Escolar Documentos

Profissional Documentos

Cultura Documentos

3.model Visco-Elasticity

Enviado por

opabalekeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3.model Visco-Elasticity

Enviado por

opabalekeDireitos autorais:

Formatos disponíveis

EBB 220/3

MODEL FOR

VISCO-ELASTICITY

DR AZURA A.RASHID

Room 2.19

School of Materials And Mineral Resources Engineering,

Universiti Sains Malaysia, 14300 Nibong Tebal, P. Pinang

Malaysia

It is difficult to predict the creep and stress relaxation

for polymeric materials.

It is easier to predict the behaviour of polymeric

materials with the assumption it behaves as linear

viscoelastic behaviour.

Deformation of polymeric materials can be divided to

two components:

Elastic component Hookes law

Viscous component Newtons law

Deformation of polymeric materials combination of

Hookes law and Newtons law.

INTRODUCTION

The behaviour of linear elastic were given by Hookes

law:

Ee = o

E= Elastic modulus

o = Stress

e=strain

de/dt = strain rate

do/dt = stress rate

q= viscosity

or

dt

de

E

dt

d

=

o

The behaviour of linear

viscous were given by

Newtons Law:

dt

de

q o =

** This equation only applicable at low strain

Hookes law & Newtons Law

Methods that used to predict the behaviour of visco-

elasticity.

They consist of a combination of between elastic

behaviour and viscous behaviour.

Two basic elements that been used in this model:

1. Elastic spring with modulus which follows Hookes

law

2. Viscous dashpots with viscosity q which follows

Newtons law.

The models are used to explain the phenomena creep

and stress relaxation of polymers involved with different

combination of this two basic elements.

Mechanical Model

CREEP

STRESS RELAXATION

Constant strain is applied

the stress relaxes as

function of time

Constant stress is applied

the strain relaxes as

function of time

The common mechanical model that use to

explain the viscoelastic phenomena are:

1. Maxwell

Spring and dashpot align in series

2. Voigt

Spring and dashpot align in parallel

3. Standard linear solid

One Maxwell model and one spring align

in parallel.

Maxwell model consist of spring and dashpot in series

and was developed to explain the mechanical

behaviour on tar.

On the application of stress, the strain in each elements

are additive.

The total strain is the sum of strain in spring & dashpot.

The stress each elements endures is the same.

Elastic spring

Viscous dashpot

Maxwell Model

Overall stress o, overall strain e in the system is given

by:

e

s

=strain in spring and e

d

=strain in dashpot dashpot

Because the elements were in series the stress is the

same for all elements,

Equations for spring and dashpot can be written as:

d s

e e e + =

d s

o o o = =

and

dt

de

E

dt

d

s

=

o

dt

de

d

q o =

For Maxwell model, the strain rate is given as

The accuracy of prediction the mechanical behaviour of

Maxwell model can be confirm.

In creep case, the stress at o = o

0

maka do/dt = 0. The

equations can be written as:

Maxwell model can predict the Newtonian behaviour

the strain is predict to increased with time

q

o o

+ =

dt

d

E dt

de 1

q

o

0

=

dt

de

.

The behavior of Maxwell

model during creep loading

(constant stress, o

0

strain

is predicted to increased

linearly with time

This is not the viscoelastic

behaviour of polymeric

materials de/dt decreased

with time

May be this model is useful to predict the behaviour of

polymeric materials during stress relaxation.

In this case, the strain is constant e=e

0

applied to the

system given de/dt =0

then

Integration at t=0 o= o

0

given

q

o o

+ =

dt

d

E dt

de 1

q

o o

+ =

dt

d

E

1

0

dt

E d

q o

o

=

|

|

.

|

\

|

=

q

o o

Et

eksp

0

o

o

= earlier stress

The term q/E is constant for Maxwell model and

sometimes can be refered as time relaxation, t

0

written

as:

The exponential decreased in stress can be predicted

give a better representation of polymeric materials

behaviour.

Stress were predicted

completely relaxed with time

period it is not the normal

case for polymer

|

|

.

|

\

|

=

0

0

t

o o

t

eksp

Can also known as the Kelvin model.

