Escolar Documentos

Profissional Documentos

Cultura Documentos

SABS Presentation PAS 220

Enviado por

Phu JieDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SABS Presentation PAS 220

Enviado por

Phu JieDireitos autorais:

Formatos disponíveis

PAS 220:2008

PREREQUISITE PROGRAMMES

ON FOOD SAFETY FOR FOOD

MANUFACTURING

A publicly available specification prepared by

the British Standards Institution (BSI) to

specify the requirements for prerequisite

programmes to assist in controlling food

safety hazards.

PAS 220

INTENTION:

To be used in conjunction with BS EN ISO

22000 to support management

systems to meet requirements with

regard to prerequisite programmes.

PAS 220

PAS 220

ISO 22000

BRC

SANS 10330

HACCP

PREREQUISITE PROGRAMS

PAS 220 is applicable to ALL organizations,

regardless of size and complexity, which are

involved in a step of the food chain.

Food manufacturing operations are diverse in

nature therefore not all the requirements in

the PAS 220 may apply to an individual

organization.

PAS 220

Why are prerequisite programmes

necessary?

PAS 220

Prerequisite programmes are the basic conditions

and activities that are necessary to maintain

a hygienic environment throughout the food

chain suitable for the production, handling

and distribution of safe food products.

PAS 220

PRPs assist in controlling the likelihood

of introducing food safety hazards

such as biological, chemical or

physical in the product or processing

environment.

PAS 220

MACHINERY

NOTE

PRPs need to be appropriate to the

product and processes of the

organization.

PAS 220

Prerequisite programmes can cover a

wide range of activities.

PAS 220 specifies requirements related to

the following:

PAS 220

CONSTRUCTION AND LAYOUT OF BUILDINGS

Appropriate design and construction of buildings

Consideration of potential sources of

contamination from the environment

Identification of boundaries and access control.

Maintenance of buildings and surrounding areas.

