Escolar Documentos

Profissional Documentos

Cultura Documentos

BCP Installation & Commissioning

Enviado por

Krishnan Santhanaraj0 notas0% acharam este documento útil (0 voto)

263 visualizações18 páginasBoiler Water Circulating Pump

Título original

2. BCP Installation & Commissioning

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBoiler Water Circulating Pump

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

263 visualizações18 páginasBCP Installation & Commissioning

Enviado por

Krishnan SanthanarajBoiler Water Circulating Pump

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 18

TORISHIMA

Boiler Circulation Pumps

HLAV

Contents

3. Motor set installation

4. Commissioning and Start-Up

5. Supervision during operation

Training course 2

Installation & commissioning

3.1 Lifting Motor set

Do not remove temporary covers !

Motor assembly : Approx. 7,300 kg

Transport motor set as shown below

Prepare to lift and install motor set

Do not damage motor set !

Lift motor unit carefully

3. Motor Set Installation

Use Chain-block 10tons/2 sets for lifting up & down

Remove temporary cover before motor set

installation, use 1ton Chain Block

Inspect casing and heat barrier sealing

faces and set spiral wound gasket on heat

barrier before motor set installation

Pump casing

Motor set

Sealing face of Pump casing

Bolts

Bottom

3. Pump/Motor Set Installation

3.1 Lifting Motor set

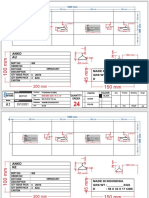

Determine Initial Tightening Starting Position

Measure dimensions B & C at 4 points using

depth gauge and micrometer.

3.1 Lifting Motor set into Pump casing

Calculate starting distance between pump

casing and motor flange (A) by formula

Initial Tightening Starting Position A=C-B+1.6mm

Record dimensions (A, B, C)

Paint bolt numbers on both pump casing and

motor flange (1-16)

Strip paint from a suitable part for micrometer

head at 4 points on bolt pitch-circle ( shown by

arrows in fig. )

Paint bolt numbers

3. Motor Set Installation

3. Motor Set Installation

CAUTION While Lifting Motor set

3.1 Lifting Motor set into Pump casing

Stop Lifting Motor set at the position

Impeller approaches Wearing Ring . Fig1.

Measure 4 points of distance A and adjust

till value of A is same at all points

Lift Motor set slowly by measuring distance

A for the 4 points and carefully operating 2

chain blocks at the same time till Impeller is

positioned into Wearing Ring smoothly as in

Fig2. Initial tightening distance A shall be

followed in item 3.3.

Stop Lifting Motor set in case the Impeller

touches Wearing Ring during lifting, then lift

down Motor set and inspect Impeller & wearing

ring for damage. Repeat lifting and setting by

to properly.

Fig.2

A

Fig.1

A

Coat molybdenum sulfide on

threads of each stud bolt and

mating surface of each washer

Locate washers, and screw nuts onto stud bolts

The head of each stud bolt is to

protrude approx.170mm from motor

flange !

Pump casing

Stud bolt

3-2 Setting Nuts/Washers to Stud Bolts

170mm

3. Motor Set Installation

3.3 Tightening the Stud Bolts

Measure each distance (A) by inside micrometer and confirm the

tolerance is less than or equal to 0.05mm

Mark each nut and motor flange

Nut Scale Division

Mating Mark

3. Motor Set Installation

3.4 Tightening by Bolt Heaters

Confirm that power source is off, then

connect cable to switch box.

Insert a bolt heater into each of 16 stud bolts

Switch on every second bolt heater (1

st

group)

(8 heaters : No.1,3,5,7,9,11,13,15)

Confirm that every second stud bolt is heated

Surface temperature of stud bolts

should not exceed 300 deg.C !

Monitor temperature using a temperature

crayon or surface thermometer

Motor

flange

Stud

bolt

Be careful

of burns !!

3. Pump/Motor Set Installation

23 scale divisions

Switch on first set of 8 bolt heaters to heat up

first 8 stud bolts, then tighten respective nuts by

further 14 scale divisions for a total of 34 scale

divisions. (No.1,3,5,7,9,11,13,15)

3.4 Tightening by Bolt Heaters

Tighten 20 scale divisions first

Switch off bolt heaters and cool

down stud bolts to approx.60 deg. C

Switch on bolt heaters for remaining 8 stud bolts.

Tighten these 8 nuts by 34 scale divisions.

