Escolar Documentos

Profissional Documentos

Cultura Documentos

Microbiological Test of Medical Devices

Enviado por

bijendra_sinhaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Microbiological Test of Medical Devices

Enviado por

bijendra_sinhaDireitos autorais:

Formatos disponíveis

Microbiological tests related to industries of medical devices..........

1. BACTERIAL ENDOTOXIN TEST BY GEL CLOT METHOD:

1.

a. b. c. d. e. f. g. h.

PROCEDURE:

MATERIALS REQUIRED:

Limulus Amoebocyte Lystate (LAL) Reagent. Control Standard Endotoxin (CSE). Lal Reagent Water (LRW). Vortex shaker. Heating Block. Micropipette with sterile tip. Depyrogenated glass test tubes (15x100 & 10x75 mm). Aluminium foil and forceps. All materials coming in contact with the specimen or test reagents must be rendered endotoxin free by heating at 2500C for 60 minutes.

PREPARATION OF ENDOTOXIN:

a. b. c. d. e. Reconstitute CSE as per Certificate of Analysis (COA). Record the date of preparation on the vial. Vortex the vial for 15 minutes after rehydration. Vortex for at least 5 minutes immediate prior to each use or as specified in COA. Reconstituted CSE can be stored at 2-80C for up to 28 days in the refrigerator or as per manufacturers instructions. Dilute the endotoxin with LRW to a concentration of 0.5 EU/ml (4). Each dilution should be vortexed for 60 seconds prior to proceeding to the next dilution. Refer table I: - If concentration of CSE is 40 EU/ml as per COA supplied by manufacturer. Using the 0.05 EU/ml endotoxin dilution, prepare the dilution of 0.125EU/ml (), where is Lysates sensitivity.

TABLE I

Example: - If as per COA stock concentration of CSE is 40 EU/ml, then: S. Dilution ratio CSE LRW Dilution Concentration of Endotoxin No. 1. 1:80 0.1 ml 7.9 ml 4 0.5 EU/ml 2. 1:4 1.0 ml of 4 3.0 ml 0.125 EU/ml

Calculate the Maximum Valid Dilution (MVD) by the formula: MVD = Endotoxin limit as specified in Pharmacopoeia. / Lysate sensitivity as per COA. ANTICOAGULANT SOLUTION: Sample size: - Three blood bag per batch and make a pooled sample. MVD calculation: MVD = 5.56EU/ml / 0.125EU/ml = 1:44. Sample dilution is prepared at MVD / 2 = 0.1 ml sample + 2.1 ml LRW. MEDICAL DEVICES: I. Sample size: 10 pieces from each lot / batch.

PREPARATIO OF SAMPLE DILUTION:

II. Preparation of Extract: The process of preparing an extract {20ml water for injection (WFI) per device} for LAL test may vary for each device. This extract is kept for 1 hour at controlled temperature (20 250C). a. Syringes (10 pieces / batch) are flushed by 20 ml WFI (20ml WFI / device). b. 3 way stop cock (10 pieces / batch) can be disassembled and immersed in 200 ml WFI. c. Tubing products (10 pieces / batch) can be immersed in 200 ml WFI by cutting into pieces and d. I.V. Cannula (10 pieces / batch) pass 200 ml of WFI through 10 pieces of I.V. Cannula (20 ml WFI / device). Calculation of MVD: The endotoxin limit for the extract is calculated by the formula: KxN / V. Where K = Amount of endotoxin allowed per device. N = Number of medical device tested. V = Total volume of the rinse. Endotoxin limit = 20x10 / 200 = 1EU/ml. Now MVD for medical devices = Endotoxin limit / Lysates sensitivity. = 1 EU/ml / 0.125 EU/ml = 8. MVD = 1:8. Sample dilution is prepared at MVD / 2 = 0.4 ml of sample + 1.6 ml LRW.

PREPARTAION OF LAL:

Reconstitute LAL Reagent as per manufacturers instruction. LAL reagent sensitivity is 0.125 EU/ml. Transfer the prepared sample dilution, LRW and CSE in the assay tubes in duplicate and add 100l of reconstituted LAL reagent to each tubes (as per table - II): -

TABLE II

TUBE NO. 1, 2 3, 4 5, 6 7, 8 9, 10 11, 12 13, 14 Blank 2 /2 /4 NPC PPC LRW 100 l 50 l 50 l 75 l 50 l CSE 50 l(4) 100 l() 50 l() 25 l() 50 l(4) PRODUCT 50 l 50 l LYSATE 100 l 100 l 100 l 100 l 100 l 100 l 100 l

Incubate the assay tubes at 370C (10C) in heating block for 60 minutes. Each tube is inverted at 1800. Compare the sample vials to the control vials. A positive reaction is characterized by the formation of a firm gel that remains intact momentarily when the tube is inverted. This should be observed in the positive control vials (2, , /2, /4) and in the positive product control (PPC) vial. A negative test is characterized by the absence of solid clot after inversion. This should be observed in the negative control (blank) vial and in the negative product control (NPC) vial. The Lysate may show an increase in turbidity or viscosity; this is considered as negative result.

