Escolar Documentos

Profissional Documentos

Cultura Documentos

Inventory - PPT Presentation For Inventory Mangment

Enviado por

PSYCHOTHEWALLDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Inventory - PPT Presentation For Inventory Mangment

Enviado por

PSYCHOTHEWALLDireitos autorais:

Formatos disponíveis

1

Dickson K.W. Chiu

PhD, SMIEEE

Text: Ballou - Business Logistics Management, 5/E (Chapter 9-10)

Inventory and Procurement

Dickson Chiu 2006 Inventory-2

Learning Objectives

To understand some basic concepts of

inventory

To anticipate typical problems involved in

supply scheduling decisions

To understand some basic concepts of

purchasing

3

4c.1 Inventory Fundamentals

Business Logistics Management, 5/E (Chapter 9)

Dickson Chiu 2006 Inventory-4

What are Inventories?

Finished product held for sale

Goods in warehouses

Work in process

Goods in transit

Staff hired to meet service needs

Any owned or financially controlled raw

material, work in process, and/or finished

good or service held in anticipation of a sale

but not yet sold

Dickson Chiu 2006 Inventory-5

What are Inventories?

Material

sources

Inbound

transportation

Production Outbound

transportation

Finished goods

warehousing

Customers

Inventory

locations

Finished goods

S

h

i

p

p

i

n

g

Inventories

in-process

R

e

c

e

i

v

i

n

g

Production

materials

Dickson Chiu 2006 Inventory-6

Reasons for Inventories

Improve customer service

Provides immediacy in product availability

Encourage production, purchase, and transportation

economies

Allows for long production runs

Takes advantage of price-quantity discounts

Allows for transport economies from larger shipment sizes

Act as a hedge against price changes

Allows purchasing to take place under most favorable price terms

Protect against uncertainties in demand and lead times

Provides a measure of safety to keep operations

running when demand levels and lead times cannot be known

for sure

Act as a hedge against contingencies

Buffers against such events as strikes, fires, and disruptions in

supply

Dickson Chiu 2006 Inventory-7

Reasons Against Inventories

They consume capital resources that might be put to

better use elsewhere in the firm

They too often mask quality problems that would

more immediately be solved without their presence

They divert managements attention away from

careful planning and control of the supply and

distribution channels by promoting an insular attitude

about channel management

Dickson Chiu 2006 Inventory-8

Types of Inventories

Pipeline

Inventories in transit

Speculative

Goods purchased in anticipation of price increases

Regular/Cyclical/Seasonal

Inventories held to meet normal operating needs

Safety

Extra stocks held in anticipation of demand and lead time

uncertainties

Obsolete/Dead Stock

Inventories that are of little or no value due to being out of

date, spoiled, damaged, etc.

Dickson Chiu 2006 Inventory-9

Nature of Demand

Perpetual demand

Continues well into the foreseeable future

Seasonal demand

Varies with regular peaks and valleys throughout the year

Lumpy demand

Highly variable (3o > Mean)

Regular demand

Not highly variable (3o < Mean)

Terminating demand

Demand goes to 0 in foreseeable future

Derived demand

Demand is determined from the demand of another item of

which it is a part

Accurately forecasting

demand is singly the

most important factor

in good inventory

management

Dickson Chiu 2006 Inventory-10

Pull vs. Push Inventory Philosophies

Plant

Warehouse #1

Warehouse #2

Warehouse #3

A

1

A

2

A

3

A = Allocation quantity to each warehouse

Q = Requested replenishment quantity

by each warehouse

Q

1

Q

2

Q

3

Demand

forecast

Demand

forecast

Demand

forecast

PULL - Replenish inventory with

order sizes based on specific needs

of each warehouse

PUSH - Allocate supply to each

warehouse based on the forecast

for each warehouse

Dickson Chiu 2006 Inventory-11

Inventory Management Philosophies

Pull

Draws inventory into the stocking location

Each stocking location is considered independent

Maximizes local control of inventories

Push

Allocates production to stocking locations based on overall demand

Encourages economies of scale in production

Just-in-time

Attempts to synchronize stock flows so as to just meet demand as it occurs

Minimizes the need for inventory

Supply-Driven

Supply quantities and timing are unknown

All supply must be accepted and processed

Inventories are controlled through demand

Aggregate Control - Classification of items

Groups items according to their sales level based on the 80-20 principle

Allows different control policies for 3 or more broad product groups

Dickson Chiu 2006 Inventory-12

Costs Relevant to Inventory Management

Carrying costs

Procurement costs

Out-of-stock costs

Dickson Chiu 2006 Inventory-13

Procurement costs

Price of the goods

Cost of preparing the order

Cost of order transmission

Cost of production setup if appropriate

Cost of materials handling or processing at

the receiving dock

Dickson Chiu 2006 Inventory-14

Carrying Costs

Cost for holding the inventory over time

The primary cost is the cost of money tied up

in inventory, but also includes obsolescence,

insurance, personal property taxes, and

storage costs

Typically, costs range from the cost of short

term capital to about 40%/year. The average

is about 25%/year of the item value in

inventory.

