Escolar Documentos

Profissional Documentos

Cultura Documentos

1.0 7a - Pipe Thickness

Enviado por

Ravindra S. Jivani100%(1)100% acharam este documento útil (1 voto)

197 visualizações11 páginasPipe Thickness calculation

Título original

Copy of 1.0 7a -Pipe Thickness

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPipe Thickness calculation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

197 visualizações11 páginas1.0 7a - Pipe Thickness

Enviado por

Ravindra S. JivaniPipe Thickness calculation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 11

PIPE THICKNESS CALCULATIONS

Pipe Thickness Calculation for Natural Gas Service

Carbon Steel Pipe:

Pipe Thickness, t = (PD)/(2*S

a

+ P) + C.A.

Where t = thickness in mm

D = outer diameter of pipe in mm

P = design pressure, Kg/cm

2

S

a

= Allowable stress of pipe material at working

temp, in Kg/cm

2

(Refer piping codes B 31.3 / B

31.8)

C.A. = Corrosion Allowance (minimum value as 1.0 mm)

Example

Trunk Pipe line, D = 200 mm

P = 40 Kg/cm

2

S

a

= 1050 kg/cm

2

C.A. = 1.6 mm

Calculate required thickness of pipeline.

t = (40*200)/((2*1050)+40) + 1.6 mm

t = 3.7 + 1.6

t = 5.3

Select the pipe of nearest schedule having higher

thickness than the above value.

ADOPT DN 200 Schedule 40, C.S. Pipe.

Few Field Questions

How long do I have to use the pipe?

What is the residual thickness of pipe?

What is the corrosion rate of pipe material under the

service fluid & environmental exposures?

Has the pipe material deteriorated due to exposure to

service fluid & conditions? What are the mechanical &

metallurgical changes? Can it be quantified?

Was the piping system exposed to cyclic service

loading?

Has the piping material experienced creep

deterioration?

Has the piping material experienced stress corrosion

cracking (SCC)?

How much pressure can this pipe take?

Burst Pressure of Pipe

P

b

= (2 Y/S

u

)*(Y/3)*Log

n

(K

2

)

Where,

P

b

= Bursting pressure, Kg/cm

2

Y = Yield stress of pipe material, in Kg/cm

2

Su = Ultimate tensile stress, in Kg/cm

2

K = (OD/ID) of pipe

Hydro test Pressure

P (test) =

1.5 P (operating) *(Allowable stress room temp. / Allowable

stress operating temp.)

Safe Life of Corroded Pipe:

Safe Life = (t

available

t

safe

) / (Corrosion Rate per year)

Safe Working Pressure for Thick-walled Pipes:

P = (((D

2

d

2

)*S) /(3D

4

+ d

4

)

0.5

)

Where, D = Outer Diameter

d = Inside Diameter

S = Allowable Stress, Kg/cm

2

HDPE Pipe

Pipe Thickness, t = (PD)/(2 S

a

+ P)

Where S

a

= S

y

/1.3

S

y

is the reference stress based on HDPE

creep resistance in certain prefixed service

life (varies from 20 year to 50 years)

Example

Low Pressure P = 2 Kg / cm

2

Distribution D = 200 mm

Branch (Nat. Gas) Life = 50 years (Normal Pipe

Temperature = 25

0

C)

S

y

= 10 N / mm

2

= 100 Kg / cm

2

(For Hostalen GM 5010) T2 (GM 5010)

= 7.3 N / mm

2

= 73 Kg/cm

2

S

a

= (S

y

/1.3) 77 Kg/cm

2

(5010 T2)

= 56 Kg/cm

2

(5010)

Example .

Wall Thickness,

t = (2*200)/(2*77+2) = 2.5 mm

(for Hostalen GM 5010 T2)

t = (2*200)/(2*56+2) = 3.5 mm (GM 5010)

Select pipe to HASTI GAS T2, CLASS..

HDPE THICKNESS, t = (P*D)/ 2*S

allowable

+ P)

Where S

allowable

= S

v

/1.3

S

v

is the reference stress based on HDPE creep

resistance in certain prefixed service life (varies from

20 years to 50 years)

PIPE SIZE CALCULATION

PRESSURE DROP IN GAS PIPELINES

HDPE PIPE: Use Weymouth Equation;

Q = A*(P1

2

P2

2

)

0.5

/(S.L.)