INTERPRETATION OF RESULT: -

Record positive and negative results for the test sample vials. Test results are valid only when the PPC is positive at 2 endotoxin concentration and NPC is negative. Repeat the test when a positive result is found for 1 tube of NPC and a negative result for the other one. The sample complies with the test when a negative result is found for both tubes of NPC in the repeat result. If the test is positive for sample under test at a dilution less than the MVD, the test may be repeated at a dilution not greater than MVD.

PRECAUTION DURING TEST: Careful techniques must be used to avoid microbial contamination. All glassware and materials must be endotoxin free. pH of sample should be 6.8 8.0. Samples to be tested must be stored in such a way that all bacteriological activity is stopped or the

endotoxin level may increase with time. Assay tubes should not be removed from incubation or disturbed prior to the time specified for reading the test. Switch on the heating block 1 hour before starting the test to get the constant temperature. Monitor the temperature after every 15 minutes during the incubation period.

2. ABNORMAL TOXICITY TEST: PROCEDURE: Test animal: - Select 5 healthy mice weighing between 17-23 grams.

PREPARATION OF EXTRACT: Make 50 ml saline solution (0.9% w/v) in Depyrogenated conical flask then take 5 pieces of the batch and pass 10 ml of saline from each piece with 10 mldepyrogenated glass syringe slowly. After pass the saline from piece put that piece in passed saline. The preparation of extract should be done under Laminar Air Flow. Then autoclave this extract at 1210C for 15 minutes.

METHOD: Inject intravenously each of five mice 1.0 ml of test solution using 26 gauge needle of half inch. The time of injection should normally be 15 30 seconds.

INTERPRETATION OF RESULT: Observe the mice at the time of injection after 24, 48 and 72 hours. All the mice survive; the sample passes the test for toxicity. If one or more animals die, repeat the test using at least another 10 mice, similar to those used in previous test but weighing 20 3 grams. If all mice survive for 72 hours, the sample passes the test for toxicity.

Product Bio-burden test

Sample selection: The sample for bio-burden testing are collected on random basis after they are packed and are ready for sterilization but not sterilized. Quantity: As given in table I: Table I Name of product Quantity required I.V. Cannula, Three way stop cock, Syringes 10 pieces Other disposables 05 pieces Frequency: At least one batch in every 15 days is tested for microbial bio-burden. Treatment solution: Buffered sodium chloride peptone solution pH 7.00.1 with 0.5% tween 80 made as given in table II, previously sterilized at 1210C for 15 minutes. Table II S. No. Description Quantity required 1. Di-hydrogen potassium phosphate 3.6g 2. Di-Sodium hydrogen phosphate 7.2g 3. Sodium Chloride 4.3g 4. Peptone 1.0g 5. D. M. / Distilled water 1000 ml. Preparation of Media: Prepare Soybean casein digest agar (SCDA) and Sabouraud Dextrose Agar (SDA) as per requirement and sterilize at 1210C for 15 minutes. Test procedure: Each sample is aseptically immersed separately in 100ml. of treatment solution. Shake the flask for some time. Transfer to membrane filter of size 0.45 and filter immediately. Now, transfer 5 membrane filters to the surface of SCDA and transfer the other 5 membrane filters to the surface of SDA. Incubation: The SCDA plates are incubated at 300C-350C for 3 days and SDA agar plates are incubated at 200C-250C for 5 days. Interpretation of results: On completion of incubation, the colonies of each plate are counted and average of all pates is calculated. Average bio-burden is calculated by following formula: Average Bio-burden = Total No. of cfu observed / No. of plates. Percentage recovery is calculated by using following factor: Percentage recovery = Average bio-burden X 100 / 83.39 The result should complying limits shown in table III. Table - III Name product of Medium Normal count (cfu/ml) I.V. Cannula, SCDA 30 Three way stop SDA 20 cock, Syringe Alert level (cfu/ml) 35 25 Action level (cfu/ml) 40 30

Other disposables

SCDA SDA

100 50

125 75

150 100

Steps taken on alert and action level: During alert level the corrective action like increasing the frequency of spray, mopping and fumigation of clean room is undertaken under the guidance of Q. C. Department. If total counts are crossing action level, microbiologist should advice the concerned department in writing about the preventive steps.

