Escolar Documentos

Profissional Documentos

Cultura Documentos

Bulk Deformation Processes-Forging

Enviado por

Izi0 notas0% acharam este documento útil (0 voto)

2K visualizações14 páginasThis document discusses various bulk deformation processes used in forging, including coining, upsetting, heading, swaging, radial forging, and roll forging. It also describes common forging machines like drop hammers and presses. Key terminology for impression die forging is explained, such as parting line, draft, webs/ribs, fillets/corners, and flash/trimming. Forging is used to shape and strengthen metal parts through compressive deformation in dies or between rolls.

Descrição original:

Bulk Deformation Processes-Forging

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document discusses various bulk deformation processes used in forging, including coining, upsetting, heading, swaging, radial forging, and roll forging. It also describes common forging machines like drop hammers and presses. Key terminology for impression die forging is explained, such as parting line, draft, webs/ribs, fillets/corners, and flash/trimming. Forging is used to shape and strengthen metal parts through compressive deformation in dies or between rolls.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

2K visualizações14 páginasBulk Deformation Processes-Forging

Enviado por

IziThis document discusses various bulk deformation processes used in forging, including coining, upsetting, heading, swaging, radial forging, and roll forging. It also describes common forging machines like drop hammers and presses. Key terminology for impression die forging is explained, such as parting line, draft, webs/ribs, fillets/corners, and flash/trimming. Forging is used to shape and strengthen metal parts through compressive deformation in dies or between rolls.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 14

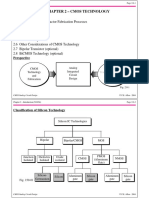

LECTURE-08

BULK DEFORMATION PROCESSES

-FORGING

Nikhil R. Dhar, Ph.D

Department of Industrial & Production Engineering

BUET

Forging Operations

Coining is a special application of flashless forging in which fine details in the die

are impressed into the top and bottom surfaces of the workpart.

Closed-die forging process

Used for minting coins, medallions, & jewelry

Lubricants can not be used in coining

Can be used to improve surface finish

Lecture-3: Forging 14/2

Upsetting: Upsetting is a deformation operation in which a cylindrical workpart is

increased in diameter and reduced in length. However, as an industrial operation, it

can also be performed as closed-die forging, as shown in the following Figure.

Upsetting is widely used in the fastener industry to form the heads of nails, bolts,

and similar hardware products.

Lecture-3: Forging 14/3

Heading: The following Figure illustrates a variety of heading applications,

indicating various possible die configurations. Owing to these types of applications,

more parts are produced by upsetting than any other forging operation. It is

performed as a mass production operation - cold, warm, or hot - on special upset

forging machines, called headers or formers.

Care must be taken so that work piece does not buckle

Can be highly automated

Lecture-3: Forging 14/4

Swaging and Radial Forging: Swaging and radial forging are forging processes

used to educe the diameter of a tube or solid rod. Swaging is often performed on the

end of a workpiece to create a tapered section. The swaging process shown is

accomplished by means of rotating dies that hammer a workpiece radially inward to

taper it as the workpiece is fed into the dies. Radial forging is similar to swaging

in its action against the work and is used to create similar shapes. The difference is

that in radial forging the dies do not rotate around the workpiece; instead , the work

is rotated at it feeds into the hammering dies.

Lecture-3: Forging 14/5

Roll Forging: Roll forging is a deformation process used to reduce the cross

section of a cylindrical (or rectangular) workpiece by passing it through a set of

opposing rolls that have grooves matching the desired shape of the part. The typical

operation is shown in the following Figure. Roll forging is generally classified as a

forging process, even though it utilizes rolls. The rolls do not turn continuously in

roll forging, but rotate through only a portion of one revolution corresponding to the

desired deformation to be accomplished on the part. Roll-forged parts are generally

stronger and possess favorable grain structure compared to competing processes,

such as machining, that might be used to produce the same part geometry.

Lecture-3: Forging 14/6

Forging Machines

Equipment used in forging consists of forging machines, classified as forging

hammers and presses, and forging dies, which are the special tooling used in

these machines. In addition, auxiliary equipment is needed, such as furnaces to

heat the work, mechanical devices to load and unload the work, and trimming

stations to cut away the flash in impression-die forging.