It consists of a spring and dashpot in parallel.

In application of strain, the stress of each element

is additive, and the strain in each element is the

same.

Voigt Model

Viscous dashpot

Elastic spring

The parallel arrangement of spring and dashpot gives

the strain e are the same for the system given by:

e

s

=strain in spring and e

d

=strain in dashpot

Because the elements in parallel stress o din every

elements are additive and the overall stress are

Equation for spring and dahpot can be written as:

and

d s

e e e = =

d s

o o o + =

Ee

s

= o

dt

de

d

q o =

For Voigt model, the strain rate are

The accuracy of prediction the mechanical behaviour of

Voigt model can be confirm.

In creep case, stress is o = o

o

so do/dt = 0. The equation

can be written as:

The simple differential equation given by:

q q

o Ee

dt

de

=

q

o

q

0

= +

Ee

dt

de

(

|

|

.

|

\

|

=

q

o Et

eksp

E

e 1

0

Constant ratio q/E can be replace with time

relaxation, t

0.

Changes in strain with time for Voigt model that

having creep are given by:

(

(

|

|

.

|

\

|

=

0

0

1

t

o t

eksp

E

e

Figure shows polymer

behavior under creep

deformation strain rate

decreased with time

e o

o

/

.

E

and t=

Voigt model fails to predict the stress relaxation

behaviour of polymer

When the strain is constant at e

0

and dan de/dt = 0 the

equation shows:

The linear response is shown in the figure:

q q

o

0

Ee

=

or

0

Ee = o

Behavior of Voigt model

at different loading

Stress relaxation

As shown:

Maxwell model can accurately predict the

phenomenon stress relaxation to a first

approximation.

Voigt Model can accurately predict the

phenomenon creep to a first

approximation.

Standard linear solid model was

developed to combined the Maxwell and

Voigt model to describe both creep &

stress relaxation to a first approximation.

Standard linear solid

In consist one Maxwell elements in parallel with a

spring.

The presence on this second spring will stop the

tendency of Maxwell element undergoing viscous flow

during creep loading but will still allow the stress

relaxation to occur

Viscous dashpot

Elastic spring

There were a lots of attempts to discover more

complex model that can give a good

approximation to predict viscoelastic behaviour

of polymeric materials.

When the elements used is increased

mathematical can be more complex.

It can be emphasis that mechanical models can

only gives mathematical representations for

mechanical behaviour only it not much

help to predict the behaviour of viscoelasticity at

molecular level.

Summary

Linear viscoelastic theory is Boltzman

superposition principle.

It is the first mathematical statement of linear

viscoelastic behaviour that allows the state of

stress or strain in a viscoelastic body to

determine from a knowledge of its entire

deformation history.

This principle can be used to predict the

overall creep and stress relaxation of

polymeric materials

Boltzman superposition principle

Botzmann proposed that:

The creep in a specimen is a function of its

entire loading history

Each loading step makes an independent

contribution to the final deformation

Overall deformation algebraic sum of each

contribution

Illustrating the Boltzman superposition principle

What is the purpose of mechanical model

in visco-elasticity theories?

Gives a brief description how the chosen

mechanical model can be used to estimate

the creep or stress relaxation behavior for

polymeric materials?

Example of the exams question

Você também pode gostar

- 15 ViscoelasticityDocumento30 páginas15 ViscoelasticityaderancAinda não há avaliações

- ViscoelasticityDocumento11 páginasViscoelasticitymchilwesaAinda não há avaliações

- Experiment 9 Young S ModulusDocumento4 páginasExperiment 9 Young S ModulusLIEW ZHUN KIT MoeAinda não há avaliações

- Mechanical Properties and Deformation Mechanisms in MetalsDocumento31 páginasMechanical Properties and Deformation Mechanisms in Metalspoom2007Ainda não há avaliações

- Sisal and BannanaDocumento13 páginasSisal and BannanavinothkumarAinda não há avaliações

- 09 Static and Kinetic FrictionDocumento6 páginas09 Static and Kinetic FrictionWanda AstariAinda não há avaliações

