Escolar Documentos

Profissional Documentos

Cultura Documentos

Busbar Design

Enviado por

gusgif0 notas0% acharam este documento útil (0 voto)

110 visualizações25 páginasThis document discusses the design basics of copper busbars. It notes that copper is well-suited for busbars due to its high electrical and thermal conductivity, strength, and ease of joining. It then covers how to determine current ratings for busbars based on working temperature, heat loss through convection and radiation, and heat generated by current. Finally, it discusses calculating the optimal economic size of busbars by balancing material, installation, and lifetime energy costs.

Descrição original:

busbar in power plant

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document discusses the design basics of copper busbars. It notes that copper is well-suited for busbars due to its high electrical and thermal conductivity, strength, and ease of joining. It then covers how to determine current ratings for busbars based on working temperature, heat loss through convection and radiation, and heat generated by current. Finally, it discusses calculating the optimal economic size of busbars by balancing material, installation, and lifetime energy costs.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

110 visualizações25 páginasBusbar Design

Enviado por

gusgifThis document discusses the design basics of copper busbars. It notes that copper is well-suited for busbars due to its high electrical and thermal conductivity, strength, and ease of joining. It then covers how to determine current ratings for busbars based on working temperature, heat loss through convection and radiation, and heat generated by current. Finally, it discusses calculating the optimal economic size of busbars by balancing material, installation, and lifetime energy costs.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 25

David Chapman

Copper Development Association

david.chapman@copperdev.co.uk

Copper Development Association

Busbar Design Basics

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

High electrical conductivity

only silver is better than copper

Good thermal conductor

heat reaches surface quickly

Strong (at working temperature)

to withstand short circuit stresses

low creep

Easy to joint

resistant to corrosion

Materials for Busbar Systems

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

Busbar ratings are determined only by the

maximum desired working temperature

At working temperature:

heat generated = heat lost

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

Busbar ratings depend on:

Working and ambient temperatures

Heat lost from the busbar

by convection

by radiation

Heat generated in the busbar

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

25 . 0

25 . 1

66 . 7

v

P

cv

u

=

Power dissipated by convection is given by:

where

u is the temperature rise above ambient

v is the vertical height of the surface

Busbar System Current Ratings

P

cv1

P

cv2

v

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Power dissipation per metre length v Vertical height

0

40

80

120

160

0 50 100 150 200

Vertical height (mm)

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

p

e

r

m

e

t

r

e

l

e

n

g

t

h

(

W

)

Convection (for 80 C temperature rise)

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Power dissipated by radiation is given by:

( )

8 4

1

4

2

10 7 . 5

= T T P

r

c

where

P

r

is the power dissipated per square metre

T

2

is the working temperature, K

T

1

is the ambient temperature, K

c is the emissivity

Busbar System Current Ratings

P

r

P

r

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

The emissivity, c, describes how effectively

the surface radiates heat

For a perfectly polished surface, the value is

close to zero - a very poor radiator

For a matt black surface, the value is close to

1 - a very good radiator

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Bright copper has an emissivity of about 0.1

During use, the emissivity of the copper

surface increases - and the current rating

increases - as the copper darkens to reach an

emissivity value of about 0.7

Tin plated copper has an emissivity of about

0.3 to 0.5

But painting bars reduces the current rating!

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

P

r

P

r

P

r

P

r

P

r

P

r

No radiation heat loss

from internal surfaces

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Radiation power dissipation v Working temperature

0

20

40

60

80

100

273 323 373

Absolute Working Temperature (K)

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

(

W

p

e

r

s

q

m

)

Radiation (for 30 C ambient)

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

for 100 mm vertical height, 30 C ambient

Total power dissipation v Working temperature

0

100

200

300

400

500

600

700

800

900

1000

40 60 80 100 120 140

Working temperature (C)

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

(

W

p

e

r

s

q

m

)

Convection

Radiation

Total

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

R I P

2

=

a

l

I P

2

=

The power generated by current in the busbar is:

where

is the resistivity of the material

a is the cross sectional area

l is the length

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

At some temperature, the heat generated in the

busbar is equal to the total heat lost by convection

and radiation.

| | | |

r c i

P P P + =

Busbar System Current Ratings

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Calculation method:

1 Select working and ambient temperatures

2 Assume initial current density of 8 amps/mm

2

3 Find appropriate size in standard range

4 Calculate heat generated due to current

5 Calculate heat loss at working temperature

6 If 4>5, increase size and return to 4

When 4=<5, this is smallest possible size

Minimum size calculation

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

The most economic size gives the lowest

lifetime cost. It is the minimum total cost of

material

installation and

energy costs

over the circuit lifetime.

