Escolar Documentos

Profissional Documentos

Cultura Documentos

ICEM2014-Thermal Model For Small Synchronous Reluctance Machine Stator Slot

Enviado por

Azrihizami RasidTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ICEM2014-Thermal Model For Small Synchronous Reluctance Machine Stator Slot

Enviado por

Azrihizami RasidDireitos autorais:

Formatos disponíveis

UNIVERSIT DE TECHNOLOGIE

COMPIGNE

LABORATOIRE ELECTROMECANIQUE DE COMPIEGNE

LEC (EA 1006)

Thermal Model of Stator Slot for

Small

Synchronous Reluctance

Photo couleur ou NB votre choix plein cadre

M. A. H. Rasid,

A.Ospina,

K. El(72

Kadri

Benkara,

V. Lanfranchi

Machine

RVB, basse

rsolution

dpi),

format JPG,

GIF

3 September 2014

Contents

1. Introduction & context

2. Choosing a modeling method for machine slot

3. Slot homogenization method

4. First model evaluation

5. Modification on slot model and results

6. Conclusion & perspectives

Modlisation thermique des machines lectriques

Introduction: Thermal issue in automotive

application

Positioning of

electrical motor

in dense

compartment

Modlisation thermique des machines lectriques

Severe

temperature

raise

Difficult heat

evacuation

Introduction: Syncrel as a solution

Massive rotor

Segmented rotor

Boldea & al.

2014

Moghaddam &

al. 2010

Boglietti & al.

2006

Rotor with flux

barrier

Axially laminated

rotor

Robust machine

for automotive

application

Passive rotor

structure

Reduced

generated heat

Different rotor

architecture

High

torque/volume

ratio

Modlisation thermique des machines lectriques

Introduction: The most fragile part of the

Syncrel machine

Insulator critical

temperature Tmax

150< Tmax <

240

Depending on

thermal class

High temperature under

the hood / confined

compartment

Precise and reliable

thermal model is crucial

Modlisation thermique des machines lectriques

Introduction: The importance of reliable thermal

6

model

Precise and reliable

thermal model

Design

optimization

Modlisation thermique des machines lectriques

Control &

command

optimization

The Syncrel prototype machine

Segmented rotor

structure

Wounded stator

Thermocouple

Modlisation thermique des machines lectriques

Complete assembled

machine

Choosing a modeling method for machine slot

Most time

consuming

8

Less time

consuming

R equivalent

Full Finite Element Analysis (FEA)

Modlisation thermique des machines lectriques

Choosing a modeling method for machine slot

Most time

consuming

Less time

consuming

R equivalent

Multi-layered equivalent slot deduced from FEA

(to be integrated into LP model)

[Nategh & al., 2012],[Wrobel & al., 2011]

Modlisation thermique des machines lectriques

Choosing a modeling method for machine slot

10

Most time

consuming

Less time

consuming

R equivalent

Adaptation of analytical winding homogenization

(to be integrated into LP model)

[Simpson & al., 2013],[Idoughi & al., 2011]

Modlisation thermique des machines lectriques

Choosing a modeling method for machine slot

11

Most time

consuming

Less time

consuming

R equivalent

Find the best compromise between the three

method:

Validation using an experimental setup in a

Light model

real slot

of a machine stator

Adequate precision

& reliability

Short time of development

Modlisation thermique des machines lectriques

First model tested

Application of winding homogenization

Composite with 3 winding materials

Winding distribution: Random

[Mori & Tanaka, 1988]

Air

and/or

resin

Parameters:

Thermal resistance

Filling factor

Modlisation thermique des machines lectriques

12

Homogenized slot integration into the LP

thermal model

13

Slot geometry is considered of square shape

Equivalent homogenized slot: divided into 2 radial branches

and 2 ortho-radial branches

Slot

homogenization

0.0367 W/m/K

Modlisation thermique des machines lectriques

First model evaluation

14

Digital signal

processor

Power electronic

Syncrel

Experiment in static mode

Current

step (IDC)

Iron losses

calculation

Mechanical

losses

No air turbulent

Only natural exterior convection

Modlisation thermique des machines lectriques

Joule losses

First model evaluation

15

44

First experimental data-model simulation comparison

42

temperature (C)

40

experimental

38

36

34

32

30

0.0367 W/m/K

28

Current step (IDC)

26

24

0

Experimental data

Model simulation

500

1000

1500

Observation:

Important offset on steady-state

temperature

Discrepancy on time constant

Sensitivity studies

Homogenized slot

Modlisation thermique des machines lectriques

2000

time (s)

2500

3000

3500

4000

Modification on slot model

16

The winding homogenization analytical model :

Empirical analytical equation

Done for resin filled winding => irregular

contact not taken into account

Model

New model

proposition

Extra thermal

resistance around the

homogenized winding

representing irregular

contact

Full contact of

Resistance

values

homogenized

slot with

stator stackusing

surface

determined

experimental

fitting

Real case

Homogenized

composites

Modlisation thermique des machines lectriques

Irregular contact of slot

with stator stack surface

Modification on slot model

17

Comparison: experimental data -model simulation

65

60

experimental data

experimental data

experimental data

model simulation

model simulation

model simulation

temperature (C)

55

Robustness of

the fitted

model

50

45

40

35

30

25

20

0

500

1000

1500

2000

time (s)

2500

3000

3500

4000

TABLE I

Error Between Experimental Data and LP Model

Simulation

Current (A)

1.7

3.4

4.8

Steady state

temperature

28C

42.C

62C

Worst case error

(C) / (%)

0C

0%

-1 C

4.9 %

-4 C

9.9%

Steady state error

(C) / (%)

0 C

0%

0 C

0%

1 C

1.8%

Modlisation thermique des machines lectriques

Conclusion & perspective

18

Compromise in modeling slot was researched.

