Escolar Documentos

Profissional Documentos

Cultura Documentos

Supply Chain Management

Enviado por

dineshsirasatDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supply Chain Management

Enviado por

dineshsirasatDireitos autorais:

Formatos disponíveis

Supply Chain Management

Strategy and Design

Beni Asllani

University of Tennessee at Chattanooga

Operations Management - 6

th

Edition

Chapter 10

Roberta Russell & Bernard W. Taylor, III

Lecture Outline

The management of supply chains

Information technology: a supply chain

enabler

Supply chain integration

Supply chain management (SCM)

software

Measuring supply chain performance

10-2

Supply Chains

All facilities, functions, and activities

associated with flow and transformation

of goods and services from raw materials

to customer, as well as the associated

information flows

An integrated group of processes to

source, make, and deliver products

10-3

Supply Chain Illustration

10-4

Supply

chain for

denim

jeans

10-5

Supply

chain for

denim

jeans

(cont.)

10-6

Supply Chain Processes

10-7

Supply Chain for Service

Providers

More difficult than manufacturing

Does not focus on the flow of physical

goods

Focuses on human resources and

support services

More compact and less extended

10-8

Value Chains

Value chain

every step from raw materials to the eventual end user

ultimate goal is delivery of maximum value to the end user

Supply chain

activities that get raw materials and subassemblies into

manufacturing operation

ultimate goal is same as that of value chain

Demand chain

increase value for any part or all of chain

Terms are used interchangeably

Value

creation of value for customer is important aspect of supply

chain management

10-9

Supply Chain Management (SCM)

Managing flow of information through supply

chain in order to attain the level of

synchronization that will make it more

responsive to customer needs while lowering

costs

Keys to effective SCM

information

communication

cooperation

trust

10-10

Supply Chain

Uncertainty and Inventory

One goal in SCM:

respond to uncertainty in

customer demand without

creating costly excess

inventory

Negative effects of

uncertainty

lateness

incomplete orders

Inventory

insurance against supply

chain uncertainty

Factors that contribute to

uncertainty

inaccurate demand

forecasting

long variable lead times

late deliveries

incomplete shipments

product changes

batch ordering

price fluctuations and

discounts

inflated orders

10-11

Bullwhip Effect

Occurs when slight demand variability is

magnified as information moves back

upstream

10-12

Risk Pooling

Risks are aggregated to reduce the

impact of individual risks

Combine inventories from multiple locations

into one

Reduce parts and product variability,

thereby reducing the number of product

components

Create flexible capacity

10-13

Information Technology:

A Supply Chain Enabler

Information links all aspects of supply chain

E-business

replacement of physical business processes with

electronic ones

Electronic data interchange (EDI)

a computer-to-computer exchange of business

documents

Bar code and point-of-sale

data creates an instantaneous computer record of a

sale

10-14

Information Technology:

A Supply Chain Enabler (cont.)

Radio frequency identification (RFID)

technology can send product data from an item to a

reader via radio waves

Internet

allows companies to communicate with suppliers,

customers, shippers and other businesses around

the world instantaneously

Build-to-order (BTO)

direct-sell-to-customers model via the Internet;

extensive communication with suppliers and

customer

10-15

Supply Chain Enablers

10-16

RFID Capabilities

10-17

RFID Capabilities (cont.)

10-18

Supply Chain Integration

Information sharing among supply chain members

Reduced bullwhip effect

Early problem detection

Faster response

Builds trust and confidence

Collaborative planning, forecasting, replenishment,

and design

Reduced bullwhip effect

Lower costs (material, logistics, operating, etc.)

Higher capacity utilization

Improved customer service levels

10-19

Supply Chain Integration (cont.)

Coordinated workflow, production and operations,

procurement

Production efficiencies

Fast response

Improved service

Quicker to market

Adopt new business models and technologies

Penetration of new markets

Creation of new products

Improved efficiency

Mass customization

10-20

Collaborative Planning,

Forecasting, and Replenishment

Process for two or more companies in a supply

chain to synchronize their demand forecasts

into a single plan to meet customer demand

Parties electronically exchange

past sales trends

point-of-sale data

on-hand inventory

scheduled promotions

forecasts

10-21

Supply Chain Management

(SCM) Software

Enterprise resource planning (ERP)

software that integrates the components of a

company by sharing and organizing

information and data

10-22

Key Performance Indicators

Metrics used to measure supply chain performance

Inventory turnover

Total value (at cost) of inventory

Days of supply

Fill rate: fraction of orders filled by a distribution center within

a specific time period

inventory of value aggregate Average

sold goods of Cost

turns Inventory

10-23

) item e (unit valu ) item for inventory (average inventory of value aggregate Average i i

days) sold)/(365 goods of (Cost

inventory of value aggregate Average

supply of Days

Computing

key

performance

indicators

10-24

Process Control and SCOR

Process Control

not only for manufacturing operations

can be used in any processes of supply

chain

Supply Chain Operations Reference

(SCOR)

a cross industry supply chain diagnostic tool

maintained by the Supply Chain Council

10-25

SCOR

10-26

SCOR

(cont.)

