Escolar Documentos

Profissional Documentos

Cultura Documentos

Mlti Stage Flash Distillation

Enviado por

Nitisha RathoreDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mlti Stage Flash Distillation

Enviado por

Nitisha RathoreDireitos autorais:

Formatos disponíveis

MULTI STAGE FLASH DISTILLATION

INTRODUCTION

Desalination Processes

Several

technologies for desalination of seawater have been developed over time and can be classified as either Distillation or membrane processes. These technologies include Multistage Flash (MSF), Multiple Effect (MED), Vapor Compression (VC), Reverse Osmosis (RO), Hybrid System (MSF/MED + RO).

DISTILLATION

Method of separating mixtures based on differences in volatility of components in a boiling liquid mixture. Phase separation method whereby saline water is heated to produce water vapor, which is then condensed to produce freshwater. Various distillation process

Multi Stage Flash Distillation(MSF) Multiple Effect Distillation (MED) Vapor Compression (VC)

FLASH DISTILLATION

Process in which the liquid is preheated and is then subjected to a pressure below its vapor pressure causing boiling or flashing to occur. Sea water first heated in tubes and then put in a chamber with a vapor pressure lower than in the heating tubes and the liquid evaporates. The vapors flash off the warm liquid and the salts exit with the remaining water. Process is inefficient.

EVAPORATORS

Thermal evaporation is the principal mechanism in generating fresh water vapor from seawater. Evaporation process is based on creating a hot surface using heating steam; the heating steam condenses on one side and vapor is formed on the other. Evaporators include Submerged tube Falling lms and Plates

SUBMERGED TUBE EVAPORATOR

Heating steam condenses on the wall of the tube in the rst effect, and releases its latent heat to a thin layer of liquid surrounding the outside surfaces of the tubes. This results in the formation and release of vapor bubbles, which rise through the liquid and are released into the vapor space. Formed vapor is routed to the second effect, where it condenses on the wall of the tube and results in the formation of a smaller quantity of vapor. Vapor released in second effect can be either routed to another effect, or condensed against the feed seawater.

FALLING FILM EVAPORATOR

Two arrangements for the falling lm system

Horizontal tubes Vertical tubes

HORIZONTAL TUBE FALLING FILM EVAPORATOR

VERTICAL TUBE FALLING FILM EVAPORATOR

PLATE EVAPORATORS

MULTI STAGE FLASH DISTILLATION

Preheated liquid passes through a series of stages or chambers with each successive stage at a lower vapor pressure so some of the liquid will flash at each stage. MSF has

Capacities ranging from 4000 to 30000 m3/day Operating temperature 90 to 120 oC 4 to 40 stages- each successive stages operating at lower temperature and pressure

MSF accounts for approximately 85% of commercial desalination worldwide

PRINCIPLE OF MSF

Consists of two chambers Preheat

chamber Flash chamber

Salt water enters a bundle of tubes located in the vapor space of the preheat chamber. Water then flows into heater consisting of a bundle of tubes which heated externally by steam. Water is heated to 100 degrees C, but it does not boil because the pressure is above 1 atm

PRINCIPLE OF MSF (contd.)

Hot sea water then enters a flash chamber kept under reduced pressure. Vapors flashed off are then condensed on tubes carrying the incoming flow of cold sea water. Condensing the water by heat exchange with the incoming flow in one of the economical advantages of this process. Distillate and remaining salt water are restored to atmospheric pressure by pumps.

MULTIPLE EFFECT DISTILLATION

Consist of multiple stages or effects. In each stage the feed water is heated by steam in tubes. Some of the water evaporates, and this steam flows into the tubes of the next stage, heating and evaporating more water. Each stage essentially reuses the energy from the previous stage.

MULTIPLE EFFECT DISTILLATION(contd.)

Tubes can be submerged in the feed water, but more typically the feed water is sprayed on the top of a bank of horizontal tubes, and then drips from tube to tube until it is collected at the bottom of the stage.

ADVANTAGES OF MED

Low energy consumption (less than 1.0 kWh/m3) compared to other thermal processes Operates at low temperature (< 70 C) and at low concentration (< 1.5) to avoid corrosion and scaling Does not need pre-treatment of sea water and tolerates variations in sea water conditions Highly reliable and simple to operate Low maintenance cost 24 hour a day continuous operation with minimum supervision Can be adapted to any heat source, including hot water, waste heat from power generation, industrial processes, or solar heating.

VAPOUR COMPRESSION

Distillation process where evaporation of sea or saline water is obtained by the application of heat delivered by compressed vapor. Compression of the vapor increases both the pressure and temperature of the vapor, it is possible to use the latent heat rejected during condensation to generate additional vapor.