(2

nd

group : No. 2,4,6,8,10,12,14,16)

Switch off bolt heaters and cool

down stud bolts to approx.60 deg. C

After all stud bolts cool down to room temperature,

measure flange to flange distance A at 4 points within

0.05mm. Record the measurements.

20

34

0

Bolt layout

14

3. Motor Set Installation

3.5 Installation of HP Motor cooler

Clean Motor Cooler by water flushing and seal

face of each welded sockets before welding work

Carry proper socket welding to position:

after confirming Motor cooler & HP piping position

Inspect each welded HP connection by PT

Clean LP cooling water piping line to Motor

cooler and carry welding socket connections

Confirm final tightening of bolts (mark ) for

Motor cooler support.

Install the instruments for each position.

3. Motor Set Installation

In case of BHEL

design, these

should be welding

connection

Check water quality and filling rate; Max.5L/min.

Valve1

from BCP purge water cooler

4. Commissioning and Start up

Drain Valve

Fill the water until the quality is

clear and colorless

Close drain valve

Point !

Do not open the drain valve once start

the water filling to the motor

4.1 Priming and venting

Close valve1 and open drain valve fully

4.1 Priming and venting

Open valve 2&3, related air venting

valves fully and open valve1 slowly

Valve2

Valve1

from BCP purge water cooler

4. Commissioning and Start up

Point 2

Priming and Flushing must always be carried

out from the motor bottom to upwards

PI

Point 1

Air shall be removed from motor

Drain valves

shall be closed

Valve3

Check valve2 : Flow rate from

valve1 is max. 5L/min.

Priming Flushing

4.2 Pre Operational Check Items

Operational check items to be monitored

- Temperatures

- Cooling water flow

- Ammeters at switch gear room

- All Motor protection switches

Confirm water filling

Confirm correct direction

Measure insulation resistance

4. Commissioning and Start up

4.2 Pre Operational Check Items

To confirm quantity of LP cooling water

To confirm Motor Cavity temp is below 63 deg. C

To check water level in drum

To complete motor flushing cleaning

To assure pressure tight seals

Need to check Item , ,

in routine starts !

LP : Auxiliary cooling water

HP : High pressure cooling water

in Motor

4. Commissioning and Start up

(1) Drum water level

(2) Differential pressure

(3) Motor current at switch gear room Refer to Data sheet

(4) Motor Cavity temperature 63 deg.C

(5) LP Cooling water flow rate

- Cooler : 150L/min.

- Heat barrier : 30L/min.

(6) LP Cooling water temperature

generally 45 deg. C

(7) Smooth

running or

not

5. Supervision during operation

5.1 At operating

Refer to Data

sheet or P&ID

Maintain the following condition until the boiler water is below 63 deg. C !

(8) LP Cooling water flow

(9) LP Cooling water temperature

(10) Motor Cavity temp.

5. Supervision during operation

5.2 At stopping (after switched off)

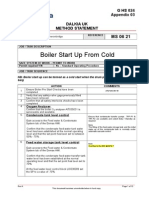

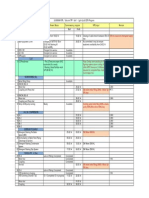

1. Daily inspection check items

No.

Inspection point Inspect. Item Method Criteria Note

1 Suction tank Water level Level detector Min. Water

Level

Daily

2 Pump suc. & dis. pipes Pump differential press.

(During operation)

Pressure gauge Specified

head

Daily

3 Power supply Motor current Current meter Specified

current

Daily

4 Motor cavity HP cooling water temp. Temp. detector Below 63 deg.

C

Daily

5 Motor cooler

LP cooling water outlet

LP cooling water temp. Temp. detector Max. 45 deg.

C

Daily

LP cooling water quantity Flow switch Refer to Data

sheet

Daily

6 Heat barrier

LP cooling water outlet

LP cooling water temp. Temp. detector Max. 45 deg.

C

Daily

LP cooling water quantity Flow switch Refer to Data

sheet

Daily

7 Pump motor Abnormal noise or

vibration

- No

abnormality

Daily

8 HP cooling water lines Leak Visual No leak Daily

(Important)

9 LP cooling water lines Leak Visual No leak Weekly

Recommended inspection;

2. Annual or monthly inspection check items

No.

