Escolar Documentos

Profissional Documentos

Cultura Documentos

GT Maintanance

Enviado por

Adam LewisDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

GT Maintanance

Enviado por

Adam LewisDireitos autorais:

Formatos disponíveis

External Services (Gas Turbines)

Heavy-Duty Gas

Turbine Operating

and Maintenance

Considerations

HDGT.PPT/ 1

External Services (Gas Turbines)

A Maintenance Program should:

Optimize owners maintenance costs

Maximize equipment availability

HDGT.PPT/ 2

External Services (Gas Turbines)

Because not all customers operate their gas turbines the same,

Case 1

Case 2

8,000 Hrs/Yr

160 Starts/Yr

HGP at 3 years

1,000 Hrs/Yr

400 Starts/Yr

HGP at 3 years, not 24 years

not all customer maintenance programs are the same.

BHEL Provides Guidance for Customer Maintenance Planning

HDGT.PPT/ 3

External Services (Gas Turbines)

Factors Affecting Maintenance Planning and

Maintenance Program

Manufacturers

Recommended

Maintenance

Program

Design

Features

Duty

Cycle

Cost of

Downtime

Type of

Fuel

Diagnostics

Maintenance

Program

Availability

Need

On-Site

Maintenance

Capability

Expert

Systems

Utilization

Need

Environment

Reserve

Requirements

HDGT.PPT/ 4

External Services (Gas Turbines)

Potential Failure Modes

Hot-Gas-Path Components

Continuous Duty Application

Creep Deflection

Creep Rupture

Corrosion

Oxidation

Erosion

High-Cycle Fatigue

Cyclic Duty Application

Themal Mechanical

Fatigue

Rubs/Wears

HDGT.PPT/ 5

External Services (Gas Turbines)

GE Bases Gas Turbine Maintenance

Requirements on Independent Counts of

Starts & Hours Fatigue Limits Life

Different

Mechanism

Limit Life

Failure Region

Starts

Design

Life

Oxidation

Creep,

Corrosion

& Wear

Limit Life

GE Inspection

Recommendation

Competition

Inspection

Recommendation

(Equivalent Hours Per Start)

Design

Life

GE Inspection

Recommendation

Hours

HDGT.PPT/ 6

External Services (Gas Turbines)

GE vs. Equivalent Hours Approach

Case 2

4000 Hrs/Yr

300 Starts/Yr

GE Every 4 Yrs

EOH Every 2.4 Yrs

1200

1000

GE

METHOD

800

EOH

METHOD

Starts 600

Case 1

8,000 Hrs/Yr

160 Starts/Yr

GE Every 3 Yrs

EOH Every 2.1 Yrs

400

200

0

0

12

16

20

24

28

Fired Hours (x1000)

HDGT.PPT/ 7

External Services (Gas Turbines)

Maintenance Cost and Equipment Life

Are Influenced by Key Service Factors

Fuel

Firing Temperature

Steam/Water Injection

Cyclic Effects (Start-up rate, number of trips)

Air Quality

Service Factors Different From the Reference Condition*

Can Increase Maintenence Cost & Reduce Maintenence Intervals

HDGT.PPT/ 8

External Services (Gas Turbines)

Maintenance Factors

Hot Gas Path (Buckets & Nozzles)

Typical Max Inspection Intervals (MS6B/Ms7EA)

Hot Gas Inspection 24,000 hrs or 1200 Starts

Major Inspection

48,000 hrs or 2400 Starts

Criterion is Hours or Starts (Whichever Occurs First)

Factors Impacting Maintenance

Hours Factors

Fuel

Gas

Distillate

Crude

Residual

Starts Factors

1

1.5

2 to 3

3 to 4

Trip From Full Load

Fast Load

Emergency Start

8

2

20

Peak Load

6

Water/Steam Injection

Dry Control 1 (GTD-222)

Wet Control 1.9 (5% H20)

HDGT.PPT/ 9

External Services (Gas Turbines)

Maintenance Factors Reduce Maintenance

Interval

1400

1200

Starts Factors

Trips, Fast Starts

1000

Starts

800

Hours Factors

Firing Temp

Steam/H2O

Injection

Fuel Type

600

400

200

0

0

12

16

20

24

28

Fired Hours (x1000)

HDGT.PPT/ 10

External Services (Gas Turbines)

Estimated Effect of Fuel Type on Maintenance

Residual

Maintenance

Factor

Distillates

Heavy

Light

Natural Gas

7 8 9 10 11 12 13 14 15

20

Fuel Percent Hydrogen by Weight in Fuel

HDGT.PPT/ 11

External Services (Gas Turbines)

Hot Corrosion

Oxidation

is

Limiting

Factor

Corrosion becomes

Limiting Factor

Component surface saturated

with condensated corrosive deposits.

