Escolar Documentos

Profissional Documentos

Cultura Documentos

3.earth Mat

Enviado por

Prabhash VermaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3.earth Mat

Enviado por

Prabhash VermaDireitos autorais:

Formatos disponíveis

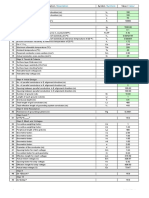

EARTH MAT DESIGN.

Estep50 Estep70 Etouch50 Etouch70 Em Es

Tolerable step voltage for human with 50Kg body weight-Volts Tolerable step voltage for human with 50Kg body weight-Volts Tolerable touch voltage for human with 50Kg body weight-Volts Tolerable touch voltage for human with 50Kg body weight-Volts Mesh voltage at the centre of the corner mesh for the simplified method. Step voltage between point above the outer corner of the grid and point 1m diagonally outside the grid of the simplified method,V

SYMBOL If s A Tf

DESCRIPTION Fault current in Amps Resistivity of soil ohm-meter Resistivity of surface layer ohm-meter Total area encloused by ground grid-Sqmtr Duration of fault current for determination of decrement factor in Sec Temprature rise in Degree Celcius GRID DETAILS. Depth of ground grid conductor-meter surface layer thickness-meter Equally spaced conductors No of CI or GI Pipe Peripheral length of of the grid in meter Maximum length of grid conductor in X direction Maximum length of grid conductor in Y direction Total length of the grid conductor Total length of ground rod in meter length of ground rod at each location in meter Total effective length of grounding system conductor,Including grid and ground rods, in meter efective length of Lc+LR for mesh voltage Diameter of grid conductors-metre Spacing between parallel conductors. FACTORS REQUIRED FOR CALCULATION Surface layer derating factor Decreament factor for determining Ig Current division factor

16000 1000 1500 100 1 250

H Hs N Np Lp Lx Ly Lc LR Lr Lt

0.6 0.6 21 2 40 10 10 210 6 3

Lm d D

216 216 0.019543 0.2

Cs Df Sf

1.0 1 0.5

I Ig R n Ki Km

Maximum grid current that flows between groung grid and surrounding earth in Amps Symmetrical grid curent in Amps Measured resistance in Ohm Geomotric factor composed of factors na,nb,nc,nd Correction factor for grid geometry,simplified method spacing factor for mesh voltage,simplified method.

8000

STEP:1

Field data Area available in Sqmeter Fault Current If=(In/%Z) Earth strip size calculation. Refer sheet earthstrip size calculation. Select appropriate flat size Diameter of the strip Surface layer derating factor Cs=1-(0.09(1-/s)/(2*Hs+.09)) PERMISSIBLE TOUCH AND STEP VOLTAGE.

100 Sqmeter

STEP:2

16000 Amps

STEP:3

265.0 Sqmm 50x6mm Al Flat 0.020 mm

STEP:4

0.977

STEP:4

Estep70 Estep70=(1000+6*Cs*s)*0.157/Tf Etouch70 Etouch70=(1000+1.5*Cs*Ps)*0.157/SqrtTf Estep50 Estep50=(1000+6*Cs*s)*0.116/Tf Etouch50 Etouch50=(1000+1.5*Cs*Ps)*0.116/SqrtTf

1537.1 Volts 502.0 Volts

1135.7 Volts 370.9 Volts

STEP:6

GROUND POTENTIAL RISE WITHOUT GROUND RODS Grid resistance in Ohm without pipe Rg=P(1/Lt+1/(20*A)*(1+1/(1+H*(20/A)))) Maximum Grid current Ig=Df*Sf*If Ground Potential rise GPR=Ig*Rg

44.6

STEP:7

8000

STEP:8

356962.8181

If GPR<Etouch 70 then design is OK If GPR>Etouch 70 then you need to calculate the mesh voltage . CALCULATION OF MESH VOLTAGE STEP:9 Em=Mesh Voltage

Em=P*Ig*Km*Ki/(Lc)

