Escolar Documentos

Profissional Documentos

Cultura Documentos

Offsite Pipe Rack Final

Enviado por

halder.kalyanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Offsite Pipe Rack Final

Enviado por

halder.kalyanDireitos autorais:

Formatos disponíveis

GUIDE No.

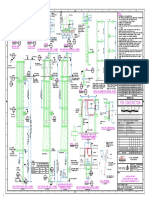

< DESIGN SHEET FOR OFFSITE PIPE RACK >

x-xxxx-xxxx Rev. 0

Page 1 of 2

DESIGN SHEET FOR OFFSITE PIPE RACK

Rev.NO.

Date

Purpose

Prepared by

Checked by

Approved by

Format No. EIL 1641-1919 Rev. 1

Copyright EIL All rights reserved

GUIDE No.

< DESIGN SHEET FOR OFFSITE PIPE RACK >

1.0

Check list

x-xxxx-xxxx Rev. 0

Page 1 of 2

Please ensure that the following design input data are available before proceeding for design.

SR NO. i)

LOADING/INFORMATION EQUIPMENT LAYOUT +GAD'S +CIVIL INFORMATION FURNISHED/NOT () / (X)

TO BE FURNISHED BY PIPING

ii) iii) iv)

a) Pipe Rack layout b) Cross Sections and Location c) Width and Span d) Portal Spacing e) Tier Elevations f) Longitudinal beam Elevations e) Requirement of intermediate beams f) Equipment placed on rack g) Monorails h) Space allocation for Electrical and i) Transfer line size,schedule,insulation j) Flare and O/H vapour line k) Location and size of platforms for l) Air fin cooler floor(if required to be in RCC m) Requirement of additional metal inserts n) Size, schedule,insulation thickness,location o) Load category giving udl for each pipe rack p) The dia of largest pipe including insulation q) Size, schedule,insulation thickness,location r) Piping and platform arrangement at battery Electrical requirment of cable trees and tiers,platforms Instrumentation requirement of cable ducts,platforms ladders,stairs,etc. Capacity of monorails if any

Electrical Instrum -entation

Rotating Eqpt.

GUIDE No.

< DESIGN SHEET FOR OFFSITE PIPE RACK >

1.0 1.0 2.0 INTRODUCTION This document presents the design for offsite pipe rack. N-S GRIDS E-W GRIDS STRUCTURAL DISCRIPTION 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 TRANSVERSE FRAME SPACING NO. OF BAYS NO.OF TIERS TIER ELEVATIONS INSTRUMENT TRAYS (NOS & ELEVATIONS) ELECTRICAL TRAYS WALKWAY LEVEL (NOS & ELEVATIONS) (NOS & ELEVATIONS)

x-xxxx-xxxx Rev. 0

Page 1 of 2

2.0

= = = = = = = = =

EQUIPMENT PPLATFORM LEVEL STAIR CASE EXPANSION JOINT i) ii) LOCATION PROVISION OF FUTURE BRACKETS

= =

11.0

BRACED BAYS NOS LOCATION = =

GUIDE No.

< DESIGN SHEET FOR OFFSITE PIPE RACK >

1.0 1.1 BASIC DESIGN INPUT /DATA METEOROLOGICAL DATA SEISMIC ZONE WIND(BASIC DESIGN WIND SPEED,TERRAIN CATEGORY) : :

x-xxxx-xxxx Rev. 0

Page 1 of 2

1.2

PLANT ELEVATIONS HIGH PAVING POINT FINISHED GROUND LEVEL NATURAL GROUND LEVEL HPP FGL NGL : : :

1.3

SOIL/PILE DATA

(REFER GEOTECHNICAL REPORT DOC NO.XXXXXXXXXXXXXXXXXXXXXXXX)

2.0

MAERIAL DATA STRUCTURAL STEEL (CONFORMING TO IS 2062): BOLTS ( as per IS 1367) High strength Bolts Ordinary Bolts Reinforcement bar (Conforming to IS 1786 ) fy : 250 MPA

: Property Class-8.8 : Property Class-4.6 : HYSD TMT steel bars of Grade Fe 500 Es : 200000 MPA (Refer Clause 38.1 of IS 456)

Modulus of elasticity of Reinforcement Steel Concrete Sub Structures & Superstructure Density of RCC Density of PCC Modulous of Elasticity of Concrete

fck yconc yconc Esc

: : : :

30 25 24 5000fck

MPA kn /m3 kn /m3 MPA

GUIDE No.