VAPOUR COMPRESSION (contd.)

Effect of compressing water vapor can be done by two methods

Ejector

system- Ejecto or Thermo Compression. Mechanical system- mechanical vapor compression (MVC)

Vapor Compression (VC)- evaporation effect takes place at manometric pressure Vacuum Vapor Compression (VVC)-evaporation takes place at sub-atmospheric pressures (under vacuum).

VAPOUR COMPRESSION (contd.)

Compression is mechanically powered by a compression turbine. Vapor generated, is passed over to a heat exchanging condenser which returns the vapor to water. Resulting fresh water is moved to storage while the heat removed during condensation is transmitted to the remaining feedstock.

ADVANTAGES OF VC

VVC process is the more efficient distillation process in terms of energy consumption and water recovery ratio. As the system is electrically driven, it is considered a "clean" process. It is highly reliable and simple to operate and maintain.

Você também pode gostar

- Fluid Mechanics 2 Experiment 1: Aerofoil Test in Wind Tunnel at Different Angles of Attack.Documento8 páginasFluid Mechanics 2 Experiment 1: Aerofoil Test in Wind Tunnel at Different Angles of Attack.Hanif MuqsitAinda não há avaliações

- DOW Water and Process Solutions: Calculation of A Demineralisation Plant With Rohm and Haas Ion Exchange ResinsDocumento2 páginasDOW Water and Process Solutions: Calculation of A Demineralisation Plant With Rohm and Haas Ion Exchange Resinsak_thimiriAinda não há avaliações

- SRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDDocumento2 páginasSRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDpetros222Ainda não há avaliações

- Fluid Statics PDFDocumento28 páginasFluid Statics PDFAnthony Leire MontealtoAinda não há avaliações

- Fluid Mechanics: Venturi MeterDocumento46 páginasFluid Mechanics: Venturi MeterJeline LunaAinda não há avaliações

- PRV Sizing For Exchanger Tube RuptureDocumento5 páginasPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- TC & GT Engineering Lateral Critical Speed MapDocumento15 páginasTC & GT Engineering Lateral Critical Speed Mapsoumya19800000000Ainda não há avaliações

- Desalination Plant of TobrukDocumento21 páginasDesalination Plant of TobrukMotaz ZgogoAinda não há avaliações

- Desalination EngineeringDocumento8 páginasDesalination EngineeringShafayet A SiddiqueAinda não há avaliações

- Advances in Seawater Desalination TechnologiesDocumento23 páginasAdvances in Seawater Desalination TechnologiesFrank FanAinda não há avaliações

- ChE-413-MSF Multi-Stage Flash Desal InationDocumento22 páginasChE-413-MSF Multi-Stage Flash Desal InationDenis TanAinda não há avaliações

- The Analysis of CarbonDioxide in Natural GasDocumento4 páginasThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiAinda não há avaliações

- Continuous Production Electrochlorinator Sea - Water - Based PDFDocumento4 páginasContinuous Production Electrochlorinator Sea - Water - Based PDFdubaisrinivasuluAinda não há avaliações

- Mass Transfer Presentation: Adsorption and Chemisorption Factors (≤40 charsDocumento14 páginasMass Transfer Presentation: Adsorption and Chemisorption Factors (≤40 charsSalim ChohanAinda não há avaliações

- Report On Multi Effect DistillationDocumento6 páginasReport On Multi Effect DistillationMohammadAsifAinda não há avaliações

- DeaeratorDocumento3 páginasDeaeratorpawangwlAinda não há avaliações

- Water Treatment Guide for Palm Oil MillsDocumento46 páginasWater Treatment Guide for Palm Oil Millsmuhammad85100% (1)

- Desalination PART 1Documento25 páginasDesalination PART 1Net_MohammedAinda não há avaliações

- Multi Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingDocumento8 páginasMulti Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingMuhammadEhtishamSiddiquiAinda não há avaliações

- Silica Removal During Lime Softening in Water Treatment Plant-Full PaperDocumento9 páginasSilica Removal During Lime Softening in Water Treatment Plant-Full PaperWaleed EmaraAinda não há avaliações

- Problems Collection-2018Documento19 páginasProblems Collection-2018calvinAinda não há avaliações

- Etp Process - RefineryDocumento3 páginasEtp Process - Refinerysumit gulatiAinda não há avaliações

- Water Softening: Removal of Hardness Hardness Is?..Documento38 páginasWater Softening: Removal of Hardness Hardness Is?..Pradhumna AdhikariAinda não há avaliações

