Escolar Documentos

Profissional Documentos

Cultura Documentos

Exterior Finishes Final

Enviado por

Ashish MarwhaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Exterior Finishes Final

Enviado por

Ashish MarwhaDireitos autorais:

Formatos disponíveis

EXTERIOR FINISHES

SUBMITTED TO : AR. ANIKET SHARMA

SUBMITTED BY : PARAS MEHTA (08618) KOMIKA WALIA (08617) JONCHA ARANG (08616)

EXTERIOR FINISHES

Exterior finish materials protect the structure from sun exposure, moisture, and wind. These materials are to be provided so that the wall can withstand extreme weather and be compatible with other components of the building.

Some examples of exterior finishes are wall cladding , wood siding , flashing , gutters & downspouts , brick veneer , corrugated metal , fiber-cement panels , stucco , paints and coatings .

Paint & coatings

Fiber cement panels

COATINGS & PAINTS

PRINCIPAL TYPES OF COATINGS Paints

Stains

Varnishes PAINTS

Its a solution of a pigment in water, oil, or organic solvent, used to cover wood or metal articles either for protection or for appearance.

PAINT COMPOSITION

Binder Binder makes the coat of paint retain its structure, and binds it to the surface to which it is applied. Solvent Solvent dissolves the paint to make it usable at normal room temperatures. Primers They are base coats applied to a surface to improve the adhesion of subsequent coats of paint or varnish. Sealers They are base coats applied to a surface to reduce absorption of subsequent coats of paint or varnish, or to prevent bleeding through the finish coat

PAINT TYPES USED IN EXTERIORS

Snowcem Washing

It consists of base of white cement mixed with finely powdered colouring pigment. It gives a waterproof surface.

It is manufactured in 50kg drums, 25kg drums and 5kg tin.

Proportions : mixing 2 parts of snowcem powder with 1 part of water by volume and then thinning it by adding another 1 part of water. Snowcem should be used within an hour of mixing. Other similar cement washing compounds are supercem, aquacem and durocem.

PAINT TYPES USED IN EXTERIORS

Decorative cement colour washing

It consists of white cement mixed with colouring pigments and other ingredients.

The solution should be thin and screened through a piece of cloth.

It should be applied in 2 coats , 2nd to be applied after 4hrs of the 1st coat. After application of the cement, the surface should be kept moist for atleast 2 days and protected from hot sun and drying winds.

PAINT DEFECTS (Exterior)

Alligatoring

Patterned cracking in the surface of the paint film resembling the regular scales of an alligator. Formation of fine powder on the surface of the paint film during weathering, which can cause color fading. Although some degree of chalking is a normal, desirable way for a paint film to wear, excessive film erosion can result in heavy chalking. Crusty, white salt deposits, leached from mortar or masonry as water passes through it. Loss of adhesion where many old coats of alkyd or oil-based paint received a latex top coat.

Chalking

Efflorescence/Mottling

Paint Incompatibility

Peeling

Loss of paint due to poor adhesion. Where there is a primer and top coat, or multiple coats of paint, peeling may involve some or all coats.

A rough, crinkled paint surface occurring when paint forms a "skin.

Wrinkling

Plaster

Plaster is a building material used for coating walls and ceilings and is usually mixed with water to form a paste which liberates heat and then hardens. Different proportion of cement and mortar are 1:3,1:4,1:5,1:6. Generally, 1:4 ration is used for plastering. Unlike mortar and cement, plaster remains quite soft after setting, and can be easily manipulated with metal tools or even sandpaper. These characteristics make plaster suitable for a finishing, rather than a load-bearing material. External plastering shall be started from top and worked down towards floor. For external finish preferred plaster thicknesses are 15 mm,18mm and 20mm. Plastering should be applied in 3 coats : 1st coat of 10mm thick, 2nd coat of 10mm-6mm and finishing coat of 56mm.

Plaster

Uses

Curing

Plaster is used to protect the actual structure of the building i.e. the masonry or the RCC units, from exposure to changes in weather. It is used as a weather proofing sealant, to protect against wind, rain and sun. Plaster also acts as a fire-proofing material both in interior as well as exterior.

Curing shall be started 24 hours after finishing the plaster.

The plaster shall be kept wet for a period of seven days. During this period, it shall be suitably protected from all damages. The dates on which the plastering is done shall be legibly marked on the various sections plastered so that curing for the specified period thereafter can be watched.

