Escolar Documentos

Profissional Documentos

Cultura Documentos

Pipe Fittings STD

Enviado por

imrancenakkDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pipe Fittings STD

Enviado por

imrancenakkDireitos autorais:

Formatos disponíveis

Ultimate in Piping Solutions

Pipe Fittings

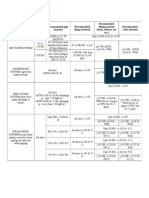

Sl. No. Dimension Standard

Standard

Grade

Scope Abstract

ASME B 16.9 ASME B 16.11 MSS SP 83 1. ASTM A105 / A105M - 05 MSS SP 95 MSS SP 97 BS 3799

Covers Forged Carbon Steel Piping Components for ambient & higher temperature service in pressure systems. Components included are Flanges, Fittings, Valves & similar parts. Forgings made to this specification are limited to a maximum weight of 10,000 lbs (4540 kgs). Larger Forgings are ordered to specification A266 / A266M.

Forged Low Alloy Steel F5, F9, F11, F22 2. ASTM A182 / A182M 05a Forged Austenitic Stainless Steel F304, F304L, F316, F316L, F321

ANSI B 16.11 MSS SP - 95 MSS SP 97 BS 3799

Covers Forged Low Alloy & Stainless Steel Piping Components for use in pressure systems. Components included are Flanges, Fittings, Valves & similar parts. Products made to this specification are limited to a maximum weight of 10,000 lbs (4540 kgs). Larger Products are ordered to specification A336 / A336M (Ferritic Grades) & A965 / 965M (Austenitic Grades).

3.

ASTM A234 / A234M 05a

WPB, WPC, WPR, WP1, WP5 (Class 1, Class 3), WP9 (Class 1, Class 3), WP11 (Class 1, Class 2, Class 3),

ASME B 16.9 ASME B 16.11

Covers Wrought Carbon Steel & Alloy Steel Fittings of Seamless & Welded construction.

Ultimate in Piping Solutions

WP12 (Class 1, Class 2), WP22 (Class 1, Class 3), WP91, WP911

ASME B 16.28 MSS SP - 43 MSS SP 79

These fittings are for use in pressure piping & in pressure vessel fabrication for service at moderate & elevated temperatures.

MSS SP 95 BS 3799

ASME B 16.9 ASME B 16.11 LF1, LF2 (Class 1, 2), LF3 (Class 1, 2), LF5 (Class 1, 2), LF6 (Class 1, 2, 3), LF9, LF787 (Class 2, 3) MSS SP - 95 MSS SP 97 BS 3799 ENI 0382 ASME B 16.9 ANSI B 16.28 MSS SP 43 MSS SP 75 DIN 2605 DIN 2606

4.

ASTM A350 / A350M 04a

Covers several grades of Carbon & Low Alloy Steel forged or ring rolled flanges, forged fittings and valves intended primarily for low temperature service and requiring notch toughness testing.

WP304 (L, H, N, LN), WP316 (L, H, N, LN, Ti), WP309, WP310S, WP317, WP321, WP347, WP348

5.

ASTM A403 / A403M - 04

Covers Wrought Stainless Steel fittings for Pressure Piping applications. Several grades of austenitic stainless steel alloys are included in this specification (with prefix WP or CR based on the applicable ASME or MSS dimensional and rating standards). For each of the WP stainless grades, several classes of fittings are covered to indicate whether seamless or welded construction was utilized. Class designations are also utilized to indicate the non destructive test method and

Ultimate in Piping Solutions

extent of non examination. ASME B 16.9 ASME B 16.11 6. ASTM A420 / A420M - 05 WPL 3, WPL6, WPL8, WPL9 ANSI B 16.28 MSS SP - 75 MSS SP 79

destructive

Covers Wrought Carbon Steel & Alloy Steel Pipe fittings of Seamless & Welded construction. These fittings are for use in pressure piping & pressure vessel service at low temperatures.

7.

ASTM A860 / A860M

WPHY 42, WPHY 46, WPHY 52, WPHY 60, WPHY 65, WPHY 70

ASME B 16.9 ASME B 16.28 MSS SP - 75

Covers Wrought High Strength Low Alloy Steel butt welding fittings of Seamless & electric fusion Welded construction. Dimensional requirements for NPS 14 & smaller butt welding fittings are provided in ASME B16.9 & ASME B16.28. Dimensional requirements for butt welding fittings larger than NPS 14 through NPS 48 are provided by MSS SP 75.