Forging Hammers: Forging hammers operate by applying an impact load against

the work. The term drop hammer is often used for these machines, owing to the

means of delivering impact energy. Drop hammers are most frequently used or

impression-die forging. The upper portion of the forging die is attached to the ram,

and the lower portion to the anvil. In the operation, the work is placed on the lower

die, and the ram is lifted and then dropped. When the upper die strikes the work,

the impact energy causes the part to assume the form of the die cavity.

Lecture-3: Forging 14/7

Drop hammers can be classified as gravity

drop hammers and power drop

hammers.

Gravity drop hammers achieve their

energy by the falling weight of a heavy ram.

The force of the blow is determined by the

height of the drop and the weight of the

ram.

Power drop hammers accelerate the

ram by pressurized air or steam. One

disadvantage of the drop hammers is that a

large amount of the impact energy is

transmitted through the anvil and into the

floor of the building. This results in a great

deal of vibration for the surrounding area.

Lecture-3: Forging 14/8

Forging Presses: Presses apply gradual

pressure, rather than sudden impact, to

accomplish the forging operation. Forging

presses include mechanical presses,

hydraulic presses, and screw presses.

Mechanical presses typically operate by

means of eccentrics, cranks, or knuckle joints,

which convert the rotating motion of a drive

motor into the translational motion of the

ram. These mechanisms are very similar to

Mechanical Press

those used in stamping presses. Mechanical

presses typically achieve very high forces at Hydraulic Press

the bottom of the forging stroke.

Hydraulic presses use a hydraulically

driven piston to actuate the ram.

Screw presses apply force by a screw

mechanism that drives the vertical ram. Both

screw drive and hydraulic drive operate at

relatively low ram speeds and can provide a

constant force throughout the stroke. These

machines are therefore suitable for forging

(and other forming) operations that require a

long stroke.

Screw Press

Lecture-3: Forging 14/9

Terminology of Impression Die Forging

Proper die design is important in the success of a forging operation. Parts to be forged

must be designed based on knowledge of the principles and limitations of this process.

The purpose of the next slides is to describe some of the terminology and guidelines

used in the design of forgings and forging dies. Design of open dies is generally

straightforward since the dies are relatively simple in shape. The following details apply

to impression dies and closed dies. The following Figure shows some of the terminology

in an impression die.

Lecture-3: Forging 14/10

Parting line: The parting line is the plane that divides the upper die from the lower die.

Called the flash line in impression-die forging, it is the plane where the two die halves meet. Its

selection by the designer affects grain flow in the part, required load, and flash formation.

Draft: Draft is the amount of taper on the sides of the part required to remove it from the die.

The term also applies to the taper on the sides of the die cavity. Typical drat angles are 3o on

aluminum and magnesium parts and 5o to 7o on steel parts. Draft angles on precision forgings

are near zero.

Webs and ribs: A web is a thin portion of the forging that is parallel to the parting line, while

a rib is a thin portion that is perpendicular to the parting line. These part features cause

difficulty in metal low as they become thinner.

Lecture-3: Forging 14/11

Fillet and corner radii: Fillet and corner radii are shown in the diagram. Small

radii tend to limit metal flow and increase stresses on the die surfaces during

forging.

Flash: Flash formation plays a critical role in impression-die forging by causing

pressure buildup inside the die to promote filling of the cavity. This pressure

buildup is controlled by designing a flash land and gutter into the die as shown. The

land determines the surface area along which lateral flow of metal occurs, thereby

controlling the pressure increase inside the die. The gutter permits excess material

to escape without causing the forging load to reach extreme values

Lecture-3: Forging 14/12

Trimming

Trimming is an operation used to remove flash on the workpart in impression-die

forging. In most cases, trimming is accomplished by shearing, as shown in the next

slide, in which a punch forces the work through a cutting die, the blades for which

have the profile of the desired part.

Trimming is usually done while the work is still hot, which means the that a separate

trimming press is included at each forging hammer or press. In cases where the

work might be damaged by the cutting process, trimming may be done by

alternative methods, such as grinding or sawing.

