeneous CatalysisDocumento40 páginasMultiscale Modelling in Computational Heterogeneous CatalysisIAMANDU COSTAAinda não há avaliações

- CREII-Module-I - Lecture 1Documento38 páginasCREII-Module-I - Lecture 1Aditya parasAinda não há avaliações

- Experiment 3A: Plug Flow Reactor: Department of Chemical EngineeringDocumento2 páginasExperiment 3A: Plug Flow Reactor: Department of Chemical EngineeringKelly Sheine SisonAinda não há avaliações

- M.tech. Chemical EngineeringDocumento20 páginasM.tech. Chemical EngineeringRajkamal TheGraduateAinda não há avaliações

- Mtech Syllabus OldDocumento11 páginasMtech Syllabus Oldabhishek kumarAinda não há avaliações

- ME ThermalSyllabus PDFDocumento28 páginasME ThermalSyllabus PDFpradeepkumar1826Ainda não há avaliações

- Chemical KineticsDocumento69 páginasChemical KineticsDaniel YakubovichAinda não há avaliações

- Chemical Engineering Iit RoorkeeDocumento69 páginasChemical Engineering Iit RoorkeeZaid ImranAinda não há avaliações

- Modelling and Simulation of The Monolithic Reactor For Gas - Liquid - Solid ReactionsDocumento9 páginasModelling and Simulation of The Monolithic Reactor For Gas - Liquid - Solid ReactionsAhmadAinda não há avaliações

- Vangood Quotation - Refrigerator Part - 2023.3.2Documento5 páginasVangood Quotation - Refrigerator Part - 2023.3.2Enmanuel Jossue Artigas VillaAinda não há avaliações

- CDKR Web v0.2rcDocumento3 páginasCDKR Web v0.2rcAGUSTIN SEVERINOAinda não há avaliações

- Termination LetterDocumento2 páginasTermination Letterultakam100% (1)

- COOKERY10 Q2W4 10p LATOJA SPTVEDocumento10 páginasCOOKERY10 Q2W4 10p LATOJA SPTVECritt GogolinAinda não há avaliações

- Labstan 1Documento2 páginasLabstan 1Samuel WalshAinda não há avaliações

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDocumento75 páginasInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspAinda não há avaliações

- BluetoothDocumento28 páginasBluetoothMilind GoratelaAinda não há avaliações

- Javascript Applications Nodejs React MongodbDocumento452 páginasJavascript Applications Nodejs React MongodbFrancisco Miguel Estrada PastorAinda não há avaliações

- Transparency Documentation EN 2019Documento23 páginasTransparency Documentation EN 2019shani ChahalAinda não há avaliações

- Aluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyDocumento2 páginasAluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyJoachim MausolfAinda não há avaliações

- Rating SheetDocumento3 páginasRating SheetShirwin OliverioAinda não há avaliações

- Prachi AgarwalDocumento1 páginaPrachi AgarwalAnees ReddyAinda não há avaliações

- PVAI VPO - Membership FormDocumento8 páginasPVAI VPO - Membership FormRajeevSangamAinda não há avaliações

- Unit-5 Shell ProgrammingDocumento11 páginasUnit-5 Shell ProgrammingLinda BrownAinda não há avaliações

- Professional Regula/on Commission: Clarita C. Maaño, M.DDocumento31 páginasProfessional Regula/on Commission: Clarita C. Maaño, M.Dmiguel triggartAinda não há avaliações

- Role of The Government in HealthDocumento6 páginasRole of The Government in Healthptv7105Ainda não há avaliações

- 18PGHR11 - MDI - Aditya JainDocumento4 páginas18PGHR11 - MDI - Aditya JainSamanway BhowmikAinda não há avaliações

- My CoursesDocumento108 páginasMy Coursesgyaniprasad49Ainda não há avaliações

- Functions of Commercial Banks: Primary and Secondary FunctionsDocumento3 páginasFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaAinda não há avaliações

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDocumento1 páginaMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VAinda não há avaliações

- Edita's Opertionalization StrategyDocumento13 páginasEdita's Opertionalization StrategyMaryAinda não há avaliações

- Cam Action: Series: Inch StandardDocumento6 páginasCam Action: Series: Inch StandardVishwa NAinda não há avaliações

- A PDFDocumento2 páginasA PDFKanimozhi CheranAinda não há avaliações

- Historical Development of AccountingDocumento25 páginasHistorical Development of AccountingstrifehartAinda não há avaliações

- HRD DilemmaDocumento4 páginasHRD DilemmaAjay KumarAinda não há avaliações

- Fake PDFDocumento2 páginasFake PDFJessicaAinda não há avaliações

- Pindyck TestBank 7eDocumento17 páginasPindyck TestBank 7eVictor Firmana100% (5)

- United Nations Economic and Social CouncilDocumento3 páginasUnited Nations Economic and Social CouncilLuke SmithAinda não há avaliações

- XgxyDocumento22 páginasXgxyLïkïth RäjAinda não há avaliações

- Feasibility Study of Diethyl Sulfate ProductionDocumento3 páginasFeasibility Study of Diethyl Sulfate ProductionIntratec SolutionsAinda não há avaliações