Stone Cladding

The commonly used stones for wall cladding in India are : Granite Kota stone Sand stone Slate Marble

Granite

Kota stone

Sand stone

Slate

Marble

Stone Cladding

The commonly used stone cladding systems are : Direct Plastered on wall Fixing Panel Stone Clips

Stone Clip

Stone cladding fixing Detail

Fixing Panel

Anchor Bracket

Aluminum Composite Panel

ALUCOBOND (commonly known as after the brand name) is a composite panel consisting of two aluminium cover sheets and a plastic core. Properties Aluminium facings in 0.020" nominal thickness (interior and exterior to ensure flatness) Polyethylene core is available in 3mm, 4mm, and 6mm thicknesses Proprietary fire-resistant core available in 4mm thickness only

Glass Panels

Glazing systems are of 3 types : 4 sided glazing panel 2 sided glazing panel Spider systems

4 sided glazing panel

Spider Systems 2 sided glazing panel

THANK YOU

Você também pode gostar

- Ontario Building Code - Concepts and Code Analysis PDFDocumento114 páginasOntario Building Code - Concepts and Code Analysis PDFG.A100% (6)

- Uniform Building CodeDocumento1.283 páginasUniform Building CodePranoy Barua100% (5)

- SPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFDocumento2 páginasSPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFsriatul2006100% (1)

- Minimal Interior Design Ideas To Beautify Your HouseDocumento3 páginasMinimal Interior Design Ideas To Beautify Your House8 SquareAinda não há avaliações

- Girbau Specifications HS4022 4040 4055 4110 STAT TILTDocumento6 páginasGirbau Specifications HS4022 4040 4055 4110 STAT TILTmairimsp2003Ainda não há avaliações

- GYPSUMDocumento38 páginasGYPSUMManjeet CinghAinda não há avaliações

- الصلاة الفيضية مع صلاة شجرة الأكوانDocumento2 páginasالصلاة الفيضية مع صلاة شجرة الأكوانJarrarArtAinda não há avaliações

- NFPA 96 Minnesota4Documento93 páginasNFPA 96 Minnesota4poetoetAinda não há avaliações

- Chapter 10wallfinishesplasteringpointingpainting 180117080527Documento61 páginasChapter 10wallfinishesplasteringpointingpainting 180117080527Jude Acepcion100% (1)

- Wall Finishes: Submitted To:-Ar. Mahima Sharma Submitted By:-Afza Shaikh Ambika Kanwar Anushka Sonania Disha YadavDocumento25 páginasWall Finishes: Submitted To:-Ar. Mahima Sharma Submitted By:-Afza Shaikh Ambika Kanwar Anushka Sonania Disha YadavAditi JalaAinda não há avaliações

- Plastering Pointing PDFDocumento35 páginasPlastering Pointing PDFMumtahina MouliAinda não há avaliações

- WALLCOVERINGDocumento54 páginasWALLCOVERINGGelli P. BacsalAinda não há avaliações

- Partition BB - PPTXPPPPPDocumento33 páginasPartition BB - PPTXPPPPPSimran DeepAinda não há avaliações

- Insulation Roofs P11 40 PDFDocumento30 páginasInsulation Roofs P11 40 PDFJennifer NavarroAinda não há avaliações

- Wall Finishes PPT (1) (1) Taniya PDFDocumento15 páginasWall Finishes PPT (1) (1) Taniya PDFRajaAinda não há avaliações

- Figure 1: Types of Wall SectionsDocumento2 páginasFigure 1: Types of Wall SectionsBianca CristeaAinda não há avaliações

- Toilet Partition CatalogDocumento16 páginasToilet Partition CatalogMartin TanAinda não há avaliações

- Flooring PresentationDocumento30 páginasFlooring PresentationNevin PudukadAinda não há avaliações

- Rev B PDFDocumento6 páginasRev B PDFpsn_kylmAinda não há avaliações

- Bitumen Modified With SBS Thermoplastic For Roofing ApplicationDocumento9 páginasBitumen Modified With SBS Thermoplastic For Roofing ApplicationResearch and Development100% (1)

- Strata Product GuideDocumento16 páginasStrata Product GuideMandar Gorhe100% (1)

- GypsumDocumento34 páginasGypsumAnjas AnjasAinda não há avaliações

- Various Types of Wall Finishes - Interior Design and ArchitectureDocumento14 páginasVarious Types of Wall Finishes - Interior Design and ArchitecturenavyaraonaviAinda não há avaliações

- Timber A Sustainable Construction MethodDocumento15 páginasTimber A Sustainable Construction MethodOluwaseyi AdegokeAinda não há avaliações

- Masonarywall 160825234415 PDFDocumento36 páginasMasonarywall 160825234415 PDFDrNallaShivamAinda não há avaliações

- Wall FinishDocumento10 páginasWall FinishMunindra MohantaAinda não há avaliações

- What Is PlasterDocumento7 páginasWhat Is PlasterRAinda não há avaliações

- CASE STUDY - California Academy of ScienceDocumento2 páginasCASE STUDY - California Academy of SciencePRIYAAinda não há avaliações