Higher purchase cost - lower running costs

Best economic sizing

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Best economic sizing

Cost of bar

0

5

10

15

0 100 200 300 400 500 600

Cross sectional area (sqmm)

C

o

s

t

o

f

b

a

r

p

e

r

m

e

t

r

e

(

$

)

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Best economic sizing

Cost of losses - 5 years

0

10

20

30

0 100 200 300 400 500 600

Cross sectional area (sqmm)

C

o

s

t

o

f

l

o

s

s

e

s

o

v

e

r

5

y

e

a

r

s

(

$

)

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Economic Sizing of Busbars

Total cost - 5 years

0

10

20

30

0 100 200 300 400 500 600

Cross sectional area (sqmm)

L

i

f

e

t

i

m

e

c

o

s

t

p

e

r

m

e

t

r

e

(

$

)

Cost of bar

Cost of loss

Total

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

Further considerations

Having calculated the size of the bar, there

are three further considerations:

voltage drop

skin effect

increases apparent resistance by reducing

effective area - important for:

^ thick busbars

^ high frequencies

^ harmonics generated by non-linear loads

short circuit current

www.leonardo-energy.org

Copper Development Association

www.cda.org.uk

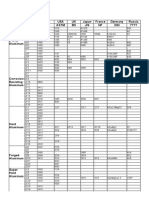

Summary of Busbar Material Characteristics

High Conductivity

low loss, low voltage drop

>101.5 % IACS

Easy Formability

due to small grain size and advanced production

technology

easy to bend without surface deformation

Good Flatness

simple reliable jointing

Good Straightness

easy installation, lower joint stress

David Chapman

Copper Development Association

david.chapman@copperdev.co.uk

Copper Development Association

Você também pode gostar

- Circuit Breaker Selections For Low Voltage Installation (With Discrimination) - EEPDocumento11 páginasCircuit Breaker Selections For Low Voltage Installation (With Discrimination) - EEPelectrifier_surenAinda não há avaliações

- Knowledge is "Real Power": Introduction to Power QualityNo EverandKnowledge is "Real Power": Introduction to Power QualityAinda não há avaliações

- Bus BarsDocumento36 páginasBus Barstceterex100% (1)

- Generator ProtectionDocumento41 páginasGenerator Protectionwaseem100% (1)

- Generator ProtectionDocumento41 páginasGenerator Protectionwaseem100% (1)

- Selecting Distribution Transformers to Meet Load DemandsDocumento12 páginasSelecting Distribution Transformers to Meet Load Demandsjbebin0% (1)

- Failure Analysis of 7500 HP MotorDocumento6 páginasFailure Analysis of 7500 HP Motorgusgif100% (1)

- Cable GlandsDocumento20 páginasCable GlandsBalaji VenkatesanAinda não há avaliações

- The Surge Protection Device (SPD) - Electrical Installation GuideDocumento5 páginasThe Surge Protection Device (SPD) - Electrical Installation GuideShaik Abdul HameedAinda não há avaliações

- Load Sharing Module WoodwardDocumento36 páginasLoad Sharing Module WoodwardgusgifAinda não há avaliações

- 21 Safety Rules For Working With Electrical EquipmentDocumento6 páginas21 Safety Rules For Working With Electrical EquipmentSumer LandAinda não há avaliações

- Generator Management Relay: Protection, Metering, and Monitoring Functions For GeneratorsDocumento38 páginasGenerator Management Relay: Protection, Metering, and Monitoring Functions For Generatorsmaheshee87Ainda não há avaliações

- How to properly size busbars in electrical panelsDocumento5 páginasHow to properly size busbars in electrical panelsZaferullah Khan100% (1)

- ASWP Manual - Section 3 - Joints (10!6!12)Documento12 páginasASWP Manual - Section 3 - Joints (10!6!12)shah1980Ainda não há avaliações

- Transformer Technical Data Sheet For The 1LAP016413Documento1 páginaTransformer Technical Data Sheet For The 1LAP016413kongkixAinda não há avaliações

- Voltage Drop PresentatnDocumento16 páginasVoltage Drop PresentatnmajortayAinda não há avaliações

- Green Box PDFDocumento20 páginasGreen Box PDFRolando El BlancoAinda não há avaliações

- ABB - Generator Protections GuideDocumento45 páginasABB - Generator Protections GuideAyesha ShaikhAinda não há avaliações

