Escolar Documentos

Profissional Documentos

Cultura Documentos

Lecture 2 - Product Development

Enviado por

Vashish Ramrecha0 notas0% acharam este documento útil (0 voto)

15 visualizações36 páginasrpd

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentorpd

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

15 visualizações36 páginasLecture 2 - Product Development

Enviado por

Vashish Ramrecharpd

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 36

Lecture 2

Product Development

Product Development

Product development needs to be considered at two

levels:

Development of existing products

New product development

The first largely involves design improvement,

while the second involves new design

!oth should be in response to customer

re"uirements

Product Development #cont$

New product development occurs before %&ob '(

in the life cycle of a product

Profit

)nd of

Product

Life *ycle

+ob '

!rea, )ven

Sales

Time

Product 2 Product 1

Product 3

g

r

o

w

t

h

maturity

d

e

c

l

i

n

e

Product Development #cont$

- manufacturing company must continually

introduce new products to remain profitable

.hy /apid0

Products are becoming more complex

1ntuitively, this would imply a longer product

development time

/ushing the process could lead to mista,es

.hy not allow the product development process to

continue at its current pace0

.hy /apid #cont$0

Product life cycles are shortening

Time

Year

Product Life

1970 1980 1990 2000

.hy /apid0 #cont$

2ore products are needed more often, eg

in '345s car models could have a ten year life

in '335s some manufacturers were releasing

new models every two years

Less time to ma,e profits

Late entry into mar,et will hit profits, eg 6

months late could lose 778 of total profit

/PD reduces time9to9mar,et

Profits

)arly 1ntroduction 1ncreases 2ar,et :hare and

;ence )xtends Product Life

Early Entry

Late Entry

Time

Sales

Volume

Longer

Sales

Life

Larger Market

Share

Source: Smith and einertsen

Profits

1nitially Pricing Premium

Later Lower 2anufacturing *osts

!om"etition

Enters

Market

Product

#ntroduced

Market Price

!ost

$d%antage

Pricing

Premium

Time

;ow /apid is /apid0

Product development times vary greatly between

manufacturing sectors, eg

-ircraft 9 '5 years

-utomobile 9 7 years

*onsumer goods 9 less than one year

Need to benchmar, against competitors

-im for continuous reduction, eg cut time9to9mar,et

by <58 every five years

;ow to :horten Time9to92ar,et0

Product development process typically covers

several stages from concept design through to

mar,et launch

)1T;)/ shorten individual stage 9 minimal effect

and only if on critical path

=/ increase overlap between stages 9 much more

potential for saving time

:econd option is *oncurrent )ngineering

*oncurrent )ngineering #*)$

*oncurrent )ngineering #*)$ is a powerful

strategy for reducing Time9to92ar,et

*) must be adapted to specific company needs

*ertain critical elements remain constant, eg

improved communication

*oncurrent )ngineering #contd$

:imultaneous execution of product development

tas,s

Typically includes design, design analysis,

testing, process design, plant layout, production

planning and mar,eting

/eplaces %se"uential( engineering

*oncurrent )ngineering

vs :e"uential )ngineering

Design

Analysis

Testing

Process Design

Plant Layout

Prod. Planning

ar!eting

Product Development using :e"uential )ngineering

"nformation

#$anges

%e&uired

*oncurrent )ngineering

vs :e"uential )ngineering

Design

-nalysis

Testing

Process Design

Plant Layout

Prod Planning

2ar,eting

Product Development using *oncurrent )ngineering

:hared

Two9way

1nformation

2ain >eatures of

/apid Product Development

Personnel from different functions wor, together

within product development teams

Decisions are made much sooner

)arly communication of information is vital

2any tools #often computer9based$ are available

to support this process

;ow does /PD reduce

Time9to92ar,et0

Design ta,es into account all subse"uent

activities, eg manufacture, mar,eting, etc

