Escolar Documentos

Profissional Documentos

Cultura Documentos

MOHAN

Enviado por

Karthigaiselvan ShanmuganathanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MOHAN

Enviado por

Karthigaiselvan ShanmuganathanDireitos autorais:

Formatos disponíveis

Study and testing of biogas based diesel dual

fuelled engine

Presented by

Name : MOHAN SINGH

Reg.no: 12PEMS 54002

Automotive Mechatronics

OBJECTIVE

To check the feasibility of biogas based

diesel dual fuelled engine for the long term

automotive application.

INTRODUCTION

The continuosly increasing international

energy demands and the induction of

stringent exhaust emission standard has

greatly pushed for the use of alternative

fuel.

Dual fuel IC Engine

Conventional ic engines operate on a

mono fuel either liquid or gaseous.

However dual fuelled engine operates on

two fuels, normally one s gaseous and

another one is liquid.

MODIFICATION NEEDED

it is possible to run a diesel vehicle on a

biogas/diesel blend (e.g., 90% biogas,

10% diesel) using a modified diesel

engine.

The modifications needed for dual-fuel

operation include two fuel injection

systems (for the biogas and the diesel), a

second fuel line and a tank to hold the

biogas.

WORKING PRINCIPLE

Primary fuel: Biomethane

Secondary fuel: Diesel

Works on diesel cycle

In four stroke cycle engine the gas is

supplied in the inlet manifold,where it

mixes with the incoming air to form a

homogeneous mixture.

Biogas

Biogas is produced from the breakdown of

organic materials such as manure, food

waste or sewage in an anaerobic digester

in the absence of oxygen. In its non-

refined state, biogas consists of 50%60%

methane (CH4), 40%50% carbon dioxide

(CO2) and some trace amounts of

impurities

Biomethane

. Biogas that has been refined or

"upgraded" to higher CH4 levels and lower

CO2 levels is called biomethane or

renewable natural gas. Once biogas is

cleaned and upgraded to biomethane, it is

(chemically) virtually the same as NG

Production of biomethane

There are 3 stages to the production of bio-methane:

Pre-treatment

Digestion

Upgrading

CO2 SURUBBING UNIT

Dual fuel IC Engine

it is possible to run a diesel vehicle on a

biogas/diesel blend (e.g., 90% biogas,

10% diesel) using a modified diesel

engine.

. The modifications needed for dual-fuel

operation include two fuel injection

systems (for the biogas and the diesel), a

second fuel line and a tank to hold the

biogas.

Working of dual fuelled

engine

The engine runs by injecting biogas into

the engine on the air intake stroke (since

the methane does not ignite upon

compression). The diesel is injected and

ignited, which then ignites the biogas,

effectively acting like a spark plug

The engine runs by injecting biogas into the engine on the air intake stroke (since the methane does not ignite upon compression). The diesel is injected and ignited, which then ignites the biogas, effectively acting like a spark plug

Continued.

In a dual-fuel configuration, the engine

starts on 100% diesel, and the fuel

injection technology increases the biogas

ratio as high as the drive cycle will allow

(to a maximum of 90%).

Altenative methods for

modification of diesel

engine

By replacing the fuel injectors with spark

plugs and replacing the fuel pump with a

gas carburetor.

By using diesel fuel for ignition and adding

a carburetor for the biogas as well as

advancing the ignition timing.

TEST PROCEDURE

The experimental investigation was

conducted in two phases. In the first phase,

engine performances and fuel

consumptions for both modes of fuelling were

determined

The engine was test at steady state with

different engine speeds and loads. The

test speeds were

1000, 1200, 1500, 1800, 2000 and 2400

rpm

TEST SYSTEM

Test system

The experimental investigation was

conducted in two phases. In the first

phase, engine performances and fuel

consumptions for both modes of fuelling

were determined.

. The engine torque was varied until the

maximum value available at each test

speed was attained. For each test point, a

set of parameters for both fuelling modes

was measured.

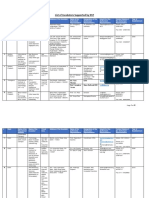

TEST RESULTS

VARIATION OF BSFC W.R.T TO

ENGINE SPEED

VARIATION OF BSFC W.R.T

ENGINE LOAD

Energy content of biogas and

diesel

11 Nm3 biogas : 6.5 KWh

1 ltr. Diesel : 9.1 KWh

Diesel fuelling

Engine

speed

(rpm)

1000 1200 1500 1800 2000 2400

Ambient

air

temp.(c)

33.1 26.1 28.1 33.2 36.2 31.1

Brake

torque(N

m)

37.51 38.66 41.97 41.36 40.59 35.93

Bmep(kp

a)

754 777 844 832 816 723

DUAL FUELLING

Engine

speed

1000.6 1200 1500 1800 2000 2400

Amb. Air

temp.(c)

33.2

26.1 28.1 33.2 36.1 31.2

Brake

Torque(N

m)

37.54 36.68 41.98 41.51 40.52 35.89

Bmep(kp

a)

755 788 844 835 815 722

conclusion

An experimental investigation of an

unmodified small biogas premixed

charge diesel CI dual fuelling engine

was conducted with the concern on

engine performance, maximizing diesel

fuel substitution, energy consumption and

long term use. The following results were

obtained and concluded.

CONTINUED..

Biogas premixed charge diesel dual

fuelling for the engine produced almost no

performance deterioration at all test

speeds.