Where A is Weymouth HDPE factor; (as listed below):

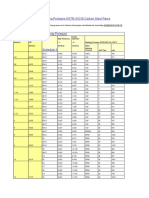

O.D. (mm) Class 3 Class 4 Class 5

50 80.5 69.7 53.6

100 640.4 546.8 410.8

160 1674.6 1460.7 1099.0

200 2987.5 2597.3 1967.2

250 5306.0 4622.2 3485.0

Q = Gas flow rate at STP, m

3

/hr

P1 = Upstream pressure, Kg/cm

2

, Abs

P2 = Down-stream pressure, Kg/cm

2

, Abs

S = Specific Gravity of gas with respect to air (0.695) or approx. 0.7

L = Pipe length in Km.

PIPE SIZE CALCULATION ..

GI PIPE / HDPE PIPE:

For low pressure/low flow conditions:

Q = 0.15228 D

2.623

(h/L)0

.541

Where D = Inside Diameter, mm

h = Pressure Drop, mm Wc.

L = length of Pipe, m.

M.S. / C.I. PIPE:

For medium pressure / flow conditions:

Q = 0.0813 d

2.6664

{(P1

2

P2

2

)/(S.L.)}

0.5

Where d = pipe diameter, mm

P

1

, P

2

= pressures, kg/cm

2

, Abs

S = 0.7 for Natural Gas

L = Pipe length, m

HDPE PIPE:

Q = 0.11672 * d

2.664

{(P1

2

-P2

2

)/(S.L.)}

0.544

FOR C.S. PIPE

HANDLING HIGH PRESSURE/HIGH FLOW GAS;

PAN-HANDLE (REVISED) FORMULA:

Q = 737 (T

o

/P

o

)

1.02

* d

2.53

{(P

1

2

-P

2

2

)/G

0.061

T

f

*L*Z}

0.51

*E

Q = K*d

2

.53 {(P

1

2

-P

2

2

)/L}

0.51

* Z-

0.51

Where, K = {737 * T

o

1.02

* P

o

-

1.02

* G

-0.49

* T

f

-0.51

* E}

Where,

Q = Gas Flow Quantity, Cfd

T

o

= Base Temperature, F Abs.

P

o

= Base Pressure, Psia

d = Pipe Inside Diameter, In.

P1 = Initial Pressure, Psia

P2 = Final Pressure, Psia

C = Specific Gravity of Gas (0.7)

T

f

= Flow Temperature of Gas, F Abs

L = Pipeline Length, Miles

Z = Compressibility Factor of Gas

E = Pipeline Efficiency Factor, (assume 0.9)

Você também pode gostar

- Asme Viii Uhx Tubesheet CalcsDocumento3 páginasAsme Viii Uhx Tubesheet CalcsjdfdfererAinda não há avaliações

- Insulated PipeDocumento54 páginasInsulated Pipedeion29Ainda não há avaliações

- Bio Gas Excel Calculation SheetDocumento5 páginasBio Gas Excel Calculation SheetsrivarmaAinda não há avaliações

- Vdocuments - MX Rectangular Tank CalculationDocumento34 páginasVdocuments - MX Rectangular Tank CalculationAtilla TekinAinda não há avaliações

- Gas Line Capacity CalcDocumento2 páginasGas Line Capacity CalcMario Mendoza100% (1)

- Desuperheater Boiler Feed Water RequirementDocumento2 páginasDesuperheater Boiler Feed Water RequirementMichael HaiseAinda não há avaliações

- Tailing Lifting Lug Design 57 V 202 r2Documento10 páginasTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarAinda não há avaliações

- Rectangular Tanks:: Rectangle Tank DesignDocumento23 páginasRectangular Tanks:: Rectangle Tank Designshna jabarAinda não há avaliações

- Pipe Weight CalculatorDocumento1 páginaPipe Weight Calculatorkenho2Ainda não há avaliações

- Point Load CalculationsDocumento3 páginasPoint Load Calculationskedar kavathekarAinda não há avaliações

- Top Pipe MomentDocumento2 páginasTop Pipe MomentrsubramaniAinda não há avaliações

- Horizontal Cylindrical Tank Volume and Level CalculatorDocumento5 páginasHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraAinda não há avaliações

- Imperial Piping Weight Load Calculation WorkbookDocumento13 páginasImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Piping DesignDocumento9 páginasPiping Designjmclaug502Ainda não há avaliações

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocumento2 páginasMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamAinda não há avaliações

- Total Length Calcs For Pipes Valves and Fittings RevADocumento9 páginasTotal Length Calcs For Pipes Valves and Fittings RevAlutfi awnAinda não há avaliações