PAS 220

LAYOUT OF PREMISES AND WORKSPACE

Designed to facilitate good hygiene and

manufacturing processes

Logical flow of materials, products and people

Physical separation of raw from processed areas

Protection of openings intended for transfer of

materials

Internal structures and fittings such as walls,

floors, ceilings, windows

Location of equipment

Laboratory facilities

Temporary structures

Storage facilities

PAS 220

UTILITIES AIR, WATER, ENERGY

Sufficient supply of potable water

Boiler chemical approved

Established requirements for filtration, humidity

and microbiological specifications for air used as

an ingredient or in direct contact with food

Compressed air

Adequate lighting to enable operation in a

hygienic manner

PAS 220

WASTE DISPOSAL

Identification, collection and disposal of waste

materials

Appropriate containers for waste

Segregation and storage of waste

Drains and drainage

PAS 220

EQUIPMENT SUITABILITY, CLEANING AND MAINTENANCE

Design and construction of food contact equipment

Hygienic design eg. Smooth, accessible, compatible with

intended products

Temperature control and monitoring equipment

Cleaning plant, utensils and equipment

Preventive and corrective maintenance

PAS 220

MANAGEMENT OF PURCHASED MATERIALS

Selection and management of suppliers

Incoming material requirements

Inspection of incoming material

Nonconforming received materials

Identification, segregation and handling of

purchased materials

PAS 220

MEASURES FOR PREVENTION OF CROSS CONTAMINATION

Microbiological cross contamination

Allergen management

Physical contamination

Chemical contamination

PAS 220

CLEANING AND SANITIZING

Cleaning and sanitizing agents and tools

Cleaning and sanitizing programmes

Cleaning in place (CIP) systems

Monitoring sanitation effectiveness

PAS 220

PEST CONTROL

Pest control programmes

Preventing access

Harborage and infestations

Monitoring and detection

Eradication

PAS 220

PERSONNEL HYGIENE AND EMPLOYESS FACILITIES

Adequate numbers, locations and means of

hygienically washing and drying

Adequate number of toilets

Not directly open into production

Changing facilities for personnel

Canteens and designated areas for food storage

Work wear and protective clothing

Health status

Illness and injuries

Personal cleanliness

Personal behavior

PAS 220

REWORK

Storage, identification and traceability

Segregation requirements for rework

Classification for rework

Rework usage permissible incorporation

PAS 220

PRODUCT RECALL PROCEDURES

Recall requirements

System for identification, location and removal

Need for public warning

PAS 220

WAREHOUSING

Effective control of warehousing temperature,

humidity and environmental conditions

Proper stacking

Waste materials, lubricants, chemicals, cleaning

materials and pesticides stored separately

Vehicles, conveyances and containers

PAS 220

PRODUCT INFORMATION / CONSUMER AWARENESS

Proper presentation

Labeling of pre-packed foods

PAS 220

FOOD DEFENCE, BIOVIGILANCE AND TERROISIM

Assessment of hazards to products posed by

potential acts of sabotage, vandalism or terrorism

Access controls

PAS 220

PAS 220

PAS 220 IS THIS SOMETHING NEW?

SANS 10049 - REQUIREMENTS FOR A PREREQUISITE

PROGRAMME (PRP) SYSTEM

SANS 10330 PREREQUISITE REQUIREMENTS (CLAUSE 6 )

ISO 2200 - PREREQUISITE REQUIREMENTS (CLAUSE 7.2)

ESTABLISHING REQUIREMENTS FOR PAS 220

DESIGN

Buildings

Internal layout

Movement patterns

Openings

Walls, floors, drains, ceilings and overhead fixtures

Equipment

Laboratory

Storage areas

Distribution of utilities

PAS 220

PAS 220

DOCUMENTED POLICY

Personal behavior

PAS 220

PROCEDURES, PROTOCOLS, PROGRAMMES

Protocols for air quality monitoring and control

Waste management

Cleaning and sanitizing programmes

Preventative maintenance programmes

Procedures for releasing maintained equipment

Selection, approval and monitoring of suppliers

Prevention, control and detection of contamination

Defined procedures for use and breakage of glass / brittle material

Pest management

Monitoring programmes

Personnel hygiene

Product recall

Labeling procedures

PAS 220

RECORDS

Destruction of waste

Raw material conformance

Hazard assessment

Glass breakage

Pesticide usage

Traceability records for rework

Records are evidence of compliance to the

requirements and necessary for review

purposes.

PAS 220

SABS APPROACH TO AUDITING PAS 220

Requirements are audited in audits for compliance to SANS 10330 and

ISO 22000.

Previously SANS 10049 used as guideline (currently under revision)

PRPs is one of 25 clauses for requirements in SANS 10330 and one of 34 in

ISO 22000. As such, the records of the audits were included in the entire audit

scope and although records of these conformance inspection are maintained in

the auditors trails, details were not included in the report.

Report format will be altered to highlight conformance to PAS 220 requirements

(eg as in BRC report)

An additional certificate will be issued to existing companies who comply with

the requirements of the PAS 220.

PAS 220

THE END GOAL

A LOCALLY ACCEPTED AND RECOGNIZED

CERTIFICATION BY ALL PARTIES AND

STAKEHOLDERS THAT WILL CONTRIBUTE

TO A REDUCTION IN MULTPLE AUDITS

WITH THE AIM OF PROVIDING SAFE FOOD

TO CONSUMERS AT AN ECONOMICAL

PRICE.

THE END

THANK YOU

Você também pode gostar

- Production of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Documento5 páginasProduction of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Gregory Kalona100% (1)

- Dich HACCP PLANDocumento10 páginasDich HACCP PLANLinh VuAinda não há avaliações

- Microwave Oven Advantages and DisadvantagesDocumento1 páginaMicrowave Oven Advantages and DisadvantagesemrahumanAinda não há avaliações

- Factor Affecting Quality of Mozzarella CheeseDocumento5 páginasFactor Affecting Quality of Mozzarella CheeseWei Ching TayAinda não há avaliações

- Report On Industrial Visit: OrgernisedDocumento7 páginasReport On Industrial Visit: OrgernisedNguyễn Lê HuyAinda não há avaliações

- Water and Wastewater For Fruit JuiceDocumento18 páginasWater and Wastewater For Fruit JuiceJoyce Marian BelonguelAinda não há avaliações

- Production of Soy Sauce Using BiotechnologyDocumento12 páginasProduction of Soy Sauce Using BiotechnologyJs TeoAinda não há avaliações

