Escolar Documentos

Profissional Documentos

Cultura Documentos

Answers Drawing A: BS EN 22553 Course Reference WIS 10

Enviado por

JithuJohn0 notas0% acharam este documento útil (0 voto)

132 visualizações9 páginasad

Título original

Answers Drawing A

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoad

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

132 visualizações9 páginasAnswers Drawing A: BS EN 22553 Course Reference WIS 10

Enviado por

JithuJohnad

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 9

M.S.Rogers M.S.

Rogers Copyright 2003 TWI Ltd

SWI 3.2

Answers Drawing A

BS EN 22553

Course Reference WIS 10

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

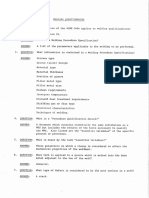

Remember in the CSWIP 3.2 Senior Welding Inspectors

examination your are required to interpret a fabrication

drawing and comment on the welding symbols

Time allowed 1 hour

The drawing will contain around 15 to 20

symbols

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

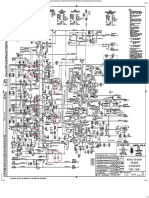

Drawings and Weld Symbol Interpretation

With the supplied drawing you are required to carry out the

following

1. Reference the drawing number onto your answer sheet

2. Specify the standard to which the weld symbols apply

3. Produce a neat sketch of how you see the welds,

numbering each weld individually.

4. Fully describe each weld symbol, example

Welded arrow side: Single-V butt

Welded other side: Sealing run.

5. On completion of the welding symbol interpretation, you

are then required to comment on the drawing with

reference to errors and incorrect set-ups

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

4. Welded arrow side: 8mm leg length fillet, welded

all way around (peripheral weld) Toes to be blended

smooth

Welded other side: Single-J butt, welded all way

around. The drawing indicates the pipe to be

prepared, incorrect set-up.

3.

2.

1.

8

8

12

BS EN 22553 Answers DRG A

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

5. Welded arrow side: Steep-flanked single-V butt weld,

with permanent backing strip.

6. Welded arrow side: Single-J butt weld, welded all way

around. Welding to be carried out on site.

7. Welded arrow side: 12mm leg length fillet weld, 8mm

throat thickness concave profile

8. Welded both sides: 6mm leg length fillet weld

BS EN 22553 Answers DRG A

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

9. Welded both sides: 8mm leg length fillet weld

10. Welded arrow side: Single-bevel butt, depth of

penetration 10mm, partial penetration.

Welded other side: 6mm leg length fillet weld.

11. Welded both sides : 8mm leg length fillet weld

12. Welded arrow side: 20mm leg length fillet weld, 14mm

throat thickness

Welded other side: 10mm leg length fillet weld, 7mm

throat thickness,

BS EN 22553 Answers DRG A

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

13. Welded arrow side: Single-J butt, welded using the

MAG process.

14. Welded both sides: 6mm leg length fillet welds, 50mm

in length, 25mm gap between each weld. Welds to be

staggered.

15. Welded arrow side: Baking run flat (flush) finish.

Welded other side: Single-V butt, 8mm depth of

preparation.

16. Welded arrow side: Single-J butt, flat (flush) finish.

50 25 50

50 50

25

BS EN 22553 Answers DRG A

M.S.Rogers M.S.Rogers Copyright 2003 TWI Ltd

SWI 3.2

17. Welded all way around: Square butt weld cap

reinforcement convex profile. Welding to be carried out

on site. Note dotted line missing

18. Welded arrow side: Single-U butt.

19. Welded arrow side: Backing run

Welded other side: Single-V butt, flat (flush) finish.

20. Welded both sides: Double-J butt weld with a

superimposed 8mm leg length fillet welded arrow side

21. Welded arrow side: Single-bevel butt weld, 14mm

depth of penetration, 6mm leg length fillet weld

superimposed.

