Escolar Documentos

Profissional Documentos

Cultura Documentos

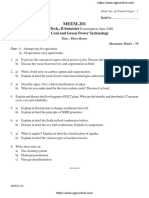

Esp 130420042913 Phpapp01 - 2

Enviado por

ramprakashpatelTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Esp 130420042913 Phpapp01 - 2

Enviado por

ramprakashpatelDireitos autorais:

Formatos disponíveis

Ash resistivity

. Particle size distribution

. Number of ESP per boiler

. Minimum No. of fields required

. Minimum specific collecting area

. Maximum gas velocity

. Minimum aspect ratio

. Maximum area connected to one TR

set

. Collecting electrode spacing

. Recovery of material for economic reasons

Pulp and paper Industries (sodium sulphate )

. Removal of abrasive material in the dust to

reduce wear and tear of the Fan components

. Removal of objectionable matter in the dust -

NO2 and SO2

Specific Collecting Area

Amount of collecting area required to be provided to

collect dust in gas flow rate of 1 m3 /s.

Flue gas Velocity, m/s = Flue gas flow in m3

ESP effective cross section m2

Aspect ratio = Effective Length of ESP

Collecting electrode height

Treatment Time, sec =Effective Length of ESP in m

Flue gas Velocity in m/s

Gas Velocity.

. Velocity is decided by the gas flow and

collection efficiency required

. Higher the gas velocity,higher the carryover of

dust particles without Collection - Re

entertainment

. Very poor velocity alters the flow distribution

and effects settling of Dust particles

. Optimum velocity depends upon the

application will improve the Performance.

Aspect Ratio.

. During the rapping, the falling of dust particle

take a trajectory form

. Lower the aspect ratio, the trajectory dust travel

along with gas flow

Without falling in to hoppers Leads to re-

entrainment loss.

. Higher the ratio, performance will be good

. Optimum aspect ratio depends on allowable

velocity, required collection

Efficiency and available space.

Treatment Time.

. Time available for capturing the dust particle

. More treatment time at reasonable velocity

improves the collection efficiency

. Probability of capturing the re-entrained

particles improves with time.

RECOVERY ELECTOSTATIC

PRECIPITATOR

The Paper mills are often located in a sensitive

environment with strict requirements of emission of

dust particles and gaseous pollutants to the

atmosphere. The dust particles are very fine and sticky

in nature. The gases are also highly corrosive.

Dedusting by means of Electrostatic Precipitators are

the preferred technology in Paper mills. Black liquor

recovery boilers are de-dusted by a multi chamber

ElectrostatiC Precipitator often with a casing made of

concrete

The casing of the precipitator for recovery boiler

applications are preferred to be made of

REINFORCED CEMENT CONCRETE. As the gas is

rich in moisture and highly corrosive due to the

presence of sulphur compounds ( sodium sulphate

and sodium sulphide used in the pulp digesters ), the

concrete casing is preferred to withstand corrosion.

For the same reason, the collecting electrode ( the

thinnest part in the electrode system ) is made of

corrosion resistant steels CORTEN - A or CORTEN

B or equivalent. The thickness can be 1.5 mm to

provide for an enhanced life of the collecting system.

The emitting electrode shall be of austenitic

stainless steel having excellent corrosion resistant

properties (conforming to UHB 904L or AISI 316L or

equivalent)

The load of the collecting and emitting systems

are transferred to the casing through load bearing

members called casing inserts. These are small parts

made of steel and embedded in the concrete casing at

the time of casting the same. This is done in-site.

The hopper system for these precipitators shall be

of flat bottom. No pyramidal nor trapezoidal type of

hoppers are used for such applications. The bottom

floor of the casing itself serves as the hopper and the

dust from the collecting / emitting and the gas

distribution screens are allowed to fall on to this floor.

The collected dust on the floor is scrapped by means

of SCRAPPER CONVEYOR which runs between the

inlet of the precipitator and the outlet. Structural

members are mounted at desired locations on two

end-less chains and scrap the collected dust to bring it

to the inlet end of the precipitator casing. The

conveyor is electrically driven by motors mounted on

the outside of the casing

In addition to the scrapper conveyor, a CHAIN

CONVEYOR is also employed to transfer the dust to a

ROTARY FEEDER mounted external to the

precipitator casing. The chain conveyor runs across the

precipitator at the inlet end of the casing and is

located inside the precipitator casing. The chain

conveyor is also electric driven by a motor mounted

external to the precipitator casing.