- FDA Recommended Pasteurization TimeDocumento2 páginasFDA Recommended Pasteurization TimeMarquel Audreyan0% (1)

- Yakuly Study Field TripDocumento4 páginasYakuly Study Field TripSya DeqAinda não há avaliações

- The Technology of Hard Candy: Walter VinkDocumento57 páginasThe Technology of Hard Candy: Walter VinkAnh CottoncandyAinda não há avaliações

- Certificate of Analysis: Address: No. 43, 6 Road Hi-Tech, Hi-Tech Zone, Xi'an, ChinaDocumento1 páginaCertificate of Analysis: Address: No. 43, 6 Road Hi-Tech, Hi-Tech Zone, Xi'an, ChinabluemyAinda não há avaliações

- Introduction To HACCP Plan For MayonnaiseDocumento8 páginasIntroduction To HACCP Plan For Mayonnaiseshaimamoh225279Ainda não há avaliações

- Alpha Amylase PDFDocumento10 páginasAlpha Amylase PDFnadiaAinda não há avaliações

- Interaction Between Food Flavour & Packaging Material: Monika Mathur 2014FST29DDocumento45 páginasInteraction Between Food Flavour & Packaging Material: Monika Mathur 2014FST29DMonika Mathur100% (3)

- Đánh Giá Cảm Quan Thực PhẩmDocumento355 páginasĐánh Giá Cảm Quan Thực PhẩmTuyền Nguyễn Trần ThanhAinda não há avaliações

- HiStory of Mozzarella CheeseDocumento2 páginasHiStory of Mozzarella CheesewijayantiAinda não há avaliações

- Codex For Jam, Jellies, and MermaladeDocumento14 páginasCodex For Jam, Jellies, and MermaladeatihidayatiAinda não há avaliações

- The Effect of Liming Conditions in Juice ClarificationDocumento12 páginasThe Effect of Liming Conditions in Juice Clarificationmohammed amerAinda não há avaliações

- Effect of Different Treatments For The Destabilization of Coconut Milk EmulsionDocumento7 páginasEffect of Different Treatments For The Destabilization of Coconut Milk EmulsionAn TrầnAinda não há avaliações

- SQF-2000-Code For HACCP ImplementationDocumento80 páginasSQF-2000-Code For HACCP ImplementationFlorence Reid100% (1)

- Midterm Enzyme Fermentation 1Documento20 páginasMidterm Enzyme Fermentation 1Thuỳ TrangAinda não há avaliações

- Review of Antimicrobial Food packaging-SD PDFDocumento14 páginasReview of Antimicrobial Food packaging-SD PDFSunil AdsuleAinda não há avaliações

- Charantin HPLCDocumento4 páginasCharantin HPLCReymart SangalangAinda não há avaliações

- New Haccp Manual DD 02 Feb 17 (1) BijaliDocumento89 páginasNew Haccp Manual DD 02 Feb 17 (1) BijaliRavinder Singh RajanAinda não há avaliações

- Grape Wine - Generic HACCP PlanDocumento9 páginasGrape Wine - Generic HACCP PlanYulian Tutunaru100% (1)

- Dairy Chapter 1 PDFDocumento76 páginasDairy Chapter 1 PDFSteven LiberatoAinda não há avaliações

- Noodle (Fu, 2007)Documento15 páginasNoodle (Fu, 2007)Diana HartonoAinda não há avaliações

- Pas 220 2008Documento35 páginasPas 220 2008Gameel Thabit100% (3)

- Waste Water Disposal and Pollution Control in DairyDocumento14 páginasWaste Water Disposal and Pollution Control in Dairy19 CH 056 Vaishali Vivek100% (1)

- Quản trị thực phẩm -Chapter 2 Food Value Chain Management Part 1 Dhdd15 2021 E-learning IUHDocumento38 páginasQuản trị thực phẩm -Chapter 2 Food Value Chain Management Part 1 Dhdd15 2021 E-learning IUHNam NguyenHoangAinda não há avaliações

- BlanchingDocumento22 páginasBlanchingKOWSHALYA M 15BBT029100% (1)

- Unit Opertations in Juice IndustryDocumento7 páginasUnit Opertations in Juice IndustryThomas John KayyanickalAinda não há avaliações

