Escolar Documentos

Profissional Documentos

Cultura Documentos

Whirlpool Case Sudy Soln

Enviado por

Anubhav KumarDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Whirlpool Case Sudy Soln

Enviado por

Anubhav KumarDireitos autorais:

Formatos disponíveis

Managing the Value Chain Amit Khattar Enrollment Number: 6010090920123

CASE ANALYSIS OPERATIONS AT WHIRLPOOL Assignment: 1. Whirlpool launched several initiatives in operations management in the 1990s and early 2000s, as a result of which, by the early 2000s, it product availability, inventory, and the lead time improved. Critically discuss the initiatives taken. 2. Whirlpool launched several e-initiatives to streamline its operations. How far did these initiatives contribute to the success of Whirlpool? Also discuss the importance of integrating e-initiatives with the other organizational processes Analysis of Assignment 1: Long before corporate social responsibility and corporate governance became a focus of business and society, Whirlpool Corporation employees were conducting business with integrity and extending a helping hand to stakeholders in times of need. Throughout the years, Whirlpool has built a culture of doing the right things based on living up to their commitments to stakeholders. Background Synopsis: Near the shores of Lake Michigan, Lou, Emory and Fred Upton created the Upton Machine Company in 1911 to produce electric, motordriven wringer washers. The company's first major order for 100 washing machines came almost immediately. A problem arose when a cast-iron gear in the transmission failedin every single machine. Upon learning of the issue, Lou Upton replaced the defective parts with a new cut-steel gear. Impressed with the fledgling company's business ethics, the customer doubled its order to 200 washing machines In the late 1980s, Whirlpool Corporation set out on a course of growth that would eventually transform the company into the leading global manufacturer of major home appliances, with operations based in every region of the world. At the time, Dave Whitwam, Whirlpool's chairman and CEO, had recognized the need to look for growth beyond the mature and highly competitive U.S. market. Under Mr. Whitwam's leadership, Whirlpool began a series of acquisitions that would give the company the scale and resources to participate in global markets. In the process, Whirlpool established new relationships with millions of customers in countries and cultures far removed from the U.S. market - and the company's roots in rural Benton Harbor, MI, U.S.

Managing the Value Chain Amit Khattar Enrollment Number: 6010090920123

The company had launched initiatives to have a competitive edge in the market. Some of the key initiatives that were driven internally were: 1. Globalization of a key function 2. Push and Pull Manufacturing 3. E-Initiatives Details of the Initiatives: 1. Globalization of a key function: In this process, Whirlpool globalized its procurement and product development functions. Whirlpool first globalized its procurement function. Being a global player, Whirlpool selected and partnered with the best suppliers globally. The company was clear of the objectives, which were: a) It would use products which are high quality and low cost materials and components and b) Deliver the best value to the customers Globalization of procurement was a win win for Whirlpool, as suppliers found it a lucrative partnership, due to the companys global presence, it gave them an opportunity to sell globally. For Whirlpool, it could get the best products at cost effective prices. As a second step, Whirlpool also globalized the product development. The intent behind taking this step was, to evolve quickly from the regional platforms to a global platform, while ensuring that the company meets the unique needs of consumers in all the diverse markets they serve. This would be achieved through a transfer of technology and knowledge around the globe - the product reaches the marketplace faster. The benefits realized from globalization of product development were: a) Fewer platforms gave the company the flexibility to design global products with regional features, such as energy efficiencies b) Performance variations were reduced c) Engineering costs were reduced d) Better performance and better features were delivered to the customer, hence increasing demand and the customer base 2. Push and Pull Manufacturing: In 1992, Dittmann was handed over the responsibility of restructuring the Whirlpools logistics in North America. Dittman chartered a team that consisted members from manufacturing, sales,

Managing the Value Chain Amit Khattar Enrollment Number: 6010090920123

procurement, accounting and material management. The team identified the opportunity areas in the manufacturing strategy that was being followed at Whirlpool, which was a Push method. The strategy had its strengths and weakness, which are elaborated in the table below: Strengths of the strategy Plants operated at full capacity Weaknesses of the strategy High Inventory: Oversupply at the distribution channel Unavailability of products: Production system was predesigned which did not allow flexibility for nonstandard orders. Hence a delay of 4 weeks to deliver. Low Efficiency

The companys supply chain chartered the vision, Winning companies will be those who come the closest to achieving an inter-enterprise pull system. They will be linked in a short cycle response mode to the customer. The illustration below shows the difference in the Pull and Push Model.