< DESIGN SHEET FOR OFFSITE PIPE RACK >

x-xxxx-xxxx Rev. 0

Page 1 of 2 (Refer clause 6.2.3.1 of IS 456)

Anchor Bolts

: Bolts shall be turned from mild steel rounds conforming to IS 2062 grade-A

Friction Coefficient Concrete to Soil

: 0.5

GUIDE No.

< DESIGN SHEET FOR OFFSITE PIPE RACK >

1.0 Design Considerations/ Philosophy Important Elevations Ground Water table elevation Bottom of Steel Column Elevation Foundation depth below HPP Bottom of Foundation Elevation 2.0 Framing Arrangement Transverse Frame Longitudinal frame GWT BOPC BOF : : : :

x-xxxx-xxxx Rev. 0

Page 1 of 2

: Moment Connected Structural Steel frames : Braced Vertical and Plan Bracing Members (structural steel)

Connection between Steel columns and base plate Steel beams in transverse direction Steel beams in longitudinal direction Braced bay in longitudinal frame Secondary beams

: Fixed : Fixed : Pinned : : Pinned

< DESIGN SHEET FOR OFFSITE PIPE RACK >

GUIDE No.

x-xxxx-xxxx Rev. 0

Page 1 of 2

1.0 1.1

LOAD CALCULATION DEAD LOAD (D) The self weight of the member will directly be calculated by STAAD.PRO Dead load of platforms (including grating and grating supported beams) is assumed as 1.2 kn/m2 and applied : -Y 1.0

as uniformly distributed load on the transverse beams of platform accordingly.(Grating supporting beams are not modelled).

Sample Calculation Dead load intensity UDL on main Frame beams = Dead load intensity x Eff. span Effective Span(m) 6 7 6.5 The UDL is applied on the platform Beams at El Fire Proofing Load(Fp) ( as applicable) UDL on Main Frame Beams(kn/m) 7.2 8.4 7.8

1.2

kN/m

1.2 i)

Cable Tray load (Dc) Electrical Cable Tray Load

(as furnished by electrical department)

kN/m

Sample Calculation Electrical Cable Tray Load (say) per tier Dead Load= Electrical Cable Tray Load x No. Of Tiers = 1.225 x 4 UDL on Beams= Dead Load x Effective Span = 4.9 x 6 Elevation (mm) e.g. Effective Span (m) 6 No. of Tiers 4 Dead Load kN/m2 4.9

= = =

1.2225 4.9 29.4

kN/m kN/m kN/m

2 2 2

UDL on Beams (kN/m) 29.4

< DESIGN SHEET FOR OFFSITE PIPE RACK >

x-xxxx-xxxx Rev. 0

Page 1 of 2

ii)

Instrument Cable Tray Load Instrument Cable Tray Load

(as furnished by Instrumentation department)

kN/m

e.g.

Sample Calculation Instrument Cable Tray size (1200 W x 400 D ) Instrument Cable Tray Load (say) per Duct Dead Load= Instrument Cable Tray Load / Width = 8.82 / 1.2 UDL on Beams= Dead Load x Effective Span = 7.35 x 6 Elevation (mm) Effective Span (m) 6 Width (m) 1.2 Dead Load kN/m2 7.35

= = = =

900 8.82 7.35 44.1

kg/m kN/m kN/m kN/m

2

UDL on Beams (kN/m) 44.1

1.3

Equipment Load

1.3.1 Equipment Empty Load (EQE) Equipment Tag no. Reference Drawing P/F elevation No. (m) e.g 11-EE-201 xxx xxx

EQE(kg)