Dickson Chiu 2006 Inventory-15

Out-of-stock costs

Lost sales cost

Profit immediately foregone

Future profits foregone through loss of goodwill

Backorder cost

Costs of extra order handling

Additional transportation and handling costs

Possibly additional setup costs

Dickson Chiu 2006 Inventory-16

Inventory Management Objectives

Good inventory management is a careful balancing

act between stock availability and the cost of holding

inventory.

Service objectives

Setting stocking levels so that there is only a specified

probability of running out of stock

Cost objectives

Balancing conflicting costs to find the most economical

replenishment quantities and timing

Customer Service ,

i.e., Stock Availability

Inventory Holding costs

Dickson Chiu 2006 Inventory-17

Typical Inventory Conflicting Cost Patterns

C

o

s

t

Replenishment quantity

Stockout cost

Procurement cost

Total cost

Minimum cost

reorder quantity

Dickson Chiu 2006 Inventory-18

Pull - Single Order Purchasing

Make a one-time purchase of an item. How

much to order?

Procedure: Balance incremental profit

against incremental loss.

Estimated these expected values

Dickson Chiu 2006 Inventory-19

Simple Two-Bin Pull Method

Develop a simple control system by finding the

replenishment quantity (Q) and the reorder point (ROP).

Applicability: no uncertainty in demand or lead time:

manage regular (cycle) stock only

0 Time

Lead

time

Lead

time

Order

Placed

Order

Placed

Order

Received

Order

Received

Reorder

point, R

Q

Quantity on-hand

plus on-order

Dickson Chiu 2006 Inventory-20

Reorder Point Control for a Single Item

ROP

Q

u

a

n

t

i

t

y

o

n

h

a

n

d

0

Q

Q

Receive

order

Place

order

Stockout

LT

Time

LT

Demand

During

LT

P

Dickson Chiu 2006 Inventory-21

Reorder Point Control for a Single Item (2)

ROP

Q

0

I

n

v

e

n

t

o

r

y

l

e

v

e

l

LT

LT

Time

Safety stock

Actual

on hand

Quantity on hand

+on order

backorders

Quantity for

control

Dickson Chiu 2006 Inventory-22

Reorder Point Control for a Single Item (3)

Weekly demand is normally distributed

with a mean of d = 100 and a standard

deviation of s

d

= 10

Lead time is 3 weeks

Finding the reorder point requires an understanding of

the demand-during-lead-time distribution

s

d

=10

d

=100

s

d

=10

d

=100

s

d

=10

d

=100

+ +

=

Week 3 Week 2 Week 1

z

P

DDLT

X = 300 ROP

17.3 3 10

300 100(3)

= = =

= = =

LT s s

LT d X

d

'

S

=17.3

Dickson Chiu 2006 Inventory-23

Pull Methods

Non-instantaneous re-supply - At times, production or

supply continues while demand is depleting inventories.

Reorder point control with demand and lead time

uncertainties

The combined effect of these two uncertainties is particularly hard

to estimate accurately.

It is the standard deviation of the demand-during-lead-time

distribution that is the problem, especially if the level of demand

and the length of the lead time are related to each other.

Ideally, we would simply observe the actual demand occurring

over each lead time period.

If the demand and lead time are independent of each other and

each are represented by separate distributions, we may estimate

the standard deviation (s) from

) ( ) (

2 2 2 '

LT d

s d s LT s + =

Dickson Chiu 2006 Inventory-24

Periodic review control with demand

uncertainty

The inventory is reviewed at the time

interval (T) to determine the quantity on

hand. The replenishment quantity (Q) to be

ordered is the difference between a target

level called MAX and the quantity on hand.

Good method for products:

Of low value

That are purchased from the same vendor

Having economies of scale in production,

purchasing, and transportation

Dickson Chiu 2006 Inventory-25

Periodic review control with demand

uncertainty (2)

Q

1

Stock

level

reviewed

T

T

LT

LT

Order

received

Q

2

M

q

0

Q

u

a

n

t

i

t

y

o

n

h

a

n

d

Time

M = maximum level

M - q = replenishment quantity

LT = lead time

T = review interval

q = quantity on hand

Q

i

= order quantity

~

Dickson Chiu 2006 Inventory-26

Joint ordering

Perpetual inventory control for most firms is the

problem of managing items jointly rather than singly.

This occurs since more than one item is typically

purchased from the same vendor.

The approach to joint ordering is to find a common

order review interval (T) and then to set separate

target levels (MAX) based on specific item costs and

service levels.

A common review time may be specified, or it may

be computed based on appropriate economics.

Dickson Chiu 2006 Inventory-27

The Min-Max variant

basically a reorder point system, but the order quantity is

incremented by the amount of the difference between the

reorder point quantity and the quantity on hand + quantity on

order backorders.

takes into account that demand does not decrement inventory

levels evenly. Therefore, inventory levels may fall below the

reorder point at the time that it is reached.

~

Q

1 Q

2

Q

*

ROP

q

LT

LT

Time

Q

u

a

n

t

i

t

y

o

n

h

a

n

d

M

Add increment ROPq to order size

Dickson Chiu 2006 Inventory-28

The T, R, M variant

a combination of the min-max and the periodic review systems.

stock levels are reviewed periodically, but control the release of

the replenishment order by whether the reorder point is reached.

useful where demand is low, such that small quantities might be

released under a periodic review method.