Welded other side: 4mm leg length fillet weld

BS EN 22553 Answers DRG A

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hanson Rivet Catalog Web PDFDocumento93 páginasHanson Rivet Catalog Web PDFhvdb72Ainda não há avaliações

- Pressure Vessel Exm QuestionsDocumento4 páginasPressure Vessel Exm QuestionsJithuJohn100% (1)

- General Questions4Documento31 páginasGeneral Questions4JithuJohnAinda não há avaliações

- General Questions4Documento31 páginasGeneral Questions4JithuJohnAinda não há avaliações

- General Questions4Documento31 páginasGeneral Questions4JithuJohnAinda não há avaliações

- General Questions4Documento31 páginasGeneral Questions4JithuJohnAinda não há avaliações

- Storage Tank Erection Procedure PDFDocumento6 páginasStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Method Statement & Risk Assessment For Hot Works WeldingDocumento4 páginasMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- Heat Exchanger-Design and ConstructionDocumento46 páginasHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Heat Exchanger-Design and ConstructionDocumento46 páginasHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Ansi-Aws d1.2 PDFDocumento208 páginasAnsi-Aws d1.2 PDFzokytoAinda não há avaliações

- Handbook MetrodeDocumento371 páginasHandbook Metrodejf2587Ainda não há avaliações

- Defecte La SuduraDocumento50 páginasDefecte La Suduradanut_horincas4988Ainda não há avaliações

- Asme B31.3-2016 CC 181Documento3 páginasAsme B31.3-2016 CC 181MubeenAinda não há avaliações

- Material With Electrode SelectionDocumento2 páginasMaterial With Electrode SelectionJithuJohn100% (3)

- Din en 12252Documento8 páginasDin en 12252biancogallazziAinda não há avaliações

- 02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemDocumento10 páginas02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemPhucChuVanAinda não há avaliações

- Aramco vendor inspection for line pipe API standardsDocumento3 páginasAramco vendor inspection for line pipe API standardsJithuJohnAinda não há avaliações

- Canada RN CCNDocumento1 páginaCanada RN CCNJithuJohnAinda não há avaliações

- 2015 Rev-Ect Feb 17 ListDocumento7 páginas2015 Rev-Ect Feb 17 ListJithuJohnAinda não há avaliações

- 21a1004 02Documento1 página21a1004 02JithuJohnAinda não há avaliações

- 2015 Rev-Ect Feb 17 ListDocumento7 páginas2015 Rev-Ect Feb 17 ListJithuJohnAinda não há avaliações

- Resume Ofjithu John (API, CSWIP & ASNT)Documento6 páginasResume Ofjithu John (API, CSWIP & ASNT)JithuJohnAinda não há avaliações

- 1-3 Email Nurse - Role PlayDocumento2 páginas1-3 Email Nurse - Role PlayJithuJohnAinda não há avaliações

- Hy Are Jews So SmartDocumento2 páginasHy Are Jews So SmartJithuJohnAinda não há avaliações

- Canada RN CCNDocumento1 páginaCanada RN CCNJithuJohnAinda não há avaliações

- Hy Are Jews So SmartDocumento2 páginasHy Are Jews So SmartJithuJohnAinda não há avaliações

- Aramco QuestionDocumento72 páginasAramco QuestionZuberYousuf100% (1)

- Aramco QuestionDocumento72 páginasAramco QuestionZuberYousuf100% (1)

- Ut Q 5Documento4 páginasUt Q 5JithuJohnAinda não há avaliações

- Pumps API 610Documento2 páginasPumps API 610JithuJohnAinda não há avaliações

- Welding AnswersDocumento4 páginasWelding AnswersJithuJohnAinda não há avaliações

- QADocumento3 páginasQAJithuJohnAinda não há avaliações

- CopyDocumento2 páginasCopyJithuJohnAinda não há avaliações

- OET Test 3 Listening Answers - Part A and BDocumento6 páginasOET Test 3 Listening Answers - Part A and BJithuJohn100% (1)

- Resume Ofjithu John (API, CSWIP & ASNT)Documento6 páginasResume Ofjithu John (API, CSWIP & ASNT)JithuJohnAinda não há avaliações