50000

N Load Per o. Support of (kN) S 4 122.5

1.3.2 Equipment Operating Load (EQO) Equipment Tag no. Reference Drawing P/F elevation No. (m) e.g 11-EE-201 xxx xxx

EQO(kg) 60000

N Load Per o. Support 4 147

1.3.3 Equipment Hydrotest LoadLoad (EQT) e.g Equipment Tag no. Reference Drawing P/F elevation No. (m) 11-EE-201 xxx xxx

EQT(kg)

70000

N Load Per o. Support of (kN) S 4 171.5

< DESIGN SHEET FOR OFFSITE PIPE RACK >

x-xxxx-xxxx Rev. 0

Page 1 of 2

1.4

Pipe Loads

1.4.1 Pipe Operating Load (PO) Piping Loads are applied as per Civil Information Drawings.( Refer Drawing no.xxxxxxxx) Dia of Pipes (inch) >30'' <30 '' Span(m) 12 6

As Applicable

Pipe Operating Load is applied as UDL for pipes less than 12" dia and an additional Point Load for pipes of dia 12" and above. Calculation of Point Load : EL Pipe Dia Pipe UDL Span Point Load mm inch kg/m m (kN) 6500 26 533 6 23.81 12 147 6 5.17 28 575 6 25.70 12 178 6 6.99 20 351 6 14.85

1.4.2 Piping Loads On the Longitudinal Beams Same as above. 1.4.3 PIPE FRICTION (PF) Pipe friction load on each pipe tier, in longitudinal direction is considered as 10% of pipe operating load.

1.4.4 PIPE ANCHOR LOAD (PA) ( as per civil information drawing) Anchor loads of 5 kN each are typically applied at 1/3rd span locations at all pipe supporting tiers and on all bents. ( except for those tiers where flare and steam line anchors are present). 50 % of the anchor load is considered as thermal component (conservatively) and added withwind or seismic load in respective load combinations. 1.4.5 PIPE GUIDE LOAD (PG) ( as per civil information drawing)

< DESIGN SHEET FOR OFFSITE PIPE RACK >

x-xxxx-xxxx Rev. 0

Page 1 of 2

1.5

LIVE LOAD CATEGORY (LL) Live load on Operating and Maintenance platforms is taken as 5.0kN/m2 and Access Platforms and Walkways is taken as 2.5kN/m2 and applied as uniformly distributed load on the Platform supporting beams accordingly. Sample Calculation : Live load Intensity Effective Span UDL on beams = Live load Intensity X Eff. Span Elevation (mm) Effective Span (m) 6 Live Load kN/m2 2.5

= = = UDL on Beams (kN/m) 15

2.5 5 12.5

kN/m m kN/m

e.g.

1.6

BUNDLE PULL LOAD Equipment Tag No. And Drawing Reference Platform Elevation Bundle Weight =2700 kgs Length of Saddle No. of Saddles Spacing of Saddles Bundle Pull at fixed Support (Considering 100 % bundle Pull at fixed Side conservatively) Bundle Pull per post Center of Bundle above saddle Push Pull due to removing of bundle WIND LOAD IN Z DIRECTION (WZ)

= = = = = = = = =

26.46 0.6 2 3 27 13.5 0.78

kN m m kN kN m

1.7

Você também pode gostar

- Welcome To Inhouse Training Session: Design of PiperackDocumento23 páginasWelcome To Inhouse Training Session: Design of Piperackibson045001256Ainda não há avaliações

- Design Consideration of PiperackDocumento3 páginasDesign Consideration of PiperackPrantik Adhar SamantaAinda não há avaliações

- 1.1 Design of Pipe Racks Writeup PDFDocumento5 páginas1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasAinda não há avaliações

- Two-Tier Pipe Rack Connection DesignDocumento4 páginasTwo-Tier Pipe Rack Connection DesignNicoleta cristianAinda não há avaliações

- Pipe Rack Loading Data - 2 PDFDocumento55 páginasPipe Rack Loading Data - 2 PDFGalih PrianggodoAinda não há avaliações

- SAECS Company ProfileDocumento8 páginasSAECS Company ProfileBec EnggAinda não há avaliações

- Anewa Corporate Presentation PDFDocumento51 páginasAnewa Corporate Presentation PDFsmartravi222Ainda não há avaliações

