Escolar Documentos

Profissional Documentos

Cultura Documentos

Jet Engine Propulsion in Aircraft

Enviado por

fadyDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jet Engine Propulsion in Aircraft

Enviado por

fadyDireitos autorais:

Formatos disponíveis

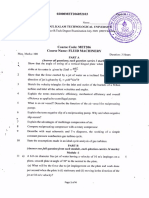

JET ENGINE PROPULSION IN AIRCRAFT

MAYANK BHARDWAJ

8MA1

HISTORY OF JET ENGINES

The first jet engine was built by Egyptian

scientists during 100 B.C.

The device was known as Aeolipile and

used steam power directed through two

nozzles to cause a sphere to spin rapidly

on its axis

It was not used for supplying mechanical

power and was simply considered a

curiosity

Dr. Hans von Ohain and Sir Frank Whittle

were the pioneers behind todays jet

engines.

INTRODUCTION

Jet engine is also called Gas Turbine Engine.

It works under the principle of Newtons third law

which states that For every acting force there is an

equal and opposite force.

FAN

COMPRESSOR

COMBUSTOR

TURBINE

MIXER

NOZZLE

MAIN COMPONENTS OF JET ENGINE

WHAT IS A JET ENGINE ?

A jet engine is a machine designed for the purpose of

creating large volumes of high velocity exhaust gases.

This is done in order to overcome the aerodynamic drag of

an airplane.

In the process of producing high velocity exhaust, the

engine also produces:

Electrical Power

Hydraulic Power

Pneumatic power for air-conditioning & pressurization

Hot Air for anti-icing protection

BASIC OPERATION OF A JET ENGINE

The basic operations of Jet Engine are as follows:

Air enters the compressor where it is compressed.

Fuel is then added and ignited.

The resulting gas spins the gas turbine.

The turbine powers the compressor.

The gas then exists the engine at tailpipe.

The way a jet engine operates is similar

To the way an automobile

engine operates i.e.

Intake

Compression

Ignition

exhaust

STRUCTURE OF JET ENGINE

STRUCTURE OF JET ENGINE

The engine shown below is known as Whittle Type

Engine, since it follows the original design features

developed by Sir Frank Whittle in the 1930s.

The first flight of a jet engine of his design was in 1941.

All engines in use on today's commercial jet aeroplanes

have been developed based on this original design.

TYPES OF JET ENGINES

Turbojet

Turbofan

Turboprop

Turbo shaft

Pratt-Whitney Turbofan Engine

Pratt Whitney Turbojet Engine

TURBOJET ENGINE

The turbojet engine is a reaction engine.

A turbojet engine works by compressing air in

compressor, mixing fuel with the compressed

air, burning the mixture in the combustor, and

then passing the hot, high pressure air through a

turbine and a nozzle.

Substantial increases in thrust can be further

obtained by employing an afterburner

Used in fighter planes, and were used in the

Concorde.

A turboprop engine is a jet engine with a propeller attached in front.

Majority of their thrust as in turbofan is obtained from propeller.

However, it is efficient only up to certain height and speed.

TURBOPROP ENGINE

TURBOFAN ENGINE

A turbofan engine is a gas turbine engine which is similar to a turbojet.

Turbofans differ from turbojets as they have an additional component, a

fan.

Fan in the engine produces as high as it 70-80 % of the total engine

thrust without increasing fuel consumption because the fan air can exit

separately from the core engine in other words 70-80% of the air is

bypassed from core engine.

It achieves this by increasing the total air-mass flow and reducing the

velocity within the same total energy supply.

Turboshaft engines are very similar to turboprops, with a difference that

nearly all energy in the exhaust is extracted to spin the shaft.

They therefore generate little to NO jet thrust.

This engine is used to drive shaft which in turn provides power to rotate

helicopter rotor.

The engine also has provision through Gear Box mechanism to maintain

rotor speed constant even when the speed of the generator is varied .

TURBO SHAFT ENGINE

The earliest commercial jet engine airplanes used a

Single Spool turbojet engine like shown below.

STRUCTURE OF JET ENGINE SINGLE SPOOL

The term Single Spool refers to the fact that

there is only one Shaft.

This shaft connects the Turbine section to one

compressor section.

All Jet engines in current use are Axial Flow

Engines meaning that the compression phases

is done axially (parallel to the axis of the

engine) as the airflows through the compressor.