T,R,M variant

LT LT

T

T

Time

R

q

I

n

v

e

n

t

o

r

y

l

e

v

e

l

T = review time

R = reorder point

M Q = replenishment quantity

Q

1

Q

2

Inventory not below

R, so dont place an

order

Dickson Chiu 2006 Inventory-29

Stock to demand - a periodic review

method

This is an important periodic review method, not so

much because of its accuracy but because of its

popularity in practice.

The method is synchronized with the period of the

forecast. The target quantity (MAX) is developed as

follows.

Set the period of the forecast, say 4 weeks

Add time for lead time, say 1 week

Add an increment of time for safety stock, say 1 week

Dickson Chiu 2006 Inventory-30

Multiple item, multiple-location control

The theory that has been discussed previously is useful when designing inventory

control systems for the practical problem of controlling many items at many

locations.

Consider how a specialty chemical company designed such a practical system.

TASO is the time to accumulate a stock order (truckload) for all items in

warehouse.

Q

1

Stock

order

TASO TASO

LT

Order

received

LT

Q

2

M

0

Q

u

a

n

t

i

t

y

o

n

h

a

n

d

Time

M = maximum level

TASO = time to accumulate stock order

Q

i

= order quantity

LT = lead time

TASO

~

~

Q

3

Dickson Chiu 2006 Inventory-31

Customer Service Level

The service level (stock availability) actually achieved

by inventory control methods is not best represented

by the probability (P) of a stockout during the lead time.

This actual level is higher that was used to set the

inventory level.

The reason is that there are periods of time when the

stock level is above the reorder point and there is no

risk of being out of stock.

Methods for defining stock availability include:

Probability of filling all item demand

Probability of filling an order completely

Probability of filling a percent of all item demand

Weighted average of items filled on an order (fill rate)

Dickson Chiu 2006 Inventory-32

Multi-Echelon Inventories

Control the entire channel inventory levels, not just a

single echelon.

E

n

d

c

u

s

t

o

m

e

r

d

e

m

a

n

d

R

1

R

2

R

3

1

,

1 d

s d

2

,

2 d

s d

3

,

3 d

s d

W

R

e

t

a

i

l

l

e

a

d

-

t

i

m

e

,

L

TR

Retailer

Warehouse

S

Supplier

Warehouse

lead-time, LT

w

Warehouse

echelon

How much stock here when

retailers also carry stock?

Dickson Chiu 2006 Inventory-33

Aggregate Inventory Control

Product items can be grouped according to 80-20

curve, each with different stocking policies

0

10

20

30

40

50

60

70

80

90

100

0 20 40 60 80 100

Total items (%)

T

o

t

a

l

s

a

l

e

s

(

%

)

A items B items C items

Dickson Chiu 2006 Inventory-34

Inventory Consolidation

(Risk Pooling)

There is a reduction in the average inventory

level of an item as the number of stocking

points in the supply channel is decreased.

Both regular stock and safety stock decline.

Dickson Chiu 2006 Inventory-35

Virtual Inventories

Stockouts are filled from other stocking locations

in the distribution network

Customers assigned to a primary stocking

location

Backup locations are usually determined by

zoning rules

Expectation is that lower system-wide

inventories can be achieved while maintaining or

improving stock availability levels

Total distribution costs should be lower to

support the cross filling of customer demand

Dickson Chiu 2006 Inventory-36

Cross Filling Virtual Inventory

Suppose that an item is stocked at a fill rate of 80% in

4 stocking locations. If cross filling is used, what is the

effective fill rate for the customer?

Fill rate = [1 (.20)(.20)(.20)(.20)] x 100 = 99.8%

Customer service levels can be quite high even if the

item fill rate is low!

Stock

location A

Stock

location B

Demand 1

Demand 2

P

r

i

m

a

r

y

a

s

s

i

g

n

m

e

n

t

P

r

i

m

a

r

y

a

s

s

i

g

n

m

e

n

t

Secondary

assignment

Stock

location A

Stock

location B

Demand 1

Demand 2

P

r

i

m

a

r

y

a

s

s

i

g

n

m

e

n

t

P

r

i

m

a

r

y

a

s

s

i

g

n

m

e

n

t

Secondary

assignment

Dickson Chiu 2006 Inventory-37

Safety Stock Reduction due to Cross

Filling

0

5

10

15

20

25

0 5 15 25 35 45 55 65 75 85 95 100

One warehouse's demand as a percent of

the system-wide demand

P

e

r

c

e

n

t

r

e

d

u

c

t

i

o

n

FR=70%

FR=90%

No cross-

filling

0

5

10

15

20

25

0 5 15 25 35 45 55 65 75 85 95 100

One warehouse's demand as a percent of

the system-wide demand

P

e

r

c

e

n

t

r

e

d

u

c

t

i

o

n

FR=70%

FR=90%

No cross-

filling

Lower safety

stocks from

lower fill rates

Dickson Chiu 2006 Inventory-38

Performance Metrics - Turnover Ratio

inventory Average

sales Annual

ratio Turnover =

$ are at cost

39

4c.2 Supply Scheduling Decision

Business Logistics Management, 5/E (Chapter 10)

Dickson Chiu 2006 Inventory-40

A Typical Scheduling Diagram

Forecast Orders

Build

schedule

Inventory Shortages

Purchase

order

releases

To vendors

Production

release

Bill of

materials

The point: Supply

is to inventory or to

requirements

Dickson Chiu 2006 Inventory-41

Supply to Requirements

Methods of scheduling

Just-in-time concept

Material requirements planning (MRP)

KANBAN

Dickson Chiu 2006 Inventory-42

Just-in-time Philosophy

A philosophy of scheduling where the entire supply

channel is synchronized to respond, in as short a

time as possible, to the requirements of operations

Close relationship with a few suppliers and transport

carriers

Information is shared between buyers and suppliers

Frequent production/purchase and transport of goods

in small quantities

Minimum inventory levels

Uncertainties are to be eliminated wherever possible

throughout the supply channel

Dickson Chiu 2006 Inventory-43

Requirements planning

A formal, mechanical method of scheduling

whereby the timing of purchases or supplies

is determined by offsetting the requirements

in the master production schedule.