Trimming operation

(shearing process) to

remove the flash after

impression die forging

Lecture-3: Forging 14/13

Lecture-3: Forging 14/14

Você também pode gostar

- Die CastingDocumento48 páginasDie CastingramuthukumarAinda não há avaliações

- Introduction To Forging ProcessDocumento8 páginasIntroduction To Forging ProcessSirat kalsiiAinda não há avaliações

- Orbital ForgingDocumento4 páginasOrbital ForgingMrLanternAinda não há avaliações

- Flowforming or Metal Spinning (Spin Forming)Documento2 páginasFlowforming or Metal Spinning (Spin Forming)ShivajiAinda não há avaliações

- Roll ForgingDocumento6 páginasRoll ForgingSaptarshi SinhaAinda não há avaliações

- Deep Drawing Literature ReviewDocumento37 páginasDeep Drawing Literature ReviewS T100% (3)

- A Survey of Metal Forming Process TechnologyDocumento30 páginasA Survey of Metal Forming Process Technologyharikg21Ainda não há avaliações

- Product Design Guide For ForgingDocumento31 páginasProduct Design Guide For ForgingVikram Borkhediya100% (1)

- Upset Forging Die DesignDocumento4 páginasUpset Forging Die DesignChinmay Das50% (2)

- Basic Concepts of Sequence Design For Cold Forging Parts.Documento3 páginasBasic Concepts of Sequence Design For Cold Forging Parts.david2404Ainda não há avaliações

- TB Grinding EnglishDocumento20 páginasTB Grinding EnglishVk PrabakranAinda não há avaliações

- Gating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesDocumento10 páginasGating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesKhin Aung ShweAinda não há avaliações

- Deep Drawing - ProjectDocumento112 páginasDeep Drawing - ProjectideepujAinda não há avaliações

- Eyelet DrawingDocumento49 páginasEyelet DrawingPra Vee33% (3)

- Unit I - Theory of Metal CuttingDocumento111 páginasUnit I - Theory of Metal CuttingSaravana KumarAinda não há avaliações

- Pr2302 Metal Forming TechnologyDocumento1 páginaPr2302 Metal Forming TechnologyarunsunderAinda não há avaliações

- Hot Forge UpsetDocumento13 páginasHot Forge UpsetAnonymous QiMB2lBCJLAinda não há avaliações

- Force Power in Metal CuttingDocumento7 páginasForce Power in Metal CuttingRavinder AntilAinda não há avaliações

- A Complete HandBook For Metal Die CastingDocumento37 páginasA Complete HandBook For Metal Die CastingSuhas KrishnaAinda não há avaliações

- Deep Drawing Process PDFDocumento34 páginasDeep Drawing Process PDFCADCAM CAEAinda não há avaliações

- Dry MachiningDocumento13 páginasDry Machiningbanteshyam100% (3)

- Forging ApplicationsDocumento24 páginasForging ApplicationsdstifterAinda não há avaliações

- 3475331Documento41 páginas3475331Nguyen Trong TanAinda não há avaliações

- SolidWorks 2017 Black Book: SolidWorks Black BookNo EverandSolidWorks 2017 Black Book: SolidWorks Black BookNota: 3.5 de 5 estrelas3.5/5 (3)

- Modern Blanking and Piercing DiesDocumento58 páginasModern Blanking and Piercing DiesMustafa Sert100% (4)

- Casting Processes: DR Ajay BatishDocumento46 páginasCasting Processes: DR Ajay BatishAlisha GuptaAinda não há avaliações

- CH 2 Metal Cutting ToolsDocumento19 páginasCH 2 Metal Cutting ToolsAlex AdmasAinda não há avaliações

- U BendingDocumento31 páginasU BendingbabutyAinda não há avaliações

- ForgingDocumento13 páginasForgingstallone21Ainda não há avaliações

- FormingDocumento381 páginasFormingArjun RoyAinda não há avaliações

- Squeeze CastingDocumento38 páginasSqueeze Castingjishnus100% (1)

- Interview QuestionDocumento22 páginasInterview QuestionsugeshAinda não há avaliações

- Tool Engineering and Design Design of SiDocumento23 páginasTool Engineering and Design Design of Simulugeta assefaAinda não há avaliações

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaDocumento4 páginasConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476Ainda não há avaliações

- ForgingDocumento38 páginasForgingapi-26546070100% (2)

- Surface GrindingDocumento18 páginasSurface GrindingSachin MohandasAinda não há avaliações