An additional layer (representing contact resistance) needs to

be added to the homogenized winding.

A better model to reduce the transient prediction error to be

researched (addition of capacitive component).

Tool: evaluating the need of filling the slot with resin

Modlisation thermique des machines lectriques

19

Thank you for your attention

Questions?

Modlisation thermique des machines lectriques

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Unit2 MachinesDocumento35 páginasUnit2 MachinesdineshkumarAinda não há avaliações

- Commissioning Procedure of Electric Equipment (Rev.0)Documento10 páginasCommissioning Procedure of Electric Equipment (Rev.0)Fuad Burhani100% (1)

- Service Manual Delco-Remy CS-130Documento10 páginasService Manual Delco-Remy CS-130api-2614064475% (4)

- Electric Unicycle (EUC)Documento15 páginasElectric Unicycle (EUC)HimanshuAinda não há avaliações

- EDEC - Question and AnswersDocumento41 páginasEDEC - Question and AnswersraajaAinda não há avaliações

- Lecture1 - History & IntroductionDocumento20 páginasLecture1 - History & Introductionramaswamykama786100% (1)

- Recent Important Changes in IEEE Motor and Generator PDFDocumento12 páginasRecent Important Changes in IEEE Motor and Generator PDFRavinder Sharma100% (1)

- Design and Comparison of Multistage Axial Flux Permanent Magnet Machines For Potable Generating ApplicationDocumento8 páginasDesign and Comparison of Multistage Axial Flux Permanent Magnet Machines For Potable Generating Applicationray davisAinda não há avaliações

- Send Move Machine Dimension Build Hand Book: GPX 300 Fse Engine Manual ZS182MN (NC300S)Documento39 páginasSend Move Machine Dimension Build Hand Book: GPX 300 Fse Engine Manual ZS182MN (NC300S)Joel CésarAinda não há avaliações

- J14Documento10 páginasJ14RifanAinda não há avaliações

- Three Phase Induction MotorDocumento76 páginasThree Phase Induction MotorAmitava Biswas100% (2)

- Motor PMDocumento22 páginasMotor PMchinnaraoAinda não há avaliações

- Synchronous Generators NotesDocumento75 páginasSynchronous Generators NotesSaravanan T Y100% (1)

- ABB AC - Motor 500KW - Final Service ReportDocumento4 páginasABB AC - Motor 500KW - Final Service ReportZi MingAinda não há avaliações

- Electric Motor and GeneratorDocumento6 páginasElectric Motor and GeneratorJesell JeanAinda não há avaliações

- S7L1D-G4 Wdg.312 - Technical Data SheetDocumento9 páginasS7L1D-G4 Wdg.312 - Technical Data Sheet3efoo100% (1)

- Flammable Vapor Ignition Initiated by HoDocumento12 páginasFlammable Vapor Ignition Initiated by HoNurettin TERZİOĞLUAinda não há avaliações

- QE White Paper - How To Improve Asset LifespanDocumento16 páginasQE White Paper - How To Improve Asset LifespanArturo PintoAinda não há avaliações

- TechRef DoublyFedDocumento12 páginasTechRef DoublyFedJennifer YoungAinda não há avaliações

- Alternators PDFDocumento57 páginasAlternators PDFChanning Tatum100% (5)

- Amo Motors Sourcebook Web PDFDocumento96 páginasAmo Motors Sourcebook Web PDFalvaronicolas89Ainda não há avaliações

- College of Electrical and Mechanical Engineering: Final Internship ReportDocumento28 páginasCollege of Electrical and Mechanical Engineering: Final Internship ReportBereket TsegayeAinda não há avaliações

- A Sensorless Direct Torque Control Scheme Suitable For Electric VehiclesDocumento9 páginasA Sensorless Direct Torque Control Scheme Suitable For Electric VehiclesSidahmed LarbaouiAinda não há avaliações

- Case Studies in Thermal EngineeringDocumento13 páginasCase Studies in Thermal Engineeringfujy fujyAinda não há avaliações

- System Design, Load, Stress & Maintenance: There Is No Most Favourable Design Method, As Each Component VariesDocumento22 páginasSystem Design, Load, Stress & Maintenance: There Is No Most Favourable Design Method, As Each Component VariesMoslem Grimaldi100% (1)

- Three Phase Induction Motor Design in Windows Programming PlatformDocumento8 páginasThree Phase Induction Motor Design in Windows Programming PlatformNasir ArslanAinda não há avaliações

- Electric Fan: Consumer ElectronicsDocumento53 páginasElectric Fan: Consumer ElectronicsHarold MangaAinda não há avaliações

- Pemd 2004Documento6 páginasPemd 2004Deepak GehlotAinda não há avaliações

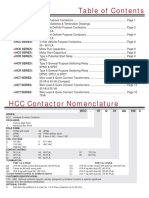

- Catalog Hartland RelayDocumento16 páginasCatalog Hartland RelayEslam SalamonyAinda não há avaliações