Você também pode gostar

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersAinda não há avaliações

- AG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseDocumento5 páginasAG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseKarina GorisAinda não há avaliações

- Sterilization Validation Report SampleDocumento2 páginasSterilization Validation Report SampleHamidAliShahAinda não há avaliações

- Revital Heathcare (Epz) Limited Quality Control Department Sterility Test Raw Data SheetDocumento2 páginasRevital Heathcare (Epz) Limited Quality Control Department Sterility Test Raw Data SheetMusyoka UrbanusAinda não há avaliações

- Sop For Bio-BurdenDocumento5 páginasSop For Bio-BurdenMusyoka UrbanusAinda não há avaliações

- Sterilization Validation QsiteDocumento52 páginasSterilization Validation Qsiteskype2121Ainda não há avaliações

- Previews 1981650 PreDocumento12 páginasPreviews 1981650 Prekhaled msalbiAinda não há avaliações

- Attachment 4 - Technical Bulletin - Selection of EpcdDocumento2 páginasAttachment 4 - Technical Bulletin - Selection of Epcdyagnaashi90920% (1)

- ETO Sterilization ValidationDocumento44 páginasETO Sterilization ValidationCRYSTAL2100100% (1)

- Validation of Sterilization ProcessesDocumento3 páginasValidation of Sterilization ProcessesNovitra DewiAinda não há avaliações

- BPSA 2014 Recommendations For Testing, Evaluation, and Control of Particulates From Single-Use Process EquipmentDocumento28 páginasBPSA 2014 Recommendations For Testing, Evaluation, and Control of Particulates From Single-Use Process EquipmentbioAinda não há avaliações

- Cleanroom Validation Results Sampling and Common DispensingDocumento18 páginasCleanroom Validation Results Sampling and Common DispensingJanple Alzar100% (2)

- Compressed Air - 2 PDFDocumento18 páginasCompressed Air - 2 PDFnuwaAinda não há avaliações

- Ethylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)Documento30 páginasEthylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)SACHIN KUMARAinda não há avaliações

- Gamma Radiation SterilizationDocumento2 páginasGamma Radiation Sterilizationananth67% (3)

- Biocontamination Control for Pharmaceuticals and HealthcareNo EverandBiocontamination Control for Pharmaceuticals and HealthcareNota: 5 de 5 estrelas5/5 (1)

- Bioburden:The Burden On Our Biological OperationsDocumento48 páginasBioburden:The Burden On Our Biological OperationsSurendar Kesavan100% (1)

- EO Annual Requalification ReviewDocumento30 páginasEO Annual Requalification ReviewVenkatesh VenkateshAinda não há avaliações

- Iso 11737 2 2019Documento11 páginasIso 11737 2 2019Mubin MuhammadAinda não há avaliações

- Ord 384-2020 - ENGLISCHDocumento54 páginasOrd 384-2020 - ENGLISCHScribdTranslationsAinda não há avaliações

- MicroDocumento3 páginasMicroPrince MoniAinda não há avaliações

- Questions On EO Sterilization ValidationDocumento2 páginasQuestions On EO Sterilization ValidationSACHIN KUMARAinda não há avaliações

- 0707-0712 (1117) Microbiological Best Laboratory PracticesDocumento6 páginas0707-0712 (1117) Microbiological Best Laboratory PracticesoliveluvpopayAinda não há avaliações

- Recovery Factor Determination in Cleaning ValidationDocumento1 páginaRecovery Factor Determination in Cleaning ValidationPrince MoniAinda não há avaliações

- A Final Floor Show For Bugs (Sandle)Documento4 páginasA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- In Use StabilityDocumento6 páginasIn Use Stabilitytantri ayu lestariAinda não há avaliações

- Standard Update ISO 11140 UpdateDocumento2 páginasStandard Update ISO 11140 Updatemuzammil21_ad100% (1)

- Technical Tip: Product Adoption For Ethylene Oxide SterilizationDocumento2 páginasTechnical Tip: Product Adoption For Ethylene Oxide SterilizationSyed Hassan Waqar Gilani100% (1)

- ISO-10334-1994 For Stainless SuturesDocumento8 páginasISO-10334-1994 For Stainless SuturesDoaa KhalilAinda não há avaliações

- Gap Analysis 11737-1 2018Documento9 páginasGap Analysis 11737-1 2018sumanAinda não há avaliações

- Val SteDocumento16 páginasVal SteThaísa ScheuerAinda não há avaliações

- Sterlization ProtocolsDocumento10 páginasSterlization ProtocolsSarathchandran BalachandranAinda não há avaliações