2ore people are involved in the early stages of

product development

2ore design iterations and changes are made

during these early stages

;ence, more time is re"uired for early stages of

product development

;ow does /PD reduce

Time9to92ar,et #contd$0

>ewer design changes in later stages

Total product development time is reduced

'um(er

of

#$anges

Time

)o( 1

*it$ #+

*it$out #+

)o( 1

.hat /PD tools are available

to help reducing Time9to92ar,et0

Pro&ect teams

?uality >unction Deployment

)ngineering data management

*omputer aided design

Design for manufacture and assembly

/PD Tools #contd$

/apid prototyping

@irtual prototyping

/apid tooling

/apid manufacturing

;igh :peed 2achining

-gile >ixturing

Pro&ect Teams

Personnel from several disciplines are co9located

#physically or virtually$

1nputs to designs reflect entire range of

re"uirements

Decisions can be made more "uic,ly

Designs satisfy all constraints and thus re"uire

fewer late changes

Pro&ect Team 2embers

?uality >unction Deployment

*ustomer re"uirements are incorporated directly

into product development process

/esponses to customer ob&ectives are prioritised

%@oice of customer( is disseminated throughout

all stages of process

2uch wasted effort is avoided as all activities are

correctly focused

)ngineering Data 2anagement

)nterprise9wide database system

:tores all product9related information

@ersion control and access control

*an be used for wor,9flow management

Promotes enterprise9wide communication

:upports earlier and shared decision ma,ing

)D2 Database :tructure

-ssembly

Data

>)2

>iles

:ub9assembly

Part Data

7D *-D

2odels

Data

N*

>iles

>ile reference list

*omputer -ided Design

Aeometric shape is fully defined

-dditional information can be added, eg tolerances,

material, surface finish

*hanges can be made more "uic,ly

Data is available to support %downstream activities(,

eg >)2, N*, /P

*an act as a communication tool across the whole

enterprise

-ssembly 2odel using *-D

Design for 2anufacture

and -ssembly

Designs are created ta,ing into account the

manufacturing and assembly processes to be

used

-voids late changes in the design

:hortens time of preparation for manufacture

*an also shorten manufacturing lead9time

)xample of Design for

-ssembly

good design

inferior design

)xample of Design for

)xtrusion

inferior design good design

.hat experiences have

companies had0

2any companies have implemented rapid

product development

Typical reduction in Time9to92ar,et has been

from 758 to 458

Two examples will be used to illustrate this

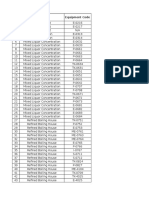

:unstrand )lectric Power :ystems

72

/PD at :unstrand

Time9to92ar,et reductions for various components

*omponents Prior to *) Bsing *)

:heet metal parts 2 wee,s '97 days

Printed wiring

boards

C96 wee,s 2 wee,s

1nvestment

castings

'29'6 wee,s < wee,s

2achined plastic

parts

2 wee,s D ' wee,

/PD at :unstrand #contd$

=ther benefits were also realised:

Design cycle reduced from 4 to C months

Design costs reduced by C<8

)ngineering changes reduced by <<8

Production cycle reduced from 7< to 'E hours

2ean failure time in field increased from 'E55 to

E555 hours

1mproved reliability was attributed to more design

iterations giving optimised design

/PD at 72

72 set goal of cutting Time9to92ar,et by <58

within < years

They achieved this after only 7 years

Preliminary design time was increased by 7558

This paid off with a greater time saving later in

the product development process

;ow0

P& at 3M 'cont()

Ta,ing previous Time9to9mar,et as '55 units, this

was reduced to <5 units:

-ctivity Prior to *) F /P Bsing *) F /P

Preliminary

design

< 25

Detail design 2< '5

!uildG test

process

<5 '<

Documentation 25 <

Total time '55 <5

*onclusions

/PD is an effective strategy for reducing Time9to9

2ar,et

2ore effort earlier will produce greater savings

later

There are many /PD tools available

:election of tools depends upon company

circumstances

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- CBT For BDDDocumento13 páginasCBT For BDDGregg Williams100% (5)