- 2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaDocumento5 páginas2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaRahul TripathiAinda não há avaliações

- Effluent Treatment Plant (ETP) - Process Flow DiagramDocumento4 páginasEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthAinda não há avaliações

- Unit Operation: 2 Chemical EngineeringDocumento3 páginasUnit Operation: 2 Chemical EngineeringMohammad Hosein KhanesazAinda não há avaliações

- Sistem SelcopermDocumento39 páginasSistem SelcopermGROIIM100% (1)

- MF Uf NFDocumento69 páginasMF Uf NFNguyen Huu HieuAinda não há avaliações

- 07 - Lime SofteningDocumento4 páginas07 - Lime SofteningRAJ_1978Ainda não há avaliações

- Basic Cooling Water Management IIDocumento32 páginasBasic Cooling Water Management IIDiaa GobranAinda não há avaliações

- Groundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsDocumento1 páginaGroundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsherikAinda não há avaliações

- Demin PlantDocumento9 páginasDemin PlantBlitz XyrusAinda não há avaliações

- Distillation TypesDocumento34 páginasDistillation TypesJoshua Johnson100% (1)

- 7.0 Chemical Treatment: Association of Water Technologies - Technical ManualDocumento38 páginas7.0 Chemical Treatment: Association of Water Technologies - Technical ManualWaleed Emara100% (1)

- RO REVERSE OSMOSIS: MEMBRANE TECHNOLOGY FOR WATER PURIFICATIONDocumento29 páginasRO REVERSE OSMOSIS: MEMBRANE TECHNOLOGY FOR WATER PURIFICATIONHafsa Iqbal100% (1)

- PPE - Feed Water Treatment SystemDocumento6 páginasPPE - Feed Water Treatment SystemSandeep ChhabraAinda não há avaliações

- Sodium Carbonate Process DetailDocumento10 páginasSodium Carbonate Process DetailZain Ul Abideen100% (1)

- Ion Exchange Removes Heavy Metals from Industrial WastewaterDocumento4 páginasIon Exchange Removes Heavy Metals from Industrial WastewaterGOWTHAM GUPTHAAinda não há avaliações

- Cleaner Production in The Solvay Process General Strategies and Recent DevelopmentsDocumento9 páginasCleaner Production in The Solvay Process General Strategies and Recent DevelopmentsCristina AndreeaAinda não há avaliações

- Phosphoric Acid PDFDocumento24 páginasPhosphoric Acid PDFabderrahimnAinda não há avaliações

- Demineralized Process Water..Documento52 páginasDemineralized Process Water..teweleAinda não há avaliações

- 16 - Residual Chlorine and Chlorine DemandDocumento29 páginas16 - Residual Chlorine and Chlorine DemandHayden Chappelear-RobbinsAinda não há avaliações

- Lect FractionizationDocumento57 páginasLect Fractionizationraja.mtAinda não há avaliações

- Everything about superheatersDocumento6 páginasEverything about superheatersHari HaranAinda não há avaliações

- Basic Mass Balance Calculation Using PythonDocumento9 páginasBasic Mass Balance Calculation Using PythonMuhammad Nanda FariaAinda não há avaliações

- 500 02006Documento24 páginas500 02006zizitro100% (1)

- Lecture 1 - Sulfur and Sulfuric AcidDocumento9 páginasLecture 1 - Sulfur and Sulfuric AcidNayan HalderAinda não há avaliações

- Vacuum Distillation for DesalinationDocumento10 páginasVacuum Distillation for DesalinationMark Anthony HenryAinda não há avaliações

- Evaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enDocumento24 páginasEvaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enhardik033Ainda não há avaliações

- Water Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniDocumento24 páginasWater Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniAbhishek Prakash Srivastava100% (1)

- Evaluating The Performance of Water Treatment PlanDocumento9 páginasEvaluating The Performance of Water Treatment Planghina aldilaAinda não há avaliações

- Water Treatment Chemicals ListDocumento7 páginasWater Treatment Chemicals ListAlvin KimAinda não há avaliações

- Optimizing Water Treatment ProcessDocumento30 páginasOptimizing Water Treatment ProcessEri VirnandoAinda não há avaliações

- Boiler Water TreatmentDocumento22 páginasBoiler Water TreatmentTarun Patel100% (1)

- CA PlantDocumento47 páginasCA PlantHarsh KumarAinda não há avaliações

- Chapter 1 DistillationDocumento73 páginasChapter 1 DistillationNUR HIDAYAHAinda não há avaliações

- Reverse Osmosis System FaridDocumento30 páginasReverse Osmosis System FaridAchFaridWadjdiAinda não há avaliações