- Biocompatibility ISO 10993 - Material Certificates Are Not Enough!Documento7 páginasBiocompatibility ISO 10993 - Material Certificates Are Not Enough!Vidyashree PujariAinda não há avaliações

- Environment Validation SopDocumento8 páginasEnvironment Validation SopNguyen ChienAinda não há avaliações

- Validation Req. in CTD & ProcessDocumento38 páginasValidation Req. in CTD & ProcessOula HatahetAinda não há avaliações

- Meclizine HCLDocumento10 páginasMeclizine HCLChEng_Ainda não há avaliações

- Technical Specification: Iso/Ts 16775Documento19 páginasTechnical Specification: Iso/Ts 16775Richa RohillaAinda não há avaliações

- 21122947Documento6 páginas21122947Victor CamargoAinda não há avaliações

- Bio-Burden Test Procedure.: Revital Healthcare (Epz) LTDDocumento5 páginasBio-Burden Test Procedure.: Revital Healthcare (Epz) LTDMusyoka UrbanusAinda não há avaliações

- SOP For Analysis of WaterDocumento9 páginasSOP For Analysis of WaterGencay ErginAinda não há avaliações

- Checklist of Validation of Dy Heat SterilizerDocumento8 páginasChecklist of Validation of Dy Heat Sterilizersami2210Ainda não há avaliações

- Media Fill Indicador de ColorDocumento6 páginasMedia Fill Indicador de Colorsteven correaAinda não há avaliações

- List of Labs For PPE For Medical UseDocumento5 páginasList of Labs For PPE For Medical UseAditya MeshramAinda não há avaliações

- GMED Guide Biological Assessment MD ISO10993-1 Standard-4Documento12 páginasGMED Guide Biological Assessment MD ISO10993-1 Standard-4almudena gomezAinda não há avaliações

- 12 Performance Qualification of EO Process Method CDocumento4 páginas12 Performance Qualification of EO Process Method CRakeshAinda não há avaliações

- Biocompatibility in Eu MDRDocumento11 páginasBiocompatibility in Eu MDRsachinAinda não há avaliações

- CalibrationDocumento5 páginasCalibrationMonika KshAinda não há avaliações

- Dry Heat Sterilization 2Documento7 páginasDry Heat Sterilization 2RogerioAinda não há avaliações

- Bacterial Endotoxin Test (BET or LAL Test) Method Validation - Pharmaceutical GuidelinesDocumento3 páginasBacterial Endotoxin Test (BET or LAL Test) Method Validation - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (2)

- Validation of Sterilization: GMP and Qa Class: BDocumento50 páginasValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniAinda não há avaliações

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiDocumento46 páginasWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- 30 Overview of An Eo ValidationDocumento2 páginas30 Overview of An Eo Validationskype2121100% (1)

- 3 2 - MicrobiologicalQualityControl 1Documento37 páginas3 2 - MicrobiologicalQualityControl 1Tong ChanAinda não há avaliações

- Autoclave Validation GuideDocumento6 páginasAutoclave Validation Guidejibin100% (1)

- ICH Quality Guidelines: An Implementation GuideNo EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleAinda não há avaliações

- Microbiological Pharmaceutical Quality Control LabsDocumento7 páginasMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Calcium Chloride DihydrateDocumento2 páginasCalcium Chloride DihydrateMulayam Singh YadavAinda não há avaliações

- 5.1.6. Alternative Methods For Control of Microbiological QualityDocumento10 páginas5.1.6. Alternative Methods For Control of Microbiological QualityLEPESANTAinda não há avaliações

- EMEA EtO GuidelineDocumento3 páginasEMEA EtO GuidelineSpectre SpectreAinda não há avaliações

- Longman English Grammar PracticeDocumento83 páginasLongman English Grammar Practicebijendra_sinhaAinda não há avaliações

- Relation Between Ratti and CaratDocumento2 páginasRelation Between Ratti and Caratbijendra_sinhaAinda não há avaliações

- Petals - Edition 38Documento35 páginasPetals - Edition 38bijendra_sinhaAinda não há avaliações

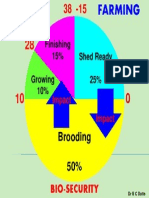

- Broiler - When & Where To ConcentrateDocumento1 páginaBroiler - When & Where To Concentratebijendra_sinhaAinda não há avaliações

- Supervisor ManualDocumento38 páginasSupervisor Manualbijendra_sinhaAinda não há avaliações

- Practical Physical Pharmaceutics 2012Documento33 páginasPractical Physical Pharmaceutics 2012sam100% (2)