- Solution For 1.4 and 1Documento4 páginasSolution For 1.4 and 1lieu_hyacinth0% (1)

- Instant NoodlesDocumento11 páginasInstant NoodlesBryan LeeAinda não há avaliações

- Codex Standard For Aqueous Coconut ProductsDocumento4 páginasCodex Standard For Aqueous Coconut ProductsMinh Võ100% (1)

- WheatFlourTestingMethods PDFDocumento73 páginasWheatFlourTestingMethods PDFGhufran Ahmed Goraya100% (1)

- Strawberry JamDocumento4 páginasStrawberry JamMaria Jiezl SantosAinda não há avaliações

- Development of HACCP Protocols For The Production ofDocumento48 páginasDevelopment of HACCP Protocols For The Production ofAdapa Prabhakara Gandhi100% (1)

- Hafiz Zahid Mehmood Ph.D. Agriculturl EconomicsDocumento17 páginasHafiz Zahid Mehmood Ph.D. Agriculturl Economicshafiz zahidAinda não há avaliações

- 8 UHT ProcessingDocumento6 páginas8 UHT ProcessingOsman Aita100% (1)

- Dầu Tường AnDocumento45 páginasDầu Tường AnAnh Vân NguyễnAinda não há avaliações

- Giáo Trình Công Nghệ Sản Xuất Các Sản Phẩm Từ Sữa Và Thức Uống Pha Chế - Tập 2 - Công Nghệ Sản Xuất Thức Uống Pha Chế - 995261Documento283 páginasGiáo Trình Công Nghệ Sản Xuất Các Sản Phẩm Từ Sữa Và Thức Uống Pha Chế - Tập 2 - Công Nghệ Sản Xuất Thức Uống Pha Chế - 995261Le Huu HungAinda não há avaliações

- About The Company: Current Market SituationDocumento4 páginasAbout The Company: Current Market SituationNguyễn XuânAinda não há avaliações

- Stackable Potato Chips TechnologyDocumento3 páginasStackable Potato Chips Technologyruanruanb100% (1)

- Cereal Waste Management2Documento14 páginasCereal Waste Management2daabgchi100% (1)

- Principles and Practice of Cleaning in PlaceDocumento41 páginasPrinciples and Practice of Cleaning in PlaceMedelky AnouwAinda não há avaliações

- ISO 22000 & HACCP: Hazard Analysis Critical Control PointDocumento29 páginasISO 22000 & HACCP: Hazard Analysis Critical Control Pointmazen fakhfakhAinda não há avaliações

- Sea Food Plant SanitationDocumento28 páginasSea Food Plant SanitationNaveen100% (2)

- Quản trị thực phẩm -Chapter 1 Food Management-An Overview Dhdd15 2021 E-learning IUHDocumento26 páginasQuản trị thực phẩm -Chapter 1 Food Management-An Overview Dhdd15 2021 E-learning IUHNam NguyenHoangAinda não há avaliações

- J 1365-2621 1997 00400 XDocumento13 páginasJ 1365-2621 1997 00400 XDilannirangaAinda não há avaliações

- Classification of CheeseDocumento6 páginasClassification of CheeseDeepak JettaAinda não há avaliações

- Introduction To PackagingDocumento84 páginasIntroduction To PackagingChamara MadugalleAinda não há avaliações

- 003070560Documento13 páginas003070560Kingsuk BurmanAinda não há avaliações

- Production Process of Stirred YoghurtDocumento3 páginasProduction Process of Stirred YoghurtIftikhar AhmadAinda não há avaliações

- Good Manufacturing PracticesDocumento123 páginasGood Manufacturing PracticessayedAinda não há avaliações

- Workshop by Emmi MigerDocumento43 páginasWorkshop by Emmi MigerRizwan AliAinda não há avaliações

- Topic 2.1 Food Safety Requirement in Plant DesignDocumento54 páginasTopic 2.1 Food Safety Requirement in Plant DesignDorothy LimAinda não há avaliações

- Facility and AHU ValidationDocumento63 páginasFacility and AHU ValidationShankar kumar roy100% (3)

- Good Manufacturing Practices.Documento123 páginasGood Manufacturing Practices.anandhra2010100% (2)