- Piping Design Criteria01Documento20 páginasPiping Design Criteria01MyraAinda não há avaliações

- Guidelines For Pipe Support AnalysisDocumento29 páginasGuidelines For Pipe Support AnalysisEarl John LugatimanAinda não há avaliações

- Report PDFDocumento108 páginasReport PDFNavneeth Kumar KorleparaAinda não há avaliações

- Client Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line SystemDocumento5 páginasClient Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line SystemIshu VohraAinda não há avaliações

- Company Profile SISTECH CONSULTANTSDocumento6 páginasCompany Profile SISTECH CONSULTANTSnagarajhebbarAinda não há avaliações

- CV-Ali Zaidi - Department Lead - Civil & Structures (14 Yrs Experience) - Jan 2021Documento6 páginasCV-Ali Zaidi - Department Lead - Civil & Structures (14 Yrs Experience) - Jan 2021smazAinda não há avaliações

- Civil Works MtoDocumento28 páginasCivil Works MtoNassim SabriAinda não há avaliações

- Piping Estimate SummaryDocumento14 páginasPiping Estimate SummaryBudi SantonyAinda não há avaliações

- Design Calculation For Pipe SupportsDocumento200 páginasDesign Calculation For Pipe Supportssanggytha100% (1)

- Piperack Design ConceptDocumento46 páginasPiperack Design ConceptNagesh Kumar100% (1)

- To-HQ-02-041-00 Philosophy Structures and Foundations OnshoreDocumento25 páginasTo-HQ-02-041-00 Philosophy Structures and Foundations Onshoremarin cristianAinda não há avaliações

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EDocumento361 páginasCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiAinda não há avaliações

- Minimum Load For Empty Minimum Load For OperatingDocumento6 páginasMinimum Load For Empty Minimum Load For OperatingjitendraAinda não há avaliações

- Pipe Rack Load CalculationDocumento3 páginasPipe Rack Load CalculationKrunalpanchalAinda não há avaliações

- Case - 1: Foundation & Pedestal Design DocumentDocumento10 páginasCase - 1: Foundation & Pedestal Design DocumentJayanti RahaAinda não há avaliações

- BPCL PuneDocumento9 páginasBPCL PuneDeependra SinghAinda não há avaliações

- Pipe RackDocumento1 páginaPipe RackJinu JacobAinda não há avaliações

- Technip Piperack PDFDocumento282 páginasTechnip Piperack PDFdeep35akAinda não há avaliações

- 25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisDocumento15 páginas25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisAnonymous FHkX0AAinda não há avaliações

- Isometric View Lifting Detail: NotesDocumento2 páginasIsometric View Lifting Detail: NotesRajveer SinghAinda não há avaliações

- Checking Procedure G00-A-PRO-0018Documento16 páginasChecking Procedure G00-A-PRO-0018Abylai MustafaAinda não há avaliações

- C-2 Piping Design in Detail Engineering PDFDocumento4 páginasC-2 Piping Design in Detail Engineering PDFRobert MagAinda não há avaliações

- Reinforced Underground Valve ChamberDocumento2 páginasReinforced Underground Valve ChamberchrisAinda não há avaliações

- 3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalDocumento6 páginas3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalStacy JohnsonAinda não há avaliações

- Pipe RackDocumento42 páginasPipe Racksantino29Ainda não há avaliações

- Training Manual-Piping: Piping Study Underground PipingDocumento30 páginasTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- DMI-DB-50-001-A4 Spec For Civil, Structural REv.2Documento49 páginasDMI-DB-50-001-A4 Spec For Civil, Structural REv.2Adhitiya Rizki Pratama100% (1)

- Steel StructureDocumento295 páginasSteel StructureSahir Khan100% (2)

- Analysis & Design - Doc Rev ADocumento21 páginasAnalysis & Design - Doc Rev AsridharAinda não há avaliações

- A-STR-STD-000-30053-0 - STD Details of Ladders SHT 1 PDFDocumento1 páginaA-STR-STD-000-30053-0 - STD Details of Ladders SHT 1 PDFHUSSEIN FNEISHAinda não há avaliações