Inspection

point

Inspect. Item

Method Criteria Note

1 Motor terminal

box

Insulation

resistance

Megger meter

At cold water filling

(at approx. 20deg.C)

At hot stand-by

(at approx. 50deg.C)

200 Mega-

ohm or more.

4 Mega-ohm

or more.

Annual

stage

2 Stand-by pump Start up check Start up stand-by pump No

abnormality

Monthly

No.

Inspection

point

Inspect. Item

Method Criteria Note

1 Pump motor Overhaul Overhaul at

Torishima Works

Instruction

manual

First 1 year

and

thereafter

every 4-

5years

3. Overhaul inspection check items

Recommended inspection;

Disconnect the power cable

Você também pode gostar

- LEGO TechniquesDocumento37 páginasLEGO TechniquesBunnyCoder1100% (3)

- Lancer 2008 PDFDocumento15 páginasLancer 2008 PDFAlejandro Lasaña100% (1)

- Tour Packaging & Sales StrategyDocumento20 páginasTour Packaging & Sales StrategyWhena RiosAinda não há avaliações

- Governor TutorialDocumento13 páginasGovernor TutorialWalid Fattah100% (1)

- Rim and Face Shaft AlignmentDocumento38 páginasRim and Face Shaft AlignmentJaime Berry100% (2)

- Thrust Bearing End PlayDocumento3 páginasThrust Bearing End PlayKrishnan SanthanarajAinda não há avaliações

- Generator Protection Unit#3 KMPCLDocumento15 páginasGenerator Protection Unit#3 KMPCLAmaresh NayakAinda não há avaliações

- Design of Major Bridge at CH 3+300 PDFDocumento363 páginasDesign of Major Bridge at CH 3+300 PDFNilay GandhiAinda não há avaliações

- Engine MechanicDocumento631 páginasEngine Mechanicgeorge100% (1)

- SOP TG Rolling and SynchronisationDocumento13 páginasSOP TG Rolling and Synchronisationmoovendan pAinda não há avaliações

- NTPC Quality InspectionDocumento39 páginasNTPC Quality InspectionPower Power60% (5)

- Review of Type IV Cracking of Weldments in 9Documento64 páginasReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajAinda não há avaliações

- TG Ele Hydro Oil PumpDocumento8 páginasTG Ele Hydro Oil PumpsambhuAinda não há avaliações

- Heavy Duty Pavement Design GuideDocumento94 páginasHeavy Duty Pavement Design GuideMMexp100% (2)

- BCP Installation & CommissioningDocumento18 páginasBCP Installation & CommissioningPradeep Srikanth100% (2)

- Final AOH Report - TMD 060818Documento15 páginasFinal AOH Report - TMD 060818sanmukhaAinda não há avaliações

- MDBFPDocumento21 páginasMDBFPRaja Vignesh100% (1)

- FIELD QUALITY PLAN FOR TURBO GENERATOR ERECTION AND COMMISSIONINGDocumento85 páginasFIELD QUALITY PLAN FOR TURBO GENERATOR ERECTION AND COMMISSIONINGjp mishraAinda não há avaliações

- Turbine Protection & InterlockDocumento7 páginasTurbine Protection & InterlockSony RamaAinda não há avaliações

- 212292Documento91 páginas212292Jaime BerryAinda não há avaliações

- NTPC Safety Rules SummaryDocumento109 páginasNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- NTPC Safety Rules SummaryDocumento109 páginasNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- 660MW Emergency Operating ProcedureDocumento117 páginas660MW Emergency Operating ProceduregARRYAinda não há avaliações

- HP LP BypassDocumento37 páginasHP LP BypassSCE RIHANDAinda não há avaliações

- 1kr Fe CoolingDocumento128 páginas1kr Fe Coolingfguij100% (1)

- 6.6 KV Switchgear Charging & IsolationDocumento12 páginas6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuAinda não há avaliações

- Report EHTC HuntingDocumento10 páginasReport EHTC HuntingOTPC POWERAinda não há avaliações

- POWER PLANT GENERATOR OPERATION & AUXILIARIESDocumento30 páginasPOWER PLANT GENERATOR OPERATION & AUXILIARIESrohit_0123100% (2)

- CMC NTPC Unchahar PDFDocumento48 páginasCMC NTPC Unchahar PDFDinoAinda não há avaliações

- 660MW Turbo Generator & Its AuxiliariesDocumento88 páginas660MW Turbo Generator & Its AuxiliariesAshvani ShuklaAinda não há avaliações