- Blank DIa1Documento1 páginaBlank DIa1Makrand SakpalAinda não há avaliações

- Max Allowable Pressure of Pipes and Pipellines CER 04022013Documento89 páginasMax Allowable Pressure of Pipes and Pipellines CER 04022013Castro Quinteros WinstonAinda não há avaliações

- Heat Loss From A Buried Oil PipeDocumento20 páginasHeat Loss From A Buried Oil PipeJuan Pablo ApazaAinda não há avaliações

- Sif B31 3Documento10 páginasSif B31 3Sergio SmithAinda não há avaliações

- Volume Calculation For Pressure VesselDocumento2 páginasVolume Calculation For Pressure VesselVikas NaikAinda não há avaliações

- 302 - Nozzle Design Tool Ver E4.01Documento2 páginas302 - Nozzle Design Tool Ver E4.01Honey TiwariAinda não há avaliações

- Flange Weight ChartDocumento1 páginaFlange Weight Chartabhishek198327Ainda não há avaliações

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDocumento19 páginasPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRaghav SharmaAinda não há avaliações

- Mitered BendsDocumento1 páginaMitered BendsTsouki TsoukiAinda não há avaliações

- Expansion Loop Calculation: IndexDocumento73 páginasExpansion Loop Calculation: IndexNoppolNorasriAinda não há avaliações

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocumento30 páginasWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilAinda não há avaliações

- Pipeline Expansion Loop CalculationsDocumento2 páginasPipeline Expansion Loop CalculationsthehraoAinda não há avaliações

- DheerajDocumento7 páginasDheerajSaksham KakarAinda não há avaliações

- Pipe Insulation THK CalculationDocumento6 páginasPipe Insulation THK Calculationnitin_bir100% (2)

- Manual Calc. of PressureDocumento1 páginaManual Calc. of PressureRio PutraAinda não há avaliações

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 páginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutAinda não há avaliações

- Design-Calculation Acid Wash TankDocumento5 páginasDesign-Calculation Acid Wash TankWiz DomAinda não há avaliações

- Bulk Air Eliminator R1Documento1 páginaBulk Air Eliminator R1hydrothermsAinda não há avaliações

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocumento8 páginasDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocumento5 páginasBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudAinda não há avaliações

- Calculator - U Tubes - HSA & QtyDocumento4 páginasCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocumento7 páginasPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryAinda não há avaliações

- DishDocumento1 páginaDishmishtinilAinda não há avaliações

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDocumento1 páginaXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuAinda não há avaliações

- Calculation BS 31.3Documento1 páginaCalculation BS 31.3prabhjot123Ainda não há avaliações

- CS SS - Pipe Weight CalculationDocumento1 páginaCS SS - Pipe Weight CalculationTashrif Yusuf0% (1)

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocumento7 páginasSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukAinda não há avaliações

- Pressure DropDocumento19 páginasPressure DropGigis Kintan MyarthalunaAinda não há avaliações

- ThicknessDocumento53 páginasThicknessRajul MuraliAinda não há avaliações

- Cast - Basket Strainers - 2nd EditionDocumento27 páginasCast - Basket Strainers - 2nd EditionmartinnovelAinda não há avaliações

- Thk. S.F. K.R.: Dish - Dish 2100Documento3 páginasThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarAinda não há avaliações

- Tank Design MKDocumento18 páginasTank Design MKJoshue AdeleAinda não há avaliações

- And Dipstick Chart: Scroll Down For InstructionsDocumento2 páginasAnd Dipstick Chart: Scroll Down For Instructionspowder18Ainda não há avaliações

- Annex V External PressureDocumento26 páginasAnnex V External PressureJohnny VillarroelAinda não há avaliações

- Pipe or Tubing Support Span CalculationsDocumento9 páginasPipe or Tubing Support Span CalculationskhaireddinAinda não há avaliações

- Pipe Support CalculationDocumento2 páginasPipe Support Calculationjsmnjasmines86% (7)

- Heater 10m2 (ASME Tubesheet)Documento17 páginasHeater 10m2 (ASME Tubesheet)Omil RastogiAinda não há avaliações

- Asme Tubesheet (Heater 10m2)Documento23 páginasAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Hydrotest Pressure CalculationDocumento26 páginasHydrotest Pressure CalculationChetan B Kapadia100% (13)