ASME B 16.9 8. ASTM B 366 ASME B16.11 ASME B16.28 MSS-SP-43 Covers Wrought Welding Fittings for Pressure Piping, Factory made from Nickel & Nickel Alloys.

IS 1239 Part 2 9. IS 1239 Part 2 MSS SP - 95

Covers the requirements for butt welded, plain end, screwed & socketed, Welded & Seamless Wrought Carbon Steel tubular & other Pipe fittings.

Ultimate in Piping Solutions

Covers factory made Seamless & Electric Fusion Welded Carbon & Low Alloy Steel Butt Welding Fittings for use in high pressure gas & oil transmission. MSS SP 75 ASME B 16.9 Covers dimensions, tolerances, ratings, testing, materials, chemical & tensile properties, heat treatment, notch toughness properties, manufacture & marking for high test Butt Welding Fittings NPS 60 & smaller. Dimension requirements for NPS 14 and smaller provided by reference to ASME B 16.9.

10.

MSS SP - 75

Você também pode gostar

- Piping Standards and Codes: American Society of Mechanical EngineersDocumento3 páginasPiping Standards and Codes: American Society of Mechanical EngineersPSKUMAR2012Ainda não há avaliações

- Piping MaterialsDocumento1 páginaPiping Materialslibid_rajAinda não há avaliações

- Piping Specification SheetDocumento63 páginasPiping Specification SheetNilesh Gohel100% (1)

- L&T Double Block and Bleed Plug ValvesDocumento12 páginasL&T Double Block and Bleed Plug Valvesvijay10484Ainda não há avaliações

- Spectacle Blind FlangeDocumento3 páginasSpectacle Blind Flangemaniastur365Ainda não há avaliações

- Task KPI Prerequisite Post Task: Code ApplicationDocumento6 páginasTask KPI Prerequisite Post Task: Code ApplicationvikasAinda não há avaliações

- Volksbolts Home Additional Options GuideDocumento12 páginasVolksbolts Home Additional Options GuideAllan EscobarAinda não há avaliações

- 6 44 0005 A2Documento25 páginas6 44 0005 A2S.selvakumarAinda não há avaliações

- Comparaison en 10253-4 Et DinDocumento32 páginasComparaison en 10253-4 Et Dinodaue100% (2)

- MSS SP53 PDFDocumento9 páginasMSS SP53 PDFdsyashankaAinda não há avaliações

- ASTM Standards: Range of Products & Material GradeDocumento1 páginaASTM Standards: Range of Products & Material Gradeeko kusumoAinda não há avaliações

- A494Documento7 páginasA494Prakash MakadiaAinda não há avaliações

- Pipingpresentationmaster 170219125347Documento61 páginasPipingpresentationmaster 170219125347Vignesh Nadimuthu100% (1)

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Documento64 páginasPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- ANSI Valve StandardDocumento5 páginasANSI Valve StandardsandystaysAinda não há avaliações

- SBU-Quality Valve InspectionDocumento85 páginasSBU-Quality Valve InspectionChetan kharkarAinda não há avaliações

- Process & Piping Design Section Plug Valves Technical SpecificationDocumento14 páginasProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- DD - 046973 - Clearances Between Underground ServicesDocumento2 páginasDD - 046973 - Clearances Between Underground ServicesvincentAinda não há avaliações

- Special Piping Materials Brochure PDFDocumento9 páginasSpecial Piping Materials Brochure PDFshankarmech04@gmail.comAinda não há avaliações

- Astm A234-A234m-06Documento8 páginasAstm A234-A234m-06NadhiraAinda não há avaliações

- AG Piping Specification SPEL en M SG 12 002 Rev0Documento31 páginasAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584Ainda não há avaliações

- BFV Butterfly Valve Features and SpecificationsDocumento18 páginasBFV Butterfly Valve Features and Specificationsyash100% (1)

- Insulating JointDocumento17 páginasInsulating Jointreza329329100% (1)

- Steel Grades Equivalent TableDocumento13 páginasSteel Grades Equivalent TableSudhir DwivediAinda não há avaliações

- Gate, Globe, Check Valve Material OptionsDocumento1 páginaGate, Globe, Check Valve Material OptionsSSSAinda não há avaliações