The dust discharged from the chain conveyor into

the rotary feeder is further conveyed to the mixing

chamber where it is mixed with the spent liquor and

recycled

The drives of the scrap per conveyor, chain conveyor and

the rotary feeder are to be interlocked in a particular

sequence by monitoring their operation through speed

monitoring devices mounted on the drive

shafts of these conveyors. This is essential to

avoid overloading of the conveyors / their

drives. The operation of the scrapper conveyor

shall be interlocked with the Transformer

Rectifier set so that the fields are de-energized

automatically when the scrapper conveyor is

NOT in operation.

As the dust is sticky in nature due to the

high moisture content, the gas distributor

screens at the inlet of the precipitator will be

rapped at the same frequency as that of the

emitting electrode system.

As the flue gas is highly corrosive and rich in

moisture content, special care has to be taken to

ensure that the flue gas temperature at the inlet of

the precipitator is sufficiently above the acid /

moisture dew point to avoid any condensation on

the precipitator surfaces and cause corrosion.

Temperature monitors are required to be installed

at the inlet duct. Some customers may prefer to

have a bye-pass duct when the gas temperature is

NOT sufficiently above the dew points. In such

cases, diverter dampers may be required at the

inlet and outlet of the precipitator casing to

prevent gas flow through the precipitator. This will

add to the cost of the precipitator system.

. Gas tight dampers are required to be installed at

the inlet and outlet of the precipitator casing for

purposes of maintenance.

The ingress / leakage of atmospheric air into the

precipitator casing has to be completely avoided

from the point of eliminating the possibility of any

local corrosion. The inspection doors on the casing

have to be therefore of double construction. One

inspection door located very close ( on the concrete

casing ) and the other one mounted over the inner

door.

The concrete casing also requires thermal

insulation on the outside. Light Resin Bonded (LRB)

mattresses of adequate thickness can be used.

CONSTRUCTION OF ELECTROSTATIC

PRECIPITATOR

This consists of Supporting structure and support

Bearing , these are the rigid structure supporting the

entire load of the ESP. The bearings are provided

between the casing colume and supporting structure to

act freely for thermal expansion.

CASING.

The casing is known as IB casing, the side walls are

made of horizontal panels, it is a leak proof arrangement

with roof beams of Longitudinal and Transverse to

support the internals of Collecting and Emitting

systems.

HOPPER.

Pyramidal and flat bottom hoppers are provided under

the casing to collect the ashes. It should not be treated as

storage bunker.

EMITTING SYSTEM.

Emitting system consists of rigid emitting frame suspended

from four points on the top. The four suspension points are

supported on support Insulators to give electrical

insulation to the emitting frame.

EMITTING

ELECTRODES.

The Discharge electrodes consist of hard drawn spiral

wires. The coil spring form emitting electrodes are self

tensioning, this stabilized

positioning permits the highest possible operating voltage.

The self tensioning spiral discharge electrodes allow for

better transmission of the rapping force. The spiral wire

electrode provides a uniform current distribution and the

corona discharge occurs around the entire surface of the

wire.

Rapping mechanism for Discharge electrode.

A Traction of the dust will be collected on the

discharge electrode and the corona will be suppressed

as the dust layer grows. Frequent rapping is required to

keep the electrode clean always.

COLLECTING SYSTEM.

The collecting system is of dimensional stability. The

upper edges of the collecting plate are hung on hooks

provided on the roof and the bottom is fixed with the

shock bar. The collecting electrodes are made of cold

rolled carbon steel or corton steel material of the order

of 1.5mm thickness with G profile at the end

RAPPING MECHANISM

FOR GOLLECTING

ELECTRODE.

The system employs tumbling hammers which are mounted on a

horizontal shaft in a staggered fashion with one hammer for each

shock bar. The shock bar transmits the blow simultaneously to

all of the collecting plates in one row because of their direct

contact with the shock bar.

ELECTRICS .

Rectifier Transformers are provided on top of ESP, the control

panels are located in ESP control room situated in the ground.

Auxiliary control panels are housed in the ESP control room to

control the auxiliary equipments of ESP like Heaters, Rapping

motors, conveyers etc.LT distribution board also housed in

control room.

OPERATION AND MAINTENANCE OF

RECOVERY ESP.

ESPs are constant efficient equipment, if the input

parameters are maintained to the design value then the out

put efficiency (emission) will be maintained, Provided the

ESP fields should be healthy.