- Steel Characteristics and Their Link To Chip Breaking and Tool Wear in Metal CuttingDocumento86 páginasSteel Characteristics and Their Link To Chip Breaking and Tool Wear in Metal CuttingOtoniel Reyes Galay100% (1)

- Die Casting ProcessDocumento35 páginasDie Casting ProcessgarciarodrigoAinda não há avaliações

- Appendix A - Tolerances For Impression DieDocumento21 páginasAppendix A - Tolerances For Impression Diekkozak99Ainda não há avaliações

- Types of Forging ProcessesDocumento9 páginasTypes of Forging ProcessesAryan Singh100% (1)

- Progressive Tool Design and Analysis For 49 Lever 5 Stage ToolsDocumento10 páginasProgressive Tool Design and Analysis For 49 Lever 5 Stage ToolsseventhsensegroupAinda não há avaliações

- Forging Rolling DefectsDocumento14 páginasForging Rolling DefectsRavichandran GAinda não há avaliações

- MES Die Castings Design and Specification Guide: Delivery Engineered SolutionsDocumento12 páginasMES Die Castings Design and Specification Guide: Delivery Engineered SolutionsRafał Lesiczka100% (1)

- ForgingDocumento44 páginasForgingMagari Frimsa GintingAinda não há avaliações

- Sheet Metal WorkingDocumento23 páginasSheet Metal WorkingSujit MishraAinda não há avaliações

- Squeeze Casting - An Overview PDFDocumento9 páginasSqueeze Casting - An Overview PDFDian Try SaputriAinda não há avaliações

- Computerized Manufacturing Planning Systems (Computerized Production)Documento15 páginasComputerized Manufacturing Planning Systems (Computerized Production)Aravind IlangoAinda não há avaliações

- Mold & Die DesignDocumento64 páginasMold & Die Designmsa_adonAinda não há avaliações

- Experiment N04-Cup DrawDocumento5 páginasExperiment N04-Cup DrawRandhir KyAinda não há avaliações

- Lec 6 Extrusion Metal WorkingDocumento29 páginasLec 6 Extrusion Metal WorkingSidra SaeedAinda não há avaliações

- Cold and Hot Stamping Dies eDocumento12 páginasCold and Hot Stamping Dies eajaygupta.af3919Ainda não há avaliações

- Mould BaseDocumento8 páginasMould BaseMould Base ManufacturerAinda não há avaliações

- Fundamentals of Metal FormingDocumento9 páginasFundamentals of Metal FormingGeorge CamachoAinda não há avaliações

- Ch21 Fundamentals of Cutting2Documento70 páginasCh21 Fundamentals of Cutting2manojc68Ainda não há avaliações

- Mechanical Working of Metals: Theory and PracticeNo EverandMechanical Working of Metals: Theory and PracticeNota: 5 de 5 estrelas5/5 (2)

- openLCA 1.10.2 User-ManualDocumento127 páginasopenLCA 1.10.2 User-ManualIziAinda não há avaliações

- Usb 1616hs BNCDocumento49 páginasUsb 1616hs BNCIziAinda não há avaliações

- 1442 IDocumento6 páginas1442 IIziAinda não há avaliações

- Diesel Fuel InjectionDocumento5 páginasDiesel Fuel InjectionIziAinda não há avaliações

- Definition of Family Member by Homeaffairs: Form 1496iDocumento2 páginasDefinition of Family Member by Homeaffairs: Form 1496iIziAinda não há avaliações

- Sinus SamuraiDocumento5 páginasSinus SamuraiIziAinda não há avaliações

- FtirDocumento21 páginasFtirGaurav AcharyaAinda não há avaliações

- AlzheimerDocumento1 páginaAlzheimerIziAinda não há avaliações

- Heat Flux Thermocouple MCTDocumento2 páginasHeat Flux Thermocouple MCTIziAinda não há avaliações

- Hybrid Electric VehicleDocumento33 páginasHybrid Electric VehicleIzi75% (4)

- Steps in Hypothesis TestingDocumento4 páginasSteps in Hypothesis TestingIzi100% (1)

- How Torque Converters WorkDocumento13 páginasHow Torque Converters WorkIziAinda não há avaliações

- Unit 7Documento39 páginasUnit 7vijay_oraerp1711Ainda não há avaliações

- Duct DesignDocumento9 páginasDuct DesignjaswanthAinda não há avaliações

- How Clutches WorkDocumento14 páginasHow Clutches WorkIziAinda não há avaliações