Life limited primarily by kinetics of the

corrosion reaction.

Life

Na Concentration in Combustion Products

HDGT.PPT/ 12

External Services (Gas Turbines)

Bucket Life Firing Temperature Effect

(MS5001P Uncooled bucket)

100

10

Life

Factor

Peak rating of

Tf + 100 F (65 C)

has life factor of 6

(MS6001B/MS7001EA/MS9001E)

0.1

0.01

-200

-100

100

200

Change in firing temperature - degrees F

HDGT.PPT/ 13

External Services (Gas Turbines)

Example 1:

A unit which has operated at Peak Load (+100 F) for

100 hours would have to be operated at - 50 F for 833

hours to maintain a maintenance factor of ONE.

MF =

Factored Hours

Actual Hours

833 hrs (0.4) + 100 hrs (6.0)

=1

(833 + 100) hrs

HDGT.PPT/ 14

External Services (Gas Turbines)

Example 2:

Determine the Maintenance Factor for a unit which

operates at Base Load for 6000 hours, Peak Load for

600 hours, and at -50 F Firing Temperature for

15000 hours.

MF =

Factored Hours

Actual Hours

6000 hrs (1.0) + 500 hrs (6.0) + 1500 hrs (0.4)

(6000 + 1500 + 500) hrs

MF = 1.2

HDGT.PPT/ 15

External Services (Gas Turbines)

Firing Temperature and Load

Heat Recovery vs Simple Cycle

2500

Close IGVs

84 to 57 deg

Tf constant @

2020 F

Heat Recovery

Simple Cycle

o

57 VIGV

2000

Firing

Temp.

o

F 1500

o

84 VIGV

Close IGVs

84 to 57 deg

Tx constant @ 700 deg F

1000

20

40

60

% Load

80

100

120

HDGT.PPT/ 16

External Services (Gas Turbines)

Heavy Fuel Maintenance Factors

(MS6001B/7001EA/9001E)

Maximum Heavy Fuel

Firing Temperature

10

5

Maintenance

Factor

Residual

Crude

1

-200

-150

-100

-50

50

Delta Firing Temperature F

HDGT.PPT/ 17

External Services (Gas Turbines)

Steam/Water Injection and Nozzle

Creep Deflection

Steam/Water Injection Impacts

Stage 2/3 Nozzle Maintenance

and Life

2nd Stage

Nozzle

3rd Stage

Nozzle

Increases Nozzle Gas Loads

Increases Downstream

Deflection Rate

Decreases Maintenance

Interval

GTD-222 Nozzle Alloy Minimizes

This Effect

HDGT.PPT/ 18

External Services (Gas Turbines)

Steam/Water Injection and Bucket/Nozzle Life

Steam/Water Injection Increases Metal Temperature

of

Hot-Gas-Path Components

Water Effects Gas Transport Properties:

- Thermal Conductivity increases

- Specific Heat increases

- Viscosity remains steady

This increases Heat Transfer Coefficients which increases metal

temperature and decreases bucket life

Example (MS7001EA Stage 1 Bucket):

3% Steam increaes bucket metal temperature 15 F and

decreases Life -33%

at constant firing temperature

HDGT.PPT/ 19

External Services (Gas Turbines)

Exhaust Temperature Control Curve

Dry Versus Wet Control

Steam Injection for 25 ppm NOX

50

Wet Control

40

Exhaust

Temperature

30

o

F

20

10

0

3% Steam Inj.

o

TF = 2020 F

Load Ratio = 1.10

Dry Control

0% Steam Inj.