10-27

10-28

Copyright 2009 John Wiley & Sons, Inc.

All rights reserved. Reproduction or translation of this

work beyond that permitted in section 117 of the 1976

United States Copyright Act without express permission

of the copyright owner is unlawful. Request for further

information should be addressed to the Permission

Department, John Wiley & Sons, Inc. The purchaser

may make back-up copies for his/her own use only and

not for distribution or resale. The Publisher assumes no

responsibility for errors, omissions, or damages caused

by the use of these programs or from the use of the

information herein.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- TAX Allowable Deductions-1Documento35 páginasTAX Allowable Deductions-1lyza nedtranAinda não há avaliações

- RB Statement 2022 12 12 448307994Documento15 páginasRB Statement 2022 12 12 448307994akhbar akhbar0% (1)

- Introduction To Travel ServicesDocumento11 páginasIntroduction To Travel ServicesShivarajkumar Jayaprakash100% (1)

- Plastic MoneyDocumento13 páginasPlastic MoneyPrashant Jadhav70% (10)

- Bank StatementsDocumento14 páginasBank StatementsDanielle Ann OreaAinda não há avaliações

- Account Statement 111021 300622Documento48 páginasAccount Statement 111021 300622My Honest TalksAinda não há avaliações

- Inter City & Intra City TrafficDocumento11 páginasInter City & Intra City TrafficDebanshu Payra100% (2)

- Monzo Bank Statement 2020 12 01-2020 12 31 8417Documento27 páginasMonzo Bank Statement 2020 12 01-2020 12 31 8417Vitor BinghamAinda não há avaliações

- Sacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20Documento5 páginasSacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20dineshsirasatAinda não há avaliações

- Antiviral Research: A A A B BDocumento4 páginasAntiviral Research: A A A B BUssr NavyAinda não há avaliações

- Union Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhDocumento1 páginaUnion Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhdineshsirasatAinda não há avaliações

- Maharashtra State Road Transport Corpora On E-Reserva On TicketDocumento1 páginaMaharashtra State Road Transport Corpora On E-Reserva On TicketdineshsirasatAinda não há avaliações

- Union Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhDocumento1 páginaUnion Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhdineshsirasatAinda não há avaliações

- DrSavkar HealthDocumento2 páginasDrSavkar HealthdineshsirasatAinda não há avaliações

- Roll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationDocumento2 páginasRoll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationdineshsirasatAinda não há avaliações

- To 2Documento2 páginasTo 2dineshsirasatAinda não há avaliações

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSDocumento1 página1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatAinda não há avaliações

- Diat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)Documento48 páginasDiat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)dineshsirasatAinda não há avaliações

- ToDocumento2 páginasTodineshsirasatAinda não há avaliações

- Instrumentation Control, Data Acquisition and Processing With MATLABDocumento1 páginaInstrumentation Control, Data Acquisition and Processing With MATLABdineshsirasatAinda não há avaliações

- Commented - Atmanirbhar Bharat in Archery - FinalDocumento3 páginasCommented - Atmanirbhar Bharat in Archery - FinaldineshsirasatAinda não há avaliações

- Standard Pipe Sizes ME303-4.1.1Documento5 páginasStandard Pipe Sizes ME303-4.1.1manashbdAinda não há avaliações

- DocumentDocumento2 páginasDocumentdineshsirasatAinda não há avaliações

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSDocumento1 página1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatAinda não há avaliações

- Vatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006Documento3 páginasVatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006dineshsirasatAinda não há avaliações

- Using The ETDR Word Template: Masters Theses and ReportsDocumento22 páginasUsing The ETDR Word Template: Masters Theses and ReportsdineshsirasatAinda não há avaliações

- FasDocumento1 páginaFasdineshsirasatAinda não há avaliações

- Tips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormDocumento6 páginasTips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormdineshsirasatAinda não há avaliações

- New Text DocumentDocumento1 páginaNew Text DocumentdineshsirasatAinda não há avaliações

- Concrete LinksDocumento2 páginasConcrete LinksdineshsirasatAinda não há avaliações