- Vibrations in Steam TurbinesDocumento11 páginasVibrations in Steam TurbinesAnudeep Chittluri100% (1)

- ELEC9713-11 Lec02 Switchboard PDFDocumento71 páginasELEC9713-11 Lec02 Switchboard PDFNiranjan PatraAinda não há avaliações

- Foundation DesignDocumento2 páginasFoundation Designhemantmech09Ainda não há avaliações

- Low Voltage Switchgear and Control Gear Application GuideDocumento152 páginasLow Voltage Switchgear and Control Gear Application GuideAntonio MejiaAinda não há avaliações

- Temperature RiseDocumento31 páginasTemperature Rise2ander100% (3)

- Pumps and System CurvesDocumento22 páginasPumps and System CurvesgusgifAinda não há avaliações

- Pumps and System CurvesDocumento22 páginasPumps and System CurvesgusgifAinda não há avaliações

- Manufacturing Electrical and PLC Panel BoardsDocumento11 páginasManufacturing Electrical and PLC Panel BoardsVikram PhalakAinda não há avaliações

- ASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsDocumento17 páginasASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsVishwanath TodurkarAinda não há avaliações

- CP Designed - Calculate Number of Galvanic Anodes for New Steel PipelineDocumento89 páginasCP Designed - Calculate Number of Galvanic Anodes for New Steel Pipelinemtuanlatoi9704100% (1)

- Current-carrying Capacity FactorsDocumento8 páginasCurrent-carrying Capacity Factorsrasheed313Ainda não há avaliações

- Current Calculation For BusbarsDocumento41 páginasCurrent Calculation For Busbarsraghuveeranush0% (1)

- Arc Guard AbbDocumento9 páginasArc Guard AbbsantoshkumarAinda não há avaliações

- Reduced Series ReactorDocumento10 páginasReduced Series ReactorclicknagpalAinda não há avaliações

- Technical Report - Internal Arc - OrmazabalDocumento10 páginasTechnical Report - Internal Arc - OrmazabalAshish RanjanAinda não há avaliações

- Starting Analysis of Induction Motor by EtapDocumento6 páginasStarting Analysis of Induction Motor by Etapgusgif50% (2)

- Iec61439 ImportanceDocumento30 páginasIec61439 Importancearkupi100% (1)

- TechCorner 29 - AutomationDirect Vs Allen Bradley PLC'sA Head To Head ComparisonDocumento3 páginasTechCorner 29 - AutomationDirect Vs Allen Bradley PLC'sA Head To Head ComparisonQuantumAutomationAinda não há avaliações

- Modeling and Simulation of Reverse PowerDocumento6 páginasModeling and Simulation of Reverse PowergusgifAinda não há avaliações

- Nulec - AutorecloserDocumento27 páginasNulec - AutorecloserSatyaAinda não há avaliações

- Long 11 PPT 01Documento32 páginasLong 11 PPT 01gusgif100% (1)

- Force Calc BusbarsDocumento7 páginasForce Calc BusbarsVimal Puthusseri100% (1)

- Cable Operating TemperatureDocumento3 páginasCable Operating TemperaturedusktodawnAinda não há avaliações

- HV CablesDocumento74 páginasHV CablesRague MiueiAinda não há avaliações

- Copper For Busbars-OrIENTAL CuDocumento27 páginasCopper For Busbars-OrIENTAL Cutenk_man83% (6)

- Gamma InsulatorsDocumento46 páginasGamma InsulatorsArturo MoreiraAinda não há avaliações

- Wood Element Axial Bending EC5Documento2 páginasWood Element Axial Bending EC5nicolaemariusAinda não há avaliações

- Design load and shear calculations for reinforced concrete beamDocumento4 páginasDesign load and shear calculations for reinforced concrete beamaremyulAinda não há avaliações

- Busbar Design Basics: David Chapman Copper Development Association David - Chapman@copperdev - Co.ukDocumento25 páginasBusbar Design Basics: David Chapman Copper Development Association David - Chapman@copperdev - Co.ukkapil100% (1)

- Calculating Conductor Resistance of Cables Using Temperature Correction FactorDocumento6 páginasCalculating Conductor Resistance of Cables Using Temperature Correction Factorhafizi07Ainda não há avaliações

- 1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationDocumento6 páginas1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationdienlangchuAinda não há avaliações

- Inspection Test and Measurement Procedures For LV and MV Up To 36kV SwitchgearsDocumento5 páginasInspection Test and Measurement Procedures For LV and MV Up To 36kV Switchgearspayolin77Ainda não há avaliações