TF = 2020 o F

Load Ratio = 1.0

3 % Steam Inj.

o

TF = 1994 F

Load Ratio = 1.08

Compressor Discharge Pressure (psig)

HDGT.PPT/ 20

External Services (Gas Turbines)

Maintenance Factors Reduce Maintenance

Interval

1400

1200

Starts Factors

Trips, Fast Starts

1000

Starts

800

Hours Factors

Firing Temp

Steam/H2O

Injection

Fuel Type

600

400

200

0

0

12

16

20

24

28

Fired Hours (x1000)

HDGT.PPT/ 21

External Services (Gas Turbines)

Turbine Start/Stop Cycle

Base Load

Acceleration

Unload Ramp

Light-off

Exh.

Temp.

Full Speed

No Load

Load Ramp

Warm-up

Full Speed

No Load

Fired Shutdown

Trip

Start-up

Time

Shutdown

HDGT.PPT/ 22

External Services (Gas Turbines)

Maint. Factor

Effect of Start Cycle Max Load Level

1.4

1.2

1

0.8

0.6

0.4

0.2

0

0

20

40

60

80

100

120

% Load

HDGT.PPT/ 23

External Services (Gas Turbines)

Low Cycle Fatigue Life

Sensitivities First-Stage Bucket

Leading Edge Temperature/Strain

Normal Start & Trip

Normal Startup/Shutdown

TMAX

Strain

-%

Temperature

Strain

-%

TMAX

Temperature

1 Trip Cycle = 8 Normal Shutdown Cycle

HDGT.PPT/ 24

External Services (Gas Turbines)

Trip Severity Factor

Maintenance Factor - Trips from Load

10

9

8

7

6

5

4

3

2

1

0

Base

For trips during Start-up

Acceleration, assume

Trip Severity Factor = 2

FSNL

20

40

60

80

100

120

% Load

HDGT.PPT/ 25

External Services (Gas Turbines)

Heavy-Duty Gas Turbine

Shutdown Inspections

Combustion

Hot-Gas-Path

Major

Major inspection

Hot-Gas-Path

Inspection

Combustion

Inspection

HDGT.PPT/ 26

External Services (Gas Turbines)

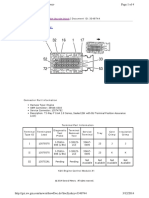

MS7001EA Combustion Inspection Intervals

NOx

Combustor Emissions

Design

Level (ppm)

Standard

Liner

65

42

Fuel

Diluent

Gas

Hours/Starts

Dry

8,000/800

Steam

Water

Steam

Water

------8,000/400

6,500/300

Distillate

Hours/Starts

8,000/800

8,000/400

6,500/300

3,000/150

1,500/100

Extendor Combustion System Wear Kit Increases

Combustion Inspection to as Much as 24,000 Hours

HDGT.PPT/ 27

External Services (Gas Turbines)

Base Line Recommended Inspection Intervals

Base Load - Gas Fuel - Dry

Hours/Starts

Type of

Inspection

Combustion

Hot-Gas Path

Major

MS32/52/51

Upgrade

12000/800

Eliminated/1200

4800/2400

MS6B

MS7E/EA

MS9E/7FA/

9FA

12000/800

8000/800

8000/800

24000/1200

24000/1200

24000/900

48000/2400

48000/2400

48000/2400

Factors That Can Reduce Maintenance Intervals

Trips from Load

Fuel

Start Cycle

Load Setting

HGP Hardware Design

Steam/Water Injection

Peak Load Tf Operation

HDGT.PPT/ 28

External Services (Gas Turbines)

Maintenance Factor Definition

IDEAL INTERVAL =

RECOMMENDED

INTERVAL

=

Interval for Continuous Base Load

on Clean Natural Gas

Ideal Interval determined from

application of maintenance factors

HDGT.PPT/ 29

External Services (Gas Turbines)

HGPI Hours Based Criterion

MS6001/7001/9001

24000

Maintenance Interval

=

(Hours)

Maintenance Factor

Where:

Factored Hours

Acutal Hours

Factored Hours = (K + (M x I)) x (G + 1.5 D + Af H + 6 P)

Actual Hours

= (G + D + H + P)

Maintenance Factor =

G = Operating Hours on Gas Fuel

D = Operating Hours on Distillate Fuel

H = Operating Hours on Heavy Fuel

Af = Heavy Fuel Severity Factor (Residual Af = 3 to 4, Crude Af = 2 to 3)