- Yub Raj Neupane M.Pharma, Sem Ii Pharmaceutics Jamia Hamdard, New DelhiDocumento41 páginasYub Raj Neupane M.Pharma, Sem Ii Pharmaceutics Jamia Hamdard, New DelhiYub Raj NeupaneAinda não há avaliações

- RM - 0. Whole Milk Powder - Fonterra Co-Operative GroupDocumento12 páginasRM - 0. Whole Milk Powder - Fonterra Co-Operative GroupPhu JieAinda não há avaliações

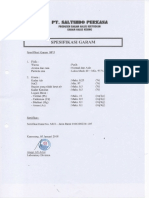

- Shipment 17 - MSDSDocumento1 páginaShipment 17 - MSDSPhu Jie100% (2)

- Halal - FatwaDocumento1 páginaHalal - FatwaPhu JieAinda não há avaliações

- Summary PDFDocumento1 páginaSummary PDFPhu JieAinda não há avaliações

- Spesifikasi Bahan Baku Tertentu - 06. YeastDocumento1 páginaSpesifikasi Bahan Baku Tertentu - 06. YeastPhu JieAinda não há avaliações

- Codex Stan 1-1985 Labelling of Prepackaged GoodsDocumento7 páginasCodex Stan 1-1985 Labelling of Prepackaged GoodsvabimhahAinda não há avaliações

- Iso 22000 2018 IntroDocumento5 páginasIso 22000 2018 IntroFrance Louie Jutiz0% (1)

- SJH - PT Prima Top BogaDocumento1 páginaSJH - PT Prima Top BogaPhu JieAinda não há avaliações

- Foreign Object 7mmDocumento2 páginasForeign Object 7mmaudrey78838649100% (1)

- List SNI PanganDocumento237 páginasList SNI PanganPhu Jie50% (2)

- Certificat Alimentaire UnibakeDocumento1 páginaCertificat Alimentaire UnibakePhu JieAinda não há avaliações

- BerusythDocumento1 páginaBerusythPhu JieAinda não há avaliações

- Joint Fao/Who Food Standards Programme: Revised 1999Documento51 páginasJoint Fao/Who Food Standards Programme: Revised 1999Phu JieAinda não há avaliações

- Unsalted Butter - FonterraDocumento1 páginaUnsalted Butter - FonterraPhu JieAinda não há avaliações

- Produksi Engineenering Ppic R&D Purchasing MR Qa/Qc HR Ga Sanitasi Faa & ItDocumento1 páginaProduksi Engineenering Ppic R&D Purchasing MR Qa/Qc HR Ga Sanitasi Faa & ItPhu JieAinda não há avaliações

- Kurikulum Magister Teknik IndustriDocumento1 páginaKurikulum Magister Teknik IndustriPhu JieAinda não há avaliações

- TRIAL 1Documento6 páginasTRIAL 1Phu JieAinda não há avaliações

- Regulation For Approving Reliability of Certification - Assurance Agency For Labels, Advertisements of Foods and Livestock Products (No.2016-119)Documento16 páginasRegulation For Approving Reliability of Certification - Assurance Agency For Labels, Advertisements of Foods and Livestock Products (No.2016-119)Phu JieAinda não há avaliações

- ITA 2005 Soil Conditioning For EPB Machines Balance of Functional and Ecological PropertiesDocumento7 páginasITA 2005 Soil Conditioning For EPB Machines Balance of Functional and Ecological PropertiesAnonymous kBl0u3nAinda não há avaliações

- Brgy-DTP-Forms Hilongos - CBMSDocumento26 páginasBrgy-DTP-Forms Hilongos - CBMSJaypee BucatcatAinda não há avaliações

- Method of Statement For Honeycomb RepairDocumento10 páginasMethod of Statement For Honeycomb RepairHansika RajapakshaAinda não há avaliações

- WMO No.168 1994Documento770 páginasWMO No.168 1994hydrologyproject0100% (1)

- Soil Moisture Distribution Under Drip Irrigation and - 2016 - Agricultural WaterDocumento10 páginasSoil Moisture Distribution Under Drip Irrigation and - 2016 - Agricultural WaterJ M Jimenez TAinda não há avaliações