- Handbook On Chlorine HandlingDocumento106 páginasHandbook On Chlorine Handlingkirandevi1981100% (1)

- Mobil Dte 10 Excel15Documento14 páginasMobil Dte 10 Excel15Om Prakash RajAinda não há avaliações

- Dic Epoxy enDocumento18 páginasDic Epoxy enSoonwook JangAinda não há avaliações

- Strain-Rate Effects On The Mechanical Behavior of The AISI 300 Series of Austenitic Stainless Steel Under Cryogenic EnvironmentsDocumento11 páginasStrain-Rate Effects On The Mechanical Behavior of The AISI 300 Series of Austenitic Stainless Steel Under Cryogenic EnvironmentsHugo IgrejaAinda não há avaliações

- Welder Monitoring SheetDocumento1 páginaWelder Monitoring SheetQC apollohx100% (1)

- Phoenix ValveDocumento4 páginasPhoenix Valvespadafora77Ainda não há avaliações

- Kris Arvid BerglundDocumento40 páginasKris Arvid BerglundckleinnikeAinda não há avaliações

- Stem11a Group2Documento32 páginasStem11a Group2fabbuddylizAinda não há avaliações

- AIM AspirinDocumento3 páginasAIM AspirinAubrey TawandaAinda não há avaliações

- Below Is The LET Reviewer For General Education GENEDDocumento16 páginasBelow Is The LET Reviewer For General Education GENEDLemmy Constantino DulnuanAinda não há avaliações

- Forensic Chemistry - Laboratory Manual ANDREWS 2001 PDFDocumento75 páginasForensic Chemistry - Laboratory Manual ANDREWS 2001 PDFjavier chavezAinda não há avaliações

- Darko and OsafoAcquaah (2007) Levels of Organochlorine Pesticides Residues in MeatDocumento4 páginasDarko and OsafoAcquaah (2007) Levels of Organochlorine Pesticides Residues in MeatgodfreddarkoAinda não há avaliações

- L10-Casting DesignDocumento42 páginasL10-Casting DesignKhayrulIslam100% (2)

- CryopreservationDocumento18 páginasCryopreservationgaurav saxenaAinda não há avaliações

- Cooling System Report (Automotive Tech.)Documento5 páginasCooling System Report (Automotive Tech.)Mohamed AhmedAinda não há avaliações

- Cemtop 200 : Cement Based, Self Levelling Thin Layer, Under Layment - 2mm To 12mmDocumento4 páginasCemtop 200 : Cement Based, Self Levelling Thin Layer, Under Layment - 2mm To 12mmSuresh BabuAinda não há avaliações

- 101 Steps To Better HistologyDocumento132 páginas101 Steps To Better HistologyJordi Farré100% (1)

- Trisodium CitrateDocumento2 páginasTrisodium CitrateAqmar Aqeem Bin AzharAinda não há avaliações

- Trends in The Periodic TableDocumento44 páginasTrends in The Periodic TableAna-Maria HodorogeaAinda não há avaliações

- Dungs ATEX en 161 Solenoid ValvesDocumento12 páginasDungs ATEX en 161 Solenoid Valvesstefan-romocki-4927Ainda não há avaliações

- MitomapDocumento1.079 páginasMitomaproymalindoAinda não há avaliações

- The Light BulbDocumento4 páginasThe Light BulbJonas SarmientoAinda não há avaliações

- 2008 Failure of Refurbished Turbine Blades in A Power Station by Improper Heat TreatmentDocumento6 páginas2008 Failure of Refurbished Turbine Blades in A Power Station by Improper Heat TreatmentArun KumarAinda não há avaliações

- Rocks PDFDocumento5 páginasRocks PDFfatwa27Ainda não há avaliações

- Eifeler Coating Guide SPRDocumento2 páginasEifeler Coating Guide SPRakshay2761Ainda não há avaliações

- Radon-222 Exhalation From Danish Building Material PDFDocumento63 páginasRadon-222 Exhalation From Danish Building Material PDFdanpalaciosAinda não há avaliações

- Yeast Cell BiologyDocumento3 páginasYeast Cell BiologyeupheemaAinda não há avaliações

- Fuel Specification Guide: Shell Marine ProductsDocumento6 páginasFuel Specification Guide: Shell Marine ProductsVilius BukysAinda não há avaliações

- TITLE: Osmosis AIM: To Observe Osmosis in A Storage Organ Equipment: Knife Materials: Salt Distilled Water PotatoDocumento3 páginasTITLE: Osmosis AIM: To Observe Osmosis in A Storage Organ Equipment: Knife Materials: Salt Distilled Water PotatoericaAinda não há avaliações