We have to ensure the healthiness of each and every

equipment independently.

The HVR and EC controllers should be tuned to the optimum

level

Depending upon the load in the steam unit.

Monitor the optimum operation of the boiler by periodical

check of O2 levels in different point in the flue gas circuit.

The controllers should be kept at just below spark level

Always monitor the conveyors to work smooth to avoid any

Jamming.

MAINTENANCE.

Check all the Heaters are in service with

thermostat control in operation.

Check all the rapping motors are working as per

the program set.

Check the conveyors are running smooth

Check the current and voltage are to the set level

in the controllers.

Check the boiler is operated with optimum design

condition without any excess flue gas

Any pluggage problem in the entire flue gas path

from boiler outlet to chimney Inlet.

To monitor the maximum solid content in the

liquor to be fired.

Maintain history of firing proportion to emission with

parameter recording

The gas distribution to be studied for better

correction.

Optimization of rapping to avoid offset in the system.

Repair and replacement of rapping mechanism by

suitably replacing the worn-out components.

Field alignment to be checked perfectly to attain max.

current and voltage

Corona quenching problems to be studied and

attended.

The ESP rapping system should impart as high

acceleration to the precipitator internals as possible to

increase the intensity of rapping by increasing the size.

Poor ESP power input

Dust build-ups

Gas flow issues

Over load

. Poor ESP power input : Due to mechanical alignment

deficiency, that reduces the gap between +ve and ve

electrodes, sparks controls the current build up and reduce

the collection efficiency.

Dust build- up : The formation of accumulation is due to

the reaction between solid sodium sulfate and gaseous So2,

which results in the formation of acid sulfate,NaHso4 and

thus corona quenching.

Gas Flow : Gas distribution, if it is not even then

current distribution will be uneven, In leakage of air

increases the flow rate , sneakage of gases flowing in

untreated levels carry the dust.

Over load : Due to higher production in the mill, Poor

boiler operation with high amount of excess air,

leakages in the flue gas path.

Leakages in the flue gas path to be controlled

Internal alignment to be checked and corrected,

Gas distribution to be checked for uniform

distribution,

Gas sneakage points to be arrested for efficiency

improvement,

Rapping mechanism to be checked for effective

dislodging of dust particles,

Cleaning of internals either by air lashing or water

washing.

Power supply sources to the ESP to be checked.

Electrical migration

Electrical mobility

Corona discharge

ESP theory

Charging mechanisms

Ash resistivity

Flue gas conditioning

Power consumption

Reading: Chap. 5

Positive

Negative

Republican

Democrat

Love Hate

Ying Yang

Man

Woman

Hell

Heaven

Cation

Anion

War

Peace

Attraction Repel

Coulombs law

Statcoulomb (stC): the charge that causes a repulsive force of

1 dyne when 2 equal charges are separated by 1 cm (3.3310

-

10

C)

Unit charge: 4.8 10

-10

stC (1.610

-19

C)

2

2 1

r

q q

K F

E E

=

E

F

q

E

=

(q=ne)

Electric Field

(Robert

Millikan, US,

1868-1953;

Nobel Prize

Laureate, 1923)

Hinds, Aerosol Technology, 1999

http://nobelprize.org/nobel_prizes/physics/laureates/1923/millikan-bio.html

Terminal velocity in an electrical field

(electrical migration velocity/drift velocity)

c

TE p

C

V d

qE

t 3

=

( ) qEB

d

qEC

w V

p

c

TE

= = =

t 3

qB

d

qC

E

V

Z

p

c TE

= = =

t 3

(force balance)

D E

F F =

(for Re < 1)

Q: What is the physical meaning of electrical mobility?

Q: When does a particle have a higher mobility?

May the force be with the

particles!

Q: Difference between

cyclone and ESP in terms

of forces acting on the

system? Whats the

effect?

Positive Corona Negative Corona

+

-

+

-

+

+

-

+

+

+

-

-

+

-

+

-

+

-

-

-

+

+

Corona Discharge

Step 1

Step 2

Step 3

Step 4

Collection Plate

Collection Plate

Electron

Molecule

Particle

Electrode

Electrode

Q: How can we generate charges?