- RGUHS MSc Nursing Exam Fee Notification April 2016Documento7 páginasRGUHS MSc Nursing Exam Fee Notification April 2016JithuJohnAinda não há avaliações

- Mpi Q-2Documento3 páginasMpi Q-2JithuJohnAinda não há avaliações

- Basic 4 QDocumento8 páginasBasic 4 QJithuJohnAinda não há avaliações

- The Relationship Between Boron Content and Crack Properties in FCAW Weld MetalDocumento6 páginasThe Relationship Between Boron Content and Crack Properties in FCAW Weld MetalVizay KumarAinda não há avaliações

- API 650 Storage Tank Inspection GuideDocumento36 páginasAPI 650 Storage Tank Inspection GuideIsmail KarmanaAinda não há avaliações

- An Investigation Into Microstructure and MechanicaDocumento10 páginasAn Investigation Into Microstructure and MechanicaGowri Shankar WuritiAinda não há avaliações

- Interview Guidance by S K MondalDocumento16 páginasInterview Guidance by S K MondaljishnuAinda não há avaliações

- Addition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Documento5 páginasAddition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Azizy ZidaneAinda não há avaliações

- HiS SYSTEM - METAL Welding MachineDocumento18 páginasHiS SYSTEM - METAL Welding MachineSharmishta AngreAinda não há avaliações

- AWS A5.6 Spec for Copper Arc Welding ElectrodesDocumento6 páginasAWS A5.6 Spec for Copper Arc Welding Electrodesalok987Ainda não há avaliações

- PTFE Sliding Bearing CatalogueDocumento5 páginasPTFE Sliding Bearing Cataloguenght7942Ainda não há avaliações

- Aludipbrochure PDFDocumento16 páginasAludipbrochure PDFflavio82pnAinda não há avaliações

- Joining Aluminum Sheet in The Automotive Industry - A 30 Year HistoryDocumento12 páginasJoining Aluminum Sheet in The Automotive Industry - A 30 Year HistoryStupinean LarisaAinda não há avaliações

- Quantitative Wear Analysis of H13 Steel Tool During Friction Stir Welding of Cu-0.8%Cr-0.1%Zr AlloyDocumento9 páginasQuantitative Wear Analysis of H13 Steel Tool During Friction Stir Welding of Cu-0.8%Cr-0.1%Zr AlloyAnmol MalgotraAinda não há avaliações

- Hydraulic Floor CraneDocumento1 páginaHydraulic Floor CraneAnto MustangsAinda não há avaliações

- Mobile: Mobile Welding Fume ExtractorDocumento3 páginasMobile: Mobile Welding Fume ExtractorBülent KabadayiAinda não há avaliações

- 5-Thrust Boring 56 Inch PipeDocumento8 páginas5-Thrust Boring 56 Inch PipeAmeerHamzaWarraichAinda não há avaliações

- High Mast SpecsDocumento5 páginasHigh Mast SpecsleodegarioporralAinda não há avaliações

- 2 - Santos vs. Employees' Compensation CommissionDocumento7 páginas2 - Santos vs. Employees' Compensation CommissionjieAinda não há avaliações

- CoorsTek SmWedgeDocumento60 páginasCoorsTek SmWedgeRonnie MagsinoAinda não há avaliações

- 3.0 Welding Imperfections and Material InspectionDocumento38 páginas3.0 Welding Imperfections and Material InspectionTrịnh Quốc Tuyến100% (1)

- Centrifugal Pumps Specification Provides Design RequirementsDocumento20 páginasCentrifugal Pumps Specification Provides Design RequirementsRochdi SahliAinda não há avaliações

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocumento4 páginasElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysNathaniel LuraAinda não há avaliações

- Manufacturing Impellers for TurbocompressorsDocumento16 páginasManufacturing Impellers for TurbocompressorsWillian Tavares de CarvalhoAinda não há avaliações