- Done - NSTP 2 SyllabusDocumento9 páginasDone - NSTP 2 SyllabusJoseph MazoAinda não há avaliações

- Pump Handbook by GrundfossDocumento156 páginasPump Handbook by GrundfossSyam TawakkalAinda não há avaliações

- Guidelines For Registration As A Professional Engineer - Peb SingaporeDocumento9 páginasGuidelines For Registration As A Professional Engineer - Peb SingaporejeffreymacaseroAinda não há avaliações

- 3 - Tips For Professional Engineer Interview in MalaysiaDocumento19 páginas3 - Tips For Professional Engineer Interview in Malaysiazahrul azha100% (8)

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Documento106 páginasMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- Speed Reducer GearboxDocumento14 páginasSpeed Reducer Gearboxعبد للهAinda não há avaliações

- Steel Beam BS 5950Documento17 páginasSteel Beam BS 5950Vashish RamrechaAinda não há avaliações

- 2017 1 Art 06 PDFDocumento12 páginas2017 1 Art 06 PDFG V LakshmiAinda não há avaliações

- DC CD Enteric Line List TemplateDocumento1 páginaDC CD Enteric Line List TemplateVashish RamrechaAinda não há avaliações

- Beam CantileverDocumento16 páginasBeam CantileverAdam SlametAinda não há avaliações

- Gantt ChartDocumento6 páginasGantt ChartVashish RamrechaAinda não há avaliações

- Steel Cals SimpleDocumento53 páginasSteel Cals SimpleVashish RamrechaAinda não há avaliações

- Piping FormulaeDocumento9 páginasPiping FormulaeVashish RamrechaAinda não há avaliações

- Equipment ListDocumento10 páginasEquipment ListVashish RamrechaAinda não há avaliações

- DC CD Enteric Line List TemplateDocumento1 páginaDC CD Enteric Line List TemplateVashish RamrechaAinda não há avaliações

- SLS in Manufacturing Sector-7thProofDocumento90 páginasSLS in Manufacturing Sector-7thProofVashish RamrechaAinda não há avaliações

- ISA SymbolsDocumento1 páginaISA SymbolsmustafasandikciAinda não há avaliações

- Gantt ChartDocumento6 páginasGantt ChartVashish RamrechaAinda não há avaliações

- Integrating New Mechanisms into a Human Heart Cell ModelDocumento1 páginaIntegrating New Mechanisms into a Human Heart Cell ModelVashish RamrechaAinda não há avaliações

- Roll 2015Documento26 páginasRoll 2015Vashish RamrechaAinda não há avaliações

- Why Isometric Drawings Are RequiredDocumento30 páginasWhy Isometric Drawings Are RequiredVashish RamrechaAinda não há avaliações

- Steel Cals SimpleDocumento53 páginasSteel Cals SimpleVashish RamrechaAinda não há avaliações

- 3.0 Strike Receivers AssessmentDocumento5 páginas3.0 Strike Receivers AssessmentVashish RamrechaAinda não há avaliações

- Edited FixturesDocumento67 páginasEdited FixturesVashish RamrechaAinda não há avaliações

- Legacy ECSA ProfEng Appform TERDocumento1 páginaLegacy ECSA ProfEng Appform TERVashish RamrechaAinda não há avaliações

- Training Record Book 2011 PDFDocumento25 páginasTraining Record Book 2011 PDFsarwarrosunAinda não há avaliações

- The Gurney Flap: A Case Study: 1.1 Issues in Wing DesignDocumento9 páginasThe Gurney Flap: A Case Study: 1.1 Issues in Wing DesignVashish RamrechaAinda não há avaliações

- Technical Report SynopsisDocumento3 páginasTechnical Report SynopsisAzharuddin_kfupmAinda não há avaliações

