Escolar Documentos

Profissional Documentos

Cultura Documentos

Applications of Carbon Nanotubes

Enviado por

Alex AntiaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Applications of Carbon Nanotubes

Enviado por

Alex AntiaDireitos autorais:

Formatos disponíveis

Alex Antia, Ingra De Queiroz Flecha, Bethany Jim, Holly Pearce, Dominic Mahoney and Jinyu Yang

Applications of Carbon Nanotubes

Applications & Discussion

Electronics Carbon Nanotubes (CNTs) and their compounds exhibit extraordinary electrical properties for organic materials, and have a huge potential in electrical and electronic applications such as photovoltaics, sensors, semiconductor devices, displays, conductors, smart textiles and energy conversion devices (e.g., fuel cells, harvesters and batteries). Carbon nanotubes for electronics applications are still a strong focus for research and printable carbon nanotube inks are beginning to hit the market. CNTs are used for making transistors and are applied as conductive layers for the rapidly growing touch screen market. CNTs are considered a viable replacement for ITO transparent conductors in some applications. Fabricated as transparent conductive films (TCF), carbon nanotubes can potentially be used as a highly conductive, transparent and cost efficient alternative in flexible displays and touch screens, for instance. Composites One of the major commercial applications of nanotubes is in the development of nanotube-based polymer composites, which have improved physical and mechanical properties. The nanotube composites present a wide range of possible applications, such as electrostatic-discharge components, sporting good (e.g. tennis rackets), electrically conductive paints, optical devices and aerospace composites. Incorporation of nanotubes into plastics results in increased stiffness, strength and toughness and allows electrical and thermal conductivity. Comparing to traditional reinforcing fibres, the nanotubes are more flexible and have molecular dimensions that are more similar to the polymer chains dimensions. Their small size improves the reinforcement effect because there is a high surface area available for contact with the polymeric matrix. The performance of carbon-nanotube composites is about 10 times better than that observed for composites with conventional carbon fibers, for the same load. Although nanotube composites have shown a great potential, some problems must be overcome. The main challenge lies in obtaining a uniform dispersion of the nanotubes within the matrix and a strong adhesion between the two components. The nanotubes tend to form aggregates, specially bundles, which may weak the composite and cause cracks in it. Moreover, the huge interfacial area and the smoothness of the particles lead to a poor nanotube/matrix adhesion. Finally, cost is also an important issue, since a large quantity of good quality nanotubes is required for application in composites. Regarding to cost, MWNTs are preferred than SWNTs. Therefore, there is still a need for further research and development of techniques to produce cost-effective nanocomposites. Energy Storage Lithium ion battery Lithium-ion batteries consist of 2 electrodes and an electrolyte. The electrodes are oppositely charged and the electrolyte allows the ions to travel between each electrode for charging and discharging. Carbon nanotubes are able to replace the traditional material used for the cathode in these batteries, as they contain many functional groups on their surface, which lets them store a large amount of lithium ions. Using carbon materials for the cathode speeds up the lithium storage reaction considerably, therefore they can deliver much more power. Electrostatic interactions in the battery causes the nanotubes to take a porous structure, leaving many exposed surfaces for reactions to take place; nanotubes usually clump together without electrostatic forces, which doesnt leave a lot of surface area. Nanotube batteries are able to output 10 times the power of a standard lithium-ion battery and keep a much better stability over time; after 1000 charging and discharging cycles there has been no change detected in tested batteries. Hydrogen Researchers have come up with a structure using carbon nanotubes that can store vast amounts of hydrogen. The nanotubes are arranged in a sponge like structure, where they are crossed over each other in a 3D grid structure. A common method of packing nanotubes is by keeping them parallel to each other, where the entire edges of the tubes touch each other; in the grid structure, there are only specific points of contact and this was found to absorb a substantial amount more hydrogen than the parallel structure. Only a model of the sponge structure has been made, because it is very difficult to make an ordered 3D network using single wall carbon nanotubes.

