Escolar Documentos

Profissional Documentos

Cultura Documentos

Bevel Gears

Enviado por

Balasoobramaniam CarooppunnenDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bevel Gears

Enviado por

Balasoobramaniam CarooppunnenDireitos autorais:

Formatos disponíveis

Mind

Works

Bevel Gears

Bevel gears have their teeth formed on a conical surface and are used to transfer

motion between intersecting shafts. This poster covers straight-tooth bevel gears. Spiral

bevel gears are quite similar but have their teeth cut so that they are no longer straight but

form a circular arc. For both straight and spiral bevel gears, the shafts have to be

perpendicular and in the same plane. Hypoid gears can transfer motion between shafts that

are offset and dont intersect.

Straight Tooth

Bevel Gear

By: Brian Chamberlin, Luke Rust, and Bryan Blakey

Source: Mechanical Engineering Design, 5th Edition, Shigley and Mischke, McGraw-Hill, 1989

Hypoid

Bevel Gear

Spiral

Bevel Gear

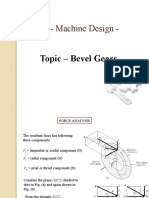

Goal:

Find the force (W) that would occur if all the forces were concentrated at the midpoint of the gear tooth. This force is composed of three component forces, a

tangential, a radial and an axial force. Once the force acting at the midpoint we can perform a simple statistical analysis to find the reactions in the shaft and/or the bearings.

W t = the tangential force at the midpoint of the tooth.

Ka = application factor (compensates for situations where the actual load exceeds the nominal tangential load Wt

and is assigned by the engineer)

W t

Pd = nominal diametral pitch in plane of rotation

W a W t tan cos

Wr Wt tan cos

( 33000 H)

= Pitch angle of the gear.

tan

tangential force is due to the amount of power transferred to the

Vgear asThe

well as the pitch line velocity. Once we calculate the tangential force

Ks = size factor (typically unity, but included to account for nonuniformity in

material properties)

=bending stress

W a = the axial force.

W r = the radial force

H = the Horsepower transferred to the gear from

the pinion

W t = transmitted tangential load computed using the pitch radius at the large end of the gear teeth

P

( 1) d

Gd

we can find the radial and axial forces if we now the pressure angle, and the

pitch angle of the gear.

P d = the diameter of the pinion

Gd

= the diameter of the gear

Km = load distribution factor

W t K a

Kv

Pd

F

K s K m

J

Ca = application factor (compensates for situations where the actual load exceeds the nominal tangential load

Wt and is assigned by the engineer)

rp = the average pitch radius, this is the distance from the

center of the pinion to the midpoint of the gear tooth

Cs = size factor (typically unity, but included to account for nonuniformity in

material properties)

Cm = load-distribution factor

c = absolute value of contact stress

n = the speed that the pinion

rotates

F = face width

J = bending strength geometry factor

K v

A V

K v

A 200 V

A=50+56(1-B)

W t C a C s C m C f

c C P

F d

I

Cv

B

for V in ft/min

for V in m/s

V = pitch-line velocity

2r pn

V

Cp = elastic coefficient

B=(12-Qv)(2/3)/4

= Allowable bending stress:

CL = life factor (from AGMA graph)

all

KT KR

= Allowable Contact stress:

KL = life factor (from AGMA graph)

c.all

KR = reliability factor

3 H BP

3

8.9810

8.2910

H BG

CH = hardness-ratio factor (used only for the gear)

m G

S c C L C H

C T C R

HBP and HBG = Brinell harnesses of pinion and gear,

respectively

dG

dG = pitch diameter of gear

dP

dP = pitch diameter of pinion

KR = CR = 0.7 0.15 log (1 R ) 0.9 R < 0.99

KR = CR = 0.5 0.25 log (1 R ) 0.99 R < 0.9999

CR = reliability factor

KT = temperature factor (unity up to gear-blank temperatures of 250F , greater

than unity for higher temperatures)

Cp is obtained from a Hertzian stress analysis of

contacting spheres, and values are given in AGMA tables.

Similarly, values for geometry factor I can be taken from

AGMA graphs for various bevel gear geometries. The

load distribution factor Cm is included to account for

misalignment of rotational axes, deviations in lead, and

load-caused elastic deflections of shafts, bearings, and/or

housing. The values for Cm can be found in a table based

on conditions of support and face width. Note: all values

apply to the large end of the teeth.