- Lab 7 Static and Kinetic Friction by Vinci NguyenDocumento5 páginasLab 7 Static and Kinetic Friction by Vinci NguyenvincinugeAinda não há avaliações

- Semiconductors & Communications (V) D Drive Theory and QuestionsDocumento63 páginasSemiconductors & Communications (V) D Drive Theory and QuestionsAvi KedarrAinda não há avaliações

- TMS 201 Engineering Mechanics StaticsDocumento17 páginasTMS 201 Engineering Mechanics StaticsFakhar ZakyAinda não há avaliações

- Mechanical Properties of MaterialsDocumento53 páginasMechanical Properties of MaterialsfanaAinda não há avaliações

- Electrostatics: Electrostatics Electric Current ElectromagnetismDocumento4 páginasElectrostatics: Electrostatics Electric Current ElectromagnetismBorisAinda não há avaliações

- Routine Tests For TrihalDocumento21 páginasRoutine Tests For Trihalyadav_sctAinda não há avaliações

- 3 Dielectric Properties of MaterialsDocumento54 páginas3 Dielectric Properties of MaterialsAkarshit NandeshwarAinda não há avaliações

- Lab Report Electrostatic PrecipitatorDocumento9 páginasLab Report Electrostatic Precipitatoraina shaminaAinda não há avaliações

- Tensile Strength of Mild SteelDocumento11 páginasTensile Strength of Mild SteelPavan Ps50% (2)

- Solids and Semiconductor Devices - I: Energy Bands and Carrier ConceptsDocumento68 páginasSolids and Semiconductor Devices - I: Energy Bands and Carrier ConceptsdhruviAinda não há avaliações

- Engineering ThermodynamicsDocumento30 páginasEngineering ThermodynamicsAddisu DagneAinda não há avaliações

- Compression Test Lab ReportDocumento11 páginasCompression Test Lab ReportRobert K OtienoAinda não há avaliações

- Solar CellDocumento24 páginasSolar CellanupamanupamAinda não há avaliações

- Lab 7 - Thevenin and Norton Equivalent CircuitsDocumento9 páginasLab 7 - Thevenin and Norton Equivalent CircuitsaliAinda não há avaliações

- Protection Circuits Types and ApplicationsDocumento21 páginasProtection Circuits Types and ApplicationsSanket PatilAinda não há avaliações

- ICEIS - Regenerative Eddy Current Braking SystemDocumento5 páginasICEIS - Regenerative Eddy Current Braking SystemTech MitAinda não há avaliações

- Low Pass Filter DesignDocumento15 páginasLow Pass Filter DesignchachunasayanAinda não há avaliações

- ELECTRIC CHARGES AND FIELDS PROJECTDocumento6 páginasELECTRIC CHARGES AND FIELDS PROJECTShifa SiddiquiAinda não há avaliações

- Chapter 1 Hydrostatic Forces On SurfacesDocumento41 páginasChapter 1 Hydrostatic Forces On SurfacesFauzan Pojan100% (1)

- Failure theories-IITMDocumento5 páginasFailure theories-IITMsunil_patil_38Ainda não há avaliações

- Soil Mechanics TestsDocumento9 páginasSoil Mechanics TestsAfifah FauziAinda não há avaliações

- Experiment 24: The Potentiometer: PurposeDocumento6 páginasExperiment 24: The Potentiometer: PurposekirtiAinda não há avaliações

- ch3Documento78 páginasch3David GaoAinda não há avaliações

- Wave Behavior of Particle and De-Broglie Hypothesis and Its TestingDocumento8 páginasWave Behavior of Particle and De-Broglie Hypothesis and Its TestingUsman Masood PhysicistAinda não há avaliações

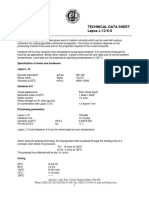

- Atul Ltd. TECHNICAL DATA SHEET for Lapox L-12 K-6 epoxy resin and hardenerDocumento2 páginasAtul Ltd. TECHNICAL DATA SHEET for Lapox L-12 K-6 epoxy resin and hardenerKarthick MuruganAinda não há avaliações