Introduction

Nanostructured carbon has been at the foreground of nanotechnology developments and applications, with a main focus being made on the potential science of carbon nanotubes. Carbon nanotubes are exciting new structures which have shown an impressive scale of properties including great thermal and electrical conductivity as well as elasticity, chemical resistance and strength. The carbon atoms making up the carbon nanotubes are arranging in layers of connected benzene rings making the structure very strong. This is because the bonds present between the six atoms in a benzene ring are highly stable as theyre fairly unreactive against most chemicals. Essentially, the structure of a carbon nanotube is, quite simply, just a graphite sheet rolled into a tube form, but its the recent development of the tubes single walls that allows the nanostructure to exhibit such a wide range of useful properties. Demonstrations have proved that single carbon nanotubes can even act as transistors, transparent electrodes in solar cells and artificial muscles. The potential to insert other complex nanostructures inside the tubes has further increased the variety applications possible.

Other types of nanostructured carbon

Conclusion

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- NecromancerDocumento3 páginasNecromancerAlex AntiaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Army RosterDocumento2 páginasArmy RosterAlex AntiaAinda não há avaliações

- ElementalistDocumento3 páginasElementalistAlex AntiaAinda não há avaliações

- UntitledDocumento1 páginaUntitledAlex AntiaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

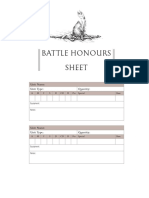

- Battle Honours SheetDocumento2 páginasBattle Honours SheetAlex AntiaAinda não há avaliações

- List of ArmiesDocumento2 páginasList of ArmiesAlex AntiaAinda não há avaliações

- UntitledDocumento1 páginaUntitledAlex AntiaAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Skyfarer Fillable SheetDocumento1 páginaSkyfarer Fillable SheetAlex AntiaAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Glitch Sheet 4pagesDocumento4 páginasGlitch Sheet 4pagesAlex AntiaAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Single Part Driving Licence Faqs 1502Documento2 páginasSingle Part Driving Licence Faqs 1502Alex AntiaAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Getting Files From Ps2Documento8 páginasGetting Files From Ps2Alex AntiaAinda não há avaliações

- Lake Skills CHI: Bro/Peaceful King GM Warrior 20Documento2 páginasLake Skills CHI: Bro/Peaceful King GM Warrior 20Alex AntiaAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Characteristics: Talents & TraitsDocumento2 páginasCharacteristics: Talents & TraitsAlex AntiaAinda não há avaliações

- TorcuilDocumento2 páginasTorcuilAlex AntiaAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Walk 7 EngDocumento2 páginasWalk 7 EngAlex AntiaAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Walk 4 Eng ENGDocumento2 páginasWalk 4 Eng ENGAlex AntiaAinda não há avaliações

- OrlanDocumento3 páginasOrlanAlex AntiaAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Character Sheet: Body Advantages and Esoteric Disciplines Charm SenseDocumento3 páginasCharacter Sheet: Body Advantages and Esoteric Disciplines Charm SenseAlex AntiaAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Attributes Abilities: Physical Mental SocialDocumento4 páginasAttributes Abilities: Physical Mental SocialAlex AntiaAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Characteristics: Talents & TraitsDocumento2 páginasCharacteristics: Talents & TraitsAlex AntiaAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- NSNSNSN SNJSJDocumento53 páginasNSNSNSN SNJSJMayank VisalparaAinda não há avaliações

- Class 8 Cbse Science Sample Paper Term 2 Model 2Documento5 páginasClass 8 Cbse Science Sample Paper Term 2 Model 2Sunaina RawatAinda não há avaliações

- CSB Case Study Hoeganaes Dec9 FinalDocumento31 páginasCSB Case Study Hoeganaes Dec9 FinalthelaceAinda não há avaliações

- Question Paper Mos r15 JntuaDocumento2 páginasQuestion Paper Mos r15 JntuaAnonymous ML4hh4MOyBAinda não há avaliações