- Explosion in SW Tanks PDFDocumento9 páginasExplosion in SW Tanks PDFJaved MohammedAinda não há avaliações

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNo EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentAinda não há avaliações

- Chlorine: International Thermodynamic Tables of the Fluid StateNo EverandChlorine: International Thermodynamic Tables of the Fluid StateAinda não há avaliações

- Fresh Water Generator On Ships 2Documento16 páginasFresh Water Generator On Ships 2Hamilton RamaAinda não há avaliações

- Food ConcentrationDocumento87 páginasFood ConcentrationAPLAshok100% (1)

- Deep 3 ProcessDocumento1 páginaDeep 3 ProcessGeorge ChedraouiAinda não há avaliações

- Nes Module IIIDocumento12 páginasNes Module IIIVenuAinda não há avaliações

- Desalination Technologies, 4th Level, ERE414, 2023, ChapterDocumento49 páginasDesalination Technologies, 4th Level, ERE414, 2023, ChapterMohamed HatemAinda não há avaliações

- 80 Homemade Snacks Recipes For Kids June 12.compressedDocumento92 páginas80 Homemade Snacks Recipes For Kids June 12.compressedNitisha Rathore0% (1)

- Marketsurvey LeadandzincDocumento299 páginasMarketsurvey LeadandzincNitisha RathoreAinda não há avaliações

- WelcomeDocumento40 páginasWelcomeNitisha RathoreAinda não há avaliações

- Baby First Food RecipesDocumento54 páginasBaby First Food RecipesRamkumar A100% (1)

- Utilizing Iron Residues From Zinc Production in The U.S.S.RDocumento5 páginasUtilizing Iron Residues From Zinc Production in The U.S.S.RNitisha RathoreAinda não há avaliações

- NPTEL - List of Available CoursesDocumento31 páginasNPTEL - List of Available CoursesNitisha RathoreAinda não há avaliações

- Chapter 2: Threats To The Marine Environment: Pollution and Physical DamageDocumento15 páginasChapter 2: Threats To The Marine Environment: Pollution and Physical DamageNitisha RathoreAinda não há avaliações

- Maha Lakshmi Ashtakam Devanagari Large PDFDocumento2 páginasMaha Lakshmi Ashtakam Devanagari Large PDFNitisha RathoreAinda não há avaliações

- Importance of PlanktonDocumento35 páginasImportance of PlanktonNitisha RathoreAinda não há avaliações

- 2000TO6QDocumento4 páginas2000TO6QNitisha RathoreAinda não há avaliações

- Index: CHAPTER-2.1 General 09 CHAPTER-2.2 Literature Review On Pushover Analysis 09-10 CHAPTER-2.3 Closure 11Documento2 páginasIndex: CHAPTER-2.1 General 09 CHAPTER-2.2 Literature Review On Pushover Analysis 09-10 CHAPTER-2.3 Closure 11Nitisha RathoreAinda não há avaliações

- Report Mercury CCMBDocumento6 páginasReport Mercury CCMBNitisha RathoreAinda não há avaliações

- Chapter 2: Threats To The Marine Environment: Pollution and Physical DamageDocumento15 páginasChapter 2: Threats To The Marine Environment: Pollution and Physical DamageNitisha RathoreAinda não há avaliações

- 3370 2Documento17 páginas3370 2DEEPAK KUMAR MALLICKAinda não há avaliações

- Essential Wastewater Math FormulasDocumento7 páginasEssential Wastewater Math Formulasnarayanan_anoobAinda não há avaliações

- AN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpDocumento6 páginasAN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpNitisha RathoreAinda não há avaliações

- Content PageDocumento2 páginasContent PageNitisha RathoreAinda não há avaliações

- RCP Method 1311 TCLPDocumento20 páginasRCP Method 1311 TCLPNitisha RathoreAinda não há avaliações

- Hazardous Wastes Management Handling and Transboundary Movement Rules 2008Documento40 páginasHazardous Wastes Management Handling and Transboundary Movement Rules 2008anpuselvi125Ainda não há avaliações

- CritiquesDocumento4 páginasCritiquesNitisha RathoreAinda não há avaliações

- Zorite - Zorite Mineral Information and DataDocumento4 páginasZorite - Zorite Mineral Information and DataNitisha RathoreAinda não há avaliações

- Indian Zinc Industry, Zinc Industry in India, Zinc Industry, Zinc IndustriesDocumento7 páginasIndian Zinc Industry, Zinc Industry in India, Zinc Industry, Zinc IndustriesNitisha RathoreAinda não há avaliações