STRUCTURE OF JET ENGINE SINGLE SPOOL

Thermodynamic Cycles Through a Jet Engine

(Similar to a 4 Stroke Engine)

(suck)

(squeeze) (bang)

(whoosh!)

The first significant development after the

introduction of the early axial-flow, single-spool

turbojets was the introduction of a second shaft.

This second shaft allowed the engine to have two

independent stages of compression powered by two

independent turbines.

STRUCTURE OF JET ENGINE TWIN SPOOL

P1, Page 11

The first stage of compression is the low-speed rotor and the

second stage is the high-speed rotor. These terms refer to the

fact that the first stage of the turbine, which rotates the second

stage compressor, turns at a faster rate than the second stage

turbine/ first stage compressor.

These are often referred to as the N1 rotor (low-speed) and the

N2 rotor (high-speed).

STRUCTURE OF JET ENGINE TWIN SPOOL

Turbofan Engine

P1, Page 13

The bypass ratio is the ratio of the air which exits the engine

without going through the rest of the engine core compared to

the amount of air which goes through the engine core (the

primary flow). Each of these produces thrust.

Turbofan engines produce lower noise levels than earlier

engines, and have considerably improved fuel economy.

High Bypass Ratio Turbofan Engine

Early turbofan engines were Low-Bypass ratio engines.

Approximately of the thrust was produced by the fan

stage, and the other half by the primary flow.

Engines currently in production for most commercial

airplanes are all high-bypass ratio turbofans. The

difference is that these engines have a much higher ratio of

bypass air compared to the primary air.

In a typical turbofan engine with bypass ratios around 5:1

and higher, the fan stage provides about 75 to 80 percent

of the total thrust produced by the engine.

All bigger aero planes operating in India with M/s Air India.

Jet Airways, Indigo, Spice jet are powered by Turbofan

Engines.

High Bypass Ratio Turbofan Engine

High bypass ratio engines take in a large amount of

air and accelerate it only a small amount (relative to

low bypass ratio engines).

High Bypass Ratio Turbo Fan Engine

P1, Page 16

Rolls Royce Trent 800 engine

bypass ratio - 6.5 :1

P & W PW 4084 engine:

Bypass ratio - 6.8:1

High Bypass Ratio Turbo Fan Engines - few examples

P1, Page 17

GE-90B engine

Bypass ratio: 9:1

High Bypass Ratio Turbo Fan Engines

Another example

P1, Page 18

High Bypass Ratio Turbo Fan Engines

P1, Page 20

RR engines now in production use a triple-spool design incorporating

three independent rotors.

Triple Spool Turbofan Engines

Designed to achieve better fuel economy due to the ability of the triple-

spool design to better match the design of the compressors and turbines

to the airflow.

Propulsive Efficiency

The propulsive efficiency of an engine can be expressed in

terms of the inlet velocity of the air and the exhaust

velocity.

Vinlet Vexit

Jet Engine

2XVinlet

(Vinlet + Vexit)

p

=

An efficiency of 100% would be attained if the exhaust velocity

was equal to the inlet velocity. However, for this to occur, the

mass flow through the engine would need to be infinite.

Infinite mass flow is obviously not achievable in the real world,

but this does indicate that greater efficiency is obtained when

a large mass of air is accelerated by a small amount rather

than a small mass of air being accelerated by a large amount.

Propulsive Efficiency

Propulsive Efficiency

From Newton's third law:

For every action there is an equal and opposite reaction

The jet engine's action is accelerating a mass of gas and

sending it out tailpipe.

The equal and opposite reaction is thrust.

The Thrust Equation

P1, Page 24

Where:

F

w

g

V1

V2

is force in pounds

is the gas flow in pounds per second

is the gravitational constant

is the initial velocity of the gas, in ft/sec

is the final velocity of the gas, in ft/sec

F=

w

g

* (V2 V1)

From Newtons second law:

F = d(mv)/dt (= ma for a constant mass)

In jet engine terms, we can re-write this as:

The Thrust Equation

We can re-write the thrust equation to make it more meaningful

in the context of a jet engine:

Fnet =

wair + wfuel

g

X Vjetexhaust

Vinlet

X

wair

g

-

thrust of

engine

incoming velocity

mass flow of incoming

of air mass flow

exhaust

velocity

total mass

flow out

tailpipe

The Thrust Equation

This is called the Net Thrust, because it accounts for the

momentum of the incoming air;

Gross Thrust is given by the first term in the equation which is

the force created at the exhaust of the engine.