Ozone generation - http://www.mtcnet.net/~jdhogg/ozone/ozonation.html

1

2 3

1 2

3

(20)

(12)

(8)

Turbulent Flow with Lateral Mixing Model

Electrostatic Precipitator

Deutsch-Anderson

Equation

R

dt V

R

dt RV

N

dN

TE TE

2 2

2

= =

t

t

)

2

exp(

) (

0

R

t V

N

t N

TE

=

|

|

.

|

\

|

= = q

Q

A V

P

c TE

exp 1 1

A

c

/Q: Specific Collection Area (SCA)

Turbulent flow: uniformly mixing

Perfect Collection

The fraction of the particles removed in

unit time = the ratio of the area traveled

by drift velocity in unit time to the total

cross-section

Q: How to increase the efficiency?

Q: An ESP that treats 10,000 m

3

/min of air is expected to

be 98% efficient. The effective drift velocity of the

particles is 6.0 m/min. (a) What is the total collection

area? (b) Assuming the plates are 6 m high and 3 m

long, what is the number of plates required?

6 m

3 m

Internal Configuration: self-review

Random collisions between ions

and particles

(

(

+ =

kT

t N e c d

e

kT d

n

i i p p

2

1 ln

2

2

2

t

Q: Does q depend on time?

Does q depend on d

p

?

The total number of charges on a particle

(c

i

~ 2.410

4

cm/s)

ne q =

The total charges on a particle

Use esu, not SI units.

Bombardment of ions in the presence of a strong

field

eZ 1

eZ

4 2

3

i

i

2

|

|

.

|

\

|

+

|

|

.

|

\

|

|

.

|

\

|

+

=

t N

t N

e

Ed

n

i

i

p

t

t

c

c

Total number of charges by field charging

Q: Is the charging rate dependent on

particle size? On field strength? On

time? On material?

Aerosol Technology, Hinds, W. C., John Wiley & Sons, 1999.

|

|

.

|

\

|

|

.

|

\

|

+

=

e

Ed

n

p

s

4 2

3

2

c

c

Saturation charge

(Z

i

~ 450 cm

2

/stVs)

Comparison of Diffusion & Field Charging

Q: Does collection efficiency increase

as particle size increase (because of a

higher number of charges)?

dp (um) n

diff

n

field

n

total

Z

diff

Z

Field

Z (stCs/g)

0.01 0.10 0.02 0.12 0.66 0.10 0.76

0.02 0.30 0.06 0.36 0.49 0.11 0.60

0.05 1.1 0.40 1.50 0.31 0.12 0.43

0.1 2.8 1.6 4.38 0.23 0.13 0.36

0.2 7 6.5 13.2 0.18 0.17 0.35

0.5 21 40 61.2 0.15 0.30 0.45

1 48 161 209 0.16 0.52 0.68

2 108 646 754 0.16 0.98 1.14

5 311 4035 4346 0.18 2.34 2.52

10 683 16140 16824 0.20 4.61 4.80

20 1490 64562 66052 0.21 9.16 9.37

50 4134 403510 407644 0.23 22.78 23.0

Number of Charges vs dp

dp (um)

0.01 0.1 1 10

n

10

-2

10

-1

10

0

10

1

10

2

10

3

10

4

10

5

10

6

Diffusion charging

Field Charging

Nit = 10

7

s/cm

3

c= 5.1

E = 5 KV/cm

T = 298 K

ELectrical Mobility vs dp

dp (um)

0.01 0.1 1 10

Z

(

s

t

C

.

s

/

g

)

0.1

1

10

Diffusion charging

Field Charging

Combined Charging

Typical fly ash

size distribution

Q: If the ESP is used to collect the fly ash,

how will the particle size distribution at

ESP outlet look like?

Impact of particles resistivity on ESPs performance:

Factors: temperature, composition

Flue gas conditioning

10

9

- 10

10

ohm-cm is desired

Q: How does resistivity affect an ESPs performance?

Effects of sulfur content and temperature on resistivity

Q: Is S in coal good or bad?

Water spray for cement kiln dust

Flue Gas Conditioning

Effective drift velocity as a function of resistivity by

measurement

Use the same Deutsch-Anderson Equation with new w

e

.

Q: Estimate the total collection area required for a 95% efficient fly-ash

ESP that treats 8000 m

3

/min. The ash resistivity is 1.610

10

ohm-cm.