PUSH BASED MANUFACTURING Supplier Push Material Supply Push Production Customer Push Distribution Consumption

PULL BASED MANUFACTURING Customer Push Consumption Push Distribution Supplier Push Production Material Supply

Source: ICFAI Center for Management Research

Managing the Value Chain Amit Khattar Enrollment Number: 6010090920123 Whirlpool adopted the Pull strategy of manufacturing in the 1997, which indicates that the organization had clearly outlined the potential benefits of the Pull strategy, once implemented. Whirlpool used the Pull strategy in two different ways to ensure it optimizes the benefits in its manufacturing and planning system: Factory Production: a) Production was based on actual customer demand b) Production time was reduced significantly as any order received was immediately sent to the plant and the order was executed c) Response time for customers order fell drastically from four weeks to five days d) Reduced cycle time and improved accuracy of forecasting demand Production Planning: a) Reality applied to Distributed Resource planning (RAD) application replaced the older application that was used in the Push strategy b) With the implementation of RAD, the cost of production and inventory was drastically reduced Whirlpool also launched a hybrid model, to cater to the demands of suppliers, who were comfortable with the Push model. The Hybrid model has the components of the newly designed Push strategy and the Pull strategy. 3. E-Initiatives: These initiatives were launched at Whirlpool, with the intent to enhance the communications with the suppliers, reduce the gaps between the suppliers and sales operations and to provide a better and faster service to the end customers. As a result of these initiatives, by the early 2000s, Whirlpool has a product availability of 90 to 95 per cent, inventories were reduced by 15 to 20 percent and the lead time became as low as five days.

Analysis of Assignment 2:

Managing the Value Chain Amit Khattar Enrollment Number: 6010090920123

Você também pode gostar

- Product Line Management A Complete Guide - 2019 EditionNo EverandProduct Line Management A Complete Guide - 2019 EditionAinda não há avaliações

- Case Study Dyson, Hoover and The Bagless Vacuum CleanerDocumento2 páginasCase Study Dyson, Hoover and The Bagless Vacuum CleanerMuhdAfiq100% (2)

- USA Today CaseDocumento10 páginasUSA Today CaseMasyitha MemesAinda não há avaliações

- Product Proliferation and Preemption Strategy SupplementsDocumento22 páginasProduct Proliferation and Preemption Strategy SupplementstantanwyAinda não há avaliações

- Segmentation CaseDocumento8 páginasSegmentation CaseHimanshu AgrawalAinda não há avaliações

- Case Kimura KK MM1Documento8 páginasCase Kimura KK MM1Anuj YadavAinda não há avaliações

- DellDocumento3 páginasDellMike PenceAinda não há avaliações

- Rang Rage: Hand-Painted Lifestyle: Group Case AssignmentDocumento5 páginasRang Rage: Hand-Painted Lifestyle: Group Case AssignmentGunjeshJhaAinda não há avaliações

- Question 3. What Recommendations Would You Make To Rolfs in Order To Address The Both Near-And Longer-Term Issues? AnswerDocumento1 páginaQuestion 3. What Recommendations Would You Make To Rolfs in Order To Address The Both Near-And Longer-Term Issues? AnswerAchal GoelAinda não há avaliações

- Honda Corporation, Case A and Case BDocumento3 páginasHonda Corporation, Case A and Case Bstar0912Ainda não há avaliações

- Markstrat - Team Nirvana - AphroditeDocumento9 páginasMarkstrat - Team Nirvana - AphroditeMaithili JoshiAinda não há avaliações

- Timbuk 2Documento6 páginasTimbuk 2foglaabhishekAinda não há avaliações

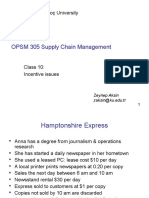

- Hampshire ExpressDocumento29 páginasHampshire Expressvivek0% (1)