28340.73222

Where Km=1/2*3.142*(In((D*D/16*H*d)+((D+2*H)*(D+H*2)/(8*D*d))-(H/4*d))+Kii/Kh*In(8/3.142*(2*n-1))) 0.48366268 -0.145198521 Km= 0.338464159 Where Kii=1/(2*n)power2/n 0.5599493 1/(2*n)= 0.047619048 Kh=Sqrt(1+H/Ho) Where Ho=1meter Grid reference path n=na*nb*nc*nd nb=1,nc=1,nd=1 for squre grid na=2*Lc/Lp Ki=0.644+0.148*n 1.264911064

10.5 10.5 2.198

If Em<Etouch Design is OK If Em>Etouch Futher modification to be done. with additional ground rounds to be insetred GROUND POTENTIAL RISE WITH GROUND RODS Rg= GPR= For ground rod Kii=1.0 0.48366268 -0.259306551 0.224356129 44.6 356962.8181

STEP:10

Km= Em=Mesh Voltage Em=P*Ig*Km*Ki/Lc+(1.55+1.22(Lr/Sqrt((Lx*Lx)+(Ly*Ly))*LR Em=

17862.9298

STEP:10

Es=Step Voltage Es=P*Ig*Ks*Ki/(0.75*Lc+0.85*LR) Where Ks=1/3.142(1/2*H+1/D+H+1/D*(1-0.5powern-2)) 243321.8129

2.25000721

FIELD DATA A,

CALCULATE CONDUCTOR SIZE

TOUCH AND STEP CRITERIA Etouch 50or 70,Estep 50 or 70

INITIAL DESIGN D.n.Lc.Lt.h

GRID RESISTANCE Rg.Lc.Lr

MODIFY DESIGN D.n.Lc.Lt

GRID CURRENT Ig.Tf

IgRg<Etouch NO MESH & STEP VOLTAGES Em.Es.Km.Ks Ki.Kii.Kh

YES

NO

Em<Etouch YES

NO

Es<Estep YES DETAIL DESIGN

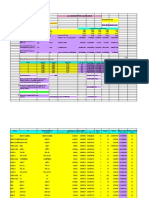

AS PER IS 3043-1987 CALCULATION OF EARTH PITS FORMULAS Earth Resistivity =2SR ohm-m Where S=Distance betweem successive electrodes in m R=Earth megger reading in ohms Current density for 3sec Copper=118Amps/Sqmm Aluminium=73Amps/Sqmm Steel(GI)=46Amps/Sqmm Current Density permissible at an Earth Electrode is given by Id= (7.57*1000)/(xt) Amps/Sqmeter Where =resistivity of soil in ohms t=Duration of fault in sec Electrode Resistance (1)Plate RI= /A*/A Ohms 100/2Llog4L/d ohms (2)Pipe or Rod= (3) Stip or Conductor=100/2Llog2L/wt ohms

NON EDITABLE DATA EDITABLE DATA

Where

=earth Resistivity ion ohms A=Area of bothsides of plate in Sq.m. L=length in cm d=Dia of Pipe or rod in cm w=Depth of Burial of stripelectrode in cm. t=Width of strip or twice the diameter of circular conductor in cm.

Short Circuit Current(Isc) Soil resistivity( ) time(t) Current Density (Id)

65000 100 1 757

Amps Ohm-mtr Sec Amps/m

Copper Plate Plate size a)Width b)Height Surface area No of Plates required Earth resistance 0.6 0.6 0.72 N=Isc/Id/S 119.2573022 290.1378214 mtr mtr Sqmtr No's Ohms

S=

Diameter of Pipe Radius of GI Pipe length of Pipe Surface area No of Pipes required Earth resistance