To compute usable thrust, the gross thrust has to be reduced by

the amount of the second term, which is the momentum already

existing because of the airplanes speed.

From the equation, it can be seen that net thrust is a function of

the mass flow rate of the air and fuel passing through the engine,

and of the exhaust velocity minus the incoming velocity.

The Thrust Equation

Additional Thrust Due to Internal Pressure

This component of thrust is small compared to the thrust due to

exhaust velocity, but should not be ignored.

F = Aexhaust X

pexhaust- pambient

The thrust equation as written is somewhat simplified in that it

ignores one more possible component of thrust i.e. Thrust due to

internal pressure.

Most of the internal pressure within the engine is converted to

velocity of the exhaust gasses, which in turn produces thrust.

At the exhaust, if the total pressure of the gasses is greater

than the total pressure at the intake, this surplus of pressure

will produce some additional thrust.

Factors Affecting Thrust

t

r

o

p

o

p

a

u

s

e

Air Temperature

Thrust

Altitude

Thrust

Air density, a function of temperature and pressure altitude, is a

very significant component affecting thrust.

Airspeed

% Thrust

with

out

ram

Velocity affects both the momentum and the pressure of

the air entering the engine intake.

Increasing aircraft speed increases the momentum of the

incoming air, lowering thrust, while at the same time

compressing the air at the intake (ram effect) increasing

thrust by increasing density. The combined effect is show

below.

100 %

with ram

0%

Factors Affecting Thrust

Other Factors Affecting Thrust

Bleed air extraction affect thrust

Power extraction for hydraulic pumps, electric generators,

fuel pumps, etc., affects thrust.

Humidity has a negligible effect on thrust.

Commonly used Jet Engine Terms

EPR - Engine Pressure Ratio:

Ratio of total pressure at the exhaust to total pressure

at the front of the fan/compressor.

This is commonly used as a measure of engine thrust, and

is the primary thrust setting parameter.

N1 or %N1:

N1 is the rotation rate, in RPM, of the low-speed rotor of a

two or three-spool engine.

N1 is usually expressed as %N1, a percentage of some

nominal value.

General Electric and CFMI engines use %N1 as the primary

thrust setting parameter.

P1, Page 39

Engine Stall (compressor stall):

A condition characterized by stalled airflow over the compressor

blades.

Surge:

Refers to a condition of unsteady airflow through an engine

as the result of abnormal flow conditions.

Surge can result from strong crosswinds at low airspeeds

(e.g., during takeoff) or other conditions such as very rapid

acceleration or deceleration of the engine.

Flameout:

A condition in which the combustion chambers lose their

ignition. This could be the result of unsteady airflow (e.g.,

strong turbulence) or other conditions.

Commonly used Jet Engine Terms

Other Commonly Encountered Jet Engine Terms

Bleed:

Extraction of compressed air from the engine.

Bleed air is used for air conditioning and

pressurization, as well as for providing icing

protection.

Engine bleeds are also used in some cases to

prevent surging.

EGT Exhaust Gas Temperature:

This is the temperature at the engine exhaust

ADVANTAGES OF JET ENGINES

Gas turbine engines have a great power-to-weight ratio

compared to reciprocating engines. That is, the amount of

power you get out of the engine compared to the weight of

the engine itself is very good.

Gas turbine engines are smaller than their reciprocating

counterparts of the same power.

Jet engine designs are frequently modified for non aircraft

applications, as industrial gas turbines. These are used in

electrical power generation, for powering water, natural

gas, or oil pumps, and providing propulsion for ships and

locomotives.

Industrial gas turbines can create up to 50,000 shaft

horsepower

DISADVANTAGES OF JET ENGINES

Compared to a reciprocating engine of the same size, they

are expensive.

Because of high speeds and high operating temperatures,

designing and manufacturing gas turbines is a challenge from

both the engineering and materials point of view.

Gas turbines also tend to use more fuel when they are idling.