Why requirements become lumpy for the

materials manager

Setting the master schedule

through derived demand patterns and bill of

materials explosion

forecasting

orders on hand

Dickson Chiu 2006 Inventory-44

Why demand becomes lumpy

Time

Time

Order

point

Order

point

L

e

v

e

l

L

e

v

e

l

0

0

Production order

release

Order

placement

(a) Field inventory (Finished product in warehouse)

(b) Factory inventory (Finished product at plant)

Time

Order

point

L

e

v

e

l

0

Purchase order

release

(c) Component inventory (Supply stocks at plant)

Dickson Chiu 2006 Inventory-45

MRP Scheduling

The mechanics of lot-for-lot scheduling given certain

requirements and lead times

Purchase orders are matched on a one-for-one basis with

requirements.

Determining lot sizes

Trading purchase price for inventory carrying cost

Vendors can set order minimum quantities to avoid the high cost of

handling small orders.

This will usually force some inventory into the system.

The economically best order quantities can be set by balancing the

cost of processing an order with the cost of carrying the inventory

associated with ordering more than what is immediately needed.

Handling uncertainties in the master schedule

Minimum inventory levels

Part-period cost balancing

Handling lead time uncertainties

Dickson Chiu 2006 Inventory-46

KANBAN

Toyotas method of scheduling using the order point inventory

control procedure, but with very low setup costs and very short lead-

times

Models are repeated frequently in the master schedule.

A typical master schedule for economies of scale might look like

AAAAAABBBBBBAAAAAABBBBBB

but a KANBAN schedule would approach

ABABABABABABABABABABABAB

Lead-times are predictable because they are short and because

suppliers are located near the site of operations

Order quantities are small because setup or procurement costs are

kept low

Few vendors are used with high expectations of vendors and high

level of cooperation with them

Classic reorder point inventory control is used to determine reorder

quantities and timing of purchases

Dickson Chiu 2006 Inventory-47

KANBAN vs. Supply to Inventory

Factors KANBAN/JIT scheduling Supply to Inventory

Set Ups Make them insignificant. This

requires either extremely rapid

changeover to minimize the

impact on operations, or the

availability of extra machines

already set up. Fast changeover

permits small lot sizes to be

practical, and allows a wide

variety of parts to be made

frequently.

Low priority. Maximum output is the usual

goal. Rarely does similar thought and effort

go into achieving quick changeover.

Queues Eliminate them. When

problems occur, identify the

causes and correct them. The

correction process is aided

when queues are small. If the

queues are small, it surfaces the

need to identify and fix the

cause.

Necessary investment. Queues permit

succeeding operations to continue in the

event of a problem with the feeding

operation. Also, by providing a selection of

jobs, the factory management has a greater

opportunity to match up varying operator

skills and machine capabilities, combine set-

ups and thus contribute to the efficiency of

the operation.

Dickson Chiu 2006 Inventory-48

KANBAN vs. Supply to Inventory (2)

Factors KANBAN/JIT Scheduling Supply to Inventory

Vendors Co-workers. They're part of the team.

Multiple deliveries for all active items

are expected daily. The vendor takes

care of the needs of the customer, and

the customer treats the vendor as an

extension of his factory.

Adversaries. Multiple sources

are the rule, and it's typical to

play them against each other.

Quality Zero defects. If quality is not 100%,

production is in jeopardy.

Tolerate some scrap. Scrap is

tracked and formulas are

developed for predicting it.

Equipment

mainten-

ance

Constant and effective. Machine

breakdowns must be minimal.

As required. But not critical

because of queues available.

Lead times Keep them short. This simplifies the

job of marketing, purchasing, and

manufacturing as it reduces the need

The longer the better. Most

foremen and purchasing agents

want more lead time, not less.

Dickson Chiu 2006 Inventory-49

KANBAN vs. Supply to Inventory (3)

Factors KANBAN/JIT Scheduling Supply to Inventory

Workers Management by consensus. Changes

are not made until consensus is

reached, whether or not a bit of arm

twisting is involved. The vital

ingredient of "ownership" is achieved.

Management by edict. New

systems are installed in spite of

the workers. The concentration

is on measurements to determine

whether or not they're doing it.