P = Peak Load Operating Hours

I = Percent Water/Steam Injection Referenced to Inlet Air Flow

M & K = Water/Steam Injection Constants

M

Control

Steam Injection

N2 / N3 Material

0

0

.18

.18

1

1

.6

1

Dry

Dry

Dry

Wet

< 2.2 %

> 2.2 %

> 2.2 %

>0%

GTD-222 / FSX-414

GTD-222

FSX-414

GTD-222 / FSX-414

HDGT.PPT/ 30

External Services (Gas Turbines)

HGPI Starts Based Criterion

MS6001/7001/9001

S

Maintenance Interval

=

(Starts)

Maintenance Factor

Where:

Maintenance Factor =

Factored Starts

Acutal Starts

Factored Starts = (0.5 NA + NB + 1.3 NP + 20 E + 2 F +

Actual Starts

aTi Ti )

i=1

= (NA + NB + NP + E + F)

S = Maximum Starts-Based Maintenance Interval (Model Size Dependent)

NA = Number of Part Load Start/Stop Cycles (< 60% Load)

NB = Number of Normal Base Load Start/Stop Cycles

NP = Number of Peak Load Start/Stop Cycles

E

= Number of Emergency Starts

S

Model Series

F

= Number of Fast Load Starts

1,200

Tn = Trips

MS6B/MS7EA

aT n = Trip Severity Factor

1,200

MS6FA

n

= Trip number

900

MS9E

900

MS7F/7FA/9F/9FA

HDGT.PPT/ 31

External Services (Gas Turbines)

First-Stage Nozzle Wear Preventive Maintenance

Gas-Fired - Continuous Duty - Base Load

New Nozzle Acceptance Standards

Repaired Nozzle

Nozzle Min. Acceptance

Condition Standard

1st

Repair

2nd

Repair

3rd

Repair

Without

Repair

Repair Cost

Exceeds

Replacement

Cost

Severe Deterioration

10,000

20,000

30,000

40,000

50,000

Operating Hours

60,000

70,000

80,000

HDGT.PPT/ 32

External Services (Gas Turbines)

Estimated Repair & Replacement

Repair

Interval

Combustion Liners

Transition Pieces

Fuel Nozzles

Cross-Fire Tubes

1st Stage Nozzles

2nd Stage Nozzles

3rd Stage Nozzles

1st Stage Buckets

CI

CI

CI

CI

HGPI

HGPI

HGPI

HGPI*

2nd Stage Buckets

3rd Stage Buckets

1st Stage Shrouds

2nd/3rd Stage Shrouds

HGPI

HGPI

HGPI

HGPI

Replace

Interval

(Hours)

5 (CI)

6 (CI)

3 (CI)

3 (CI)

3 (HGPI)

3 (HGPI)

3 (HGPI)

2 (HGPI)

3 (HGPI)**

3 (HGPI)

3 (HGPI)

2 (HGPI)

3 (HGPI)

Replace

Interval

(Starts)

5 (CI)

6 (CI)

3 (CI)

3 (CI)

3 (HGPI)

3 (HGPI)

3 (HGPI)

3 (HGPI)

4 (HGPI)

4 (HGPI)

2 (HGPI)

4 (HGPI)

CI = Combustion Inspection Interval

HGPI = Hot Gas Path Inspection Interval

* When recoating, perform after one hours-based HGPI

** Two HGPI without recoat, Three HGPI with Recoat

HDGT.PPT/ 33

External Services (Gas Turbines)

Maintenance Factors Summary

Maintenance Requirements are Based on an Independent

Count of Hours and Starts

Certain Operating Factors Reduce Maintenance Intervals

Peak Loac

Steam/Water Injection >2.2%

Liquid Fuel

Trips From Load

Fast Starts

Exceeding GE Specification Limits can Significantly

Increase Maintenance Factors and Reduce Component Life

Equations for Establishing Application Specific Hot Gas

Path Maintenance Intervals are Available

HDGT.PPT/ 34

External Services (Gas Turbines)

Bucket Life Firing Temperature Effect

MS6001B / MS7001EA / MS9001E

100

Life

10

Factor

Peak Rating

+100F (56C) T.