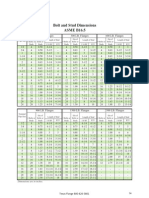

- Bolt and Stud DimentionDocumento1 páginaBolt and Stud DimentionwhngomjAinda não há avaliações

- Velan Forged Steel Gate Globe Checks PDFDocumento25 páginasVelan Forged Steel Gate Globe Checks PDFsunil kumarAinda não há avaliações

- SPREADSHEETS SERIES No. 0009S - 2Documento4 páginasSPREADSHEETS SERIES No. 0009S - 2Emma DAinda não há avaliações

- Ac 036630 001Documento1 páginaAc 036630 001navaronefraAinda não há avaliações

- Oxygen Piping Hazards and Customer Engineering ApproachDocumento67 páginasOxygen Piping Hazards and Customer Engineering ApproachKom Nak100% (1)

- VMS PaliDocumento61 páginasVMS Palichintan100% (2)

- EIL - Piping StandardsDocumento1 páginaEIL - Piping StandardsPrem DixitAinda não há avaliações

- T Type Strainer Butt Weld 1 PDFDocumento1 páginaT Type Strainer Butt Weld 1 PDFprashant mishraAinda não há avaliações

- Jet A1 Fuel Piping SpecificationDocumento17 páginasJet A1 Fuel Piping Specificationadel rihana100% (1)

- Buried Pipes and Fittings Painting SpecDocumento5 páginasBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocumento2 páginasBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004Ainda não há avaliações

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Documento2 páginasDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrAinda não há avaliações

- Flow TeeDocumento1 páginaFlow TeeMahesh BhansaliAinda não há avaliações

- UTL G GS-8 Rev10 Piping MaterialsDocumento253 páginasUTL G GS-8 Rev10 Piping Materialsmasoud132Ainda não há avaliações

- External Coatings For Corrosion Protection of Steel Pipes and ComponentsDocumento120 páginasExternal Coatings For Corrosion Protection of Steel Pipes and ComponentsadelAinda não há avaliações

- Flanges & Pipe Fittings SpecificationsDocumento3 páginasFlanges & Pipe Fittings Specificationsmcoswald83Ainda não há avaliações

- Monolithic Isolating Joint DatasheetDocumento3 páginasMonolithic Isolating Joint DatasheetEpwe100% (1)

- SP Item DatasheetsDocumento21 páginasSP Item DatasheetsSELVAMANIAinda não há avaliações

- MS-6.1 Piping SupportsDocumento19 páginasMS-6.1 Piping SupportsLe Thanh HaiAinda não há avaliações

- 03CA2SAE: Specification Piping Material ClassDocumento7 páginas03CA2SAE: Specification Piping Material Classabhishek186186Ainda não há avaliações

- Technical Requisition SummaryDocumento48 páginasTechnical Requisition Summarykunal shahAinda não há avaliações

- BE-WI-248-01-F19 Datasheet Breather ValveDocumento3 páginasBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloAinda não há avaliações

- MR ValvesDocumento56 páginasMR ValvesIdris SiddiquiAinda não há avaliações

- Curriculum Vitae: Sridhar VijayanDocumento5 páginasCurriculum Vitae: Sridhar VijayanSridhar VijayanAinda não há avaliações

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocumento1 páginaSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcAinda não há avaliações

- ASTM Specs FittingsDocumento10 páginasASTM Specs FittingskhaireddinAinda não há avaliações

- VALVE SPECIFICATIONDocumento112 páginasVALVE SPECIFICATIONjoseph.maquez24Ainda não há avaliações

- API 5l Grade x42 Psl1 PipesDocumento1 páginaAPI 5l Grade x42 Psl1 PipesFerroPipEAinda não há avaliações

- LS 545-15 Anchor supports for horizontal pipingDocumento7 páginasLS 545-15 Anchor supports for horizontal pipingtejasp8388Ainda não há avaliações

- Version 5.10 CAESAR II Applications GuideDocumento302 páginasVersion 5.10 CAESAR II Applications GuideBin XiangAinda não há avaliações

- Atlas Appendices SpecificationsDocumento4 páginasAtlas Appendices Specificationslinmar7071Ainda não há avaliações

- Essential Buttweld Pipe Fittings GuideDocumento4 páginasEssential Buttweld Pipe Fittings Guidekamal_mdAinda não há avaliações