Dickson Chiu 2006 Inventory-50

Supply Chain Dynamics Bullwhip Effect

Time

Supply channel

Customer Customer

Firm A

Firm B

Firm C

Firm C

Firm A

D

e

m

a

n

d

Demand on upstream firms varies

greatly with small changes in

downstream demand

Dickson Chiu 2006 Inventory-51

Bullwhip Effect

Internal reasons for the

effect

Demand shifts

Product/service changes

Late deliveries

Incomplete shipments

External reasons for the

effect

Supply shortages

Engineering changes

New product/service

introductions

Product/service promotions

Information errors

Remedies

Centralize demand

forecasting

Improve forecasting

accuracy

Reduce lead-time

uncertainties throughout

the channel

Smooth response to

change

Dickson Chiu 2006 Inventory-52

Vendor Managed Inventory

The supplier usually owns the inventory at

the customers location

The supplier manages the inventory by any

means appropriate and plans shipment sizes

and delivery frequency

The buyer provides point of sale information

to the supplier

The buyer pays for the merchandise at the

time of sale

The buyer dictates the level of stock

availability required

53

4c.3 Purchasing

Business Logistics Management, 5/E (Chapter 10)

Dickson Chiu 2006 Inventory-54

What is Purchasing?

Primarily a buying activity

A decision area to be integrated with overall

materials management and logistics

At times, an area to be used to the firms strategic

advantage

Mission: Securing the products, raw materials, and

services needed by production, distribution, and

service organizations at the right time, the right price,

the right place, the right quality, and in the right

quantity.

Importance

Decisions impact on 40 to 60% of sales dollar

Decisions are highly leveraged

Dickson Chiu 2006 Inventory-55

What is purchased?

Price

Cost of goods

Terms of sale

Discounts

Quality

Meeting specifications

Conformance to quality standards

Service

On-time and damage-free delivery, order-filling

accuracy, product availability

Product support

Dickson Chiu 2006 Inventory-56

Activities of purchasing

Selects and qualifies

suppliers

Rates supplier

performance

Negotiates contracts

Compares price, quality,

and service

Sources goods

Times purchases

Sets terms of sale

Evaluates the value

received

Measures inbound quality if

not a responsibility of

quality control

Predicts price, service, and

sometimes demand

changes

Specifies form in which

goods are to be received

Dickson Chiu 2006 Inventory-57

Criteria for selecting suppliers

Past or anticipated relations

Honesty

Financial viability

Reciprocity

Measured performance

Price

Responsiveness to change or

requests

On-time delivery

Product or service backup

Meeting quality goals

Weighted average of ratings

Operational compatibility

Informational compatibility

Physical compatibility

Ethical and moral issues

Minority vendors

Lowest price bidding

Patriotic purchasing

Open bidding but a pre-

selected vendor

Dickson Chiu 2006 Inventory-58

Single vs Multiple Vendors

Single vendors

Allows for economies of

scale

Consistent with the

just-in-time philosophy

Builds loyalty and trust

May be only source for

unique product or

service

Multiple vendors

Encourages price

competition

Diffuses risk

May disturb supplier

relations, reduce loyalty,

reduce responsiveness,

and cause variations in

product quality and

service

Dickson Chiu 2006 Inventory-59

Finding Suppliers

Personal contacts

Trade publications

Web sites, catalogs, and directories

Advertisements and solicitations

Dickson Chiu 2006 Inventory-60

Qualifying suppliers

Previous experiences and formal rating schemes

Word of mouth

Samples of product

Reputation

Site visits and demonstrations

Dickson Chiu 2006 Inventory-61

Allocation to Suppliers

Company policy considering risk, fairness, ethics, etc.

Definitive methods

Is buying based on lowest price a good strategy

consider other costs too

Allocate using linear programming

Asking what if questions can provide insight into

good allocation plans

weak supplier - perhaps some price concessions can be

negotiated

valuable supplier and more capacity should be sought

Dickson Chiu 2006 Inventory-62

Timing of Purchases

Through just-in-time planning

Material requirements planning for continuous work

Gantt charts and CPM/PERT for project work

Through inventory management

Push methods

Pull methods

According to market conditions

Speculative buying

Forward buying

Hand-to-mouth buying, or buying to current

requirements

Dickson Chiu 2006 Inventory-63

Speculative buying

Buying more than the foreseeable requirements at

current prices in the hope of reselling later at

higher prices.

Some of the purchased quantities may be used in

production and some simply resold.

Generally a financial activity, not a materials

management one.

Dickson Chiu 2006 Inventory-64

Hand-to-mouth buying

Buying to satisfy immediate needs such as those

generated through MRP.

Advantageous when prices are dropping

May improve cash flow by temporarily reducing

expenses of carrying inventory

Dickson Chiu 2006 Inventory-65

Forward buying

Buying in quantities exceeding current requirements, but

not beyond foreseeable needs.

Takes advantage of favorable prices in an unstable market,

or takes advantage of volume transportation rates

Reduces risk of inadequate delivery

Dollar Averaging

Spend the same amount on each purchase with the idea of buying

more when prices are low and less when they are high.

This is a good strategy when prices are expected to rise over the

long term and there is substantial uncertainty as to the actual price

level.

Because under-supply may occur, some level of inventory will need

to be maintained.