- DOP Test ProtocolDocumento10 páginasDOP Test ProtocolIzi100% (2)

- Study of Different Types of Pipe FittingsDocumento17 páginasStudy of Different Types of Pipe FittingsIzi50% (2)

- One - and Two-Tailed TestsDocumento3 páginasOne - and Two-Tailed TestsIzi100% (1)

- Chi Square DistributionDocumento4 páginasChi Square DistributionIziAinda não há avaliações

- TEMA Standard PDFDocumento302 páginasTEMA Standard PDFlubangjarumAinda não há avaliações

- 05Documento17 páginas05Andreas StathatosAinda não há avaliações

- Yr 10 Chem Summer NoteDocumento22 páginasYr 10 Chem Summer NoteTokoni DanielAinda não há avaliações

- Kobelco FillerDocumento24 páginasKobelco FillerRamzi Dol Abdul WahidAinda não há avaliações

- 8295780Documento34 páginas8295780Tong BbmAinda não há avaliações

- Alkylation Complex Start Up Plan: ObjectivesDocumento10 páginasAlkylation Complex Start Up Plan: ObjectivesBikas SahaAinda não há avaliações

- Abb Furse Catalogue UkDocumento336 páginasAbb Furse Catalogue UkBenjamin Ricardo Nasrallah Alvarez100% (2)

- Ms Ramya Swetha Paper For OUDocumento7 páginasMs Ramya Swetha Paper For OUvempadareddyAinda não há avaliações

- Nationtech Communications Ltd. (Rate of Civil Works)Documento9 páginasNationtech Communications Ltd. (Rate of Civil Works)helalAinda não há avaliações

- Replacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryDocumento2 páginasReplacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryKauser ImamAinda não há avaliações

- Fluid & LubricantsDocumento145 páginasFluid & LubricantsshashirajAinda não há avaliações

- 1-Method Statement-Installation and Handling of CablesDocumento27 páginas1-Method Statement-Installation and Handling of CablesKamila WehbeAinda não há avaliações

- Capsules VDocumento36 páginasCapsules VrandatagAinda não há avaliações

- 자재Documento7 páginas자재최경현Ainda não há avaliações

- ZF-Ecomat and Ecomat 2Documento38 páginasZF-Ecomat and Ecomat 2duongpndng80% (5)

- Torrefaction For Biomass Upgrading Into Commodity Fuels: Jaap KielDocumento12 páginasTorrefaction For Biomass Upgrading Into Commodity Fuels: Jaap KielMd Khalid SiddiquiAinda não há avaliações

- Chapter 1 Part 1Documento80 páginasChapter 1 Part 1anil kumarAinda não há avaliações

- A325n X SCDocumento1 páginaA325n X SCAnonymous ARMtmNKLAinda não há avaliações

- Hvof Coating On Turbine RunnersDocumento23 páginasHvof Coating On Turbine RunnersAliyana ShresthaAinda não há avaliações

- Groth 7618 7628Documento16 páginasGroth 7618 7628Julian GaleanoAinda não há avaliações

- JSA-009a Drilling and Mon Well Construction-SonicDocumento4 páginasJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi86% (7)

- SONY Radio ICF-SW1 Disassembly - RepairDocumento9 páginasSONY Radio ICF-SW1 Disassembly - RepairMicheal speedAinda não há avaliações

- MH1.3 Jul01 V8Documento1 páginaMH1.3 Jul01 V8Katracho2Ainda não há avaliações

- Wiper BladeDocumento3 páginasWiper Bladeghyd artiagaAinda não há avaliações

- Tangguh Condensate - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DataDocumento5 páginasTangguh Condensate - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DatarudiandriesAinda não há avaliações

- Top Drive Brochure PDFDocumento6 páginasTop Drive Brochure PDFaldino020203100% (1)

- BS2L99 Alloy DetailDocumento2 páginasBS2L99 Alloy Detailcharles_boyle_3Ainda não há avaliações

- HendrixACS - 4. Restoration GuideDocumento14 páginasHendrixACS - 4. Restoration GuideMarilyn ChimarroAinda não há avaliações

- LG wd-1457rd 1458rdDocumento42 páginasLG wd-1457rd 1458rdGlen CastlemanAinda não há avaliações