- Codes Standards For YANBU ProjectDocumento7 páginasCodes Standards For YANBU ProjectBehçet Serdal CanbazAinda não há avaliações

- SpecificationsDocumento7 páginasSpecificationsMarine SleimanAinda não há avaliações

- NSPM 12 Guidelines Guidelines For Assessment, Audit and Accreditation of Fumigation Agencies For Undertaking Methyl Bromide FumigationDocumento46 páginasNSPM 12 Guidelines Guidelines For Assessment, Audit and Accreditation of Fumigation Agencies For Undertaking Methyl Bromide FumigationimrancenakkAinda não há avaliações

- The Self-Taught ProgrammerDocumento299 páginasThe Self-Taught Programmerimrancenakk100% (1)

- 10 Secrets To A Great BodyDocumento16 páginas10 Secrets To A Great BodyimrancenakkAinda não há avaliações

- Castor Wheel CatalogueDocumento12 páginasCastor Wheel CatalogueimrancenakkAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

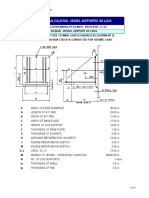

- Lug Support DesignDocumento11 páginasLug Support Designimrancenakk100% (6)

- Sample design calculation for skirt support of vertical columnDocumento8 páginasSample design calculation for skirt support of vertical columnimrancenakk100% (2)

- Shaft DeflectionDocumento15 páginasShaft Deflectionfreek_jamesAinda não há avaliações

- Solitons in Elastic SolidsDocumento9 páginasSolitons in Elastic SolidsimrancenakkAinda não há avaliações

- Valves & Fittings Catalog 2015Documento20 páginasValves & Fittings Catalog 2015imrancenakkAinda não há avaliações

- NSK CAT E1102m B304-325Documento11 páginasNSK CAT E1102m B304-325dassoumennAinda não há avaliações

- Agitator Vessel (Design&Costing)Documento34 páginasAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Design Calculations For AgitatorsDocumento5 páginasDesign Calculations For AgitatorsimrancenakkAinda não há avaliações

- A Continuum Damage Mechanics Framework For Modeling Micro-Damage HealingDocumento22 páginasA Continuum Damage Mechanics Framework For Modeling Micro-Damage HealingimrancenakkAinda não há avaliações

- Towards Optimization of Patch Shape On The Performance of Bonded Composite Repair Using FEMDocumento11 páginasTowards Optimization of Patch Shape On The Performance of Bonded Composite Repair Using FEMimrancenakkAinda não há avaliações

- Relative Equilibrium of Liquids - Advance Engineering Mathematics ReviewDocumento1 páginaRelative Equilibrium of Liquids - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Manometers - Advance Engineering Mathematics ReviewDocumento2 páginasManometers - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Assessment of Local Strain Field in Adhesive Layer of An Unsymmetrically Repaired CFRP Panel Using Digital Image CorrelationDocumento13 páginasAssessment of Local Strain Field in Adhesive Layer of An Unsymmetrically Repaired CFRP Panel Using Digital Image CorrelationimrancenakkAinda não há avaliações

- Problem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDocumento1 páginaProblem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- 02 Pressure On The Face of A Dam - Advance Engineering Mathematics ReviewDocumento1 página02 Pressure On The Face of A Dam - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Problem 03 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDocumento2 páginasProblem 03 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Energy and Head - Advance Engineering Mathematics ReviewDocumento4 páginasEnergy and Head - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- A Thermo-Viscoelastic-Viscoplastic-Viscodamage Constitutive Model Forasphaltic MaterialsDocumento17 páginasA Thermo-Viscoelastic-Viscoplastic-Viscodamage Constitutive Model Forasphaltic MaterialsimrancenakkAinda não há avaliações

- Problem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDocumento2 páginasProblem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Rectilinear Translation - Moving Vessel - Advance Engineering Mathematics ReviewDocumento2 páginasRectilinear Translation - Moving Vessel - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- 05 Depth of Water in Which Pressure Is 200 Kpa - Advance Engineering Mathematics ReviewDocumento1 página05 Depth of Water in Which Pressure Is 200 Kpa - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- 03 Pressure Below The Surface of The Ocean - Advance Engineering Mathematics ReviewDocumento1 página03 Pressure Below The Surface of The Ocean - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Discharge - Flow Rate - Advance Engineering Mathematics ReviewDocumento2 páginasDischarge - Flow Rate - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Analysis of Gravity Dam - Advance Engineering Mathematics ReviewDocumento3 páginasAnalysis of Gravity Dam - Advance Engineering Mathematics ReviewimrancenakkAinda não há avaliações