R= L=

Cast iron pipe 5 0.025 2 S=(2x3.142xRxL) 0.3142 N=Isc/Id/S 273.2821693 40.381714

cm mtr mtr Sqmtr

No's Ohms

NON EDITABLE DATA EDITABLE DATA

EARTH STRIP SIZE CALCULATION SIZE CALCULATION

The minimum cross-sectional area of Busbar required to withstand specified short-circuit current for specified time is given by NON EDITABLE DATA A= (I/8.5)x(t/) A= (I/13)x(t/) A= (I/4.5)x(t/) A= (I/2.5)x(t/) For Aluminium EDITABLE DATA For Copper For Iron For Lead

Where A=Cross sectional Area in Sqmm I=Short Circuit Current in Amps t=Withstand time in sec 8.5= Constant for Aluminium 13= Constant for Copper 4.5= Constant for Iron 2.5= Consatnt for Lead =Temprature rise in Degree Celcius 180 Degree Celcius upto 2 Sec for Uninsulated Conductors 120 Degree Celcius upto 2 Sec for insulated Conductors 215 Degree Celcius above 2 Sec for Uninsulated Conductors 145 Degree Celcius above 2 Sec for insulated Conductors I in kA 35 16 25 35 50 70 85 t in Sec 1 1 1 1 1 1 1 Temp rise 215 180 180 180 180 215 180 A=in Sqmm Aluminium Iron 281 530 140 265 219 414 307 580 438 828 562 1061 745 1408

Copper 184 92 143 201 287 367 487

Lead 955 477 745 1043 1491 1910 2534

NON EDITABLE DATA EDITABLE DATA

Você também pode gostar

- Earth Mat CalculationDocumento5 páginasEarth Mat CalculationSOUMEN100% (2)

- Substation Earthing Design: Input DataDocumento12 páginasSubstation Earthing Design: Input Datapavan3961100% (1)

- 7.Lt Cable Sizing CalculationDocumento7 páginas7.Lt Cable Sizing CalculationPrabhash Verma67% (3)

- Earthing & Lightning Protection Calculations for ONGC Uran PlantDocumento27 páginasEarthing & Lightning Protection Calculations for ONGC Uran Plantmahesh_sali200380% (5)

- Ieee 80 Tiuch and Step Volt - Full CalcDocumento22 páginasIeee 80 Tiuch and Step Volt - Full CalcVasu Iyer100% (1)

- Earthing Design Calculation ParametersDocumento10 páginasEarthing Design Calculation ParametersRahul SrivastavaAinda não há avaliações

- HT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10Documento12 páginasHT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10mahesh_sali2003Ainda não há avaliações

- Short Circuit inDocumento1 páginaShort Circuit inKartino Surodipo100% (4)

- Power Cable SizingDocumento8 páginasPower Cable SizingPagdi Srini100% (1)

- Earthing Calculations for 110KV SwitchyardDocumento8 páginasEarthing Calculations for 110KV SwitchyardGarmangh GersAinda não há avaliações

- Cable Size & Voltage Drop Calculation (1.1.17)Documento52 páginasCable Size & Voltage Drop Calculation (1.1.17)kisan singh100% (1)

- Cote Divore and Mali Interconnection Project LT Power Cable ScheduleDocumento6 páginasCote Divore and Mali Interconnection Project LT Power Cable Schedule91thiyagarajanAinda não há avaliações

- LT Cable SizingDocumento12 páginasLT Cable SizingPramod B.WankhadeAinda não há avaliações

- Below Ground & Above Ground Earthing CalculationDocumento8 páginasBelow Ground & Above Ground Earthing CalculationPramod B.Wankhade0% (1)

- Earthing DesignDocumento12 páginasEarthing DesignRamesh AnanthanarayananAinda não há avaliações

- Calculate No of Plate-Pipe Earthing & Size of Earthing Strip (1.12.12)Documento40 páginasCalculate No of Plate-Pipe Earthing & Size of Earthing Strip (1.12.12)Jignesh ParmarAinda não há avaliações

- Grounding CalculationDocumento4 páginasGrounding CalculationimhalidaAinda não há avaliações