THANK YOU

Você também pode gostar

- Jet Engine - 1Documento21 páginasJet Engine - 1MuhammedNayeemAinda não há avaliações

- Jet EnginesDocumento32 páginasJet EnginesFelichi Dacumos Balajadia50% (2)

- Simple Thermodynamics of Jet EnginesDocumento6 páginasSimple Thermodynamics of Jet EnginesKok CheongAinda não há avaliações

- Jet Engine PerformanceeDocumento13 páginasJet Engine PerformanceeSantosh Ojha100% (1)

- New 16 MW Gas Turbine Unit T16 for Power GenerationDocumento13 páginasNew 16 MW Gas Turbine Unit T16 for Power GenerationZafar AhmedAinda não há avaliações

- How Jet Engine Works PDFDocumento1 páginaHow Jet Engine Works PDFAnonymous AEt3M9T100% (1)

- Jet PropulsionDocumento40 páginasJet PropulsionDileep Kumar Manjhi100% (1)

- Lycoming Flyer Key ReprintsDocumento114 páginasLycoming Flyer Key Reprintsroux100% (2)

- Turbofan Engine Thermodynamic AnalysisDocumento47 páginasTurbofan Engine Thermodynamic AnalysisHamza ShahidAinda não há avaliações

- Gas Turbine Engines - US Army Aviation Course AL0993 WWDocumento477 páginasGas Turbine Engines - US Army Aviation Course AL0993 WWinthemoney8Ainda não há avaliações

- Aircraft EngineDocumento11 páginasAircraft EngineAjayAinda não há avaliações

- Aircraft Turbine Engine CompressorsDocumento24 páginasAircraft Turbine Engine CompressorsYasantha Pathirana100% (1)

- Turboprops TNG Manual PDFDocumento21 páginasTurboprops TNG Manual PDFIvan Bastiani100% (1)

- Why Do Military Turbofan Engines Use A Low Bypass Ratio?Documento84 páginasWhy Do Military Turbofan Engines Use A Low Bypass Ratio?Rishab SharmaAinda não há avaliações

- Rolls-Royce GnomeDocumento48 páginasRolls-Royce GnomeEstevam Gomes de Azevedo100% (2)

- JET ENGINE FundamentalsDocumento18 páginasJET ENGINE FundamentalsHareesha N GAinda não há avaliações

- Engines EssayDocumento37 páginasEngines EssayChermaine SinAinda não há avaliações

- Afterburner ReviewDocumento34 páginasAfterburner ReviewMASOUD100% (2)

- Fadec SystemDocumento12 páginasFadec Systemkats2404100% (1)

- Auxiliary Power UnitDocumento1 páginaAuxiliary Power UnitGoswamirishabhAinda não há avaliações

- 4261 CombustorsDocumento28 páginas4261 CombustorsPitr LittleAinda não há avaliações

- 103 Easa Powerplant DemoDocumento7 páginas103 Easa Powerplant DemoAniruddha DaluiAinda não há avaliações

- Enhanced Internal Cooling of Turbine Blades and VanesDocumento34 páginasEnhanced Internal Cooling of Turbine Blades and VanesmidgardsothothAinda não há avaliações

- Transition To Turbopropeller-Powered AirplanesDocumento14 páginasTransition To Turbopropeller-Powered AirplanesAditya Sinha100% (1)

- Aircraft Systems - Lec 3Documento36 páginasAircraft Systems - Lec 3aahsan345100% (1)

- Jet Prop 4Documento29 páginasJet Prop 4Paulo AguiarAinda não há avaliações

- Aircraft SystemsDocumento40 páginasAircraft SystemsRadu AndreiAinda não há avaliações

- GE Turbine n1 n2 PercentDocumento10 páginasGE Turbine n1 n2 PercentYukihira SoumaAinda não há avaliações

- GE 109: Introduction To Engineering Product: Week 1Documento22 páginasGE 109: Introduction To Engineering Product: Week 1Hemant MeenaAinda não há avaliações

- Aircraft EnginesDocumento20 páginasAircraft EnginesAlberto Martinez IgualadaAinda não há avaliações

- AIRCRAFT PRESSURIZATION AND COOLING SYSTEMSDocumento78 páginasAIRCRAFT PRESSURIZATION AND COOLING SYSTEMSsai prasad100% (3)

- TCM Powerlink Diagnostics & Simulation: Presented By: John Barton Senior V.P. of Engineering Teledyne Continental MotorsDocumento31 páginasTCM Powerlink Diagnostics & Simulation: Presented By: John Barton Senior V.P. of Engineering Teledyne Continental Motorssdgpass2585100% (1)