- SP-12-276 C.ws.v.y.e-Sw 1CDocumento3 páginasSP-12-276 C.ws.v.y.e-Sw 1CQuantudogon DangAinda não há avaliações

- How to Calculate, Size and Select LT CablesDocumento57 páginasHow to Calculate, Size and Select LT CablesefrenAinda não há avaliações

- Ladder PDFDocumento144 páginasLadder PDFAung MinsoeAinda não há avaliações

- Cable Tray Manual PDFDocumento53 páginasCable Tray Manual PDFkevinbovoAinda não há avaliações

- Vital Components and Functions of an Electrical SubstationDocumento20 páginasVital Components and Functions of an Electrical Substationsanju0156100% (1)

- Schneider Elect. CT PTDocumento48 páginasSchneider Elect. CT PThemantgupta226Ainda não há avaliações

- MV Design Guide PresentationDocumento8 páginasMV Design Guide Presentationarishkhan07Ainda não há avaliações

- Catalog Okken enDocumento26 páginasCatalog Okken enSaid BelhaimerAinda não há avaliações

- List of IEC Standards - Wikipedia, The Free EncyclopediaDocumento7 páginasList of IEC Standards - Wikipedia, The Free Encyclopedia@@ng0% (1)

- CAG11Documento2 páginasCAG11GuruAinda não há avaliações

- Bus Bar 1Documento33 páginasBus Bar 1Pin Santos100% (3)

- A Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Documento8 páginasA Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Ritaban R. BanerjeeAinda não há avaliações

- 7SR11 and 7SR12 - Argus Complete Technical ManualDocumento406 páginas7SR11 and 7SR12 - Argus Complete Technical ManualAndré Eiti KobayashiAinda não há avaliações

- Sabre 3008 WebDocumento70 páginasSabre 3008 Webjchs2880Ainda não há avaliações

- 11 kV 12.5 kA Outdoor Switchgear SpecificationDocumento48 páginas11 kV 12.5 kA Outdoor Switchgear SpecificationMekonnen ShewaregaAinda não há avaliações

- Electrical Power Transformer Engineer Rabah FDocumento107 páginasElectrical Power Transformer Engineer Rabah FAnilAinda não há avaliações

- Main LV Switchboards Dimensioning GuidelineDocumento5 páginasMain LV Switchboards Dimensioning GuidelineMichael Bou KarimAinda não há avaliações

- CEA Self Certification FormsDocumento20 páginasCEA Self Certification FormsKoti ReddyAinda não há avaliações

- BussBar CatDocumento52 páginasBussBar CatRonald H Santos100% (1)

- Site Acceptance Test Report of MV Switchgear: SnagDocumento5 páginasSite Acceptance Test Report of MV Switchgear: SnagGajendran SriramAinda não há avaliações

- Feeder Terminal Product Guide REF 542plusDocumento28 páginasFeeder Terminal Product Guide REF 542plusRazvan MaresAinda não há avaliações

- Best practices solar photovoltaic systemsDocumento43 páginasBest practices solar photovoltaic systemsphilipnart100% (1)

- Three factors and electrical safety in fire causesDocumento5 páginasThree factors and electrical safety in fire causesSUJIT KUMAR MONDALAinda não há avaliações

- Busbar Sizing CalculationDocumento5 páginasBusbar Sizing CalculationZaferullah KhanAinda não há avaliações

- Documents StackDocumento1 páginaDocuments StackDan MAinda não há avaliações

- Hint-How To Create Different Calendars in MS ProjectDocumento4 páginasHint-How To Create Different Calendars in MS ProjectgusgifAinda não há avaliações

- I gotta + (verbDocumento10 páginasI gotta + (verbgusgifAinda não há avaliações

- Differential Relay SettingDocumento6 páginasDifferential Relay SettinggusgifAinda não há avaliações

- Gek 34124GDocumento24 páginasGek 34124GgusgifAinda não há avaliações

- Ambac LSMDocumento9 páginasAmbac LSMgusgifAinda não há avaliações

- Automatic Voltage Control SystemsDocumento47 páginasAutomatic Voltage Control Systemsbacuoc.nguyen356Ainda não há avaliações

- Ger 3183Documento14 páginasGer 3183santoshkumar777Ainda não há avaliações

- GE IFCV ManualDocumento40 páginasGE IFCV ManualgusgifAinda não há avaliações

- Electric Motor StartersDocumento22 páginasElectric Motor StartersgusgifAinda não há avaliações