- Non-Continuous Piperacks System Modular Pipe RackDocumento4 páginasNon-Continuous Piperacks System Modular Pipe RackReld DavidAinda não há avaliações

- Piping Stress Engineer DJ PAULDocumento7 páginasPiping Stress Engineer DJ PAULJanakiraman MalligaAinda não há avaliações

- Hydrant Water Tank Foundation Design Calc - Ebocha1Documento39 páginasHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaAinda não há avaliações

- Appendix G Load Case CombinationsDocumento1 páginaAppendix G Load Case CombinationsAdrian García MoyanoAinda não há avaliações

- Scope of Works of A Design Consultant in Oil and Gas SectorDocumento4 páginasScope of Works of A Design Consultant in Oil and Gas SectorNareshAinda não há avaliações

- Onshore Modular ConstructionDocumento8 páginasOnshore Modular ConstructionGustavo Gonzalez ServaAinda não há avaliações

- Report Pipe RackDocumento16 páginasReport Pipe RackMochammad ShokehAinda não há avaliações

- CV-Harsha D (Structural Engg - CEng)Documento6 páginasCV-Harsha D (Structural Engg - CEng)Samantha HartAinda não há avaliações

- List of DeliverablesDocumento3 páginasList of DeliverablesPrad1979Ainda não há avaliações

- 1.JMX-XXX-XX-CAL-001-00 Rev.B1Documento18 páginas1.JMX-XXX-XX-CAL-001-00 Rev.B1Farid Ferdiansyah Tambunan0% (1)

- Prabhu - CV - Structural DesignerDocumento4 páginasPrabhu - CV - Structural DesignerprabhutmuAinda não há avaliações

- Vessel Foundation Design PhilosophyDocumento5 páginasVessel Foundation Design PhilosophyarnoldistunoAinda não há avaliações

- Compressor FoundationsDocumento11 páginasCompressor FoundationsararratiAinda não há avaliações

- CV For Project Manager - Mr. Sanjib Ghosh (13.07.18)Documento6 páginasCV For Project Manager - Mr. Sanjib Ghosh (13.07.18)sanjib ghoah100% (1)

- Concrete Silo DwgsDocumento12 páginasConcrete Silo DwgsAnonymous fLgaidVBhzAinda não há avaliações

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento36 páginasNational Oil Corporation: Rev Date Description Checked ApprovednizardsouissiAinda não há avaliações

- Nozzle Node No. 4950Documento6 páginasNozzle Node No. 4950Christopher BrownAinda não há avaliações

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteDocumento6 páginasPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11Ainda não há avaliações

- Kz01-Cv-Spe-68-0004 Design, Fabrication & Erection of Structural Steel WorkDocumento45 páginasKz01-Cv-Spe-68-0004 Design, Fabrication & Erection of Structural Steel WorkNagender KumarAinda não há avaliações

- Client Calculation of Pipe Rack Structur PDFDocumento179 páginasClient Calculation of Pipe Rack Structur PDFMegha Lakhani100% (1)

- Design of Pipe RacksDocumento23 páginasDesign of Pipe RacksDushyant Varshney100% (1)

- Piperack PresentationDocumento23 páginasPiperack PresentationOmar AlkubaiciAinda não há avaliações

- FW Pipe Rack DocumentDocumento38 páginasFW Pipe Rack DocumentSumanthAinda não há avaliações

- Kakku Heavy Duty Thrustor Brakes: Series KBTDocumento5 páginasKakku Heavy Duty Thrustor Brakes: Series KBThalder.kalyanAinda não há avaliações

- Polysulphide Sealant Technical Data.Documento2 páginasPolysulphide Sealant Technical Data.stuart3962Ainda não há avaliações

- Power Jib Crane DesignDocumento64 páginasPower Jib Crane Designhalder.kalyan100% (4)

- Design of CFBC BoilerDocumento86 páginasDesign of CFBC Boilerhalder.kalyan88% (8)

- Design of CFBC BoilerDocumento86 páginasDesign of CFBC Boilerhalder.kalyan88% (8)

- WDP Process Diagrams v1Documento6 páginasWDP Process Diagrams v1Ryan HengAinda não há avaliações