- Turbofan EngineDocumento46 páginasTurbofan EngineBookMaggotAinda não há avaliações

- Jet Engine: Made By:Sachin ChaturvediDocumento20 páginasJet Engine: Made By:Sachin ChaturvediRoi Sachin De MondeAinda não há avaliações

- 727 Fuel SystemDocumento2 páginas727 Fuel SystemafifezzatAinda não há avaliações

- 4 Gas Turbine EnginesDocumento223 páginas4 Gas Turbine Enginesupsasa100% (1)

- Turboprop EngineDocumento16 páginasTurboprop EngineFahad AliAinda não há avaliações

- Eugene M. Gluhareffs Pressure Jet Engine PDFDocumento26 páginasEugene M. Gluhareffs Pressure Jet Engine PDFstudallanAinda não há avaliações

- Gas Turbine Ignition SystemsDocumento32 páginasGas Turbine Ignition SystemsAishah HanisAinda não há avaliações

- JT3D turbofan engine components and specificationsDocumento7 páginasJT3D turbofan engine components and specificationsjunmech-1Ainda não há avaliações

- Aircraft Engines and Gas Turbines: Jack L KerrebrockDocumento2 páginasAircraft Engines and Gas Turbines: Jack L KerrebrockSreehari HAinda não há avaliações

- Combustion Chamber PDFDocumento2 páginasCombustion Chamber PDFSusanAinda não há avaliações

- History of Jet Propulsion1Documento22 páginasHistory of Jet Propulsion1Interogator5Ainda não há avaliações

- TurbojetDocumento8 páginasTurbojethafezasadAinda não há avaliações

- 5 Airbreathing Jet Engine PDFDocumento103 páginas5 Airbreathing Jet Engine PDFMahadi Hanna Mridul100% (2)

- Commercial Engines 2015Documento56 páginasCommercial Engines 2015StnslvAinda não há avaliações

- Understanding Jet Engines Through the Brayton CycleDocumento227 páginasUnderstanding Jet Engines Through the Brayton CycleSteve Palmer100% (2)

- Gas Turbine Engine Fundamentals TutorialDocumento9 páginasGas Turbine Engine Fundamentals TutorialamirzokaeiAinda não há avaliações

- Propeller TheoryDocumento9 páginasPropeller TheoryFlorenceAinda não há avaliações

- Engine PresentationDocumento231 páginasEngine Presentationjoy todi100% (3)

- Flight Testing to Win: An autobiograpghy of a test pilotNo EverandFlight Testing to Win: An autobiograpghy of a test pilotNota: 5 de 5 estrelas5/5 (2)

- Taildragger Tales: My Late-Blooming Romance with a Piper Cub and Her Younger SistersNo EverandTaildragger Tales: My Late-Blooming Romance with a Piper Cub and Her Younger SistersNota: 2 de 5 estrelas2/5 (1)

- Aircraft Systems: Mechanical, Electrical, and Avionics Subsystems IntegrationNo EverandAircraft Systems: Mechanical, Electrical, and Avionics Subsystems IntegrationNota: 4 de 5 estrelas4/5 (1)

- Pharos University in Alexandria: Faculty of Engineering Construction Engineering & Management DepartmentDocumento1 páginaPharos University in Alexandria: Faculty of Engineering Construction Engineering & Management DepartmentfadyAinda não há avaliações

- Sand Cone Test SpreadsheetDocumento2 páginasSand Cone Test SpreadsheetfadyAinda não há avaliações

- Incident Reporting FormDocumento1 páginaIncident Reporting FormCollin NguAinda não há avaliações

- Lab Experiment #5: Standard Proctor Compaction TestDocumento4 páginasLab Experiment #5: Standard Proctor Compaction TestfadyAinda não há avaliações

- Experiment 13-Unconfined CompressionDocumento2 páginasExperiment 13-Unconfined CompressionfadyAinda não há avaliações

- Need Copy of ACI Manual For Verification of Info Below.: SECTION 03371 ShotcreteDocumento4 páginasNeed Copy of ACI Manual For Verification of Info Below.: SECTION 03371 ShotcretefadyAinda não há avaliações

- CM 204 Sheet Week7 4657Documento1 páginaCM 204 Sheet Week7 4657fadyAinda não há avaliações

- Project Concept Paper: 1. Background Information About The NGODocumento3 páginasProject Concept Paper: 1. Background Information About The NGOfadyAinda não há avaliações