- XE360U Operators ManualDocumento161 páginasXE360U Operators Manualjadan tupuaAinda não há avaliações

- Monitoring Stator Water Systems for Large Turbine GeneratorsDocumento12 páginasMonitoring Stator Water Systems for Large Turbine GeneratorsUmesh HadiyaAinda não há avaliações

- Cold Startup Procedure 250 MWDocumento7 páginasCold Startup Procedure 250 MWPrudhvi RajAinda não há avaliações

- Commissioning Procedure for Turbine Barring GearDocumento9 páginasCommissioning Procedure for Turbine Barring Gearjp mishraAinda não há avaliações

- Gen-Seal&cool-New - 500 MWDocumento98 páginasGen-Seal&cool-New - 500 MWharisankar100% (2)

- Animated Soot BlowerDocumento15 páginasAnimated Soot BlowerPrudhvi RajAinda não há avaliações

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineDocumento8 páginasOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajAinda não há avaliações

- Power Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Documento43 páginasPower Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Alok Ranjan Tripathi100% (1)

- Management of DC Supply Failure.05.07.2020Documento66 páginasManagement of DC Supply Failure.05.07.2020ntpc bgtppAinda não há avaliações

- Turbine Working & ItsComponentsDocumento88 páginasTurbine Working & ItsComponentsHimanshu spoliaAinda não há avaliações

- 020-SOP of H2 CYLINDER Room ChargingDocumento4 páginas020-SOP of H2 CYLINDER Room ChargingsambhuAinda não há avaliações

- BS 873 - Traffic Cones and CylindersDocumento14 páginasBS 873 - Traffic Cones and CylindersVicky MunienAinda não há avaliações

- Generator ProtectionDocumento24 páginasGenerator ProtectionSantoshkumar Gupta100% (1)

- Turbine Operational ProblemsDocumento35 páginasTurbine Operational Problemsna2011100% (1)

- Hatch Covers Practical GuideDocumento53 páginasHatch Covers Practical Guidemaneesh100% (3)

- CC PumpsDocumento38 páginasCC PumpsvijaykrishnatennetiAinda não há avaliações

- Piston Pin Specifications for Audi, Austin, BMW, Bedford, and FordDocumento71 páginasPiston Pin Specifications for Audi, Austin, BMW, Bedford, and FordErickAinda não há avaliações

- 04 - Part A - TrackDocumento93 páginas04 - Part A - TrackJayanta MondalAinda não há avaliações

- Protection of GeneratorDocumento60 páginasProtection of GeneratorIsradani MjAinda não há avaliações

- MS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Documento12 páginasMS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Prakash WarrierAinda não há avaliações

- PGPTPT SyllabusDocumento31 páginasPGPTPT Syllabussatish20ntrAinda não há avaliações

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Documento45 páginasTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940Ainda não há avaliações

- ID FD PA Logic SystemDocumento11 páginasID FD PA Logic SystemThirumalAinda não há avaliações

- Generator Protection Theory and LogicDocumento32 páginasGenerator Protection Theory and LogicEr Jitender Kumar100% (2)

- Essential Interlocks and Protections for Feed Water and Condensate SystemsDocumento18 páginasEssential Interlocks and Protections for Feed Water and Condensate SystemsSanjay GuptaAinda não há avaliações

- Power PlantDocumento28 páginasPower PlantSanjay SharmaAinda não há avaliações

- FANS: Types, Features, Selection FactorsDocumento15 páginasFANS: Types, Features, Selection FactorsgvprambabuAinda não há avaliações

- Common Problems Observed and Its RemedyDocumento6 páginasCommon Problems Observed and Its RemedyMayank KumarAinda não há avaliações

- Steam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestDocumento10 páginasSteam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestAakash RanjanAinda não há avaliações

- Vibration of Turbine PDFDocumento4 páginasVibration of Turbine PDFsanjeevchhabraAinda não há avaliações

- MANAGEMENT OF 24V DC SUPPLY FAILURE FOR SG/TG SYSTEMDocumento23 páginasMANAGEMENT OF 24V DC SUPPLY FAILURE FOR SG/TG SYSTEMShiftinchargeengineer dadri coalAinda não há avaliações

- CW, CWR & CWX Pumps Installation, Operation and Maintenance ManualDocumento20 páginasCW, CWR & CWX Pumps Installation, Operation and Maintenance ManualNadeemAinda não há avaliações