- (UAV) - Building A Composite AircraftDocumento5 páginas(UAV) - Building A Composite AircraftVany BraunAinda não há avaliações

- What Is Atmospheric PressureDocumento10 páginasWhat Is Atmospheric Pressurenidyashree100% (1)

- Des Case PML Manual DigitalDocumento195 páginasDes Case PML Manual DigitalFraz Ahmad0% (1)

- Lecture 15Documento8 páginasLecture 15Aravindan NatarajanAinda não há avaliações

- Problem Set 1: Phase Equilibrium: Figure 1. Handwritten Sample CalculationDocumento13 páginasProblem Set 1: Phase Equilibrium: Figure 1. Handwritten Sample CalculationJay SableAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- ch03 PDFDocumento98 páginasch03 PDFMaha JanaAinda não há avaliações

- PF 42 - USP 1058 in Process RevisionDocumento16 páginasPF 42 - USP 1058 in Process Revisionrodcam1Ainda não há avaliações

- Biology Peka Sharifah Nadia Binti Syed Muhammad Naquib 4 Saidina Abu Bakar Activity 6.1 Determining The Energy Value in Food SamplesDocumento4 páginasBiology Peka Sharifah Nadia Binti Syed Muhammad Naquib 4 Saidina Abu Bakar Activity 6.1 Determining The Energy Value in Food SamplesNadia AldrsAinda não há avaliações

- Supplemental Space Shuttle Tire Lessons: Grades K-12Documento22 páginasSupplemental Space Shuttle Tire Lessons: Grades K-12Emannuel FernandesAinda não há avaliações

- CHEM-E2150 - 7 Surface Interactions Part 1van Der Waals ForcesDocumento41 páginasCHEM-E2150 - 7 Surface Interactions Part 1van Der Waals ForcesDikshit SynergyAinda não há avaliações

- The 13 Most Important Numbers in The Universe - James D. Stein's Cosmic NumbersDocumento10 páginasThe 13 Most Important Numbers in The Universe - James D. Stein's Cosmic NumbersEmerson Novais OliveiraAinda não há avaliações

- FKL BearingsDocumento41 páginasFKL BearingsTiberiu MunteanuAinda não há avaliações

- Assignment 1: Sourav Sarkar February 1, 2017Documento12 páginasAssignment 1: Sourav Sarkar February 1, 2017Sourav SarkarAinda não há avaliações

- C Pipe Material Behaviour Didier Ilunga Only)Documento24 páginasC Pipe Material Behaviour Didier Ilunga Only)AlexandraOdinevAinda não há avaliações

- Lead Acid vs. Lithium-Ion Battery ComparisonDocumento5 páginasLead Acid vs. Lithium-Ion Battery ComparisonRasbihari SharmaAinda não há avaliações

- Refrigeration Oil PDFDocumento17 páginasRefrigeration Oil PDFChristina PadillaAinda não há avaliações

- Valvula Expansao Te5 PDFDocumento6 páginasValvula Expansao Te5 PDFJosé Edgard Pereira BarrettoAinda não há avaliações

- 0 14 en PDFDocumento74 páginas0 14 en PDFPPMA IndonesiaAinda não há avaliações

- Constructing Ashby MapDocumento9 páginasConstructing Ashby MapIr FankovicAinda não há avaliações

- 2016 Powerblanket CatalogDocumento40 páginas2016 Powerblanket CatalogNathaniel EvansAinda não há avaliações

- ESA SME Initiative Course D:MaterialsDocumento64 páginasESA SME Initiative Course D:MaterialsJoseph JonathanAinda não há avaliações

- Markel Paintstik MSDSDocumento5 páginasMarkel Paintstik MSDSAnt EnnaAinda não há avaliações

- Week 1 General Chemistry 2Documento32 páginasWeek 1 General Chemistry 2Kate MontuyaAinda não há avaliações

- Influence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootDocumento11 páginasInfluence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootSharin Julia Krista SuniAinda não há avaliações

- Alfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureDocumento6 páginasAlfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureEmmaAinda não há avaliações