CH = 1.0 + A(mG 1.0) (only valid when (HBP / HBG) 1.7 )

St = AGMA bending strength (from AGMA graphs or tables)

d = pitch diameter of pinion

Cv = dynamic factor (given by the same equation as Kv in bending stress formula)

Typically, values for Kv are plotted vs. values of V and can be taken from AGMA

dynamic factor graphs. Similarly, values for geometry factor J can be taken from AGMA

graphs for various bevel gear geometries. The load distribution factor K m is included to

account for misalignment of rotational axes, deviations in lead, and load-caused elastic

deflections of shafts, bearings, and/or housing. The values for K m can be found in a table

based on conditions of support and face width.

Sc = AGMA surface fatigue strength

(from AGMA graphs or tables)

St KL

Cf = surface-condition factor (no currently established

values, but values greater than unity recommended in the

presence of obvious surface defects)

I = geometry factor

12

F = face width

Qv = AGMA transmission accuracy-level number

1

2

CT = temperature factor (unity up to gear-blank temperatures of

250F , greater than unity for higher temperatures)

R = reliability corresponding to 107 cycles of life

Você também pode gostar

- Spline Stress CalculationDocumento8 páginasSpline Stress CalculationSantiago MolinaAinda não há avaliações

- Design of Helical Gear With Involute ProfileDocumento55 páginasDesign of Helical Gear With Involute ProfileRavi TarunAinda não há avaliações

- Module IV: Gears and Gear TrainsDocumento38 páginasModule IV: Gears and Gear TrainsSuraj VinayAinda não há avaliações

- Gear Generating Profile Shift CalculationsDocumento2 páginasGear Generating Profile Shift CalculationsSanjay Shelar0% (1)

- Spur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDocumento31 páginasSpur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDipakAinda não há avaliações

- Bevel Gear Load CapacityDocumento11 páginasBevel Gear Load CapacityAriel Rasjido50% (2)

- Bev Gear Design PDFDocumento5 páginasBev Gear Design PDFMawan BentzAinda não há avaliações

- Bevel Gear CalcsDocumento11 páginasBevel Gear Calcsmanish_umdAinda não há avaliações

- GearDocumento18 páginasGearKrishna Kumar AlagarAinda não há avaliações

- Design of Bevel GearDocumento23 páginasDesign of Bevel Gearshahzadali078650% (2)

- Introduction To Direct Gear DesignDocumento15 páginasIntroduction To Direct Gear DesignburaktuncerAinda não há avaliações

- Σχεδιασμός Σε Κάμψη Μετωπικών Οδοντωτών Τροχών Κατά Agma: F Sk Kkkkk S Mbj SkkDocumento1 páginaΣχεδιασμός Σε Κάμψη Μετωπικών Οδοντωτών Τροχών Κατά Agma: F Sk Kkkkk S Mbj SkkkstayroskAinda não há avaliações

- Bevel GearDocumento9 páginasBevel GearAadil KhanAinda não há avaliações

- ISO Standardisation of Bevel Gears: Overview and Ideas On Method A"Documento28 páginasISO Standardisation of Bevel Gears: Overview and Ideas On Method A"vincemugnaioAinda não há avaliações

- Helical Spring DesignDocumento47 páginasHelical Spring DesignHKHKBOOKS100% (1)

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFDocumento6 páginasCycloid Drive - Replaced by Planocentric Involute Gearing PDFMax GrandeAinda não há avaliações

- Direct Gear DesignDocumento7 páginasDirect Gear DesignFranco Angelo RegenciaAinda não há avaliações

- Spline Design Using KISSSoftDocumento8 páginasSpline Design Using KISSSoftAllan John Sala Limson0% (1)

- Transmission System of Gear BoxDocumento86 páginasTransmission System of Gear BoxAmit Kumar Uke100% (4)

- Elements of GearDocumento7 páginasElements of GearShashindra DhopeshwarAinda não há avaliações

- Formulas For Gear Calculation - Internal GearsDocumento7 páginasFormulas For Gear Calculation - Internal Gearssuna06m6403Ainda não há avaliações

- Machine Design Lec3Documento75 páginasMachine Design Lec3sam0415Ainda não há avaliações

- University of Southern Philippines Foundation. College of Engineering and ArchitectureDocumento12 páginasUniversity of Southern Philippines Foundation. College of Engineering and ArchitectureJason OwiaAinda não há avaliações