- Resume 3 How To Fail in Project Management (Without Really Trying)Documento6 páginasResume 3 How To Fail in Project Management (Without Really Trying)eshaeelelyeAinda não há avaliações

- Icrosoft Canada Sales AND Product Management Working TogetherDocumento7 páginasIcrosoft Canada Sales AND Product Management Working TogetherManoj TyagiAinda não há avaliações

- Presentation ITC EchoupalDocumento20 páginasPresentation ITC Echoupalsatabdi_123Ainda não há avaliações

- End TermDocumento2 páginasEnd TermRahul GuptaAinda não há avaliações

- Peperfry NetDocumento14 páginasPeperfry Netsatyam palAinda não há avaliações

- Case 1 - Group 8Documento10 páginasCase 1 - Group 8VishvendraAinda não há avaliações

- A Roadmap For Branding in Industrial MarketsDocumento15 páginasA Roadmap For Branding in Industrial MarketsVicky Lo NgocAinda não há avaliações

- Executive Shirt Company - Group 6Documento8 páginasExecutive Shirt Company - Group 6Puneet Agarwal100% (1)

- Cradle To Cradle Design at Herman Miller: by Group MDocumento10 páginasCradle To Cradle Design at Herman Miller: by Group MParas AgarwalAinda não há avaliações

- Q.1What Is The Competitive Priorities For Synthite?: Input DataDocumento4 páginasQ.1What Is The Competitive Priorities For Synthite?: Input DatarakeshAinda não há avaliações

- Case Analysis RTE CerealDocumento5 páginasCase Analysis RTE CerealArisnal Marajo100% (1)

- Destin Brass ProductDocumento5 páginasDestin Brass ProductRamalu Dinesh ReddyAinda não há avaliações

- Harrington Collection: Sizing Up The Active-Wear Market: Presented By: Rachit Gupta Poonam Chauhan Subhasish DasDocumento13 páginasHarrington Collection: Sizing Up The Active-Wear Market: Presented By: Rachit Gupta Poonam Chauhan Subhasish DasPoonam Chauhan100% (2)

- Rupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)Documento8 páginasRupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)RupeshGupta50% (2)

- Industrial Chemical Inc - Pigment DivisionDocumento8 páginasIndustrial Chemical Inc - Pigment DivisionRahul NiranwalAinda não há avaliações

- Reinventing Best Buy: Group 1: Akash Khemka DM22106 Aman Pathak DM22108 Dinakaran S DM22118Documento4 páginasReinventing Best Buy: Group 1: Akash Khemka DM22106 Aman Pathak DM22108 Dinakaran S DM22118Shubham ThakurAinda não há avaliações

- Case AnalysisDocumento11 páginasCase AnalysisSrinivasan IyerAinda não há avaliações

- Assigment 6 - Managerial Finance Capital BudgetingDocumento5 páginasAssigment 6 - Managerial Finance Capital BudgetingNasir ShaheenAinda não há avaliações

- Dell Case Study QuestionsDocumento4 páginasDell Case Study QuestionsMike PenceAinda não há avaliações

- Kristen's Cookie CompanyDocumento18 páginasKristen's Cookie CompanyJasim ShaikhAinda não há avaliações

- BA363 Le Petit Chef Case AnalysisDocumento2 páginasBA363 Le Petit Chef Case AnalysisAdisorn SribuaAinda não há avaliações

- Scotts Miracle GroDocumento10 páginasScotts Miracle GromsarojiniAinda não há avaliações

- Cleanspritz ReDocumento2 páginasCleanspritz ReSiddharthAinda não há avaliações

- Donner Company 2Documento6 páginasDonner Company 2Nuno Saraiva0% (1)

- Craddle To Craddle Design at Herman Miller: Case Study: Sumbitted by (Group 1)Documento14 páginasCraddle To Craddle Design at Herman Miller: Case Study: Sumbitted by (Group 1)Chetan SahuAinda não há avaliações

- Syndicate 2-Industry 4.0Documento11 páginasSyndicate 2-Industry 4.0Dina Rizkia RachmahAinda não há avaliações