- Dielectric Properties of Ceramics: Understanding Dielectric Constant, Loss and Strength (EBB 443Documento38 páginasDielectric Properties of Ceramics: Understanding Dielectric Constant, Loss and Strength (EBB 443kanita_jaww100% (1)

- UCT Sarawak Lab Report Expansion Processes Perfect GasDocumento18 páginasUCT Sarawak Lab Report Expansion Processes Perfect GasSia How TanAinda não há avaliações

- Plastic Collapse PDFDocumento13 páginasPlastic Collapse PDFrajashrismdAinda não há avaliações

- The Fundamentals of Materials Science 2122Documento13 páginasThe Fundamentals of Materials Science 2122Lara Mae BuragayAinda não há avaliações

- (Experiment 3) BJT - Common Emiter Amplifier PDFDocumento9 páginas(Experiment 3) BJT - Common Emiter Amplifier PDFArik JuniarAinda não há avaliações

- Beams On Elastic FoundationDocumento11 páginasBeams On Elastic Foundationسـرى صالح ثجيلAinda não há avaliações

- Concrete Mix Design ExampleDocumento4 páginasConcrete Mix Design ExampleTheke MarkAinda não há avaliações

- Working of CapacitorDocumento5 páginasWorking of CapacitoradimeghaAinda não há avaliações

- Chapter 3 Dmt234Documento75 páginasChapter 3 Dmt234AmriAinda não há avaliações

- Deflectio N of Beams:: Geometri C MethodsDocumento20 páginasDeflectio N of Beams:: Geometri C MethodsKing Cedric100% (1)

- Transformer: Component CoreDocumento4 páginasTransformer: Component CoreSameer SabirAinda não há avaliações

- Ac Three-Phase SystemDocumento12 páginasAc Three-Phase Systemdeskaug1Ainda não há avaliações

- Tensile TestDocumento15 páginasTensile TestLilac ClassAinda não há avaliações

- Concurrent Forces Vs Non-Concurrent ForcesDocumento15 páginasConcurrent Forces Vs Non-Concurrent ForcesInocent FarrukhAinda não há avaliações

- Composite WallDocumento6 páginasComposite WallRushabh PatelAinda não há avaliações

- Static Electricity and Charge Conservation of Charge PDFDocumento9 páginasStatic Electricity and Charge Conservation of Charge PDFDavid I. Chamorro AriasAinda não há avaliações

- Static and Kinetic FrictionDocumento7 páginasStatic and Kinetic FrictionvmscottiAinda não há avaliações

- Experiment No.5Documento6 páginasExperiment No.5Abdul RehmanAinda não há avaliações

- JPD - 2M Vibrations NotesDocumento46 páginasJPD - 2M Vibrations NotesHillel BadermanAinda não há avaliações

- Creep and FatigueDocumento20 páginasCreep and Fatiguecheveresan123100% (2)

- The Qur'an and Water, Properties of Water-Water Cycle and Other IssuesDocumento66 páginasThe Qur'an and Water, Properties of Water-Water Cycle and Other Issuesনাহিদ মাহমুদAinda não há avaliações

- Dasgupta - Variation of Surface Tension With TemperatureDocumento3 páginasDasgupta - Variation of Surface Tension With Temperaturewbechara103Ainda não há avaliações

- Validation of Bernoulli's Equation in a Convergent-Divergent DuctDocumento4 páginasValidation of Bernoulli's Equation in a Convergent-Divergent DuctGabriel VaughnAinda não há avaliações

- Dynamics Tutorial 11-Damped Vibrations-13p PDFDocumento13 páginasDynamics Tutorial 11-Damped Vibrations-13p PDFmanfredm6435100% (1)

- Lab ReportDocumento3 páginasLab Reportdeanellis100% (1)

- Conservation of EnergyDocumento7 páginasConservation of EnergyJohn Nathaniel GutierrezAinda não há avaliações

- EBB 220/3 Model For Visco-ElasticityDocumento25 páginasEBB 220/3 Model For Visco-ElasticityBen MiSawoAinda não há avaliações

- Viscoelastic Nature in Polymers: Understanding Time-Temperature SuperpositionDocumento28 páginasViscoelastic Nature in Polymers: Understanding Time-Temperature SuperpositionaliAinda não há avaliações