- Https Communities - BentleyDocumento14 páginasHttps Communities - Bentley2009tamerAinda não há avaliações

- Australian Police Survival GuideDocumento88 páginasAustralian Police Survival GuideRodrigo P AvorAinda não há avaliações

- The Earth Provides Enough To Satisfy Every Person's Need But Not Every Person's Greed"Documento50 páginasThe Earth Provides Enough To Satisfy Every Person's Need But Not Every Person's Greed"Darshan M MAinda não há avaliações

- PEDH 2122 WEEK 1 10 KeenplifyDocumento7 páginasPEDH 2122 WEEK 1 10 KeenplifyCarlbryan NomongAinda não há avaliações

- Touching The Void - ReflectionDocumento10 páginasTouching The Void - Reflectionapi-287873406Ainda não há avaliações

- Runway Extension Feasibility Study: Concept Design ReportDocumento177 páginasRunway Extension Feasibility Study: Concept Design ReportCosminAinda não há avaliações

- Flocculation BasinDocumento10 páginasFlocculation BasinImran GoharAinda não há avaliações

- Pump and Compressor 2Documento52 páginasPump and Compressor 2SaravananRamasamy100% (3)

- Shomudrobôn "Sea Forest") or "Chandra-Bandhe" (Name of A Primitive Tribe) - But The Generally AcceptedDocumento6 páginasShomudrobôn "Sea Forest") or "Chandra-Bandhe" (Name of A Primitive Tribe) - But The Generally AcceptedAakash PatelAinda não há avaliações

- Costa Cálida Chronicle's Monthly Magazine October 2016Documento104 páginasCosta Cálida Chronicle's Monthly Magazine October 2016costacalidachronicleAinda não há avaliações

- 19 - Storvik - Subsea SeparationDocumento19 páginas19 - Storvik - Subsea SeparationMarco Andrés Guevara LunaAinda não há avaliações

- Test PHDocumento16 páginasTest PHMarielys DoranteAinda não há avaliações

- Hho en Motores CiDocumento18 páginasHho en Motores CiALEX LOPEZAinda não há avaliações

- GEK1515 - L1 Introduction IVLE VersionDocumento52 páginasGEK1515 - L1 Introduction IVLE VersionYan Ting ZheAinda não há avaliações

- Nital Etch Procedure PDFDocumento1 páginaNital Etch Procedure PDFKazuoAinda não há avaliações

- Tugas Bahasa InggrisDocumento2 páginasTugas Bahasa InggrisrovikaAinda não há avaliações

- C M W S S B (CMWSSB) : Hennai Etropolitan Ater Upply AND Ewerage OardDocumento206 páginasC M W S S B (CMWSSB) : Hennai Etropolitan Ater Upply AND Ewerage OardKumaresh DeenadayalanAinda não há avaliações

- Precis & Drafting Question Paper 2018Documento4 páginasPrecis & Drafting Question Paper 2018Sunil Teron A 2 ZAinda não há avaliações

- Tank 150KL 16M Green - 21 Layout1 PDFDocumento1 páginaTank 150KL 16M Green - 21 Layout1 PDFTarun SinghalAinda não há avaliações

- MTC 05 Water Pressure SystemsDocumento10 páginasMTC 05 Water Pressure SystemsboyAinda não há avaliações

- 1169 BOK Apr-Dec-2017 Final-011117 PDFDocumento9 páginas1169 BOK Apr-Dec-2017 Final-011117 PDFUnni CyriacAinda não há avaliações

- Multi-Column Elevated Storage Tank (LEG) : POSITIVE USES (When It's Best)Documento2 páginasMulti-Column Elevated Storage Tank (LEG) : POSITIVE USES (When It's Best)Reza KhajeAinda não há avaliações

- How To Grow Goji Berry PlantsDocumento6 páginasHow To Grow Goji Berry PlantsCodruța RăuțăAinda não há avaliações

- 2 Company Profile SPP Pumps - Oil & Gas - BrochureDocumento10 páginas2 Company Profile SPP Pumps - Oil & Gas - Brochurelemuel bacsaAinda não há avaliações

- 3 Cleaning Wet EtchDocumento34 páginas3 Cleaning Wet EtchPieter RobaeysAinda não há avaliações