- Final Project Strategic Management and PolicyDocumento10 páginasFinal Project Strategic Management and PolicyBushra ImranAinda não há avaliações

- Case 1 AnswersDocumento3 páginasCase 1 AnswersMuhammad SulemanAinda não há avaliações

- Case QuestionsDocumento2 páginasCase Questionsarpit_96880% (1)

- Atul Pgp09074Documento20 páginasAtul Pgp09074atulAinda não há avaliações

- Vdocuments - MX Bayonne Packaging Inc Case StudyDocumento11 páginasVdocuments - MX Bayonne Packaging Inc Case StudyPaula Andrea GarciaAinda não há avaliações

- Operations Management Dr. Rogelio OlivaDocumento8 páginasOperations Management Dr. Rogelio OlivaA SAinda não há avaliações

- Gillette - Indonesia TemplateDocumento3 páginasGillette - Indonesia TemplateSona VardanyanAinda não há avaliações

- Classic Ltd.Documento3 páginasClassic Ltd.Alexandra CaligiuriAinda não há avaliações

- Markstrat - Users Guide, Positioning and RDDocumento22 páginasMarkstrat - Users Guide, Positioning and RDkanishka sharmaAinda não há avaliações

- Consumer BehaviourDocumento20 páginasConsumer BehaviourNeelam MahatoAinda não há avaliações

- Case AnalysisDocumento3 páginasCase AnalysisVIPUL TUTEJAAinda não há avaliações

- DWDG Case 1 - MewDocumento3 páginasDWDG Case 1 - MewJAY BHAVIN SHETH (B14EE014)Ainda não há avaliações

- Accounting For The Intel Pentium Chip Flaw - QuestionsDocumento1 páginaAccounting For The Intel Pentium Chip Flaw - QuestionsShaheen MalikAinda não há avaliações

- IKEA Child LabourDocumento17 páginasIKEA Child LabourMrityunjai kushawahaAinda não há avaliações

- Illinois Tool Works Case OutlineDocumento2 páginasIllinois Tool Works Case Outlinehhunter530Ainda não há avaliações

- B2B Term PaperDocumento8 páginasB2B Term PaperSamyukt AgrawalAinda não há avaliações

- GI - Case Analysis Note-1 15.01Documento3 páginasGI - Case Analysis Note-1 15.01Manish CarpenterAinda não há avaliações

- GE Health Care Case: Executive SummaryDocumento4 páginasGE Health Care Case: Executive SummarykpraneethkAinda não há avaliações

- Decision Tree To Evaluate Capacity AlternativesDocumento2 páginasDecision Tree To Evaluate Capacity AlternativesShashank TewariAinda não há avaliações

- Great Lakes PLPDocumento6 páginasGreat Lakes PLPJoydip Sarkar0% (2)

- This Study Resource Was: Rural MarketingDocumento4 páginasThis Study Resource Was: Rural MarketingMelvin ShajiAinda não há avaliações

- Fly Ash MissionDocumento8 páginasFly Ash MissionAnubhav KumarAinda não há avaliações

- IHS McCloskey Coal Report Summary - Mar 22, 2013Documento2 páginasIHS McCloskey Coal Report Summary - Mar 22, 2013Anubhav KumarAinda não há avaliações

- Walmart Case SolutionDocumento4 páginasWalmart Case SolutionAnubhav Kumar100% (2)

- Global Marketing AssignmentDocumento6 páginasGlobal Marketing AssignmentAnubhav KumarAinda não há avaliações

- What Is The Theory of Constraints?: The Goal Focuses On Constraints As Bottleneck ProcessesDocumento12 páginasWhat Is The Theory of Constraints?: The Goal Focuses On Constraints As Bottleneck ProcessesAnubhav KumarAinda não há avaliações

- Pune Consultants ListDocumento5 páginasPune Consultants Listvineet 25Ainda não há avaliações

- Operation Management Case MRP at A Cat Corp PDFDocumento44 páginasOperation Management Case MRP at A Cat Corp PDFSanju Durgapal100% (2)

- SAP Project LifecycleDocumento2 páginasSAP Project LifecyclepoonamAinda não há avaliações