Good for moderate collection

efficiency (90% ~ 95%)

High Efficiency ESP (>95%)

Matts-Ohnfeldt Equation

(

(

|

|

.

|

\

|

=

k

e

C

w

Q

A

exp 1 q

Use k = 1 for fly ash

k = 0.5 or 0.6 for

industrial category

Rule of Thumb

Below 95%, use Deutsch-Anderson Equation

Above 99%, use Matts-Ohnfeldt Equation

Between them, use an average

Q: In designing a high

efficiency ESP, a smaller

drift velocity is to be

used. Why?

avg C C

V I P =

C

C

e

A

kP

w =

Power density ~ 1-2 W/ft

2

|

|

.

|

\

|

=

Q

kP

C

exp 1 q

Corona power

Drift velocity

Efficiency vs. Corona Power

k = 0.55 for P

c

/Q in W/cfs up to 98.5%

03-03-2014

56

03-03-2014

57

03-03-2014

58

Positive Corona Negative Corona

+

- -

- +

-

-

-

+

+

+

-

+

electron molecule

particle

Collection Plate Collection Plate Electrode Electrode

Step 1

+

-

+

Step 2

+

-

+

Step 3

+

+

-

Step 4

03-03-2014

59

Electrostatic Precipitator (ESP)

Drift velocity of particles between the ESP

plates

03-03-2014

60

Types of ESPs in terms of shape

Cylindrical type

Plate type

Types of ESPs in terms of flow

direction

Vertical gas-flow

Horizontal gas-flow

Types of ESPs in terms

performance

One stage or two stages

Dry or wet

Plate type, horizontal gas-flow, one stage

and dry ESPs are the most common ESP type

in industrial application.

03-03-2014

61

Electrostatic Precipitator (ESP)

One-stage ESP Two-stage ESP

Discharge

electrodes

Collecting

electrodes

The observed

minimum is because

of Cunningham

factor in calculation

of drift velocity.

03-03-2014

62

03-03-2014

63

03-03-2014

64

03-03-2014

65

03-03-2014

66

03-03-2014

67

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Meem 202 Wind Power Generation Jun 2020Documento1 páginaMeem 202 Wind Power Generation Jun 2020ramprakashpatelAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Meem 201 Clean Coal and Green Power Technology Jun 2020Documento1 páginaMeem 201 Clean Coal and Green Power Technology Jun 2020ramprakashpatelAinda não há avaliações

- Presentation o Surge Protection DevicesDocumento50 páginasPresentation o Surge Protection DevicesramprakashpatelAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Ppi Controler 90.1055 Blms As BuiltDocumento25 páginasPpi Controler 90.1055 Blms As BuiltramprakashpatelAinda não há avaliações

- Segmant ProtectorDocumento24 páginasSegmant ProtectorramprakashpatelAinda não há avaliações

- Intecont Tersus - MulticorDocumento182 páginasIntecont Tersus - Multicorramprakashpatel100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Abb Emax-E2Documento120 páginasAbb Emax-E2ramprakashpatelAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Air CompreesorDocumento59 páginasAir CompreesorramprakashpatelAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Machine Operator Mahendra PatelDocumento2 páginasMachine Operator Mahendra PatelramprakashpatelAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- PGDCA MS Access All UnitsDocumento33 páginasPGDCA MS Access All Unitsramprakashpatel100% (1)

- Difference Between Synchronous and Induction MotorDocumento2 páginasDifference Between Synchronous and Induction MotorramprakashpatelAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Descripcion UMC100Documento158 páginasDescripcion UMC100José RamosAinda não há avaliações

- Newmicrosoftofficepowerpointpresentation 130309031327 Phpapp02 PDFDocumento38 páginasNewmicrosoftofficepowerpointpresentation 130309031327 Phpapp02 PDFtaiptc4Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Lecture 09 - Transmission LinesDocumento55 páginasLecture 09 - Transmission LinesDorcas Jay B. RegaladoAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Earthinginelectricalnetwork 130426195622 Phpapp02Documento17 páginasEarthinginelectricalnetwork 130426195622 Phpapp02ramprakashpatelAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- DCCC Moter QuestionDocumento7 páginasDCCC Moter QuestionramprakashpatelAinda não há avaliações

- Transformer TestingDocumento64 páginasTransformer TestingramprakashpatelAinda não há avaliações

- PCJ Testing 2Documento16 páginasPCJ Testing 2ramprakashpatelAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- All Electrical InterviewDocumento20 páginasAll Electrical InterviewramprakashpatelAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Formation EvaluationDocumento267 páginasFormation EvaluationROHIT ARORAAinda não há avaliações

- Electron Configuration DLP CalatravaDocumento13 páginasElectron Configuration DLP CalatravaGwendolyn CalatravaAinda não há avaliações