- Cycloid Drive - Replaced by Planocentric Involute GearingDocumento6 páginasCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeAinda não há avaliações

- Design of Spur GearDocumento67 páginasDesign of Spur GearShubham DhurjadAinda não há avaliações

- Bevel Gear - Force Analysis of Bevel GearDocumento16 páginasBevel Gear - Force Analysis of Bevel GearRohit GhulanavarAinda não há avaliações

- Circlip Design PDFDocumento6 páginasCirclip Design PDFSandeep KumarAinda não há avaliações

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocumento42 páginasDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaAinda não há avaliações

- Shigley Formula SheetDocumento12 páginasShigley Formula SheetWesley Botha100% (1)

- Designing Parametric Bevel Gears With Catia V5: 1 Sources, Credits and LinksDocumento10 páginasDesigning Parametric Bevel Gears With Catia V5: 1 Sources, Credits and Linksimrans04Ainda não há avaliações

- Gears KinematicsDocumento19 páginasGears Kinematicsavinashn12Ainda não há avaliações

- Optimization of Gear Reduction Unit Through Ray DiagramDocumento7 páginasOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Design of ShaftDocumento73 páginasDesign of ShaftVratraj JoshiAinda não há avaliações

- Gears - Engineering InformationDocumento138 páginasGears - Engineering InformationGiang T LeAinda não há avaliações

- Gear DesignDocumento53 páginasGear Designtheleovn100% (3)

- Kisssoft Bolt Analysis ManualDocumento24 páginasKisssoft Bolt Analysis Manualanhntran4850Ainda não há avaliações

- Machine Design - Design of ClutchesDocumento12 páginasMachine Design - Design of ClutchesSachin Chaturvedi90% (21)

- Objective:: Material Aluminium 7075 GradeDocumento12 páginasObjective:: Material Aluminium 7075 Gradevishal yadav100% (1)

- Kisssoft Tut 015 E BevelgearDocumento22 páginasKisssoft Tut 015 E BevelgearJorge Ronald Cabrera ÑaupaAinda não há avaliações

- Spur Gears - SlidesDocumento45 páginasSpur Gears - SlidesKim Jeff BeringuelAinda não há avaliações

- Gear 1Documento9 páginasGear 1Ariyant CreativeAinda não há avaliações

- Tooth ThicknessDocumento9 páginasTooth ThicknessPraveen VundrajavarapuAinda não há avaliações

- Gear DesignDocumento83 páginasGear DesignmuhammadaminjamalmutAinda não há avaliações

- Design of Helical and Bevel GearDocumento53 páginasDesign of Helical and Bevel GearPRANAY SHRIDHAR100% (1)

- Lecture - 3 - SHAFT DESIGNDocumento48 páginasLecture - 3 - SHAFT DESIGNHammad RazaAinda não há avaliações

- Gear Design ProcedureDocumento9 páginasGear Design Procedurenithree100% (1)

- Gear NomenclatureDocumento41 páginasGear NomenclatureViswanathan SrkAinda não há avaliações

- Mechanical DesignDocumento141 páginasMechanical DesignAhmed EĻ-dawodyAinda não há avaliações

- Introduction To GearsDocumento30 páginasIntroduction To GearsPrakash Joshi100% (5)

- Spiral Bevel Gear Arcoid System ZFTKK 250-1Documento4 páginasSpiral Bevel Gear Arcoid System ZFTKK 250-1er_winwibowo100% (2)

- Lecture 5-Gears - General - 4-L - Helical and Bevel ForceDocumento41 páginasLecture 5-Gears - General - 4-L - Helical and Bevel ForceAhmed Al SayedAinda não há avaliações

- Lecture 16 - Worm Gears Worked Out ProblemsDocumento19 páginasLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- Helical Gears: (Buckingham) Book)Documento18 páginasHelical Gears: (Buckingham) Book)govindarajan017100% (1)

- Helical GearsDocumento24 páginasHelical GearsPrakash Joshi88% (8)

- BevelDocumento20 páginasBevelOmer NadeemAinda não há avaliações

- Capitulo 6 - Torsion en Ejes Prismaticos PDFDocumento42 páginasCapitulo 6 - Torsion en Ejes Prismaticos PDFCristian David BravoAinda não há avaliações

- TorsionDocumento20 páginasTorsionSathish SelvaAinda não há avaliações

- Torsion of Circular ShaftsDocumento26 páginasTorsion of Circular ShaftsNaveen Kumar0% (1)

