Escolar Documentos

Profissional Documentos

Cultura Documentos

TWI CSWIP 3.0 Inspection of Fillet Welds

Enviado por

Onur AltuntaşDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TWI CSWIP 3.0 Inspection of Fillet Welds

Enviado por

Onur AltuntaşDireitos autorais:

Formatos disponíveis

CSWIP 3.

0 INSPECTION OF FILLET WELDS

TWI

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

CSWIP 3.0 Fillet Welded T Joint

F 123

Part of the CSWIP 3.0 examination is to inspect & assess a Fillet welded Tee for its size & visual acceptance to the applicable code.

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

Fillet Weld Inspection

1. The plate reference number must be recorded in the top left hand corner of the report sheet, then the thickness of the plate must be measured and entered in the top right hand corner of the report sheet in the boxes provided.

Specimen Number F123 Material thickness: 6mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

2) Both the Vertical and Horizontal fillet weld leg lengths must be measured to find the minimum and maximum sizes. These values are entered in the boxes provided on the report sheet. Use the gauge as shown below:

Fillet Weld Leg Length: The gauge may be used to measure fillet weld leg lengths up to a maximum of 25mm, as shown on left.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

3) The minimum and maximum throat thickness are measured and entered in the boxes provided on the report sheet. These values are measured as shown below:

Fillet Weld Throat Thickness:

The small sliding pointer reads up to 20mm, or inch. When measuring the throat it is supposed that the fillet weld has a nominal throat thickness, as an effective throat thickness cannot be measured in this manner.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

Having made all the above measurements they can be assessed to a set of values that may be simply calculated from the plate thickness. a) The minimum leg length size is the plate thickness b) The maximum leg length size is: The plate thickness + 3mm c) The minimum throat thickness is: The plate thickness x 0.7 d) The maximum throat thickness is: The plate thickness + 0.5mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

For example if the plate thickness is 6mm then the following will apply:

6mm

F 123

a) The minimum leg length size is 6mm (Plate thickness) b) The maximum leg length size is 9mm (Plate thickness + 3mm) c) The minimum throat thickness is 4.2mm (Plate thickness x 0.7) d) The maximum throat thickness is 6.5mm (Plate thickness + 0.5mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

This means that the measurements taken must fall inside BOTH the tolerances calculated i.e. Leg lengths must be between 6mm 9mm Throat thickness must be between 4.2 and 6.5mm If all the values are within these tolerances they are acceptable. If any of the values fall outside of the calculated tolerances then it becomes unacceptable. It is important to remember that any change in thickness will change the acceptance values calculated above.

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

Fillet Weld Inspection

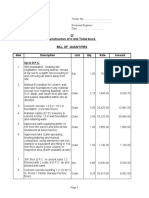

Vertical Leg Length Lowest leg measurement 7mm Highest leg measurement 8mm Actual Throat Thickness Lowest throat measurement 4.5mm Highest throat measurement 8mm Horizontal Leg Length Lowest leg measurement 5mm Highest leg measurement 10mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

Practical Exam Report Sheet

Specimen Number F123 Material thickness: 6mm

1) Measure and record the following details: VERTICAL LEG LENGTH (Max & Min) HORIZONTAL LEG LENGTH (Max & Min) = Max 8mm Min 7mm

= Max 10mm Min 5mm Min 4.5mm

DESIGN THROAT THICKNESS (Max & Min) = Max 8mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

2) Sentence the fillet weld dimensions using the following design criteria: MINIMUM LEG LENGTH: Material thickness (6mm) MAXIMUM LEG LENGTH: Material thickness + 3mm (9 mm) MINIMUM THROAT THICKNESS: Material thickness x 0.7 (4.2 mm) MAXIMUM THROAT THICKNESS: Material thickness + 0.5mm (6.5 mm)

The VERTICAL LEG LENGTH Please state: ACCEPT The HORIZONTAL LEG LENGTH Please state: REJECT The THROAT THICKNESS Please state: REJECT

Copyright 2004, TWI Ltd

ACCEPT or REJECT?