- American J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismDocumento9 páginasAmerican J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismeyeohneeduhAinda não há avaliações

- Busbusilak - ResearchPlan 3Documento4 páginasBusbusilak - ResearchPlan 3zkcsswddh6Ainda não há avaliações

- BIM and Big Data For Construction Cost ManagementDocumento46 páginasBIM and Big Data For Construction Cost Managementlu09100% (1)

- Practical Organic ChemistryDocumento598 páginasPractical Organic ChemistryGerardo Estrada99% (127)

- Chapter 3: Verbal Communication SkillsDocumento14 páginasChapter 3: Verbal Communication SkillsFares EL DeenAinda não há avaliações

- OMN-TRA-SSR-OETC-Course Workbook 2daysDocumento55 páginasOMN-TRA-SSR-OETC-Course Workbook 2daysMANIKANDAN NARAYANASAMYAinda não há avaliações

- IMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFDocumento28 páginasIMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFNorman AinomugishaAinda não há avaliações

- Comsol - Guidelines For Modeling Rotating Machines in 3DDocumento30 páginasComsol - Guidelines For Modeling Rotating Machines in 3DtiberiupazaraAinda não há avaliações

- Mericon™ Quant GMO HandbookDocumento44 páginasMericon™ Quant GMO HandbookAnisoara HolbanAinda não há avaliações

- Ugtt April May 2019 NewDocumento48 páginasUgtt April May 2019 NewSuhas SAinda não há avaliações

- BIO122 - CHAPTER 7 Part 1Documento53 páginasBIO122 - CHAPTER 7 Part 1lili100% (1)

- Final Project Synopsis 1Documento90 páginasFinal Project Synopsis 1Shyam YadavAinda não há avaliações

- Model Personal StatementDocumento2 páginasModel Personal StatementSwayam Tripathy100% (1)

- Exam TimetableDocumento16 páginasExam Timetablenyarko_eAinda não há avaliações

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Documento222 páginasMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesAinda não há avaliações

- SQL TestDocumento10 páginasSQL TestGautam KatlaAinda não há avaliações

- Plantas Con Madre Plants That Teach and PDFDocumento15 páginasPlantas Con Madre Plants That Teach and PDFJetAinda não há avaliações

- SAP Environment, Health, and Safety (EHS)Documento13 páginasSAP Environment, Health, and Safety (EHS)SAFETY VOFPLAinda não há avaliações

- Pre K Kindergarten Alphabet Letter TracingDocumento28 páginasPre K Kindergarten Alphabet Letter TracingNeha RawatAinda não há avaliações

- Cognitive-Behavioral Interventions For PTSDDocumento20 páginasCognitive-Behavioral Interventions For PTSDBusyMindsAinda não há avaliações

- Experiment 2: Multimeter Laboratory ReportDocumento4 páginasExperiment 2: Multimeter Laboratory ReportNoir SalifoAinda não há avaliações

- Historical Roots of The "Whitening" of BrazilDocumento23 páginasHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasAinda não há avaliações

- Real Options BV Lec 14Documento49 páginasReal Options BV Lec 14Anuranjan TirkeyAinda não há avaliações

- Normal Consistency of Hydraulic CementDocumento15 páginasNormal Consistency of Hydraulic CementApril Lyn SantosAinda não há avaliações

- IJISRT23JUL645Documento11 páginasIJISRT23JUL645International Journal of Innovative Science and Research TechnologyAinda não há avaliações

- List of Institutions With Ladderized Program Under Eo 358 JULY 2006 - DECEMBER 31, 2007Documento216 páginasList of Institutions With Ladderized Program Under Eo 358 JULY 2006 - DECEMBER 31, 2007Jen CalaquiAinda não há avaliações

- Ems Speed Sensor Com MotorDocumento24 páginasEms Speed Sensor Com MotorKarina RickenAinda não há avaliações

- Master Thesis On Smart GridDocumento6 páginasMaster Thesis On Smart Gridsandraandersondesmoines100% (2)

- EHVACDocumento16 páginasEHVACsidharthchandak16Ainda não há avaliações