- CM 204 Sheet Week7 4657Documento1 páginaCM 204 Sheet Week7 4657fadyAinda não há avaliações

- CM 204 Sheet Week7 4657Documento1 páginaCM 204 Sheet Week7 4657fadyAinda não há avaliações

- 02768SF - Stamped Cement Concrete PavingDocumento5 páginas02768SF - Stamped Cement Concrete PavingfadyAinda não há avaliações

- Scofield Stamped SpecDocumento7 páginasScofield Stamped SpecfadyAinda não há avaliações

- CM 301 Project Week11 15793Documento1 páginaCM 301 Project Week11 15793fadyAinda não há avaliações

- CM 204 Lecture Week8 4653Documento1 páginaCM 204 Lecture Week8 4653fadyAinda não há avaliações

- Spec Guide-ShotcretemsDocumento5 páginasSpec Guide-ShotcretemsfadyAinda não há avaliações

- CM 307 Lecture Week9 4601Documento1 páginaCM 307 Lecture Week9 4601fadyAinda não há avaliações

- Brickform Stamped Concrete Guide Specifications B24121Documento8 páginasBrickform Stamped Concrete Guide Specifications B24121fadyAinda não há avaliações

- CM 204 Lecture Week8 4653Documento1 páginaCM 204 Lecture Week8 4653fadyAinda não há avaliações

- CM 307 Lecture Week9 4601Documento1 páginaCM 307 Lecture Week9 4601fadyAinda não há avaliações

- Spec ShortcreateDocumento5 páginasSpec ShortcreatenalakasaAinda não há avaliações

- MT Pra-Glac 10 (33) ShotcreteDocumento10 páginasMT Pra-Glac 10 (33) ShotcreteMostafa OraeiAinda não há avaliações

- Read Me SAP2000 V 1600Documento11 páginasRead Me SAP2000 V 1600Rendo RendiAinda não há avaliações

- CM 301 Assignement Week12 15794Documento1 páginaCM 301 Assignement Week12 15794fadyAinda não há avaliações

- CM 307 Lecture Week9 4601Documento1 páginaCM 307 Lecture Week9 4601fadyAinda não há avaliações

- Determintion of Unit Weight: B.D. Mass of Oven Dry Soil (Grams) Total Volume of Soil (CM)Documento2 páginasDetermintion of Unit Weight: B.D. Mass of Oven Dry Soil (Grams) Total Volume of Soil (CM)fadyAinda não há avaliações

- Determination of Water Content in Soil: Testing ObjectivesDocumento5 páginasDetermination of Water Content in Soil: Testing Objectivesfady100% (1)

- CM 301 Assignement Week6 11794Documento3 páginasCM 301 Assignement Week6 11794fadyAinda não há avaliações

- Experiment 4-Specific GravityDocumento7 páginasExperiment 4-Specific GravityfadyAinda não há avaliações

- LaborDocumento23 páginasLaborVernie BacalsoAinda não há avaliações

- CM 307 Lecture Week9 4570 PDFDocumento1 páginaCM 307 Lecture Week9 4570 PDFfadyAinda não há avaliações

- Yamaha FX HO Service ManualDocumento515 páginasYamaha FX HO Service ManualDanijal Korajkic66% (35)

- Effects of Adiabatic Flame Temperature On Flames CharacteristicDocumento12 páginasEffects of Adiabatic Flame Temperature On Flames CharacteristicAhmed YasiryAinda não há avaliações

- Kilkenny's untapped hydro power potentialDocumento54 páginasKilkenny's untapped hydro power potentialmachinejigAinda não há avaliações

- UNMANNED AERIAL VEHICLES BASICS & APPLICATIONSDocumento24 páginasUNMANNED AERIAL VEHICLES BASICS & APPLICATIONSBeeresh KumarAinda não há avaliações

- About Pumps and Turbines PDFDocumento5 páginasAbout Pumps and Turbines PDFabdullahaafaqAinda não há avaliações

- Service Manual Watercraft VX1100Documento341 páginasService Manual Watercraft VX1100Rosana Espinola82% (22)

- Ejectors and Jet Pumps - Design and Perfo 2Documento101 páginasEjectors and Jet Pumps - Design and Perfo 2rezarossAinda não há avaliações

- 476B, Lab 5 Manual, TurboGenDocumento73 páginas476B, Lab 5 Manual, TurboGenMuhammad Bin AshiqAinda não há avaliações