ACCEPT or REJECT?

ACCEPT or REJECT?

World Centre for Materials Joining Technology

Fillet Weld Inspection

Having assessed the weld for its size an inspection can then be made on the surface to locate any imperfections. Firstly; the report sheet requests the inspector to indicate the number of locations that the following imperfections occur, if any? 3) The number of places that they occur should now be entered in the box as follows: UNDERCUT APPEAR? OVERLAP APPEAR? LACK OF FUSION APPEAR? CRACKS APPEAR? POROSITY APPEAR? SOLID INCULSIONS? MISC: [ARC STRIKES etc] 3 places None None None 2 Areas 1 Slag Inclusion Spatter

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

4) For the defects recorded state: MAXIMUM length (and DEPTH if applicable) of each defect UNDERCUT: OVERLAP: LACK OF FUSION: CRACKS: POROSITY: SOLID INCLUSIONS: Length: 15 mm Depth: Smooth 1.0mm Length: -------- Depth: --------Length: -------- Depth: --------Length: -------- Depth: --------Length: 6mm Length: 4mm Depth: Maximum Depth: ---------

MISC:[ ARC STRIKES] Length: Spatter Depth: --------Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

5) Then, assess the levels of imperfections allowed by the applicable code which is provided: UNDERCUT: OVERLAP: LACK OF FUSION: CRACKS: POROSITY: SOLID INCLUSION: MISC: [ARC STRIKES] ACCEPT ACCEPT ACCEPT ACCEPT REJECT REJECT REJECT* (Accept (Accept (Accept (Accept (Accept (Accept (Accept or Reject?) or Reject?) or Reject?) or Reject?) or Reject?) or Reject?) or Reject?)

* All spatters should have been removed prior to submission for inspection

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Fillet Weld Inspection

6) Finally accept or reject the weld used for your visual inspection as follows: IS THE WELD ACCEPTABLE? Signature: Name: Date: I C Plenty I C Plenty 01-01-04 NO YES/NO?

This now completes the Fillet Welded T Joint Inspection Assessment.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Você também pode gostar

- TWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyDocumento9 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyOnur AltuntaşAinda não há avaliações

- TWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyDocumento46 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyOnur AltuntaşAinda não há avaliações

- Welding Symbols & Weld PreparationsDocumento54 páginasWelding Symbols & Weld PreparationsOnur AltuntaşAinda não há avaliações

- TWI CSWIP 3.1 Wis 5 Welding Inspection Calibration: World Centre For Materials Joining TechnologyDocumento3 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Calibration: World Centre For Materials Joining TechnologyOnur AltuntaşAinda não há avaliações

- TWI CSWIP 3.1 Wis 5 Welding Inspection Four Factors: World Centre For Materials Joining TechnologyDocumento7 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Four Factors: World Centre For Materials Joining TechnologyOnur AltuntaşAinda não há avaliações

- TWI CSWIP 3.1 Wis 5 Welding Inspection Destructive Tests: World Centre For Materials Joining TechnologyDocumento20 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Destructive Tests: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyDocumento53 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Consumables Identification and ControlDocumento24 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Consumables Identification and ControlOnur Altuntaş100% (1)

- TWI CSWIP Visual Inspection of WeldDocumento102 páginasTWI CSWIP Visual Inspection of WeldOnur Altuntaş100% (24)

- CSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetDocumento4 páginasCSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetOnur Altuntaş100% (2)

- TWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyDocumento91 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyOnur AltuntaşAinda não há avaliações

- Welded and Seamless PipesDocumento36 páginasWelded and Seamless Pipesssen8Ainda não há avaliações

- Asme 31.9Documento86 páginasAsme 31.9Onur AltuntaşAinda não há avaliações

- Information Handling Services, 2000Documento27 páginasInformation Handling Services, 2000Onur Altuntaş100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Dbms UPDATED MANUAL EWITDocumento75 páginasDbms UPDATED MANUAL EWITMadhukesh .kAinda não há avaliações

