Escolar Documentos

Profissional Documentos

Cultura Documentos

Untitled

Enviado por

Wesame ShnodaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Untitled

Enviado por

Wesame ShnodaDireitos autorais:

Formatos disponíveis

Chapter One Crude Oil Properties 1 Introduction Crude petroleum is very complex and, except for the low-boiling

components, no a ttempt is made by the refiner to analyze for the pure components contained in th e crude oil. Relatively simple analytical tests are run on the crude and the res ults of these are used with empirical correlations to evaluate the crude oils as feedstocks for the particular refinery. Each crude is compared with the other fe edstocks available and, based upon the operating cost and product realization, i s assigned a value. The more useful properties are discussed. 2 The crude oil assay The crude oil assay is a compilation of laboratory and pilot plant data that def ine the properties of the specific crude oil. At a minimum the assay should cont ain a distillation curve for the crude and a specific gravity curve. Most assays however contain data on pour point (flowing criteria), sulfur content, viscosit y, and many other properties. The assay is usually prepared by the company selli ng the crude oil, it is used extensively by refiners in their plant operation, development of product schedul es, and examination of future processing ventures. Engineering companies use the assay data in preparing the process design of petroleum plants they are bidding on or, having been awarded the project, they are now building. 2.1 The true boiling point curve This is a plot of the boiling points of almost pure components, contained in the crude oil or fractions of the crude oil. In earlier times this curve was produc ed in the laboratory using complex batch distillation apparatus of a hundred or more equilibrium stages and a very high reflux ratio. Nowadays this curve is pro duced by mass spectrometry techniques much quicker and more accurately than by b atch distillation. A typical true boiling point curve (TBP) is shown in Figure 1 .1.

Figure 1.1. Typical pseudo component breakdown. 2.2 API Gravity The density of petroleum oils is expressed in the United States in terms of API gravity rather than specific gravity; it is related to specific gravity in such a fashion that an increase in API gravity corresponds to a decrease in specific gravity. The units of API gravity are API and can be calculated from specific gra vity

by the following:

In equation (1), specific gravity and API gravity refer to the weight per unit v olume at 60 F as compared to water at 60 F. Crude oil gravity may range from less th an 10 API to over 50 API but most crudes fall in the 20 to 45 API range. API gravity a lways refers to the liquid sample at 60 F (15.6 C). API gravities are not linear and , therefore, cannot be averaged. For example, a gallon of 30 API gravity hydrocarb ons when mixed with a gallon of 40 API hydrocarbons will not yield two gallons of 35 API hydrocarbons, but will give two gallons of hydrocarbons with an API gravity different from 35 API. Specific gravities can be averaged. 2.3 Sulfur Content, wt% Sulfur content and API gravity are two properties which have had the greatest in fluence on the value of crude oil, although nitrogen and metals contents are inc reasing in importance. The sulfur content is expressed as percent sulfur by weig ht and varies from less than 0.1% to greater than 5%. Crudes with greater than 0 .5% sulfur generally require more extensive processing than those with lower sul fur content. Although the term sour crude initially had reference to those crudes co ntaining dissolved hydrogen sulfide independent of total sulfur content, it has come to mean any crude oil with a sulfur content high enough to require special processing. There is no sharp dividing line between sour and sweet crudes, but 0 .5% sulfur content is frequently used as the criterion. 2.4 Pour Point, F ( C) The pour point of the crude oil, in F or C, is a rough indicator of the relative p araffinicity and aromaticity of the crude. The lower the pour point, the lower t he paraffin content and the greater the content of aromatics. 2.5 Carbon Residue, wt% Carbon residue is determined by distillation to a coke residue in the absence of air. The carbon residue is roughly related to the asphalt content of the crude and to the quantity of the lubricating oil fraction that can be recovered. In mo st cases the lower the carbon residue, the more valuable the crude. This is expr essed in terms of the weight percent carbon residue by either the Ramsbottom (RCR) or Con radson (CCR) ASTM test procedures (D-524 and D-189). 2.6 Salt Content, lb/1000 bbl If the salt content of the crude, when expressed as NaCl, is greater than 10 lb/ 1000 bbl, it is generally necessary to desalt the crude before processing. If t he salt is not removed, severe corrosion problems may be encountered. If residua are processed catalytically, desalting is desirable at even lower salt contents of the crude. Although it is not possible to have an accurate conversion unit betwe en lb/1000 bbl and ppm by weight because of the different densities of crude oil s, 1 lb/1000 bbl is approximately 3 ppm. 2.7 Characterization Factors There are several correlations between yield and the aromaticity and paraffinici ty of crude oils, but the two most widely used are the UOP or Watson characterization factor (KW) and the U.S. Bureau of Mines correlation index (CI).