- Floor FinishesDocumento24 páginasFloor FinishesEdgar JavierAinda não há avaliações

- الادارة الهندسيةDocumento3 páginasالادارة الهندسيةhassanien mohammedAinda não há avaliações

- Wallpaper and VeneerDocumento6 páginasWallpaper and VeneerYogirajsinh GohilAinda não há avaliações

- Introduction To SurveyingDocumento33 páginasIntroduction To SurveyingChristian Mark BalidoAinda não há avaliações

- الالواح الجبسية PDFDocumento16 páginasالالواح الجبسية PDFali3 ALAAAinda não há avaliações

- Application of Nanotechnologies in Sustainable ArcDocumento10 páginasApplication of Nanotechnologies in Sustainable ArcLinh LêAinda não há avaliações

- W3 - L8 - MRCS - Concrete Deterioration - 3 PDFDocumento42 páginasW3 - L8 - MRCS - Concrete Deterioration - 3 PDFsrinivasanAinda não há avaliações

- Chapter 10 Manufactured BoardsDocumento5 páginasChapter 10 Manufactured Boardsapi-528243784Ainda não há avaliações

- 8.تنفيذ اعمال الانارة PDFDocumento17 páginas8.تنفيذ اعمال الانارة PDFAhmed Gomaa GhanemAinda não há avaliações

- Bfc10502 Chapter 1 CementDocumento33 páginasBfc10502 Chapter 1 Cement佳俐Ainda não há avaliações

- Wallpape R: Submitted by Astami Das (BSC Id 2 Semester)Documento15 páginasWallpape R: Submitted by Astami Das (BSC Id 2 Semester)Saurabh DeyAinda não há avaliações

- Curing Cement PlasterDocumento3 páginasCuring Cement PlasterChristian LlagasAinda não há avaliações

- Roff New Construction Tile Adhesives PDFDocumento2 páginasRoff New Construction Tile Adhesives PDFUmeshchandra PatilAinda não há avaliações

- Bituminous CoalDocumento4 páginasBituminous CoalLLAinda não há avaliações

- SP FinalDocumento27 páginasSP FinalMin Htet MyintAinda não há avaliações

- الاعمال الصحية فى المبانىDocumento19 páginasالاعمال الصحية فى المبانىArch Azmi100% (1)

- Precast Glass Block FlooringDocumento6 páginasPrecast Glass Block FlooringLevenția LauraAinda não há avaliações

- Partion Wall by Sallu 09Documento33 páginasPartion Wall by Sallu 09Ali Azhar RajputAinda não há avaliações

- R AnushreeDocumento15 páginasR AnushreeJuvilasri VigneshAinda não há avaliações

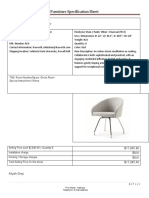

- Furniture Specification SheetDocumento1 páginaFurniture Specification SheetAliyah GrayAinda não há avaliações

- Bituproof 50RDocumento2 páginasBituproof 50RBulmez VeronicaAinda não há avaliações

- Cmci Cmci: CEMTEC 227 P.UDocumento2 páginasCmci Cmci: CEMTEC 227 P.Upravi3434Ainda não há avaliações

- Successful Plastering PDFDocumento8 páginasSuccessful Plastering PDFDean KoortzenAinda não há avaliações

- Insulation TypesDocumento16 páginasInsulation TypesBrankoAinda não há avaliações

- Cartonal N1300-3mmDocumento2 páginasCartonal N1300-3mmrangarajan1989100% (1)

- Renderoc BFDocumento2 páginasRenderoc BFMansoor AliAinda não há avaliações

- Nanotechnology: Sangeetha. S & Jagadeesh. CDocumento17 páginasNanotechnology: Sangeetha. S & Jagadeesh. CvlsiprabhuAinda não há avaliações

- Floor and Floor Covering Chapter 1Documento63 páginasFloor and Floor Covering Chapter 1amrithakhubaAinda não há avaliações

- Glass: Submitted By: Manav Batch 19 Submitted To: Soniya TiwariDocumento35 páginasGlass: Submitted By: Manav Batch 19 Submitted To: Soniya TiwarimanavAinda não há avaliações

- الإبداع الفكرى للتصميم الداخلي والمتطلبات الوظيفيةDocumento19 páginasالإبداع الفكرى للتصميم الداخلي والمتطلبات الوظيفيةmalak elmeligyAinda não há avaliações

- High Strength Concrete Using Chemical AdmixtureDocumento21 páginasHigh Strength Concrete Using Chemical AdmixtureYati AggarwalAinda não há avaliações

