Escolar Documentos

Profissional Documentos

Cultura Documentos

Ash Pond Sizing Criteria

Enviado por

srigirisetty208Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ash Pond Sizing Criteria

Enviado por

srigirisetty208Direitos autorais:

Formatos disponíveis

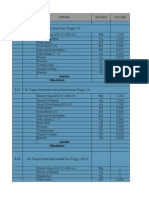

Water reqt.

for ash disposal of 100 MW

(000 cubic meter / yr)

power plant.

WATER & LAND USAGE FOR ASH DISPOSAL

Conventional Vs HCSD (High concentration slurry disposal)

FEATURES OF HCSD SYSTEM

500

- Reduction in water consumption by 60%.

- Reduction in land requirement by 79%

- Reduction in power consumption by 50%

197

.

Conventional

- Environment friendly ash disposal and

coagulated ash doesnt fly under wind.

- Chances of accidents in ash pond

are completely nullified due to low

quantity of water in ash pond

HCSD

Land reqt. for ash disposal of 100 MW

power plant for 25 years

(acre)

150

32

Adoption of HCSD in KORBA

region power plants alone may result in

an annual availability 21 MCM of water

which may be utilized to generate

700-900 MW electricity.

.

ASSUMPTIONS:

1.

Ash Content

2.

Water to Ash ( Conventional)

3.

Water to Ash ( HCSD)

4.

Re-circulation ( Conventional)

=

=

=

=

42 %

80 to 20 %

40 to 60 %

60 %

HASDEO BANGO DAM an OVERVIEW

(MCM = million cubic

meter)

Elevation level (mtrs)

363.08

downstream

359.66

In the shown line diagram:

Live capacity of dam = 3046 MCM

345.66

Reserve Stock for emergency = 336.35 MCM .

329.79

316.00

329.79 m is the design driving head to drive the turbine.

Reserve Stock

penstock

310.00

292.60

Dead stock

turbine

LBC = 70

Cumecs

river

Reduced level

in meters

Sill level of irrigation sluice

310.00

Draw down level of dam

329.79

Crest level (radial gate)

345.66

Full reservoir level

359.66

Maximum water level

363.08

Particulars

1.

2.

3.

4.

5.

Gross capacity

in MCM

34.65

370.00

1468.00

3416.00

4002.65

Hasdeo Barrage

RBC = 117 Cumecs

Parsahi lift irrigation area of flow

7 Cumecs (=220 MCM) from RBC

yet to be developed.

BRIEF CALCULATION OF WATER CONSUMPTION:

100 MW requires approx. 7 lacs MTPA coal annually = 2.94 lac MT ash annually

(Considering 42% ash in coal)

Water through HCSD to handle above quantity of ash:

(67/100) X 294000= 197000

Approx.=197000 cum/yr

(40 ton water required to dispose 60 ton ash)

Water through Conventional system to handle above quantity of ash:

(170/100) X 294000= 500000 cum/yr

With 60% re-circulation.

(80 ton water required to dispose 20 ton

And 34 ton water required for above with 60% re-circulation)

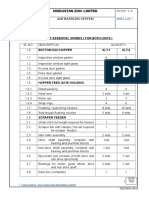

BHARAT ALUMINIUM COMPANY LIMITED, KORBA

(A UNIT OF VEDANTA GROUP)

ASH POND AREA CALCULATION FOR 2x600MW POWER PLANT

Coal Requirement with 100% PLF

600x24x0.742 =

10685

MT/day

Ash generation

Considering 42% ash content,

Total ash generation per day (10685*0.42)=

4488

MT/day

Assuming fly ash 80% of total ash generation,

The Fly ash quantity (4488*0.8)=

3590

MT/day

Assuming bottom ash 20% of total ash generation,

The Fly ash quantity (4488*0.2)=

898

MT/day

Assuming the Plant life of 25 years,

Total ash generation for (25*365*4488)=

Say

40949496 MT

41

Million MT

Considering ash density 0.8MT/cum, (Conventional) the ash volume =

51

Million Cum

Considering ash density 1.0MT/cum, (HCSD) the ash volume =

41

Million Cum

Ash Pond area for conventional method of disposal

Assuming 15m height,

Area required (51000000/15)=

Dyke construction area required =

Approach area required=

Total area required=

Say

Say

3412458

149383

75491

3637332

899

364

Sqm

Sqm

Sqm

Sqm

Acres

Hectares

511869

237135

34168

783622

194

78

50%

Sqm

Sqm

Sqm

Sqm

Acres

Hectares

Ash Pond area for High Concentration slurry Disposal method

Assuming 80m height, considering a pond width of minimum 400m

Area required (41000000/80)=

Dyke construction area required =

Approach area required=

Total area required=

Reduction in corridor required for piping

Say

Say

By

SUMMARY-ASH POND LAND REQUIRED

PLANT

CAPACITY

1x600MW

2x600MW

PLANT

ASH GENERATION

LIFE

VOLUME

25 years

51x106 Cum

25 years

102x106 Cum

CONVENTIONAL

HEIGHT AREA

15

899 Acres

15

1798 Acres

HCSD

HEIGHT

AREA

25

194 Acres

25

388 Acres

Types of Ash Disposal Systems used in India & Abroad

Conventional Lean Slurry Disposal method using an effective ash to water ratio of 100:170 after

considering 60% recirculation of water. (Normal pumping is at 100: 400)

Mechanical Disposal method to form Ash mounds using an ash to water ratio of 100:35 (no

recirculation of water is required)

High Concentration Slurry Disposal method using an ash to water ratio of 100:67 (no

recirculation of water is required)

Conventional Lean Slurry Disposal method

High quality water retaining structure is required for the pond

Accidents like ash pond breakages may occur with disastrous consequences

Overall height of ash pond is limited

Holding capacity per unit area is very low

Water from the pond leaches into the ground water system

Expensive water recycling & treatment system is required

Slurry requires high velocity to prevent settlement, hence high wear & tear of the pipes

Initial cost is lower but cost of water consumption and land required is very high per

tonnage. Also the power consumption cost is very high.