The Watson characterization factor ranges from less than 10 for highly aromatic materials to almost 15 for highly paraffinic compounds. Crude oils show a narrow er range of KW and vary from 10.5 for a highly naphthenic crude to 12.9 for a pa raffinic base crude. The correlation index is useful in evaluating individual fr actions from crude oils. The CI scale is based upon straight-chain paraffins hav ing a CI value of 0 and benzene having a CI value of 100. The CI values are not quantitative, but th e lower the CI value, the greater the concentrations of paraffin hydrocarbons in the fraction; and the higher the CI value, the greater the concentrations of na phthenes and aromatics [3]. 2.8 Nitrogen Content, wt% A high nitrogen content is undesirable in crude oils because organic nitrogen co mpounds cause severe poisoning of catalysts used in processing and cause corrosi on problems such as hydrogen blistering. Crudes containing nitrogen in amounts a bove 0.25% by weight require special processing to remove the nitrogen. 2.9 Distillation Range The boiling range of the crude gives an indication of the quantities of the vari ous products present. The most useful type of distillation is known as a true bo iling point (TBP) distillation and generally refers to a distillation performed in equipment that accomplishes a reasonable degree of fractionation. There is no specific test procedure called a TBP distillation, but the U.S. Bureau of Mines Hempel and ASTM D-285 distillations are the tests most commonly used. Neither o f these specify either the number of theoretical plates or the reflux ratio used and, as a result, there is a trend toward using the results of a 15:5 distillat ion (D- 2892) rather than the TBP. The 15:5 distillation is carried out using 15 theoretical plates at a reflux ratio of 5: 1. The crude distillation range also has to be correlated with ASTM distillations because product specifications are generally based on the simple ASTM distillati on tests D-86 and D-1160. The TBP cut point for various fractions can be approxi mated by use of Figure 3.1. A more detailed procedure for correlation of ASTM an d TBP distillations is given in the API Technical Data BookPetroleum Refining pub lished by the American Petroleum Institute, Washington, DC.

2.10 Metals

Você também pode gostar

- PGP030 031 SeriesDocumento28 páginasPGP030 031 SeriesWesame ShnodaAinda não há avaliações

- Galtech Pumps MotorsDocumento0 páginaGaltech Pumps MotorsWesame ShnodaAinda não há avaliações

- A6 VDocumento40 páginasA6 VWesame Shnoda100% (1)

- ETC ETC ETC ETC: Egyptian Technology CommunicationDocumento2 páginasETC ETC ETC ETC: Egyptian Technology CommunicationWesame ShnodaAinda não há avaliações

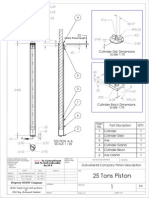

- 1 25 Tons Piston: (Gland Thread Length)Documento1 página1 25 Tons Piston: (Gland Thread Length)Wesame ShnodaAinda não há avaliações

- BTL5-A11-M0650-B-S32 Ordering Code: BTL0174: Output Signal 0 10 V and 10 0 V Nominal Stroke 650 MMDocumento2 páginasBTL5-A11-M0650-B-S32 Ordering Code: BTL0174: Output Signal 0 10 V and 10 0 V Nominal Stroke 650 MMWesame ShnodaAinda não há avaliações

- Hydraulic System Troubleshooting Guide PDFDocumento13 páginasHydraulic System Troubleshooting Guide PDFWesame Shnoda100% (1)

- Elevators Type From OttisDocumento2 páginasElevators Type From OttisWesame ShnodaAinda não há avaliações

- Elevators From WikepediaDocumento47 páginasElevators From WikepediaWesame ShnodaAinda não há avaliações

- Report No (1) Haydrulic MachinesDocumento15 páginasReport No (1) Haydrulic MachinesWesame Shnoda100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Ofsaai Ic 72 E22351 01Documento312 páginasOfsaai Ic 72 E22351 01Mohamed AbrarAinda não há avaliações