- Compress 5800i AW Heat Pump Outdoor Unit Installation ManualDocumento36 páginasCompress 5800i AW Heat Pump Outdoor Unit Installation ManualGeorge PopaAinda não há avaliações

- Hydrogen Peroxide Oxidation of Tertiary AminesDocumento4 páginasHydrogen Peroxide Oxidation of Tertiary AminesRadja LintangAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Full Download Solution Manual For Chemistry An Atoms First Approach 2nd Edition PDF Full ChapterDocumento36 páginasFull Download Solution Manual For Chemistry An Atoms First Approach 2nd Edition PDF Full Chapterloudly.nereisnai6100% (15)

- Warm-Up Reading 1Documento9 páginasWarm-Up Reading 1benihimebankai92Ainda não há avaliações

- Desalting Crude OilsDocumento3 páginasDesalting Crude OilsEdgar YoveraAinda não há avaliações

- Fermentation in LiebigDocumento8 páginasFermentation in LiebigIngrid Nunes DerossiAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Diafiltration For Desalting or Buffer ExchangeDocumento6 páginasDiafiltration For Desalting or Buffer ExchangeAura UrregoAinda não há avaliações

- PLC Questions and AnswersDocumento13 páginasPLC Questions and AnswersInstrumentation ToolsAinda não há avaliações

- Glycol Ether EBA (TDS)Documento1 páginaGlycol Ether EBA (TDS)Tâm TrầnAinda não há avaliações

- 2023 ONLINE JEE MAIN-2 Questions Batch B1 To B4Documento26 páginas2023 ONLINE JEE MAIN-2 Questions Batch B1 To B4MandhirAinda não há avaliações

- Meshless Methods in LS-DYNA: An Overview of EFG and SPHDocumento43 páginasMeshless Methods in LS-DYNA: An Overview of EFG and SPHLe Anh TuanAinda não há avaliações

- Penetration of Microwaves Into AluminumDocumento5 páginasPenetration of Microwaves Into AluminumJohn Michael WilliamsAinda não há avaliações

- Tutorial Test 3 QPDocumento3 páginasTutorial Test 3 QPMohan Kumar100% (1)

- AP Physics B Exam Topics Since 1970Documento7 páginasAP Physics B Exam Topics Since 1970Chris HansenAinda não há avaliações

- 7 Theories On The Origin of LifeDocumento9 páginas7 Theories On The Origin of LifeNoela AlbosAinda não há avaliações

- Why Does Charge Concentrate On Points?Documento5 páginasWhy Does Charge Concentrate On Points?Tashi DendupAinda não há avaliações

- Einstein's and Debye's Theory, TC - FinalDocumento13 páginasEinstein's and Debye's Theory, TC - FinalMuthuLakshmi Rajendran100% (1)

- Final Titrations AsgDocumento21 páginasFinal Titrations AsgHira KhanAinda não há avaliações

- MSDS Rheofit 762Documento3 páginasMSDS Rheofit 762EMINAT PRINCEAinda não há avaliações

- Assignment2 Solution CIVE207 W24Documento11 páginasAssignment2 Solution CIVE207 W24tasnim.tanvir99Ainda não há avaliações

- Cyanobacteria: A Precious Bio-Resource in Agriculture, Ecosystem, and Environmental SustainabilityDocumento6 páginasCyanobacteria: A Precious Bio-Resource in Agriculture, Ecosystem, and Environmental SustainabilityJoshua De LeonAinda não há avaliações

- End Group 2Documento22 páginasEnd Group 2Sabha Khalid shafiqAinda não há avaliações

- Formulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateDocumento16 páginasFormulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateSiva PrasadAinda não há avaliações

- Lab Report of Fundamentals of Polymer Engineering LabDocumento40 páginasLab Report of Fundamentals of Polymer Engineering LabHafiz Tanveer86% (14)

- Lab Report Experiment 1Documento5 páginasLab Report Experiment 1Jessica NicholsonAinda não há avaliações

- HW 1Documento1 páginaHW 1mnzAinda não há avaliações

- Nitrogen PSA Brochure US - tcm136-454333Documento12 páginasNitrogen PSA Brochure US - tcm136-454333barun1977Ainda não há avaliações

- Summary and Interpretation of Reality TransurfingNo EverandSummary and Interpretation of Reality TransurfingNota: 5 de 5 estrelas5/5 (5)