Dickson Chiu 2006 Inventory-66

Effect of Quantity Discounts

Inclusive Price Breaks

Price break curves

$

500

Order quantity, Q

Q

2

Q

1

Curve for Q<500

Total cost

Curve for Q>500

Feasible curve

Quantity, Q

i

Price,

P

i

0 < Q

i

< Q

1

P

1

Q

i

> Q

1

P

2

Dickson Chiu 2006 Inventory-67

Effect of Quantity Discounts

Non-inclusive Price Breaks

Cost for

Cost for

Q

1

0

T

o

t

a

l

c

o

s

t

Purchase quantity, Q

i

0

1

< s Q Q

i

Q Q

i

>

1

Price break curve: non-inclusive discounts

Price discount only

applies to the items

beyond the price break

quantity.

Dickson Chiu 2006 Inventory-68

Deal Buying

A one-time buying opportunity.

Determining the quantity to purchase

requires balancing the benefits of a price

discount against extra inventory holding costs.

69

4c.4 Summary

Dickson Chiu 2006 Inventory-70

Summary

Inventories is a major use of capital in the supply channel.

Key tradeoff: lead time, demand, service, cost

Key difficulties: demand uncertainty together with lead time

Push vs pull

Purchasing and scheduling involve decisions that affect the

efficient movement and storage of goods.

Just-in-time scheduling procedures become popular

Toyotas KANBAN and MRP scheduling

Combining Distribution and Materials Requirements Planning

(DRP and MRP) allows integration of the supply chain from

suppliers to customers.

Purchasing is important, accounting for 40-60% of dollar

sales typically.

Impact on the efficiency of logistical activities

Key purchasing decision: quantities, timing, and sourcing

Dickson Chiu 2006 Inventory-71

Summary (2)

Again much domain knowledge is required.

Note the data / information requirements and how IT helps

to collect / integrate the data for calculations and decision

making.

Capture forecasting and ordering signals (either

determined by a business analyst or automatically by a

sub-system) as events / exceptions / alerts and forward

them to the appropriate system and personnel for decision

/ action.

Effective collaboration with retailers and suppliers requires

much new IT in the process and information integration, as

well as relying on integrating with existing enterprise

systems (e.g., MRP / DRP).

Note the difficulties in integrating with multiple suppliers,

especially dynamic ones.

Você também pode gostar

- Inventory Management - Lecture 15.04.2015Documento56 páginasInventory Management - Lecture 15.04.2015Asia Oleśków SzłapkaAinda não há avaliações

- sales and operations planning A Complete Guide - 2019 EditionNo Everandsales and operations planning A Complete Guide - 2019 EditionAinda não há avaliações

- Inventory Management System A Complete Guide - 2019 EditionNo EverandInventory Management System A Complete Guide - 2019 EditionAinda não há avaliações

- Inventory ManagementDocumento26 páginasInventory ManagementAmit mehlaAinda não há avaliações

- The ABC Inventory MatrixDocumento9 páginasThe ABC Inventory MatrixOtis MelbournAinda não há avaliações

- Inventory ManagementDocumento13 páginasInventory ManagementJosephin DynaAinda não há avaliações

- 5.4 Inventory MagtDocumento48 páginas5.4 Inventory Magtbha_goAinda não há avaliações

- Value Stream MappingDocumento35 páginasValue Stream MappingNevets NonnacAinda não há avaliações

- Welcomes All The Participants To The: Continuous Training & Development ProgramDocumento47 páginasWelcomes All The Participants To The: Continuous Training & Development Programselvarangam govindarajanAinda não há avaliações

- Handbook of Industrial EngineeringDocumento24 páginasHandbook of Industrial EngineeringRanachetan SinghAinda não há avaliações

- Lean Manufacturing - An IntroductionDocumento44 páginasLean Manufacturing - An IntroductionSiva Rama Krishna Patimalla100% (1)

- Cellular ManufacturingDocumento25 páginasCellular ManufacturingApoorv Mathur100% (1)

- Boost productivity with Total Factor Productivity analysisDocumento72 páginasBoost productivity with Total Factor Productivity analysisSameer Sawant100% (1)

- What is Kanban? Scheduling, Types & MoreDocumento20 páginasWhat is Kanban? Scheduling, Types & MoresentaprilepAinda não há avaliações

- Make or Buy ApproachDocumento4 páginasMake or Buy Approachporseena100% (1)

- Unblocking BottlenecksDocumento3 páginasUnblocking BottlenecksMaggie GonzalesAinda não há avaliações

- One Piece FlowDocumento31 páginasOne Piece Flowakdmech9621100% (1)

- Lean ManufacturingDocumento20 páginasLean ManufacturingPranav SharmaAinda não há avaliações

- KiazenDocumento12 páginasKiazenAmogh KulkarniAinda não há avaliações

- Poka YokeDocumento22 páginasPoka YokeAnonymous I7dJ0lmdAinda não há avaliações

- KaizenDocumento40 páginasKaizenAshish KulkarniAinda não há avaliações

- One Day Training On KAIZEN: Hilton HotelDocumento74 páginasOne Day Training On KAIZEN: Hilton HotelyinueAinda não há avaliações

- Case StudyDocumento15 páginasCase StudyReynaldo NyotoAinda não há avaliações

- Kanban SystemDocumento4 páginasKanban SystemDivakar RanjanAinda não há avaliações

- MUDA (7 Waste)Documento3 páginasMUDA (7 Waste)Shamshair Ali100% (1)

- 7 Types of Waste Guidance ExplainedDocumento20 páginas7 Types of Waste Guidance ExplainedjogedhayalAinda não há avaliações