Life Factor -6

1

Change in 0

Firing

0

Temperature

50

25

100

150

50

75

200

100

250

125

C

HDGT.PPT/ 35

External Services (Gas Turbines)

Operating Inspection Data Parameters

Speed

Load

Fired Starts

Fired Hours

Site Barometric Reading

Temperatures

Inlet Ambient

Compressor Discharge

Turbine Exhaust

Turbine Wheelspace

Lube Oil Header

Lube Oil Tank

Bearing Drains

Exhaust Spread

Pressures

Compressor Discharge

Lube Pump(s)

Bearing Header

Cooling Water

Fuel

Filters (Fuel, Lube, Inlet Air)

Vibration Data for Power Train

Generator

Output Voltage Field Voltage

Phase Current Field Current

VARS

Stator Temp.

Load

Vibration

Start-Up Time

Coast-Down Time

HDGT.PPT/ 36

External Services (Gas Turbines)

Deterioration of Gas Turbine Performance

Due to Compressor Blade Fouling

8

6

4

Fouling

2

Heat Rate

Increase

%

5% Loss of

Airflow

-2

-4

Output

Decrease

%

-6

-8

-10

Fouling

-12

-14

-1 -2 -3 -4 -5 -6 -7 -8

Pressure Ratio Decrease - %

HDGT.PPT/ 37

External Services (Gas Turbines)

Maintenance Inspections

Hot Gas Path Inspection - Key Elements

Combustion Inspection Work Scope Plus:

Key Hardware

Nozzles (1,2,3)

Buckets (1,2,3)

Stator Shrouds

IGVs & Bushings

Compressor Blading

(Borescope)

Criteria:

Inspect for:

Potential Actions:

Foreign Objects Damage

Repair/Refurbishment

Nozzles

Oxidation/Corrosion/Erosion

Weld Repair

Cracking

Reposition

Cooling Hole Plugging

Recoat

Remaining Coating Life

Buckets

Nozzle Deflection/Distortion

Strip & Recoat

Weld Repair

Abnormal Deflection/Distortion

Blend

Abnormal Wear

Missing Hardware

Clearance Limits

Op. & Instr. Manual

TILs

Field Engineers

Inspection

Methods:

Visual

LP

Boroscope

Availability of On Site

Spares Is Key to

Minimizing Downtime

HDGT.PPT/ 38

External Services (Gas Turbines)

Maintenance Inspections

Combustion Inspection - Key Elements

Key Hardware

Combustion Liners

Combustion Covers

Fuel Nozzles

Transition Pieces

Cross Fire Tubes

Flow Sleeves

Check Valves

Spark Plugs

Flame Detectors

Flex Hoses

Criteria:

Op. & Instr. Manual

TILs

Field Engineers

Inspect for:

Potential Actions:

Foreign Objects

Abnormal Wear

Cracking

Liner Cooling Hole Plugging

TBC Coating Condition

Oxidation/Corrosion/Erosion

Hot Spots/Burning

Missing Hardware

Clearance Limits

Borescope Compressor and

Turbine

Inspection

Methods:

Repair/Refurbishment

Liners

Cracking/Erosion/Wea

r

TBC Repair

Transition Pieces

Wear

TBC Repair

Distortion

Fuel Nozzles

Plugging

Erosion/Wear

Cross Fire Tubes

Wear/Burning

Visual

Availability of On Site

Spares Is Key to

LP

Minimizing Downtime

Boroscope

HDGT.PPT/ 39

External Services (Gas Turbines)

Maintenance Inspections

GT Major Inspection - Key Elements

Combustion Inspection Work Scope

HotGas Path Inspection Work Scope Plus

Key Hardware

Inspect for:

Potential Actions:

Repair/Refurbishment

Foreign Objects Damage

Stator Shrouds

Oxidation/Corrosion/Erosion

Turbine Wheels Dovetails

Oxidation/Corrosion/Erosio

Cracking

n

Journal and Seal Surfaces

Buckets

Leaks

Coating Deterioration

Bearing Seals

Abnormal Wear

FOD/Rubs/Cracking

Missing Hardware

Inlet System

Tip Shroud Deflection

Creep Life Limit

Clearance Limits

Exhaust System

Nozzles

Severe Deterioration

IGV Bushings

Criteria: Op. & Instr. Manual Inspection Visual

Wear

Bearings/Seals

Methods: LP

TILs

Booring/Wear

Field Engineers

Borescope

Compressor Blades

Corrosion/Erosion HDGT.PPT/ 40

Compressor Blading

Você também pode gostar

- Manual Kubota m130xDocumento654 páginasManual Kubota m130xRaul Soteras Esteban100% (6)