- Optimum Layout For A Turbofan EngineDocumento37 páginasOptimum Layout For A Turbofan Enginevinod kapateAinda não há avaliações

- Turbojet Engines - TechnologyDocumento3 páginasTurbojet Engines - TechnologyzahraAinda não há avaliações

- Aerospace Inventics Visual GuideDocumento178 páginasAerospace Inventics Visual GuideValeriu Dragan100% (1)

- Aircraft Propulsion Lecture OverviewDocumento53 páginasAircraft Propulsion Lecture OverviewJosue Eleazar Guerrero Duran100% (1)

- Afterburners Systems of Turbine EnginesDocumento5 páginasAfterburners Systems of Turbine EnginesAzmah EskandriAinda não há avaliações

- General Electric: Lessons in Strategic Management: P.R. BhattDocumento8 páginasGeneral Electric: Lessons in Strategic Management: P.R. BhattLM_SAinda não há avaliações

- The Role of Drag Prediction in Combat Aircraft Design and DevelopmentDocumento6 páginasThe Role of Drag Prediction in Combat Aircraft Design and DevelopmentLeiser HartbeckAinda não há avaliações

- Eductor Jet PumpDocumento2 páginasEductor Jet PumpPiyapiya Oh PiyapiyaAinda não há avaliações

- Uniflor Brochure English72Documento6 páginasUniflor Brochure English72gaggy1983Ainda não há avaliações

- I. Models CFM56-5 CFM56-5-A1/F CFM56-5A3: Legend: " - " Indicates "Same As Preceding Model" " - " Not ApplicableDocumento7 páginasI. Models CFM56-5 CFM56-5-A1/F CFM56-5A3: Legend: " - " Indicates "Same As Preceding Model" " - " Not ApplicableakeelAinda não há avaliações

- Halton - Kitchen Canopy (Eng. Guide)Documento8 páginasHalton - Kitchen Canopy (Eng. Guide)picnarukAinda não há avaliações

- PASSIVE VOICE-16/9/2021 Name: Nguyễn Bá Thành School: - - - - THCS NGỌC LÂM - - - - - - - - - - - - - - - - - - - - - - - Exercise 1: Turn into passiveDocumento4 páginasPASSIVE VOICE-16/9/2021 Name: Nguyễn Bá Thành School: - - - - THCS NGỌC LÂM - - - - - - - - - - - - - - - - - - - - - - - Exercise 1: Turn into passiveditmethangvutruongAinda não há avaliações

- Discrete Noise Spectrum Generated by Acoustically Excited Jet 1980Documento13 páginasDiscrete Noise Spectrum Generated by Acoustically Excited Jet 1980Souhardya BanerjeeAinda não há avaliações

- Met206 Fluid Machinery, July 2021Documento4 páginasMet206 Fluid Machinery, July 2021AkashAinda não há avaliações

- Simple Turbojet Cycle: Alberto Mag-Aso IIIDocumento22 páginasSimple Turbojet Cycle: Alberto Mag-Aso IIIAlberto Mag-aso IIIAinda não há avaliações

- Advanced Fluid DynamicsDocumento282 páginasAdvanced Fluid DynamicsDjalma G. de SousaAinda não há avaliações

- Engineering Guide to Air Distribution SystemsDocumento0 páginaEngineering Guide to Air Distribution SystemsmohdnazirAinda não há avaliações

- CHAPTER 3 Turbine EnginesDocumento43 páginasCHAPTER 3 Turbine EnginesJP DavidAinda não há avaliações

- Impact of Jet Lab ReportDocumento7 páginasImpact of Jet Lab ReportMohamad Hilmy HaririeAinda não há avaliações

- MCQs ME6604 SCAD MSM by EasyEngineeringDocumento93 páginasMCQs ME6604 SCAD MSM by EasyEngineeringrameshneupane33% (3)

- Novenco Car Park Ventilation SystemsDocumento24 páginasNovenco Car Park Ventilation SystemsErica MorrisonAinda não há avaliações

- Design and Fabrication of Oil Burner, Based On Used Engine Oil As A Sustainable Source of EnergyDocumento7 páginasDesign and Fabrication of Oil Burner, Based On Used Engine Oil As A Sustainable Source of EnergyLEONARDO ELIAS MENDANGAinda não há avaliações