- OPTIMIZE PRODUCTION WITH JUST IN TIME MANUFACTURINGDocumento21 páginasOPTIMIZE PRODUCTION WITH JUST IN TIME MANUFACTURINGEllan EncaboAinda não há avaliações

- 5S PresentationDocumento31 páginas5S PresentationManoj Pandey100% (2)

- KANBANDocumento59 páginasKANBANMURALIDHRA100% (1)

- Inventory Management and ControlDocumento24 páginasInventory Management and ControlSathvik ReddyAinda não há avaliações

- LEANDocumento29 páginasLEANkmsteamAinda não há avaliações

- Inventory Models Guide for BusinessesDocumento24 páginasInventory Models Guide for BusinessesRichard Sinchongco Aguilar Jr.Ainda não há avaliações

- 5 S ProgramDocumento118 páginas5 S ProgramNatarajan RajAinda não há avaliações

- Inventory ManagementDocumento40 páginasInventory Managementganesh100% (1)

- 5S Best Practices For Lean WarehousingDocumento3 páginas5S Best Practices For Lean WarehousingDharmvir UppalAinda não há avaliações

- Inventory and Risk Management-AbstractDocumento2 páginasInventory and Risk Management-AbstractSaritha ReddyAinda não há avaliações

- Takt TimeDocumento28 páginasTakt Timejcruz909Ainda não há avaliações

- Aggregate PlanningDocumento47 páginasAggregate Planningmarah nimerAinda não há avaliações

- Manufacturing ExcellenceDocumento17 páginasManufacturing ExcellenceAnthony Cappucci100% (5)

- The 5 S'S: Japanese Transliterated EnglishDocumento4 páginasThe 5 S'S: Japanese Transliterated EnglishRishita TandonAinda não há avaliações

- Lean Brief Takt TimeDocumento2 páginasLean Brief Takt TimeBala Kumar M PAinda não há avaliações

- Manufacturing CellDocumento19 páginasManufacturing CellRavi Nawal100% (1)

- 5 S & Lean 6 SigmaDocumento16 páginas5 S & Lean 6 SigmaAkshay KumarAinda não há avaliações

- Inventory ManagementDocumento121 páginasInventory ManagementAbdul Aziz100% (1)

- Kanban: - A System That Uses Replenishment Signals To Simplify Inventory ManagementDocumento31 páginasKanban: - A System That Uses Replenishment Signals To Simplify Inventory ManagementdaranivelAinda não há avaliações

- INVENTORY MANAGEMENT TechniquesDocumento24 páginasINVENTORY MANAGEMENT TechniquesWessal100% (1)

- Just-In-Time Inventory Management TechniqueDocumento6 páginasJust-In-Time Inventory Management Techniquetyavanee19Ainda não há avaliações

- Ch-8 (Business Process Reengineering)Documento22 páginasCh-8 (Business Process Reengineering)Shrutit21Ainda não há avaliações

- Economic Order QuantityDocumento33 páginasEconomic Order QuantitySunny PanditAinda não há avaliações

- 00the 7 MFG WasteDocumento15 páginas00the 7 MFG WasteRohit PrakashAinda não há avaliações

- Total Preventive Maint.Documento18 páginasTotal Preventive Maint.No HopeAinda não há avaliações

- Lean Manufacturing and It's Implementation in Automotive IndustryDocumento48 páginasLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshAinda não há avaliações

- OEE PresentationDocumento15 páginasOEE PresentationIbrahim FaragAinda não há avaliações

- 5s CSRDocumento69 páginas5s CSRFadzilahMohamadAinda não há avaliações

- Inventory Management: Kharylle Conol Stefie Marie Lee Honey Gladys MonteadoraDocumento22 páginasInventory Management: Kharylle Conol Stefie Marie Lee Honey Gladys MonteadoraCorazon Lim LeeAinda não há avaliações

- Inventory Management ProjectDocumento11 páginasInventory Management ProjectMOHD.ARISH100% (1)

- Bimco Bill of Lading Code Name: GrainconbillDocumento2 páginasBimco Bill of Lading Code Name: GrainconbillPSYCHOTHEWALLAinda não há avaliações

- COAL-OREVOY BILL OF LADINGDocumento2 páginasCOAL-OREVOY BILL OF LADINGPSYCHOTHEWALLAinda não há avaliações

- Bimco contracts1CEMENTVOY 2006Documento18 páginasBimco contracts1CEMENTVOY 2006PSYCHOTHEWALLAinda não há avaliações

- Cargo Handling PortDocumento29 páginasCargo Handling PortHarry PasaribuAinda não há avaliações

- Cement VoyDocumento2 páginasCement VoyPSYCHOTHEWALLAinda não há avaliações

- Materials Requirements Planning (MRP) PDFDocumento19 páginasMaterials Requirements Planning (MRP) PDFPSYCHOTHEWALLAinda não há avaliações

- The Bill of Lading As A Document of Title at Common LawDocumento24 páginasThe Bill of Lading As A Document of Title at Common LawPSYCHOTHEWALLAinda não há avaliações

- 12 Common Types of Bill of Lading FormsDocumento12 páginas12 Common Types of Bill of Lading FormsPSYCHOTHEWALLAinda não há avaliações