- Maintenance Frame 9E GTDocumento6 páginasMaintenance Frame 9E GTOctavianus Harahap100% (1)

- Digifant 45 IntDocumento6 páginasDigifant 45 Int2791957Ainda não há avaliações

- Combustion 6FADocumento30 páginasCombustion 6FAprasad5034100% (5)

- Turbine TroubleshootingDocumento15 páginasTurbine TroubleshootingBrian ASAinda não há avaliações

- GT Various Systems (G)Documento62 páginasGT Various Systems (G)shtiwari2002100% (2)

- Control Gas Turbine Power Output in Conjuction With Grid FrequencyDocumento32 páginasControl Gas Turbine Power Output in Conjuction With Grid Frequencysmart_eng2009100% (3)

- Gas Turbine Maintenance: GE Power SystemsDocumento60 páginasGas Turbine Maintenance: GE Power SystemsHoucine Belhaska100% (2)

- Water Plasma Spark Plug ResearchDocumento104 páginasWater Plasma Spark Plug ResearchBernd Kochs100% (1)

- Cryogenic Vaporisation SystemsDocumento30 páginasCryogenic Vaporisation SystemsAnonymous 1XHScfCI100% (1)

- Steam Turbine PowerpointDocumento25 páginasSteam Turbine PowerpointMohammed Fares88% (8)

- Drive ActiveHybrid - V.4 GA8P70HZDocumento15 páginasDrive ActiveHybrid - V.4 GA8P70HZTimur GorgievAinda não há avaliações

- (CHEVROLET) Manual de Taller Chevrolet Orlando 2014Documento12 páginas(CHEVROLET) Manual de Taller Chevrolet Orlando 2014Daniel Gomez100% (1)

- Heavy Duty Gas Turbine Maintenance From GEDocumento36 páginasHeavy Duty Gas Turbine Maintenance From GEJitu Jena100% (3)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingNo EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingNota: 5 de 5 estrelas5/5 (1)

- Frame 9e Gas Turbine PresentationDocumento98 páginasFrame 9e Gas Turbine PresentationSONU100% (1)

- Industrial Gas Turbines - Siemens PDFDocumento8 páginasIndustrial Gas Turbines - Siemens PDFeankiboAinda não há avaliações

- Material Inspection of Hot Gas PathDocumento2 páginasMaterial Inspection of Hot Gas Patheankibo100% (1)

- Compressor Maintenance Water WashingDocumento30 páginasCompressor Maintenance Water WashingMajid Motahari100% (1)

- Liners FaliureDocumento17 páginasLiners Faliurefarhanzafar736Ainda não há avaliações

- IGV Operational Principle - 1Documento5 páginasIGV Operational Principle - 1ramkrishnaAinda não há avaliações

- Power Plant Engineering Final Exam 2013-2014:) ططخم و راخبلا لودج مادختساب حمسي s - h (Answer Five Questions OnlyDocumento7 páginasPower Plant Engineering Final Exam 2013-2014:) ططخم و راخبلا لودج مادختساب حمسي s - h (Answer Five Questions Onlyxan pitchuAinda não há avaliações

- Accessories of A Gas Turbine EngineDocumento20 páginasAccessories of A Gas Turbine EngineJames VillezaAinda não há avaliações

- Ger 3620fDocumento34 páginasGer 3620ftechnica100% (1)

- Gas Turbine MaintenanceDocumento47 páginasGas Turbine MaintenanceMohammad Ibnul Hossain100% (1)

- GT PresentaionDocumento98 páginasGT Presentaionmujeebtalib100% (5)

- 06 UCH GT 9001E - Inlet Filter & Duct SystemsDocumento113 páginas06 UCH GT 9001E - Inlet Filter & Duct SystemsHassan Mahmood100% (1)

- Gas TurbineDocumento14 páginasGas Turbinevasanth11kv100% (2)

- Training Session4 - Heat Recovery Steam GeneratorsDocumento34 páginasTraining Session4 - Heat Recovery Steam GeneratorsarianaseriAinda não há avaliações

- What Is Plant MaintenanceDocumento5 páginasWhat Is Plant Maintenancesamplc2011Ainda não há avaliações