. The DDF mode resulted in lower

exhaust gas temperature regardless of

engine load and speed, higher cooling

water and lube oil temperatures at high

loads and high engine speeds.

.

The efficiency deterioration reduced when

engine load increased. At full load, the

efficiency was comparable with that in

diesel fuelling. It is then inferred that at

low/medium loads, the DDF engine

produced higher unburned hydrocarbon

and less soot.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Synchro IzerDocumento3 páginasSynchro IzerKarthigaiselvan ShanmuganathanAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- List of IncubatorsDocumento41 páginasList of IncubatorsKarthigaiselvan ShanmuganathanAinda não há avaliações

- Atm WorkingDocumento4 páginasAtm WorkingKarthigaiselvan ShanmuganathanAinda não há avaliações

- Drum Brake CalculationDocumento3 páginasDrum Brake CalculationKarthigaiselvan Shanmuganathan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Design and Development of Automatic Start Stop System For Two WheelerDocumento10 páginasDesign and Development of Automatic Start Stop System For Two WheelerKarthigaiselvan ShanmuganathanAinda não há avaliações

- Montly Expences Credit Card and LoanDocumento2 páginasMontly Expences Credit Card and LoanKarthigaiselvan ShanmuganathanAinda não há avaliações

- Cerdit TypesDocumento16 páginasCerdit TypesKarthigaiselvan ShanmuganathanAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Internet WasteDocumento1 páginaInternet WasteKarthigaiselvan ShanmuganathanAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Starting SystemDocumento20 páginasThe Starting SystemRuth MwendaAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Merlin Gerin Masterpact (00689992a) PDFDocumento161 páginasMerlin Gerin Masterpact (00689992a) PDFyerut0130100% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Case Study - BoilerDocumento17 páginasCase Study - BoilerMohd Shafuaaz KassimAinda não há avaliações

- P445PTDocumento141 páginasP445PTRafael ArandaAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- LITIX™ Power Flex TLD5190: Voltage Regulator in Buck-Boost TopologyDocumento23 páginasLITIX™ Power Flex TLD5190: Voltage Regulator in Buck-Boost TopologyManoel Camargo SampaioAinda não há avaliações

- DOL Vs Soft StarterDocumento12 páginasDOL Vs Soft Startersathishnallathambi100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Specification Aeration BlowerDocumento52 páginasSpecification Aeration BlowerPendeta MudaAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- 7FBR 1.0 To 3.0 Ton: Electric Powered Reach TruckDocumento6 páginas7FBR 1.0 To 3.0 Ton: Electric Powered Reach TruckGilang RifaniAinda não há avaliações

- Climate Change and Vulnerability in The Middle East - Carnegie Endowment For International PeaceDocumento26 páginasClimate Change and Vulnerability in The Middle East - Carnegie Endowment For International PeaceEhzaz Ahmad ZahidAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Live Line Insulator WashingDocumento8 páginasLive Line Insulator WashingWjdan Al ZwaiAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- 2018 JC2 H2 Physics SA2 Anglo Chinese Junior College PDFDocumento109 páginas2018 JC2 H2 Physics SA2 Anglo Chinese Junior College PDFeternal vorceAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- ABBDocumento133 páginasABBIulian Luncan100% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- ME MotronicDocumento3 páginasME Motronicdory7dawAinda não há avaliações

- Human Energy Requirements - FaoDocumento2 páginasHuman Energy Requirements - FaoKaren MazariegosAinda não há avaliações

- Signature RedactedDocumento49 páginasSignature RedactedG Pavan KumarAinda não há avaliações

- Eks Energy PresentationDocumento17 páginasEks Energy PresentationFrancisco Javier Marín SuárezAinda não há avaliações

- Lyophilization of Parenterals FinalDocumento25 páginasLyophilization of Parenterals FinalMostofa RubalAinda não há avaliações

- Integrated CircuitsDocumento46 páginasIntegrated CircuitsSai LakshmiAinda não há avaliações

- Innovation in ConstructionDocumento165 páginasInnovation in Constructionfoush bashaAinda não há avaliações

- Coulson MethodDocumento17 páginasCoulson MethodSanjeeb SutradharAinda não há avaliações

- Caixa Amplifica Stagg 40GAR - DSP - USADocumento2 páginasCaixa Amplifica Stagg 40GAR - DSP - USAMarcelo M. MachadoAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 48 Case HistoryDocumento17 páginas48 Case HistorySamir Benabdallah100% (1)

- Demand and Supply CurveDocumento3 páginasDemand and Supply CurveJanella Umieh De UngriaAinda não há avaliações

- Momento de Inercia GD2 PDFDocumento9 páginasMomento de Inercia GD2 PDFDavid Delgado RendónAinda não há avaliações

- PneumaticACtuator Masoneilan - Linear Setpoint PDFDocumento63 páginasPneumaticACtuator Masoneilan - Linear Setpoint PDFAnonymous e7DNMZ100% (1)

- Glycolysis TCA ETCDocumento61 páginasGlycolysis TCA ETCLê Trà GiangAinda não há avaliações

- Combustion Lecture Midterm ExamDocumento3 páginasCombustion Lecture Midterm ExamNazareno Religioso MateoAinda não há avaliações

- AIIMS Solved Paper 2017Documento30 páginasAIIMS Solved Paper 2017Jagmohan SinghAinda não há avaliações

- Sheer Driving PleasureDocumento25 páginasSheer Driving Pleasuremst317Ainda não há avaliações

- Wind Energy - University QuesDocumento2 páginasWind Energy - University QuesKsn Hari100% (2)