- Transom cw03Documento2 páginasTransom cw03Pamps MangampoAinda não há avaliações

- Water Salinity To Gradient ConversionDocumento2 páginasWater Salinity To Gradient ConversionStanley OkaforAinda não há avaliações

- Membrane Potential MCQ-WPS OfficeDocumento5 páginasMembrane Potential MCQ-WPS OfficeFavourAinda não há avaliações

- Tic Reinforced AmcDocumento27 páginasTic Reinforced AmcarlyAinda não há avaliações

- Air PollutionDocumento19 páginasAir PollutionMika Hakimie100% (1)

- Molar Mass of A SolidDocumento10 páginasMolar Mass of A SolidTrong DuongAinda não há avaliações

- Ultimate Cheatcode CematconDocumento82 páginasUltimate Cheatcode CematconJulian Deleon100% (1)

- CAPE Biology Lab - EnzymesDocumento10 páginasCAPE Biology Lab - EnzymesAshleigh SmithAinda não há avaliações

- A Project of Mechanics of MaterialsDocumento13 páginasA Project of Mechanics of MaterialsShahZaib AnwarAinda não há avaliações

- GSI SLV SFI Whitepaper EN PDFDocumento9 páginasGSI SLV SFI Whitepaper EN PDFjayahasanAinda não há avaliações

- Thermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)Documento3 páginasThermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)rajaraghuramvarmaAinda não há avaliações

- Pages From SAES-H-001-19Documento1 páginaPages From SAES-H-001-19mohammed s fawabAinda não há avaliações

- EnzymeDocumento3 páginasEnzymemiriam harriottAinda não há avaliações

- Ejercicios PDFDocumento4 páginasEjercicios PDFserepoesia10Ainda não há avaliações

- Die-Materials classEDITDocumento45 páginasDie-Materials classEDITSatya AsatyaAinda não há avaliações

- 780HT - Catalytic Gas DetectorDocumento48 páginas780HT - Catalytic Gas DetectorinelecstarAinda não há avaliações

- Properties of Water Table Temperature Density Dynamic ViscosityDocumento1 páginaProperties of Water Table Temperature Density Dynamic ViscosityCstiosenAinda não há avaliações

- Nanotechnology: Yung Liou P601 Yung@phys - Sinica.edu - TW Institute of Physics Academia SinicaDocumento58 páginasNanotechnology: Yung Liou P601 Yung@phys - Sinica.edu - TW Institute of Physics Academia SinicaPragyaAinda não há avaliações

- Olaer VguDocumento2 páginasOlaer Vguadyro12Ainda não há avaliações

- Viscoelastic Creep and Stress-Strain BehaviorDocumento11 páginasViscoelastic Creep and Stress-Strain BehaviorHARIMETLYAinda não há avaliações

- A Genomic LibraryDocumento5 páginasA Genomic LibraryPabloAinda não há avaliações

- CR8047 Sulzer CompaX Short Report1Documento20 páginasCR8047 Sulzer CompaX Short Report1DucVikingAinda não há avaliações

- Creep and Failure of Lead-Free Solder AlloysDocumento77 páginasCreep and Failure of Lead-Free Solder AlloysTamara KhasimaAinda não há avaliações

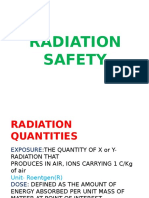

- RADIATION SAFETY FUNDAMENTALSDocumento69 páginasRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Pressure Swing Adsorption in The Unit Operations LaboratoryDocumento8 páginasPressure Swing Adsorption in The Unit Operations Laboratorydilip matalAinda não há avaliações

- Lead Acid Batteries in Critical ApplicationsDocumento24 páginasLead Acid Batteries in Critical Applicationsger80100% (1)

- OzonolysisDocumento1 páginaOzonolysisThu NguyenAinda não há avaliações

- Carboxyl GroupDocumento13 páginasCarboxyl GroupMuhammad Syazwan SapirenAinda não há avaliações

- SMAW LessonDocumento8 páginasSMAW LessonOJ DogplaceAinda não há avaliações

- MSCCH 506Documento176 páginasMSCCH 50620tamilselvi-ugcheAinda não há avaliações