- PGT25DLE MaintenanceDocumento61 páginasPGT25DLE Maintenanceolegprikhodko2809100% (1)

- Heavy-Duty Gas Turbine Operating and MaintenanceDocumento60 páginasHeavy-Duty Gas Turbine Operating and MaintenanceAnte Bučević100% (1)

- Challenges and Opportunities in Turbomachinery ControlDocumento163 páginasChallenges and Opportunities in Turbomachinery ControlLarry Smith100% (2)

- 04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDocumento18 páginas04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDangolAinda não há avaliações

- GE Gas Turbine IGV AngleDocumento8 páginasGE Gas Turbine IGV Angleramkrishna100% (1)

- 6B9E UpratesDocumento58 páginas6B9E UpratesMegiovandi Purba Pak Pak100% (3)

- Inspections, As A Part of A Maintenance Program That Must Be Put in Place With TheDocumento29 páginasInspections, As A Part of A Maintenance Program That Must Be Put in Place With TheFrankAinda não há avaliações

- Gas Turbine IntroductionDocumento84 páginasGas Turbine IntroductionMohammad Akram100% (2)

- 04 - Dry Low NOxDocumento15 páginas04 - Dry Low NOxdenmas90Ainda não há avaliações

- Technical TrainingDocumento7 páginasTechnical Trainingjenz84rulez0% (1)

- Torque Converter Voith Torque ConverterDocumento22 páginasTorque Converter Voith Torque ConverterDewayne MaddenAinda não há avaliações

- GE 9FA Water Wash PROCEDURE FinalDocumento43 páginasGE 9FA Water Wash PROCEDURE FinalAbdelaziz EldeebAinda não há avaliações

- 1-Gas Turbine DesignDocumento56 páginas1-Gas Turbine DesignMohammed Yusuf100% (2)

- ASME Presentation Nov 2014 PDFDocumento56 páginasASME Presentation Nov 2014 PDFdf_campos33530% (2)

- Learn Gas Turbine by SimulationDocumento41 páginasLearn Gas Turbine by SimulationAnonymous 8RRc42G100% (1)

- Availability Analysis of Gas TurbinesDocumento10 páginasAvailability Analysis of Gas TurbinesEman ZabiAinda não há avaliações

- Gas TurbineDocumento122 páginasGas Turbinechetana100% (1)

- Fundamentals of Gas Turbine Operation MaintenanceDocumento21 páginasFundamentals of Gas Turbine Operation MaintenanceAndre JosuaAinda não há avaliações

- GEK103623 DDocumento18 páginasGEK103623 DNouman Saeed100% (1)

- Combustion Monitor GEK106832Documento16 páginasCombustion Monitor GEK106832alaal67% (3)

- 3 - Gas Turbine Overview 8.09Documento25 páginas3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Gas Turbine ManualDocumento48 páginasGas Turbine ManualShivam Kumar100% (3)

- Gas Turbine MaintenanceDocumento3 páginasGas Turbine MaintenanceMohamed NawarAinda não há avaliações

- Smple Cycle Thermodynamics OverviewDocumento31 páginasSmple Cycle Thermodynamics OverviewONURAinda não há avaliações

- Borsecope Inspection PDFDocumento9 páginasBorsecope Inspection PDFahmedAinda não há avaliações

- M7278 - General Electric-AlstomDocumento611 páginasM7278 - General Electric-AlstomcgmenesesAinda não há avaliações

- Overview of Start-Up of Gas TurbineDocumento38 páginasOverview of Start-Up of Gas TurbineJulio Cesar Barajas Aguilar100% (1)

- EEI 7FA Supplement r1 2octDocumento42 páginasEEI 7FA Supplement r1 2octkshalawi0% (1)

- Siemens Gas Turbine SGT 500 Crude OilDocumento10 páginasSiemens Gas Turbine SGT 500 Crude Oilgeverett2765Ainda não há avaliações

- IGV, Servos and LVDT - Automation & Control Engineering ForumDocumento1 páginaIGV, Servos and LVDT - Automation & Control Engineering ForumHBNBILAinda não há avaliações

- GE Gas TurbineTheoryDocumento62 páginasGE Gas TurbineTheorysalamadel100% (2)

- 2015 Gas Turbines Final QuestionsDocumento14 páginas2015 Gas Turbines Final QuestionsEnaj Olea Buenviber100% (1)