- Critique Research PaperDocumento13 páginasCritique Research PaperNitisha Rathore100% (1)

- Content PageDocumento2 páginasContent PageNitisha RathoreAinda não há avaliações

- Environment PPT Template 020Documento4 páginasEnvironment PPT Template 020Nitisha RathoreAinda não há avaliações

- Particulate Matter ModuleDocumento23 páginasParticulate Matter ModuleNitisha RathoreAinda não há avaliações

- Introductory Design ConsiderationsDocumento13 páginasIntroductory Design ConsiderationsNitisha RathoreAinda não há avaliações

- SanthiniDocumento31 páginasSanthiniNitisha Rathore100% (1)

- OutlineDocumento5 páginasOutlineNitisha RathoreAinda não há avaliações

- Sai WSDocumento32 páginasSai WSNitisha RathoreAinda não há avaliações

- A Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisDocumento7 páginasA Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisSalma SherbazAinda não há avaliações

- Type of Business VentureDocumento3 páginasType of Business VentureSasheen Dela CruzAinda não há avaliações

- HydraulicsDocumento36 páginasHydraulicsMark Lorenz DiolataAinda não há avaliações

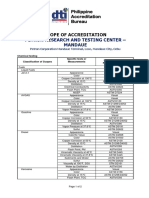

- Scope of Accreditation PRTC MandaueDocumento2 páginasScope of Accreditation PRTC MandaueKent DoyuhimAinda não há avaliações

- E-2215A Equipment Number: Piping and Instrumentation DiagramDocumento1 páginaE-2215A Equipment Number: Piping and Instrumentation DiagramMohd KhaidirAinda não há avaliações

- Flow Properties of Stirred Yogurt Calculation of The PDFDocumento22 páginasFlow Properties of Stirred Yogurt Calculation of The PDFandres332Ainda não há avaliações

- Abstract/Summary: V K M DP DLDocumento17 páginasAbstract/Summary: V K M DP DLAdnan Nanda100% (1)

- Fluid Mechanics: Topic 001: Fundamentals of FluidsDocumento11 páginasFluid Mechanics: Topic 001: Fundamentals of FluidsairaAinda não há avaliações

- Artificial LiftDocumento11 páginasArtificial Liftdriller22100% (2)

- Introduction to Wind Turbine Aerodynamics TheoryDocumento23 páginasIntroduction to Wind Turbine Aerodynamics TheoryAlexandreSidantAinda não há avaliações

- Pipe Flow Expert Quick Start GuideDocumento12 páginasPipe Flow Expert Quick Start Guidemetasoniko2014Ainda não há avaliações

- Course Outline of 4th Year - ME 4135Documento6 páginasCourse Outline of 4th Year - ME 4135shamiul himelAinda não há avaliações

- Practical Experience With Oil Mist LubricationDocumento8 páginasPractical Experience With Oil Mist Lubricationannccknarime100% (1)

- Module 2 - Fluid StaticsDocumento11 páginasModule 2 - Fluid StaticsNiaz KilamAinda não há avaliações

- Introduction - PumpsDocumento35 páginasIntroduction - PumpsMohamed MoatazAinda não há avaliações

- Thermal Engineering Research PaperDocumento29 páginasThermal Engineering Research PaperVighnesha SNAinda não há avaliações

- Bab Bahasan Buku QasimDocumento2 páginasBab Bahasan Buku QasimRd Nur MuhammadAinda não há avaliações

- Milton Roy Metering PumpDocumento22 páginasMilton Roy Metering PumpFa ChAinda não há avaliações

- Project Report New Okhla BarrageDocumento85 páginasProject Report New Okhla BarrageAbhishek Koul100% (2)

- Use of CFD To Predict and Reduce Erosion in An Industrial Slurry Piping SystemDocumento6 páginasUse of CFD To Predict and Reduce Erosion in An Industrial Slurry Piping Systemcybot112100% (1)

- Development of A Multi-Pump Test Rig: Background of The StudyDocumento58 páginasDevelopment of A Multi-Pump Test Rig: Background of The StudyMarc Danielle G Josue IIAinda não há avaliações

- Lab 2 Mini FLow ChannelDocumento16 páginasLab 2 Mini FLow ChannelIr Fik TAinda não há avaliações

- Multistage Centrifugal Pump Test RigDocumento13 páginasMultistage Centrifugal Pump Test Rigأشرف علي100% (1)

- Properties of Oilfield WatersDocumento7 páginasProperties of Oilfield WatersMaisam AbbasAinda não há avaliações

- Mikaela XinDocumento28 páginasMikaela XinclcasalAinda não há avaliações