- BD ReviewerDocumento8 páginasBD ReviewerMicah Dianne DizonAinda não há avaliações

- Division 8 Windows and Openings Division 9 Finishes Division 22 PlumbingDocumento50 páginasDivision 8 Windows and Openings Division 9 Finishes Division 22 PlumbingHealthene Joy Familara AlesnaAinda não há avaliações

- PAINTINGDocumento20 páginasPAINTINGMiguel BernabeAinda não há avaliações

- BT6 - FinishesDocumento36 páginasBT6 - FinishesHatdugAinda não há avaliações

- QCDD BP GuidelinesDocumento6 páginasQCDD BP Guidelines남광연0% (1)

- Const Specs (Gutierrez Residence)Documento6 páginasConst Specs (Gutierrez Residence)Ernane RitaAinda não há avaliações

- Truss (Sefi)Documento16 páginasTruss (Sefi)DharaneshskumarAinda não há avaliações

- Cold and Cloudy ClimateDocumento61 páginasCold and Cloudy ClimateSAURABH KUMAR SINGHAinda não há avaliações

- Introduction, Beam and SlabDocumento6 páginasIntroduction, Beam and SlabNinie AzrinAinda não há avaliações

- CRTICAL Force and Moment Outputs From SAP2000: SLS ULS Bending Moment (M), Shear Force (V) & Direct Tension (T)Documento4 páginasCRTICAL Force and Moment Outputs From SAP2000: SLS ULS Bending Moment (M), Shear Force (V) & Direct Tension (T)risrizAinda não há avaliações

- Holiday Inn, Zirakpur-HVAC Draft Tender-R0-25-09-18Documento200 páginasHoliday Inn, Zirakpur-HVAC Draft Tender-R0-25-09-18Jatin KumarAinda não há avaliações

- A Review of Self Compacting ConcreteDocumento23 páginasA Review of Self Compacting Concretedhwani100% (1)

- Procedure For Flooring WorksDocumento4 páginasProcedure For Flooring WorksAkhilesh Kumar0% (1)

- W L 1176Documento1 páginaW L 1176shama093Ainda não há avaliações

- 03 38 00 Post Tensioned ConcreteDocumento15 páginas03 38 00 Post Tensioned ConcretegullipalliAinda não há avaliações

- Friend of KimDocumento1 páginaFriend of KimBernie QuepAinda não há avaliações

- Twin City Fan&BlowerDocumento24 páginasTwin City Fan&BloweryaidragonAinda não há avaliações

- 575.09.S01 Quantity Surveying ConstructionDocumento6 páginas575.09.S01 Quantity Surveying ConstructionMuchena Stephen GiftAinda não há avaliações

- Composite GREEN BUILDING CASE STUDYDocumento7 páginasComposite GREEN BUILDING CASE STUDYPooja PrakashAinda não há avaliações

- Roof Slab PlanDocumento10 páginasRoof Slab PlanghansaAinda não há avaliações

- Us Army Engineer Center and School Masonry: Subcourse Edition EN5157 ADocumento102 páginasUs Army Engineer Center and School Masonry: Subcourse Edition EN5157 ADan JohnsonAinda não há avaliações

- India Habitat Centre, New Delhi, India 12 and 13 January 2012Documento2 páginasIndia Habitat Centre, New Delhi, India 12 and 13 January 2012CHINTA SOWMYAAinda não há avaliações

- Ebcs 2 Structural Use of Concrete PDFDocumento175 páginasEbcs 2 Structural Use of Concrete PDFTesfayeHailuB100% (5)

- Building Technology: Hearst TowerDocumento15 páginasBuilding Technology: Hearst TowerAsavariAinda não há avaliações

- National Building CodeDocumento135 páginasNational Building CodeVikas Goel75% (4)

- Ping An Finance CenterDocumento18 páginasPing An Finance CenterShikhar Singh100% (1)

- Blast Proof BuildingsDocumento35 páginasBlast Proof BuildingsAnonymous I1tOPIZSkAinda não há avaliações

- Fan Coil Units (DX-COIL With Heat Pump) : High WallDocumento9 páginasFan Coil Units (DX-COIL With Heat Pump) : High WallSTANDARD EDUCATION ACADEMY M.E.P CENTERAinda não há avaliações

- Timber Design - ConnectionsDocumento10 páginasTimber Design - ConnectionsEmmanuel LazoAinda não há avaliações

- Piles Design Calc PDFDocumento15 páginasPiles Design Calc PDFMukhlish Akhatar100% (1)

- (Victor E Saouma) Machanics and Design of Reinforc PDFDocumento173 páginas(Victor E Saouma) Machanics and Design of Reinforc PDFAadithya ThampiAinda não há avaliações