- Legacy ECSA ProfEng Appform TESDocumento1 páginaLegacy ECSA ProfEng Appform TESVashish RamrechaAinda não há avaliações

- DSG MechDocumento8 páginasDSG MechVashish RamrechaAinda não há avaliações

- CH-4 Shells Under External PressureDocumento64 páginasCH-4 Shells Under External PressureVashish RamrechaAinda não há avaliações

- Condition Based Monitoring System Using IoTDocumento5 páginasCondition Based Monitoring System Using IoTKaranMuvvalaRaoAinda não há avaliações

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiDocumento8 páginasCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiAinda não há avaliações

- LegoDocumento30 páginasLegomzai2003Ainda não há avaliações

- PowerPointHub Student Planner B2hqY8Documento25 páginasPowerPointHub Student Planner B2hqY8jersey10kAinda não há avaliações

- ALXSignature0230 0178aDocumento3 páginasALXSignature0230 0178aAlex MocanuAinda não há avaliações

- Guia de Usuario GPS Spectra SP80 PDFDocumento118 páginasGuia de Usuario GPS Spectra SP80 PDFAlbrichs BennettAinda não há avaliações

- Vector 4114NS Sis TDSDocumento2 páginasVector 4114NS Sis TDSCaio OliveiraAinda não há avaliações

- What Is A Problem?: Method + Answer SolutionDocumento17 páginasWhat Is A Problem?: Method + Answer SolutionShailaMae VillegasAinda não há avaliações

- Flowmon Ads Enterprise Userguide enDocumento82 páginasFlowmon Ads Enterprise Userguide ennagasatoAinda não há avaliações

- United-nations-Organization-uno Solved MCQs (Set-4)Documento8 páginasUnited-nations-Organization-uno Solved MCQs (Set-4)SãñÂt SûRÿá MishraAinda não há avaliações

- Computer Networks Transmission Media: Dr. Mohammad AdlyDocumento14 páginasComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Ainda não há avaliações

- Ultra Slimpak G448-0002: Bridge Input Field Configurable IsolatorDocumento4 páginasUltra Slimpak G448-0002: Bridge Input Field Configurable IsolatorVladimirAinda não há avaliações

- 2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationDocumento17 páginas2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationwahidAinda não há avaliações

- CDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Documento152 páginasCDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Gilles DellaccioAinda não há avaliações

- BIT 4107 Mobile Application DevelopmentDocumento136 páginasBIT 4107 Mobile Application DevelopmentVictor NyanumbaAinda não há avaliações

- Breaking NewsDocumento149 páginasBreaking NewstigerlightAinda não há avaliações

- Methods to estimate stakeholder views of sustainabilityDocumento7 páginasMethods to estimate stakeholder views of sustainabilityAlireza FatemiAinda não há avaliações

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocumento3 páginasCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikAinda não há avaliações

- Unr Ece R046Documento74 páginasUnr Ece R046rianteri1125Ainda não há avaliações

- Developing the cycle of maslahah based performance management system implementationDocumento27 páginasDeveloping the cycle of maslahah based performance management system implementationM Audito AlfansyahAinda não há avaliações

- Assignment - Final TestDocumento3 páginasAssignment - Final TestbahilashAinda não há avaliações

- 2020 Global Finance Business Management Analyst Program - IIMDocumento4 páginas2020 Global Finance Business Management Analyst Program - IIMrishabhaaaAinda não há avaliações

- Big Joe Pds30-40Documento198 páginasBig Joe Pds30-40mauro garciaAinda não há avaliações

- Paper SizeDocumento22 páginasPaper SizeAlfred Jimmy UchaAinda não há avaliações

- Emergency Management of AnaphylaxisDocumento1 páginaEmergency Management of AnaphylaxisEugene SandhuAinda não há avaliações

- Physioex 9.0 Exercise 1 Act 1Documento5 páginasPhysioex 9.0 Exercise 1 Act 1Adela LhuzAinda não há avaliações