- FD FanDocumento5 páginasFD FanPrudhvi RajAinda não há avaliações

- ESP Hopper Heaters Are Continuously Energised Due To Insulation FailureDocumento3 páginasESP Hopper Heaters Are Continuously Energised Due To Insulation FailuresanjeevchhabraAinda não há avaliações

- Generator Seal Oil System-X9000067EDocumento24 páginasGenerator Seal Oil System-X9000067EOry'sSebayang100% (1)

- Frequent Tripping of VFD On BUSHOG - JUN10 PDFDocumento2 páginasFrequent Tripping of VFD On BUSHOG - JUN10 PDFsanjeevchhabraAinda não há avaliações

- Missed Hole Caused Malfunction of Hydraulic Low Vacuum Trip DeviceDocumento3 páginasMissed Hole Caused Malfunction of Hydraulic Low Vacuum Trip Devicetsrinivasan5083Ainda não há avaliações

- ESP Charging ProcedureDocumento3 páginasESP Charging ProcedurevikramshounAinda não há avaliações

- Testing of Turbo GeneratorsDocumento4 páginasTesting of Turbo Generatorsemmanuel akaAinda não há avaliações

- CEP Isolation & Normalisation ProcedureDocumento2 páginasCEP Isolation & Normalisation ProcedureVishal GuptaAinda não há avaliações

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Documento14 páginasSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaAinda não há avaliações

- 10 - Bus Transfer System Retroffiting - Concept NoteDocumento9 páginas10 - Bus Transfer System Retroffiting - Concept Notevitthal01Ainda não há avaliações

- Esp 100 TPD Precicon 3 Drawing PDFDocumento1 páginaEsp 100 TPD Precicon 3 Drawing PDFSteve WanAinda não há avaliações

- Troubleshoot Power Issues & Detect Faults QuicklyDocumento10 páginasTroubleshoot Power Issues & Detect Faults QuicklyBala SubramanianAinda não há avaliações

- Scanner Air FanDocumento3 páginasScanner Air FanSamAinda não há avaliações

- Power Plant C&I Systems: Coordinated Master ControlDocumento30 páginasPower Plant C&I Systems: Coordinated Master ControlStage2 C&I ShiftAinda não há avaliações

- HP Heaters Operation During Start Up of UnitDocumento1 páginaHP Heaters Operation During Start Up of UnitMuhammad luqman100% (1)

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Documento9 páginasSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraAinda não há avaliações

- Easidew Manual (BHEL)Documento57 páginasEasidew Manual (BHEL)NILESH100% (1)

- BCP Dismantling & OH With Trouble ShootingDocumento24 páginasBCP Dismantling & OH With Trouble ShootingKrishnan SanthanarajAinda não há avaliações

- Shutdown Maintenance ScaffoldDocumento1 páginaShutdown Maintenance ScaffoldKrishnan SanthanarajAinda não há avaliações

- Instant Up Right Cat 2015Documento40 páginasInstant Up Right Cat 2015Krishnan SanthanarajAinda não há avaliações

- Us5282442 PDFDocumento6 páginasUs5282442 PDFKrishnan SanthanarajAinda não há avaliações

- Bowl Mill-Feb 2009Documento12 páginasBowl Mill-Feb 2009Krishnan SanthanarajAinda não há avaliações

- Unit I Divisional Superheater Coil Puncture On 10Documento1 páginaUnit I Divisional Superheater Coil Puncture On 10Krishnan SanthanarajAinda não há avaliações

- Managing Air To Improve Combustion EfficiencyDocumento12 páginasManaging Air To Improve Combustion EfficiencyKrishnan SanthanarajAinda não há avaliações

- A System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsDocumento25 páginasA System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsKrishnan SanthanarajAinda não há avaliações

- Pulverizer Fire and ExplosionDocumento4 páginasPulverizer Fire and ExplosionKrishnan SanthanarajAinda não há avaliações

- The Thrust PadDocumento2 páginasThe Thrust PadKrishnan SanthanarajAinda não há avaliações

- Plant Schematics Rev.01Documento67 páginasPlant Schematics Rev.01Krishnan SanthanarajAinda não há avaliações

- Tri Sec AphDocumento36 páginasTri Sec AphKrishnan Santhanaraj100% (1)