- Lecture 4 - ViscoelasticDocumento50 páginasLecture 4 - ViscoelasticHani Syakira NordinAinda não há avaliações

- SILIKO - Technical Products Made of ElastomersDocumento3 páginasSILIKO - Technical Products Made of ElastomersopabalekeAinda não há avaliações

- Pages From Engineering Maths - John BirdDocumento12 páginasPages From Engineering Maths - John BirdopabalekeAinda não há avaliações

- Pages From Engineering Maths - John BirdDocumento12 páginasPages From Engineering Maths - John BirdopabalekeAinda não há avaliações

- Geometry Notes 1 PDFDocumento54 páginasGeometry Notes 1 PDFsai ramakrishAinda não há avaliações

- Base Dataroaming enDocumento1 páginaBase Dataroaming enopabalekeAinda não há avaliações

- Cit 726 Computers in Society-2016Documento1 páginaCit 726 Computers in Society-2016opabalekeAinda não há avaliações

- MIS Management: An IntroductionDocumento99 páginasMIS Management: An IntroductionopabalekeAinda não há avaliações

- MONEY MattersDocumento11 páginasMONEY MattersopabalekeAinda não há avaliações

- Engr. G. C. Abaleke (Course Examiner)Documento1 páginaEngr. G. C. Abaleke (Course Examiner)opabalekeAinda não há avaliações

- Ralph Woodrow Babylon, Mystery Religion - Ancient and Modern 1981Documento177 páginasRalph Woodrow Babylon, Mystery Religion - Ancient and Modern 1981opabaleke100% (1)

- Edu 716 Sociology of Education-2014Documento1 páginaEdu 716 Sociology of Education-2014opabalekeAinda não há avaliações

- In A Metal Accounts For Its Electrical Conductivity, Luster, Malleability, and Ductility". (10 Marks)Documento1 páginaIn A Metal Accounts For Its Electrical Conductivity, Luster, Malleability, and Ductility". (10 Marks)opabalekeAinda não há avaliações

- National Open University of Nigeria: "Registerable" CoursesDocumento4 páginasNational Open University of Nigeria: "Registerable" CoursesopabalekeAinda não há avaliações

- Edu 711 Foundations of Education-2016Documento2 páginasEdu 711 Foundations of Education-2016opabalekeAinda não há avaliações

- Edu 716 Sociology of Education-2016Documento1 páginaEdu 716 Sociology of Education-2016opabalekeAinda não há avaliações

- Developing LeadershipDocumento3 páginasDeveloping LeadershipMohan ShanmugamAinda não há avaliações

- M.ed. Style Guide 2011Documento33 páginasM.ed. Style Guide 2011opabalekeAinda não há avaliações

- INTERFACIAL RHEOLOGYpdfDocumento0 páginaINTERFACIAL RHEOLOGYpdfopabalekeAinda não há avaliações

- Living AbroadDocumento6 páginasLiving AbroadopabalekeAinda não há avaliações

- Masoud Hassan 201212 PHD PDFDocumento146 páginasMasoud Hassan 201212 PHD PDFopabalekeAinda não há avaliações

- Journal of Applied Polymer Science Volume 16 Issue 2 1972 (Doi 10.1002/app.1972.070160213) B. Hlaváček F. A. Seyer - Determination of Parameters in Convected Maxwell Model From Linear ViscoeDocumento17 páginasJournal of Applied Polymer Science Volume 16 Issue 2 1972 (Doi 10.1002/app.1972.070160213) B. Hlaváček F. A. Seyer - Determination of Parameters in Convected Maxwell Model From Linear ViscoeopabalekeAinda não há avaliações

- The Synthesis EssayDocumento17 páginasThe Synthesis EssayAlbert ChonAinda não há avaliações

- Portrait Power Spectra LyapunovDocumento121 páginasPortrait Power Spectra LyapunovopabalekeAinda não há avaliações

- M.ed. Style Guide 2011Documento33 páginasM.ed. Style Guide 2011opabalekeAinda não há avaliações

- Lorenz EquationsDocumento11 páginasLorenz EquationsopabalekeAinda não há avaliações