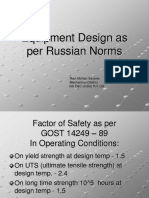

- Equipment Design As Per Russian Norms - 20090218Documento45 páginasEquipment Design As Per Russian Norms - 20090218vikasAinda não há avaliações

- Ibr Calc GSRDocumento4 páginasIbr Calc GSRAniket GaikwadAinda não há avaliações

- Hydrotest Pressure CalculationDocumento26 páginasHydrotest Pressure Calculationrudrakr0% (1)

- K-4b Perhitungan PipaDocumento51 páginasK-4b Perhitungan PipaIndra MaulanaAinda não há avaliações

- Pipe Bend Againts Coating 3LPE AnalisisDocumento25 páginasPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Assessment Plan Welder Level 2Documento14 páginasAssessment Plan Welder Level 2Ravindra S. JivaniAinda não há avaliações

- Welding Processes & Welding Defects: Welding Metallurgy Kanchan KumarDocumento74 páginasWelding Processes & Welding Defects: Welding Metallurgy Kanchan KumarsubhaAinda não há avaliações

- Piping Fabrication Procedure.Documento58 páginasPiping Fabrication Procedure.Janardhan Surya78% (23)

- Welding Procedure SpecificationDocumento1 páginaWelding Procedure Specificationfallalovaldes100% (1)

- Welding Procedure SpecificationDocumento1 páginaWelding Procedure Specificationfallalovaldes100% (1)

- QAQC References 2Documento138 páginasQAQC References 2Mohd SharainiAinda não há avaliações

- Welding PositionDocumento6 páginasWelding Positionenels77Ainda não há avaliações

- Heat ExchangerDocumento420 páginasHeat ExchangerRavindra S. Jivani75% (4)

- Jointech PDFDocumento1 páginaJointech PDFRavindra S. JivaniAinda não há avaliações

- Welding Processes & Welding Defects: Welding Metallurgy Kanchan KumarDocumento74 páginasWelding Processes & Welding Defects: Welding Metallurgy Kanchan KumarsubhaAinda não há avaliações

- Aluminium Welding Pocket GuideDocumento31 páginasAluminium Welding Pocket GuideRavindra S. Jivani100% (1)

- AC and DC WeldingDocumento18 páginasAC and DC WeldingSds Mani SAinda não há avaliações

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Documento18 páginasWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruAinda não há avaliações

- VESSELDocumento350 páginasVESSELRavindra S. JivaniAinda não há avaliações

- Heat ExchangerDocumento420 páginasHeat ExchangerRavindra S. Jivani75% (4)

- RT ProcedureDocumento22 páginasRT ProcedureRavindra S. JivaniAinda não há avaliações

- Coating Adhesion TestingDocumento37 páginasCoating Adhesion TestingRavindra S. Jivani75% (4)

- API 580 Closed Book QuestionsDocumento18 páginasAPI 580 Closed Book QuestionsRavindra S. Jivani86% (7)

- Spiral Pipe FormulaDocumento5 páginasSpiral Pipe FormulaRavindra S. Jivani89% (9)

- API-510 Questions & Answers Closed Book 1Documento12 páginasAPI-510 Questions & Answers Closed Book 1Ravindra S. Jivani70% (10)

- Coating Types and SelectionDocumento48 páginasCoating Types and Selectionalremyze1664Ainda não há avaliações

- API 510 Closed Book QuestionsDocumento16 páginasAPI 510 Closed Book QuestionsRavindra S. Jivani100% (1)

- 6D RootDocumento1 página6D RootRavindra S. JivaniAinda não há avaliações

- BeamDocumento2 páginasBeamRavindra S. JivaniAinda não há avaliações

- 04 - HT - QI - Rev. 0 Hardness ProcedureDocumento4 páginas04 - HT - QI - Rev. 0 Hardness ProcedureviswamanojAinda não há avaliações

- 6C CapDocumento1 página6C CapRavindra S. JivaniAinda não há avaliações

- 6a RootDocumento1 página6a RootRavindra S. JivaniAinda não há avaliações

- Test Pack Table of ContentsDocumento1 páginaTest Pack Table of ContentsRavindra S. JivaniAinda não há avaliações

- 6C CapDocumento1 página6C CapRavindra S. JivaniAinda não há avaliações

- Welding Processes: EN358 - Ship StructuresDocumento27 páginasWelding Processes: EN358 - Ship StructuresMayur PatelAinda não há avaliações