- A Guide To Become A Succesful Marine EngineerDocumento99 páginasA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- Rae Systems Parts List October 26 2010Documento2 páginasRae Systems Parts List October 26 2010Mike HastingsAinda não há avaliações

- World Is Flat Thomas FriedmanDocumento10 páginasWorld Is Flat Thomas FriedmanGilean DalidaAinda não há avaliações

- Detector Demetales Manuel 103Documento6 páginasDetector Demetales Manuel 103wilfredoAinda não há avaliações

- 1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)Documento1 página1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)raacontreras21Ainda não há avaliações

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocumento2 páginasFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryAinda não há avaliações

- Soundtrack: Aden LeeDocumento7 páginasSoundtrack: Aden Lee이성진Ainda não há avaliações

- Roman Helmet From SivacDocumento33 páginasRoman Helmet From SivacArachne DreamweaverAinda não há avaliações

- Wartsila O Env Multi Stage Flash EvaporatorsDocumento2 páginasWartsila O Env Multi Stage Flash EvaporatorsRichard Periyanayagam0% (1)

- Yuasa Technical Data Sheet: The World's Leading Battery ManufacturerDocumento1 páginaYuasa Technical Data Sheet: The World's Leading Battery ManufacturerAshraf Sayed ShabaanAinda não há avaliações

- Present Simple Present ContinuousDocumento3 páginasPresent Simple Present ContinuousFernando SabinoAinda não há avaliações

- Behaviour Modification Testbank PDFDocumento118 páginasBehaviour Modification Testbank PDFjade tagabAinda não há avaliações

- Huawei FusionServer RH2288 V3 Data Sheet PDFDocumento2 páginasHuawei FusionServer RH2288 V3 Data Sheet PDFMartenMattisenAinda não há avaliações

- BITS Pilani: Scale Up and Post Approval ChangesDocumento56 páginasBITS Pilani: Scale Up and Post Approval ChangesshrikantmsdAinda não há avaliações

- CSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamDocumento57 páginasCSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamNadia Anjum100% (1)

- SuperboltDocumento32 páginasSuperboltRajeev Chandel100% (1)

- Synchronous Motor AC DrivesDocumento40 páginasSynchronous Motor AC DrivesHarshal Thakur100% (1)

- Jurnal Ari Maulana Ullum Sasmi 1801038Documento12 páginasJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10Ainda não há avaliações

- SOM-based Generating of Association RulesDocumento5 páginasSOM-based Generating of Association RulesKishor PeddiAinda não há avaliações

- Ipcrf Core Values 2019 - FinalDocumento23 páginasIpcrf Core Values 2019 - FinalFrendelyn p. Gador100% (4)

- Press Releases Are Not A PR Strategy An Executive Annas ArchiveDocumento200 páginasPress Releases Are Not A PR Strategy An Executive Annas Archivehelenajosemacuacua31Ainda não há avaliações

- Digital Album On Prominent Social ScientistsDocumento10 páginasDigital Album On Prominent Social ScientistsOliver Antony ThomasAinda não há avaliações

- Audio Level Meter - ProjectDocumento4 páginasAudio Level Meter - ProjectMircea PanzariuAinda não há avaliações

- Manual of Armacad v9 PDFDocumento102 páginasManual of Armacad v9 PDFCristiana FelicianoAinda não há avaliações

- Experimental Psychology & The Scientific MethodDocumento73 páginasExperimental Psychology & The Scientific MethodRuru LavariasAinda não há avaliações

- The Cheetah Light CL-360 - A Short Review: Blog - Wedding & Portrait NewsDocumento3 páginasThe Cheetah Light CL-360 - A Short Review: Blog - Wedding & Portrait NewsSupratim ChoudhuryAinda não há avaliações

- Toyota Motor Manufacturing (TMM)Documento20 páginasToyota Motor Manufacturing (TMM)Lekha ShahAinda não há avaliações

- 747Documento12 páginas747GurdevBaines100% (3)

- Bollard Pull Calculations For Towing OperationsDocumento8 páginasBollard Pull Calculations For Towing OperationsDiegoAinda não há avaliações

- Links of XII Physics Investigatory Project Allowtment 2Documento3 páginasLinks of XII Physics Investigatory Project Allowtment 2yashtomarsoop07Ainda não há avaliações