- Nanoindentation in Materials ScienceDocumento320 páginasNanoindentation in Materials ScienceopabalekeAinda não há avaliações

- Engineering DrawingDocumento240 páginasEngineering DrawingKhelly Shan C. Sta. RitaAinda não há avaliações

- Engineering DrawingDocumento30 páginasEngineering DrawingDeepak MmechAinda não há avaliações

- WWW - Commonsensemedia - OrgDocumento3 páginasWWW - Commonsensemedia - Orgkbeik001Ainda não há avaliações

- Audi Q5: First Generation (Typ 8R 2008-2017)Documento19 páginasAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- HP HP3-X11 Exam: A Composite Solution With Just One ClickDocumento17 páginasHP HP3-X11 Exam: A Composite Solution With Just One ClicksunnyAinda não há avaliações

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Documento18 páginasCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamAinda não há avaliações

- Philippine Army BDU BidDocumento2 páginasPhilippine Army BDU BidMaria TeresaAinda não há avaliações

- Computer Networks Transmission Media: Dr. Mohammad AdlyDocumento14 páginasComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Ainda não há avaliações

- An Introduction To Ecology and The BiosphereDocumento54 páginasAn Introduction To Ecology and The BiosphereAndrei VerdeanuAinda não há avaliações

- Alternate Tuning Guide: Bill SetharesDocumento96 páginasAlternate Tuning Guide: Bill SetharesPedro de CarvalhoAinda não há avaliações

- Oxygen Cost and Energy Expenditure of RunningDocumento7 páginasOxygen Cost and Energy Expenditure of Runningnb22714Ainda não há avaliações

- CENG 5503 Intro to Steel & Timber StructuresDocumento37 páginasCENG 5503 Intro to Steel & Timber StructuresBern Moses DuachAinda não há avaliações

- Weone ProfileDocumento10 páginasWeone ProfileOmair FarooqAinda não há avaliações

- Revision Worksheet - Matrices and DeterminantsDocumento2 páginasRevision Worksheet - Matrices and DeterminantsAryaAinda não há avaliações

- A Princess of Mars Part 3Documento4 páginasA Princess of Mars Part 3Sheila Inca100% (1)

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocumento564 páginasPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuAinda não há avaliações

- Case Study IndieDocumento6 páginasCase Study IndieDaniel YohannesAinda não há avaliações

- Mobile ApplicationDocumento2 páginasMobile Applicationdarebusi1Ainda não há avaliações

- 202112fuji ViDocumento2 páginas202112fuji ViAnh CaoAinda não há avaliações

- Pfr140 User ManualDocumento4 páginasPfr140 User ManualOanh NguyenAinda não há avaliações

- Manual WinMASW EngDocumento357 páginasManual WinMASW EngRolanditto QuuisppeAinda não há avaliações

- Astm D7928 - 17Documento25 páginasAstm D7928 - 17shosha100% (2)

- Baobab MenuDocumento4 páginasBaobab Menuperseverence mahlamvanaAinda não há avaliações

- 7 Aleksandar VladimirovDocumento6 páginas7 Aleksandar VladimirovDante FilhoAinda não há avaliações

- Evaluative Research DesignDocumento17 páginasEvaluative Research DesignMary Grace BroquezaAinda não há avaliações

- Dance Appreciation and CompositionDocumento1 páginaDance Appreciation and CompositionFretz Ael100% (1)

- SOP-for RecallDocumento3 páginasSOP-for RecallNilove PervezAinda não há avaliações

- Learning Activity Sheet: 3 Quarter Week 1 Mathematics 2Documento8 páginasLearning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dom MartinezAinda não há avaliações

- TJUSAMO 2013-2014 Modular ArithmeticDocumento4 páginasTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonAinda não há avaliações

- Cot 2Documento3 páginasCot 2Kathjoy ParochaAinda não há avaliações

- Methods to estimate stakeholder views of sustainabilityDocumento7 páginasMethods to estimate stakeholder views of sustainabilityAlireza FatemiAinda não há avaliações

- Ovr IbDocumento27 páginasOvr IbAriel CaresAinda não há avaliações