- FIATA A - Guide - To - Logistics - Agreements - 04 PDFDocumento3 páginasFIATA A - Guide - To - Logistics - Agreements - 04 PDFPSYCHOTHEWALLAinda não há avaliações

- What Is LogisticsDocumento4 páginasWhat Is LogisticsPSYCHOTHEWALLAinda não há avaliações

- Assignment A2 - NUR AZMINA NADIA ROSLIE - 2019222588 - ENT300Documento10 páginasAssignment A2 - NUR AZMINA NADIA ROSLIE - 2019222588 - ENT300minadiaAinda não há avaliações

- NSU FALL 2012 FIN254.9 Term Paper On Aramit LimitedDocumento24 páginasNSU FALL 2012 FIN254.9 Term Paper On Aramit LimitedSamaan RishadAinda não há avaliações

- FEU V TrajanoDocumento1 páginaFEU V TrajanoPeperonii0% (2)

- GodrejDocumento4 páginasGodrejdeepaksikriAinda não há avaliações

- Fin 416 Exam 2 Spring 2012Documento4 páginasFin 416 Exam 2 Spring 2012fakeone23Ainda não há avaliações

- GPB Rosneft Supermajor 25092013Documento86 páginasGPB Rosneft Supermajor 25092013Katarina TešićAinda não há avaliações

- Quiz - 1Documento3 páginasQuiz - 1Faiz MokhtarAinda não há avaliações

- Analisis Cost Volume Profit Sebagai Alat Perencanaan Laba (Studi Kasus Pada Umkm Dendeng Sapi Di Banda Aceh)Documento25 páginasAnalisis Cost Volume Profit Sebagai Alat Perencanaan Laba (Studi Kasus Pada Umkm Dendeng Sapi Di Banda Aceh)Fauzan C LahAinda não há avaliações

- Special Offers to Colombo from London on SriLankan AirlinesDocumento32 páginasSpecial Offers to Colombo from London on SriLankan AirlinesSri Sakthi SumananAinda não há avaliações

- Roberto Guercio ResumeDocumento2 páginasRoberto Guercio Resumeapi-3705855Ainda não há avaliações

- Software PatentsDocumento13 páginasSoftware PatentsIvan Singh KhosaAinda não há avaliações

- Marketing ChannelDocumento21 páginasMarketing ChannelNikhil DubeyAinda não há avaliações

- Dynamic Cables Pvt. LTD.: WORKS ORDER-Conductor DivDocumento2 páginasDynamic Cables Pvt. LTD.: WORKS ORDER-Conductor DivMLastTryAinda não há avaliações

- JDA Demand - Focus 2012Documento43 páginasJDA Demand - Focus 2012Abbas Ali Shirazi100% (1)

- 2015-16 VDC Lease Body - FinalDocumento9 páginas2015-16 VDC Lease Body - FinalAndrew BimbusAinda não há avaliações

- Ministry of Transportation Audit Finding DetailsDocumento6 páginasMinistry of Transportation Audit Finding DetailsAmalia Resky100% (1)

- Chapter 4 - Fire InsuranceDocumento8 páginasChapter 4 - Fire InsuranceKhandoker Mahmudul HasanAinda não há avaliações

- Class 11 CH 2 NotesDocumento10 páginasClass 11 CH 2 NotesJay KakadiyaAinda não há avaliações

- Marketing Quiz on Product Life Cycle, Pricing Strategies, Distribution Channels, Promotion ToolsDocumento7 páginasMarketing Quiz on Product Life Cycle, Pricing Strategies, Distribution Channels, Promotion ToolsDisha MathurAinda não há avaliações

- Finance TestDocumento3 páginasFinance TestMandeep SinghAinda não há avaliações

- FM S Summer Placement Report 2024Documento12 páginasFM S Summer Placement Report 2024AladeenAinda não há avaliações

- CE462-CE562 Principles of Health and Safety-Birleştirildi PDFDocumento663 páginasCE462-CE562 Principles of Health and Safety-Birleştirildi PDFAnonymous MnNFIYB2Ainda não há avaliações

- Whitepaper - State of Construction TechnologyDocumento16 páginasWhitepaper - State of Construction TechnologyRicardo FigueiraAinda não há avaliações

- Competitive Advantage in Mature Industries: OutlineDocumento9 páginasCompetitive Advantage in Mature Industries: OutlineRohanAinda não há avaliações

- Griffin Chap 11Documento34 páginasGriffin Chap 11Spil_vv_IJmuidenAinda não há avaliações

- Gestion de La Calidad HoqDocumento8 páginasGestion de La Calidad HoqLuisa AngelAinda não há avaliações

- Lemon MaltDocumento33 páginasLemon MaltUmar AsifAinda não há avaliações

- Reporting Outline (Group4 12 Abm1)Documento3 páginasReporting Outline (Group4 12 Abm1)Rafaelto D. Atangan Jr.Ainda não há avaliações

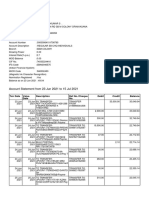

- Account Statement From 23 Jun 2021 To 15 Jul 2021Documento8 páginasAccount Statement From 23 Jun 2021 To 15 Jul 2021R S enterpriseAinda não há avaliações

- Ch03 - The Environments of Marketing ChannelsDocumento25 páginasCh03 - The Environments of Marketing ChannelsRaja Muaz67% (3)