- Earthing Calculation, Touch VoltageDocumento20 páginasEarthing Calculation, Touch VoltageApsi Lal100% (8)

- Calculation of Earthing Sys.Documento12 páginasCalculation of Earthing Sys.Rania Fathy Mohammed100% (4)

- HV Cable Size Calculation ToolDocumento7 páginasHV Cable Size Calculation Tooltutti.frutti_virgo9470Ainda não há avaliações

- Annex 1 Revised Lightning Prot Calc REVISED PDFDocumento1 páginaAnnex 1 Revised Lightning Prot Calc REVISED PDFVasudevan KunjithapathamAinda não há avaliações

- 66kv Earthing System R-1 (For Print Out)Documento8 páginas66kv Earthing System R-1 (For Print Out)g_nraja100% (1)

- Earthing CalculationDocumento14 páginasEarthing CalculationNatarajan Ramakrishnan100% (18)

- Earthing Calculation IEEE 80Documento1 páginaEarthing Calculation IEEE 80HassenAinda não há avaliações

- Transformer SizingDocumento7 páginasTransformer SizingKarthikeyan VkAinda não há avaliações

- North Chennai Thermal Power Project Stage II (2x525 MW)Documento20 páginasNorth Chennai Thermal Power Project Stage II (2x525 MW)Hesham Abdullah AlAdwan100% (3)

- AC Cable SizingDocumento42 páginasAC Cable SizingMuhammad Mahmud100% (1)

- Cable Sizing CalculationDocumento2 páginasCable Sizing CalculationYrty Kdfg100% (1)

- Earthing Calculation 5Documento4 páginasEarthing Calculation 5rajpre1213100% (2)

- How To Build Solar FarmDocumento30 páginasHow To Build Solar Farmfibref100% (3)

- LT Cable Sizing Calculation SheetDocumento12 páginasLT Cable Sizing Calculation Sheet2003vinay100% (5)

- EarthingDocumento2 páginasEarthingApsi LalAinda não há avaliações

- Spray Shine Car WaxDocumento1 páginaSpray Shine Car Waxyilmaz_uuur100% (3)

- Earthing Calculation (DJS) - REV-1Documento7 páginasEarthing Calculation (DJS) - REV-1Bijaya Kumar MohantyAinda não há avaliações

- Earthing Calculation - Grid (Exm)Documento33 páginasEarthing Calculation - Grid (Exm)balaeee123Ainda não há avaliações

- Transmission Insulator SpecificationDocumento0 páginaTransmission Insulator Specificationrenjithas2005Ainda não há avaliações

- Earthing Resistance Calculations Is-3043Documento14 páginasEarthing Resistance Calculations Is-3043lrpatra67% (3)

- MD1-0-E-505!06!00001 Generator Transformer Sizing CalculationDocumento19 páginasMD1-0-E-505!06!00001 Generator Transformer Sizing Calculationtvpham12350% (2)

- 4.Ht Short Circuir CalculationDocumento11 páginas4.Ht Short Circuir CalculationPrabhash VermaAinda não há avaliações

- 4.Ht Short Circuir CalculationDocumento11 páginas4.Ht Short Circuir CalculationPrabhash VermaAinda não há avaliações

- SPL Bsts Jandaha Earthmat - Cal 005Documento11 páginasSPL Bsts Jandaha Earthmat - Cal 005rahulnegi19170% (1)

- Ground Grid SizingDocumento65 páginasGround Grid SizingMohan SaravanaAinda não há avaliações

- Optimization of Drum-Boiler Control Using State FeedbackDocumento70 páginasOptimization of Drum-Boiler Control Using State FeedbackAli Almisbah50% (2)

- Capacitor Sizing Calculation (5015 LT 00 EL 03 CA 0003) Rev 00Documento4 páginasCapacitor Sizing Calculation (5015 LT 00 EL 03 CA 0003) Rev 00Vineeta YadavAinda não há avaliações

- Lightning Protection Calculation for E-House Metalclad SubstationDocumento133 páginasLightning Protection Calculation for E-House Metalclad SubstationEkoFujisyahMaulwanto50% (2)