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Documento50 páginasDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RAinda não há avaliações

- Module 5 - Multimedia Storage DevicesDocumento10 páginasModule 5 - Multimedia Storage Devicesjussan roaringAinda não há avaliações

- Annotated Portfolio - Wired EyeDocumento26 páginasAnnotated Portfolio - Wired Eyeanu1905Ainda não há avaliações

- Frito Lay AssignmentDocumento14 páginasFrito Lay AssignmentSamarth Anand100% (1)

- 01 Eh307 Crimpro Case Digests Part 1Documento214 páginas01 Eh307 Crimpro Case Digests Part 1Kimberly PerezAinda não há avaliações

- Stainless Steel 1.4404 316lDocumento3 páginasStainless Steel 1.4404 316lDilipSinghAinda não há avaliações

- I.V. FluidDocumento4 páginasI.V. FluidOdunlamiAinda não há avaliações

- Minas-A6 Manu e PDFDocumento560 páginasMinas-A6 Manu e PDFJecson OliveiraAinda não há avaliações

- Alphacenter Utilities: Installation GuideDocumento24 páginasAlphacenter Utilities: Installation GuideJeffersoOnn JulcamanyanAinda não há avaliações

- BS en Iso 11666-2010Documento26 páginasBS en Iso 11666-2010Ali Frat SeyranAinda não há avaliações

- ESK-Balcony Air-ADocumento2 páginasESK-Balcony Air-AJUANKI PAinda não há avaliações

- h6811 Datadomain DsDocumento5 páginash6811 Datadomain DsChristian EstebanAinda não há avaliações

- Mix Cases UploadDocumento4 páginasMix Cases UploadLu CasAinda não há avaliações

- Procurement Audit PlanDocumento12 páginasProcurement Audit PlanMustafa Bilal100% (1)

- T&B Detailed Plan: Ceiling LineDocumento1 páginaT&B Detailed Plan: Ceiling LineKuthbert NoceteAinda não há avaliações

- Ahakuelo IndictmentDocumento24 páginasAhakuelo IndictmentHNNAinda não há avaliações

- DPC SEMESTER X B Project ListDocumento2 páginasDPC SEMESTER X B Project ListVaibhav SharmaAinda não há avaliações

- Common OPCRF Contents For 2021 2022 FINALE 2Documento21 páginasCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Technical Manual: 110 125US 110M 135US 120 135UR 130 130LCNDocumento31 páginasTechnical Manual: 110 125US 110M 135US 120 135UR 130 130LCNKevin QuerubinAinda não há avaliações

- MSEA News, Jan-Feb 2014Documento20 páginasMSEA News, Jan-Feb 2014Justin HinkleyAinda não há avaliações

- Double Inlet Airfoil Fans - AtzafDocumento52 páginasDouble Inlet Airfoil Fans - AtzafDaniel AlonsoAinda não há avaliações

- Business-Model Casual Cleaning ServiceDocumento1 páginaBusiness-Model Casual Cleaning ServiceRudiny FarabyAinda não há avaliações

- Dreamfoil Creations & Nemeth DesignsDocumento22 páginasDreamfoil Creations & Nemeth DesignsManoel ValentimAinda não há avaliações

- Fammthya 000001Documento87 páginasFammthya 000001Mohammad NorouzzadehAinda não há avaliações

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Documento7 páginasINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeAinda não há avaliações

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 páginasWWW - Manaresults.co - In: Internet of Thingsbabudurga700Ainda não há avaliações

- Irrig in AfricaDocumento64 páginasIrrig in Africaer viAinda não há avaliações

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Documento6 páginasType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheAinda não há avaliações

- MG206 Chapter 3 Slides On Marketing Principles and StrategiesDocumento33 páginasMG206 Chapter 3 Slides On Marketing Principles and StrategiesIsfundiyerTaungaAinda não há avaliações