- Class 8 Civics Chapter 3 Extra Questions and Answers Why Do We Need A ParliamentDocumento7 páginasClass 8 Civics Chapter 3 Extra Questions and Answers Why Do We Need A ParliamentTanuj100% (1)

- House Judiciary Summary of USA Liberty Act To Reform and Reauthorize Section FISA Section 702Documento2 páginasHouse Judiciary Summary of USA Liberty Act To Reform and Reauthorize Section FISA Section 702Beverly TranAinda não há avaliações

- Table of Specifications For Philippine Politics and GovernanceDocumento3 páginasTable of Specifications For Philippine Politics and GovernanceCaptain Obvious100% (1)

- RA 8436 As Amended by RA 9369 - Election Modernization ActDocumento8 páginasRA 8436 As Amended by RA 9369 - Election Modernization ActWeng CuevillasAinda não há avaliações

- Menjadi KasekDocumento19 páginasMenjadi Kasekjoseph sulistyoAinda não há avaliações

- Pembagian Kursi - Peserta Peg Fix 210219Documento105 páginasPembagian Kursi - Peserta Peg Fix 210219Catherine Nur KomaraAinda não há avaliações

- Republic Act No. 9369, Which Is The Amended Elections Automation Law ProvidesDocumento5 páginasRepublic Act No. 9369, Which Is The Amended Elections Automation Law ProvidesNanceAinda não há avaliações

- ISO 9001 Awareness TrainingDocumento27 páginasISO 9001 Awareness TrainingA MAinda não há avaliações

- Asemahle MdokoDocumento12 páginasAsemahle MdokovinnieverilAinda não há avaliações

- 14 - Professional ResponsibilityDocumento31 páginas14 - Professional ResponsibilityJenish PanchalAinda não há avaliações

- Bussiness Process Management Chapter 1 ResumeDocumento8 páginasBussiness Process Management Chapter 1 ResumexcavoxAinda não há avaliações

- AIBE 2016 List of FP Books (English and Hindi)Documento3 páginasAIBE 2016 List of FP Books (English and Hindi)asb231Ainda não há avaliações

- Citizen CharterDocumento25 páginasCitizen CharterRuby Ana Aceret86% (7)

- Brunai ReformDocumento16 páginasBrunai ReformPanji WinataAinda não há avaliações

- IS&T Project Management: Project Management 101: June, 2006Documento17 páginasIS&T Project Management: Project Management 101: June, 2006Anurag PharkyaAinda não há avaliações

- The Scale of GlobalizationDocumento387 páginasThe Scale of GlobalizationLaur GoeAinda não há avaliações

- Value Stream MappingDocumento3 páginasValue Stream MappingMuhammad Fatah KaryadiAinda não há avaliações

- Six Steps For Enterprise Architecture As StrategyDocumento2 páginasSix Steps For Enterprise Architecture As StrategyoparikokoAinda não há avaliações

- Business AcumenDocumento28 páginasBusiness AcumenJustin Chia100% (3)

- Line & StaffDocumento5 páginasLine & StaffngjrAinda não há avaliações

- Online Voting System PresentationDocumento9 páginasOnline Voting System PresentationZaeem AzeemAinda não há avaliações

- Pew Upgrading Voter RegistrationDocumento12 páginasPew Upgrading Voter RegistrationLaney SommerAinda não há avaliações

- 2016 Pcso Manual of Corporate GovernanceDocumento167 páginas2016 Pcso Manual of Corporate GovernanceRufino Gerard Moreno100% (1)

- Nature of Operations Strategy: Different Competitive Factors Imply Different Performance ObjectivesDocumento4 páginasNature of Operations Strategy: Different Competitive Factors Imply Different Performance ObjectivesAnggini PangestuAinda não há avaliações

- A. Libanan vs. House of Representatives Electoral TribunalDocumento19 páginasA. Libanan vs. House of Representatives Electoral TribunalAlexAinda não há avaliações

- Chap002 DemandDocumento30 páginasChap002 DemandVikas KashyapAinda não há avaliações

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsDocumento3 páginasCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsAinda não há avaliações