- Saso 2203 - DSDocumento11 páginasSaso 2203 - DSAhmedAinda não há avaliações

- A Coupled Thermal-Granular Model in Flights Rotary Kiln: Industrial Validation and Process DesignDocumento12 páginasA Coupled Thermal-Granular Model in Flights Rotary Kiln: Industrial Validation and Process DesignDouglas TondelloAinda não há avaliações

- Properties of Solution and Vapor/Liquid Equilibrium (VLE)Documento48 páginasProperties of Solution and Vapor/Liquid Equilibrium (VLE)LornaAhlaamiAinda não há avaliações

- Obj 2Documento12 páginasObj 2Himanshu PareekAinda não há avaliações

- C136 PDFDocumento5 páginasC136 PDFleo_pio_ochoaAinda não há avaliações

- Impact Initiation of Explosives and Propellants Via Statistical Crack Mechanics (SD)Documento39 páginasImpact Initiation of Explosives and Propellants Via Statistical Crack Mechanics (SD)kingmajorAinda não há avaliações

- Facade ManualDocumento124 páginasFacade ManualAbdul Boji100% (12)

- READING Chapter 7.1 Life Is CellularDocumento3 páginasREADING Chapter 7.1 Life Is Cellularkathryn_bruyère100% (1)

- Simulation Design Project 2013 PDFDocumento167 páginasSimulation Design Project 2013 PDFNhut NguyenAinda não há avaliações

- Co-Crystal and Eutatic MixtureDocumento11 páginasCo-Crystal and Eutatic MixtureQA Dhq OkaraAinda não há avaliações

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocumento2 páginasExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanAinda não há avaliações

- Seaflo Neo SL Z (1606) PDFDocumento2 páginasSeaflo Neo SL Z (1606) PDFTrịnh Minh KhoaAinda não há avaliações

- 2003 ISJ Mersadetal Colorants PDFDocumento15 páginas2003 ISJ Mersadetal Colorants PDFJose LopezAinda não há avaliações

- Low Mach Number ApproximationDocumento42 páginasLow Mach Number ApproximationDiana MitroiAinda não há avaliações

- Service ProductsDocumento122 páginasService ProductsIswahyudi Aprilyastono100% (1)

- ADA Assay Beckman AU5800 Parameters Rev ADocumento1 páginaADA Assay Beckman AU5800 Parameters Rev AAlberto MarcosAinda não há avaliações

- Class03 ChemistryG12 Notes and HomeworkDocumento68 páginasClass03 ChemistryG12 Notes and HomeworkAndy Rei KouAinda não há avaliações

- Catabolism of Proteins and Amino AcidsDocumento63 páginasCatabolism of Proteins and Amino Acidsflairtique shopAinda não há avaliações

- GRCDocumento3 páginasGRCAristo OnanAinda não há avaliações

- 07 Reactions With CopperDocumento6 páginas07 Reactions With CopperEloizaDaSilvaNunesAinda não há avaliações

- Vogel LS LC LCP BrochureDocumento12 páginasVogel LS LC LCP BrochureDwi Sulistyo BudiAinda não há avaliações

- Microsoft PowerPoint - Strip TheoryDocumento48 páginasMicrosoft PowerPoint - Strip Theoryphantom29Ainda não há avaliações

- Transportation Dangerous GoodsDocumento8 páginasTransportation Dangerous GoodsGreg SanjayaAinda não há avaliações

- PHY 462-Atomic PhysicsDocumento3 páginasPHY 462-Atomic PhysicsAnil karela100% (1)

- Performance On Mechanics of Materials - MAE 243 (Section 002)Documento18 páginasPerformance On Mechanics of Materials - MAE 243 (Section 002)Reivax50Ainda não há avaliações

- January 2017 (IAL) QP - Unit 4 Edexcel Physics A-LevelDocumento24 páginasJanuary 2017 (IAL) QP - Unit 4 Edexcel Physics A-LevelAssad JafferAinda não há avaliações

- Cell Disruption Techquines: By: Ritika SharmaDocumento20 páginasCell Disruption Techquines: By: Ritika SharmaArup ChakrabortyAinda não há avaliações

- Fyp Silica FumeDocumento14 páginasFyp Silica FumeSamiUllahAinda não há avaliações

- 2013 MICAFLUID PresentationDocumento58 páginas2013 MICAFLUID Presentationdenis_alexAinda não há avaliações

- Turbulence InteractionsDocumento402 páginasTurbulence InteractionsMartínAinda não há avaliações