- GTG MaintenanceDocumento40 páginasGTG MaintenanceKalyankumar Kumar100% (1)

- Gas Turbine 4Documento40 páginasGas Turbine 4Ali Eng100% (1)

- Gas Turbine Maintenence AspectsDocumento38 páginasGas Turbine Maintenence Aspectsprasad5034100% (1)

- SGT-600 GT PowerGen ENDocumento4 páginasSGT-600 GT PowerGen ENBehnamayoubzadehAinda não há avaliações

- Gas Turbines Technical PerformanceDocumento2 páginasGas Turbines Technical PerformanceLTE002100% (1)

- Module-1 ATF - IC Engine - Fundamental of IC EngineDocumento50 páginasModule-1 ATF - IC Engine - Fundamental of IC EngineNandepu Sravan KumarAinda não há avaliações

- Engineering ChemistryDocumento293 páginasEngineering ChemistrySun Tzu67% (3)

- Evs 5Documento130 páginasEvs 5shaikmanojAinda não há avaliações

- Production Planning LPP CaseDocumento2 páginasProduction Planning LPP Caserinkirola7576Ainda não há avaliações

- POWERTRAIN Product Booklet Final 2017Documento118 páginasPOWERTRAIN Product Booklet Final 2017Wilhelm ThorleyAinda não há avaliações

- Oil Gas Operations Consultant in Houston Texas Resume David HuntingtonDocumento4 páginasOil Gas Operations Consultant in Houston Texas Resume David HuntingtonDavid HuntingtonAinda não há avaliações

- Course 228 FileDocumento7 páginasCourse 228 FilegrfAinda não há avaliações

- SM 33Documento68 páginasSM 33Enrique Arevalo LeyvaAinda não há avaliações

- 304D TYK00743 TA1 - Excavator Inpection ReportDocumento11 páginas304D TYK00743 TA1 - Excavator Inpection ReportCesar Eduardo Contreras CastilloAinda não há avaliações

- BCM One Marks & Two Marks Question With AnswerDocumento10 páginasBCM One Marks & Two Marks Question With AnswerSathis KumarAinda não há avaliações

- Assignment 1 - ProsperDocumento9 páginasAssignment 1 - ProsperMuhammad Amirullah SanadiAinda não há avaliações

- 1a) III) Importance of MTBEDocumento4 páginas1a) III) Importance of MTBEMuhammad HaikalAinda não há avaliações

- Diesel Generator Fuel Consumption Chart in LitresDocumento1 páginaDiesel Generator Fuel Consumption Chart in LitresAnkur mittalAinda não há avaliações

- Fact Sheet: Engine D13K500, EU6SCRDocumento3 páginasFact Sheet: Engine D13K500, EU6SCRfrank mutale100% (1)

- Aqua Blend AB1 PDFDocumento4 páginasAqua Blend AB1 PDFusaid saifullahAinda não há avaliações

- DC13 072A. 356-415 KW (408-471 kVA) : Fuel OptimizedDocumento2 páginasDC13 072A. 356-415 KW (408-471 kVA) : Fuel OptimizedbrayandparavicinoAinda não há avaliações

- 4000 Engines Industrial Mining ApplicationsDocumento2 páginas4000 Engines Industrial Mining ApplicationsedgarwalterAinda não há avaliações

- SMLDocumento23 páginasSMLਸਰਦਾਰ Supreet SinghAinda não há avaliações

- Volvo Penta AQ125A - AQ145A Engine Unit Workshop Manual (En) (01-37)Documento37 páginasVolvo Penta AQ125A - AQ145A Engine Unit Workshop Manual (En) (01-37)Edgar Maldonado100% (1)

- Global Gear Tuthill PDFDocumento6 páginasGlobal Gear Tuthill PDFJose VargasAinda não há avaliações

- Microcrystalline GraphiteDocumento4 páginasMicrocrystalline GraphiteFamiloni LayoAinda não há avaliações

- Mini Project PDFDocumento111 páginasMini Project PDFAnisAsyiqinAinda não há avaliações

- SY Echanic Auto Ele Elecn 08 06-14 PDFDocumento28 páginasSY Echanic Auto Ele Elecn 08 06-14 PDFSasidharanAinda não há avaliações