- Lossofexcitation 130805045350 Phpapp01Documento52 páginasLossofexcitation 130805045350 Phpapp01ahvaz1392bAinda não há avaliações

- Comparison Between Direct On Line, Star DeltaDocumento6 páginasComparison Between Direct On Line, Star DeltaReza Kandhy WindakaAinda não há avaliações

- Gek 34124GDocumento24 páginasGek 34124GgusgifAinda não há avaliações

- Calculate Vehicle Registration CostsDocumento41 páginasCalculate Vehicle Registration CostsgusgifAinda não há avaliações

- PART 2 - Starting Method For Induction Motors - Dr. Inaam IbrahimDocumento50 páginasPART 2 - Starting Method For Induction Motors - Dr. Inaam Ibrahimlbk50100% (2)

- ABS On PlaneDocumento2 páginasABS On PlanegusgifAinda não há avaliações

- Chapter 3 KomputasiDocumento15 páginasChapter 3 KomputasigusgifAinda não há avaliações

- Charging Current For Long Line and High Voltage CableDocumento17 páginasCharging Current For Long Line and High Voltage CablerantaroAinda não há avaliações

- Day 3: Rest From WeightsDocumento2 páginasDay 3: Rest From WeightsgusgifAinda não há avaliações

- R 22Documento22 páginasR 22Luis MartinezAinda não há avaliações

- Cálculo Sin ModificacionesDocumento26 páginasCálculo Sin ModificacionesAngel MingaAinda não há avaliações

- China (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????Documento2 páginasChina (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????payara111Ainda não há avaliações

- Thornel T300 052112 PDFDocumento2 páginasThornel T300 052112 PDFDavid CoutinhoAinda não há avaliações

- Parker Pneumatic Stainless Steel FRL Catalogue PDE2504TCUKDocumento24 páginasParker Pneumatic Stainless Steel FRL Catalogue PDE2504TCUKJas SumAinda não há avaliações

- ZeCor CaseStudy 002 1008 PDFDocumento1 páginaZeCor CaseStudy 002 1008 PDFjavoidea696526Ainda não há avaliações

- Uday Vaidya 654141576 PDFDocumento5 páginasUday Vaidya 654141576 PDFVictor Daniel WaasAinda não há avaliações

- Sugastune CATDocumento613 páginasSugastune CATDeceuninckDeforceAinda não há avaliações

- Water Wastewater BrochurelrDocumento7 páginasWater Wastewater Brochurelrlamia97Ainda não há avaliações

- Utilisation of Waste Plastic in Bituminous Roads ReviewDocumento14 páginasUtilisation of Waste Plastic in Bituminous Roads ReviewCivil StructureAinda não há avaliações

- PROPOSAL SMELTER Project-Bintan Island - ElectDocumento314 páginasPROPOSAL SMELTER Project-Bintan Island - Electagung100% (1)

- GE Circuit Breaker EnclosuresDocumento8 páginasGE Circuit Breaker Enclosuresdiscovery198Ainda não há avaliações

- Reference: Frank MonaghanDocumento20 páginasReference: Frank MonaghanIeeeChannaAinda não há avaliações

- Miscellaneous Accessories: Submittal A-338GDocumento2 páginasMiscellaneous Accessories: Submittal A-338Gfernandoperdomo20-1Ainda não há avaliações

- Materials List: Alloy FamilyDocumento3 páginasMaterials List: Alloy FamilydiwakarAinda não há avaliações

- Test Certificate DetailsDocumento2 páginasTest Certificate Detailsshrikant bhirudAinda não há avaliações

- 3.BSEEP Passive Design GuidebookDocumento194 páginas3.BSEEP Passive Design GuidebookDennis Lai Zhan WenAinda não há avaliações

- BDK ValveDocumento12 páginasBDK ValvevinaypAinda não há avaliações

- Group 15 : Relief Valves AccessoriesDocumento4 páginasGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesAinda não há avaliações

- Basalt Fiber PDFDocumento2 páginasBasalt Fiber PDFsalvepramod99Ainda não há avaliações

- DAIKIN VAM VRV HVE ModelDocumento5 páginasDAIKIN VAM VRV HVE ModelPads PrietoAinda não há avaliações

- Serie HPRDocumento4 páginasSerie HPREstebanRojasKrustofskyAinda não há avaliações

- Applications of Bernoulli's Equation for flow analysisDocumento17 páginasApplications of Bernoulli's Equation for flow analysisAboo Sdam AL Mkahal100% (2)

- TR 60Documento3 páginasTR 60Narayanan MoorthyAinda não há avaliações