- UPS Battery SizingDocumento2 páginasUPS Battery SizingAbhijeet Durge100% (1)

- Earthmat Calculations For WTG HT YardDocumento3 páginasEarthmat Calculations For WTG HT YardSanthosh KumarAinda não há avaliações

- Earthing Calculation IEEEDocumento4 páginasEarthing Calculation IEEEAitor Lander Iza75% (4)

- Design Calculation For Electrical Earthing System: Client: Anrak Aluminium LimitedDocumento9 páginasDesign Calculation For Electrical Earthing System: Client: Anrak Aluminium Limitedparuchurivenkat5272100% (1)

- 2.battery SizingDocumento14 páginas2.battery SizingPrabhash Verma0% (1)

- 2.battery SizingDocumento14 páginas2.battery SizingPrabhash Verma0% (1)

- Earthing Calculation: Va Tech WabagDocumento8 páginasEarthing Calculation: Va Tech Wabaghari sudhanAinda não há avaliações

- Anodising Vs Powder CoatingDocumento3 páginasAnodising Vs Powder CoatingCgpscAspirantAinda não há avaliações

- Fault Level CalculationDocumento43 páginasFault Level Calculationmazumdar_satyajitAinda não há avaliações

- Summary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVDocumento42 páginasSummary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVPramod B.Wankhade100% (1)

- DSLP CalculationDocumento23 páginasDSLP CalculationMunusamyKarthikeyan100% (1)

- EarthingDocumento8 páginasEarthingboopelectraAinda não há avaliações

- Iran South Pars Gas Field cable sizingDocumento38 páginasIran South Pars Gas Field cable sizingNESHAT657100% (1)

- 132kv Cables For Transformer Feeder, Cables in Duct at 9029Documento4 páginas132kv Cables For Transformer Feeder, Cables in Duct at 9029Muhammad MahmudAinda não há avaliações

- Caclation of Short CircuitDocumento3 páginasCaclation of Short CircuitMohamed Mostafa100% (1)

- Quality and Testing of Packaging Materials & PackagesDocumento41 páginasQuality and Testing of Packaging Materials & PackagesChamara MadugalleAinda não há avaliações

- 5 EarthingDocumento4 páginas5 EarthingPrabhash Verma0% (1)

- 5 EarthingDocumento4 páginas5 EarthingPrabhash Verma0% (1)

- Calculation Cover Sheet: ClientDocumento8 páginasCalculation Cover Sheet: Clientanamaria ursuAinda não há avaliações

- SV POWER Lightning Protection Calculation Sheet - T.G BuildingDocumento11 páginasSV POWER Lightning Protection Calculation Sheet - T.G BuildingPrabhash Verma100% (2)

- SV POWER Lightning Protection Calculation Sheet - T.G BuildingDocumento11 páginasSV POWER Lightning Protection Calculation Sheet - T.G BuildingPrabhash Verma100% (2)

- 6.kvar CalculationDocumento4 páginas6.kvar CalculationPrabhash Verma100% (1)

- 6.kvar CalculationDocumento4 páginas6.kvar CalculationPrabhash Verma100% (1)

- Design Procedure Block Diagram Earthing CalculationDocumento17 páginasDesign Procedure Block Diagram Earthing CalculationMauricio Cesar Molina ArtetaAinda não há avaliações

- Water Quality WSO Student Workbook Water Supply OperationsDocumento69 páginasWater Quality WSO Student Workbook Water Supply OperationsdikeAinda não há avaliações

- Lightning ProtectionDocumento5 páginasLightning Protectionke72012100% (1)

- Design of Insulator - 07.11.11Documento1 páginaDesign of Insulator - 07.11.11Natarajan RamakrishnanAinda não há avaliações

- Grounding Calculation of Yards (r0)Documento13 páginasGrounding Calculation of Yards (r0)nidnitrkl051296100% (1)