- Zoom MeetingDocumento2 páginasZoom MeetingdineshsirasatAinda não há avaliações

- CoronaDocumento1 páginaCoronadineshsirasatAinda não há avaliações

- Motor PoDocumento2 páginasMotor PodineshsirasatAinda não há avaliações

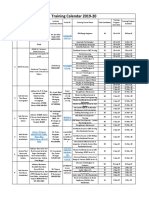

- Training Calender 2019-20Documento3 páginasTraining Calender 2019-20dineshsirasatAinda não há avaliações

- ToDocumento1 páginaTodineshsirasatAinda não há avaliações

- ApprciationDocumento1 páginaApprciationdineshsirasatAinda não há avaliações

- Nashik Profile PDFDocumento33 páginasNashik Profile PDFsusegaad100% (1)

- FIR SubmissionDocumento1 páginaFIR SubmissiondineshsirasatAinda não há avaliações

- Account Statement: Date Value Date Description Cheque Deposit Withdrawal BalanceDocumento2 páginasAccount Statement: Date Value Date Description Cheque Deposit Withdrawal Balanceanil sangwanAinda não há avaliações

- Xtreme Dance January Newsletter 2012Documento1 páginaXtreme Dance January Newsletter 2012incontroltechAinda não há avaliações

- Offer: It Part No. Quty PU Price/unit Total Price Description Extra Deduction or Surchar EUR EURDocumento3 páginasOffer: It Part No. Quty PU Price/unit Total Price Description Extra Deduction or Surchar EUR EURMichelAinda não há avaliações

- Fraud Email Examples PDFDocumento83 páginasFraud Email Examples PDFnacyAinda não há avaliações

- PI FormatDocumento5 páginasPI FormatKalkidan BekeleAinda não há avaliações

- BPI Express Online PDFDocumento2 páginasBPI Express Online PDFAce ViarAinda não há avaliações

- Asset Issuance SlipDocumento105 páginasAsset Issuance SlipMuneer HussainAinda não há avaliações

- NEFT Form - South Indian BankDocumento1 páginaNEFT Form - South Indian BankNETWAY SOLUTIONS KAYAMKULAMAinda não há avaliações

- ReportDocumento4 páginasReportredwanAinda não há avaliações

- 2013 Bar Questions On Taxation Gen Pri and IncomeDocumento4 páginas2013 Bar Questions On Taxation Gen Pri and IncomeSheena PalmaresAinda não há avaliações

- SKCC of Barangay Station Church SiteDocumento3 páginasSKCC of Barangay Station Church SiteRolito AvilaAinda não há avaliações

- Standard Bank Elite Banking 2020Documento7 páginasStandard Bank Elite Banking 2020BusinessTechAinda não há avaliações

- Chapter-20 Inventory ManagementDocumento20 páginasChapter-20 Inventory ManagementPooja SheoranAinda não há avaliações

- Oracle Apps - Third Party Payments in Oracle Payables R12 PDFDocumento6 páginasOracle Apps - Third Party Payments in Oracle Payables R12 PDFAhmed ElhendawyAinda não há avaliações

- Fendy Yudha Ci 29 JanDocumento3 páginasFendy Yudha Ci 29 JanEcommerce The ManoharaAinda não há avaliações

- Bharat Bill Payments System: Cash Management ServicesDocumento8 páginasBharat Bill Payments System: Cash Management ServicesGaurav GuptaAinda não há avaliações

- Formular Rezervare DfdsDocumento1 páginaFormular Rezervare Dfdscriss5078Ainda não há avaliações

- Biaya Pengantar Do Bma-2001002-1 PPJK MBS PDFDocumento1 páginaBiaya Pengantar Do Bma-2001002-1 PPJK MBS PDFBella TanuAinda não há avaliações

- Transaction Date Value Date Cheque Number/ Transaction Number Description Debit Credit Running BalanceDocumento3 páginasTransaction Date Value Date Cheque Number/ Transaction Number Description Debit Credit Running BalancejyothiAinda não há avaliações

- IRS Publication 15 Withholding Tax Tables 2010Documento73 páginasIRS Publication 15 Withholding Tax Tables 2010Wayne Schulz100% (1)

- MM300 - Introduction To MM: Intro/Overview of MM MM - 300 - 1.1Documento7 páginasMM300 - Introduction To MM: Intro/Overview of MM MM - 300 - 1.1arunvasamAinda não há avaliações

- Waterfront v. CIRDocumento18 páginasWaterfront v. CIRaudreydql5Ainda não há avaliações