- Учебный предметDocumento2 páginasУчебный предметorang shabdizAinda não há avaliações

- HLA HART Concept of LawDocumento19 páginasHLA HART Concept of LawHarneet KaurAinda não há avaliações

- Understanding PumpDocumento113 páginasUnderstanding Pumpnyr1981_942955963100% (5)

- Calculating Staff Strength:: Find Latest Hospitality Resources atDocumento8 páginasCalculating Staff Strength:: Find Latest Hospitality Resources atPriyanjali SainiAinda não há avaliações

- Diagnostic Test - Tle8Documento2 páginasDiagnostic Test - Tle8rose mae marambaAinda não há avaliações

- IO5 Future Skills Foresight 2030 ReportDocumento96 páginasIO5 Future Skills Foresight 2030 ReportjuliavalleAinda não há avaliações

- MODULE 1 - Contemporary WorldDocumento4 páginasMODULE 1 - Contemporary WorldaapAinda não há avaliações

- Learning Theories Behaviourism, Cognitivism, Social ConstructivismDocumento39 páginasLearning Theories Behaviourism, Cognitivism, Social ConstructivismJuan Miguel100% (3)

- Test Bank For Body Structures and Functions 11th Edition Ann ScottDocumento27 páginasTest Bank For Body Structures and Functions 11th Edition Ann Scottpellucidutter.uka6lr100% (38)

- Finite Element Modeling Analysis of Nano Composite Airfoil StructureDocumento11 páginasFinite Element Modeling Analysis of Nano Composite Airfoil StructureSuraj GautamAinda não há avaliações

- The FlyDocumento8 páginasThe FlyDrei Tiam Lacadin100% (1)

- D4462045416 PDFDocumento3 páginasD4462045416 PDFSamir MazafranAinda não há avaliações

- Application Tracking System: Mentor - Yamini Ma'AmDocumento10 páginasApplication Tracking System: Mentor - Yamini Ma'AmBHuwanAinda não há avaliações

- Course Information2009 2010Documento4 páginasCourse Information2009 2010shihabnittAinda não há avaliações

- To Tell The TruthDocumento5 páginasTo Tell The TruthNabeel Ahmed KhanAinda não há avaliações

- Research Paper OutlineDocumento2 páginasResearch Paper Outlineapi-270769683Ainda não há avaliações

- SWAMINATHAN Ajanta RhapsodyDocumento227 páginasSWAMINATHAN Ajanta RhapsodyRoberto E. García100% (1)

- Using The Words in The Box, Fill in All The GapsDocumento23 páginasUsing The Words in The Box, Fill in All The GapsMo NoAinda não há avaliações

- Jungbluth Main Catalogue-LanacDocumento60 páginasJungbluth Main Catalogue-LanacMilenkoBogdanovicAinda não há avaliações

- Lesson 7Documento6 páginasLesson 7Jeya Plays YTAinda não há avaliações

- CIT 811 TMA 4 Quiz QuestionDocumento3 páginasCIT 811 TMA 4 Quiz QuestionjohnAinda não há avaliações

- Orange County Sheriff's Office SeaWorld Death Investigative ReportDocumento43 páginasOrange County Sheriff's Office SeaWorld Death Investigative ReportWESH2News100% (1)

- Homeopatia Vibracional RatesDocumento45 páginasHomeopatia Vibracional RatesAugusto Bd100% (4)

- Module 2 - Part III - UpdatedDocumento38 páginasModule 2 - Part III - UpdatedDhriti NayyarAinda não há avaliações

- Volcanic SoilsDocumento14 páginasVolcanic SoilsVictor Hugo BarbosaAinda não há avaliações

- STRESS HealthDocumento40 páginasSTRESS HealthHajra KhanAinda não há avaliações

- British Airways Culture and StructureDocumento29 páginasBritish Airways Culture and Structure陆奕敏Ainda não há avaliações

- Isp List MatiurDocumento3 páginasIsp List Matiurmatiur7Ainda não há avaliações

- Technology For Duck - Fish Integrated Farming System in GoaDocumento4 páginasTechnology For Duck - Fish Integrated Farming System in GoagavinilaaAinda não há avaliações