- Sag ChartDocumento1 páginaSag ChartKrishnan SanthanarajAinda não há avaliações

- 226Documento2 páginas226Krishnan SanthanarajAinda não há avaliações

- 33-1985 Evaluating Thrust Bearing Operating TemperaturesDocumento7 páginas33-1985 Evaluating Thrust Bearing Operating TemperaturesMohammad Fikri JalaludinAinda não há avaliações

- Boilers 1Documento29 páginasBoilers 1Thakur Kamal Prasad50% (2)

- History of Hitachi Power EuropeDocumento4 páginasHistory of Hitachi Power EuropeKrishnan SanthanarajAinda não há avaliações

- Dry Flue Gases Losses in BoilerDocumento2 páginasDry Flue Gases Losses in BoilerKrishnan SanthanarajAinda não há avaliações

- Tri Sec AphDocumento36 páginasTri Sec AphKrishnan Santhanaraj100% (1)

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Documento74 páginasPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Krishnan SanthanarajAinda não há avaliações

- NTPL U1 Edta Prog 200214Documento2 páginasNTPL U1 Edta Prog 200214SethuRamalingamAinda não há avaliações

- HILUX - TCM 3040 1610330Documento2 páginasHILUX - TCM 3040 1610330aaaAinda não há avaliações

- Customer Perceptions of Honda CarsDocumento66 páginasCustomer Perceptions of Honda CarsPankajPetwalAinda não há avaliações

- Autoflug Fuel en 2016 RZ WebDocumento2 páginasAutoflug Fuel en 2016 RZ WebanuradhaAinda não há avaliações

- Rouen Vor Replaced by A Temporary Vor On Freq 117.2, Ident VMP Operating at Same PositionDocumento31 páginasRouen Vor Replaced by A Temporary Vor On Freq 117.2, Ident VMP Operating at Same PositionAugustin PAinda não há avaliações

- 58X32X17Documento2 páginas58X32X17mungkin bisaAinda não há avaliações

- Data Gearmotor Gearbox DMILDocumento1 páginaData Gearmotor Gearbox DMILDedi Arisman SaputraAinda não há avaliações

- 6 ASEGH - Marshalling AircraftDocumento38 páginas6 ASEGH - Marshalling AircraftRon McintyreAinda não há avaliações

- Jack+Knife+Diagram CompletedDocumento2 páginasJack+Knife+Diagram CompletedrafaelgrippAinda não há avaliações

- Tata Motors Limited (Formerly TELCO, Short For Tata Engineering and Locomotive Company) Is An IndianDocumento2 páginasTata Motors Limited (Formerly TELCO, Short For Tata Engineering and Locomotive Company) Is An IndianLevale XrAinda não há avaliações

- Business Proposal: by Anand. TDocumento14 páginasBusiness Proposal: by Anand. TAnand ThiyagarajanAinda não há avaliações

- TRAFFICDocumento4 páginasTRAFFICJuan, Daniella MarieAinda não há avaliações

- Maintenance Schedule of Electrical Point Detector (EPD) : para No. 19.9.5Documento1 páginaMaintenance Schedule of Electrical Point Detector (EPD) : para No. 19.9.5Saurabh MoharirAinda não há avaliações

- STUDENT DATA LIST WITH FATHER'S NAME AND CATEGORYDocumento12 páginasSTUDENT DATA LIST WITH FATHER'S NAME AND CATEGORYsavan anvekarAinda não há avaliações

- The Enhancement of Shore EquipmentDocumento2 páginasThe Enhancement of Shore EquipmentÓranAinda não há avaliações

- BMW Inspection II Guide for E36 E46 E39 E38 E52Documento3 páginasBMW Inspection II Guide for E36 E46 E39 E38 E52Douglas fabian PeñaililloAinda não há avaliações

- Strategic Renewal and Action Plan For: Kilcona ParkDocumento62 páginasStrategic Renewal and Action Plan For: Kilcona ParkTessa VanderhartAinda não há avaliações

- Train Accident Prevention by Fault Track: Aurora'S Technological and Research InstituteDocumento16 páginasTrain Accident Prevention by Fault Track: Aurora'S Technological and Research InstituteSandhya SanviAinda não há avaliações

- Case Study of Delhi MetroDocumento14 páginasCase Study of Delhi MetroMaria FernandesAinda não há avaliações

- Volvo S40 ManualDocumento226 páginasVolvo S40 ManualJiannis Kouts100% (1)

- Yale Warranty 2020Documento6 páginasYale Warranty 2020Lực NguyễnAinda não há avaliações