- 3 Earth MatDocumento9 páginas3 Earth MatdesignselvaAinda não há avaliações

- Ground CalculationDocumento12 páginasGround CalculationafmAinda não há avaliações

- Cable CalculationDocumento5 páginasCable CalculationPrabhash VermaAinda não há avaliações

- LD Didactic OpticsDocumento42 páginasLD Didactic OpticsJames SullivanAinda não há avaliações

- A Facile Strategy To Simultaneously Improve The Mechanical and Fire SafetyDocumento43 páginasA Facile Strategy To Simultaneously Improve The Mechanical and Fire SafetyTia Nico Rossi RossiAinda não há avaliações

- 8629 - 1t3 Protection of Steel From CorrosionDocumento50 páginas8629 - 1t3 Protection of Steel From Corrosionkranthi kumarAinda não há avaliações

- Cooling System of TransformerDocumento6 páginasCooling System of TransformerFaiza RafliAinda não há avaliações

- Ball PistonDocumento15 páginasBall PistonNm5793100% (1)

- Cutting Fluids and Machining ProcessesDocumento19 páginasCutting Fluids and Machining Processescasey rimAinda não há avaliações

- Bohr-Sommerfeld QuantizationDocumento6 páginasBohr-Sommerfeld QuantizationabihagulAinda não há avaliações

- Power Engineering FundamentalsDocumento5 páginasPower Engineering FundamentalsShriram SinghAinda não há avaliações

- Surface TextureDocumento27 páginasSurface Texturesohkimfai6340100% (5)

- User Manual of Laser Engraving Machine PDFDocumento36 páginasUser Manual of Laser Engraving Machine PDFRobby SubhansyahAinda não há avaliações

- Algebra:: N N N N N N 1B 2B ZoneDocumento6 páginasAlgebra:: N N N N N N 1B 2B Zonevenedick sapongayAinda não há avaliações

- Physical Science 20 - Lesson PlanDocumento7 páginasPhysical Science 20 - Lesson Planapi-349567441Ainda não há avaliações

- Chemistry May:June 2015 Paper 43Documento9 páginasChemistry May:June 2015 Paper 43Kamini Maria SaldanhaAinda não há avaliações

- Alloy Cuni 70-30Documento2 páginasAlloy Cuni 70-30didiethardoyoAinda não há avaliações

- Chapter 8 - Synthesis of Nanomaterials - 2009 Ashby - Nanomaterials Nanotechnology An Introduction PDFDocumento17 páginasChapter 8 - Synthesis of Nanomaterials - 2009 Ashby - Nanomaterials Nanotechnology An Introduction PDFkaoru9010-1Ainda não há avaliações

- Syed Sabir - The Recovery of Gold From Secondary Sources-Imperial College Press (2016)Documento233 páginasSyed Sabir - The Recovery of Gold From Secondary Sources-Imperial College Press (2016)RODRIGO ARTURO BORJA CALDERÓNAinda não há avaliações

- Calibration Frequency enDocumento4 páginasCalibration Frequency enGrandy Anantha SaktiAinda não há avaliações

- Design and Simulation of Planar Archimedean Spiral AntennaDocumento4 páginasDesign and Simulation of Planar Archimedean Spiral AntennaHieu NgAinda não há avaliações

- Outline For PhotosynthesisDocumento6 páginasOutline For Photosynthesiswitzy11Ainda não há avaliações

- Morlina S1 B PDFDocumento4 páginasMorlina S1 B PDFerfan kurniawanAinda não há avaliações

- Intrinsic and Extrinsic N Type P TypeDocumento4 páginasIntrinsic and Extrinsic N Type P TypeDinesh VelAinda não há avaliações

- Industrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl AlcoholDocumento6 páginasIndustrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl AlcoholJoshita KusumadewiAinda não há avaliações

![Industrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl Alcohol](https://imgv2-2-f.scribdassets.com/img/document/249581212/149x198/5265f135b4/1418085576?v=1)