Mechanical Disposal method to form Ash Mounds

Very few plants have such system. 2-3 outside India and one at NTPC - Dadri

Power consumption is reasonable comparable to HCSD

Requires long belt conveyor system to transfer ash, stackers, sprinkling, dozers,

compacting equipments

Extensive man power requirement for ash mound management.

Requires expensive chemicals to consolidate the ash

Ash has to be very timely consolidated to avoid fly off by strong winds creating massive

air pollution

During monsoon, water collection system is required at periphery thru drains to prevent

out flow of contaminated ash

Height of ash pond can be upto 50 60 M which gives good storage

Extensive maintenance required due to mechanical equipments

Initial cost is very high

Not a perfect system due to its complication & heavy maintenance

High Concentration Slurry Disposal method

This is the latest technology developed over last 15 20 years. With its perfection new

generation power plants can enjoy its benefits. Also existing plants can be converted to

this new concept

Water consumption is very low. No water retaining structure is required for the pond,

except for a small toe dyke for rain water collection

No ground water contamination as literally no water is released from the slurry.

No water recycling system is required

Power consumption is comparable to Dry ash mound type disposal & much lower than

the conventional system

Due to cementing properties of fly ash, the ash density at ash pond is much higher by 20

30%, Hence that much extra ash can be stored per unit area

Ash pond height can be above 100Mtrs giving a massive storage per unit area

High Concentration Slurry Disposal method

Pipe sizes are lesser by half of the conventional slurry pipes

Slurry is highly viscous & soft, hence less abrasive. It conveys at 60 65% of velocity of

conventional system. Hence wear is very low and pipe line rarely requires any

replacement

Initial cost is slightly higher by 15 20% which will be recovered in few months on

account of lower power consumption. Additionally cost of water consumption and land

required is very low per tonnage

Maintenance cost is low

Você também pode gostar

- Coal Bottom Ash As Sand Replacement in ConcreteDocumento9 páginasCoal Bottom Ash As Sand Replacement in ConcretexxqAinda não há avaliações

- Utilization of Fly Ash in Rural Road Construction in India and Its Cost EffectivenessDocumento6 páginasUtilization of Fly Ash in Rural Road Construction in India and Its Cost Effectivenessceanil100% (1)

- Artigo - Hulya Arslan, 2019 - Síntese de Um Novo Superplastificante À Base deDocumento9 páginasArtigo - Hulya Arslan, 2019 - Síntese de Um Novo Superplastificante À Base deLucasAinda não há avaliações

- Slipform BrochureDocumento8 páginasSlipform BrochureRen SalazarAinda não há avaliações

- Fly Ash Fly Ash: Utility Bonanza From DustDocumento8 páginasFly Ash Fly Ash: Utility Bonanza From DustRajanmyth Mala100% (1)

- Determining Electric Motor Load and Efficiency: F A C T S H E E TDocumento16 páginasDetermining Electric Motor Load and Efficiency: F A C T S H E E TwahonotAinda não há avaliações

- Piling equipment and methodsDocumento2 páginasPiling equipment and methodsvisvisvisvis100% (1)

- Development of Economic Corridors Improves Freight MovementDocumento18 páginasDevelopment of Economic Corridors Improves Freight Movementvikki chowdaryAinda não há avaliações

- Rate Analaysis of 124 ConcreteDocumento2 páginasRate Analaysis of 124 ConcreteMian M KhurramAinda não há avaliações

- Fly AshDocumento16 páginasFly AshSavita Sehrawat0% (1)

- Ash Dyke 2.1 (SEC 1)Documento11 páginasAsh Dyke 2.1 (SEC 1)karthikraja21Ainda não há avaliações

- Malaysia Malakoff PresentationDocumento37 páginasMalaysia Malakoff PresentationPongphong PhornngamAinda não há avaliações

- Construction cost estimate sheet for building materials and laborDocumento178 páginasConstruction cost estimate sheet for building materials and laborDony DoanxAinda não há avaliações

- Guideline On RSA ManagementDocumento103 páginasGuideline On RSA ManagementAmirul BassAinda não há avaliações

- Backfilling Practices With Fly Ash in Underground Coal MinesDocumento19 páginasBackfilling Practices With Fly Ash in Underground Coal MinesmanikantaAinda não há avaliações

- Surface Treatment of Flexible PavementDocumento36 páginasSurface Treatment of Flexible PavementUsman Ahmad0% (1)

- Concrete Bridge CodeDocumento124 páginasConcrete Bridge CodeanjaliAinda não há avaliações

- Detailed Project Report for Coal Handling Terminal at Berth No. 7 in Mormugao PortDocumento643 páginasDetailed Project Report for Coal Handling Terminal at Berth No. 7 in Mormugao PortMinh TríAinda não há avaliações

- Precast Construction: Prepared By: Parth S. Patel SD1510Documento55 páginasPrecast Construction: Prepared By: Parth S. Patel SD1510Gireesh Gowda GiriAinda não há avaliações

- Draft TRH 20 The Structural Design, Construction and Maintenance of Unpaved Roads 1990Documento40 páginasDraft TRH 20 The Structural Design, Construction and Maintenance of Unpaved Roads 1990winzo01100% (1)

- Crane Load CalculationDocumento1 páginaCrane Load CalculationvkAinda não há avaliações

- DSR 2013-14 - E&mDocumento44 páginasDSR 2013-14 - E&mAHMED SOHEL50% (2)

- NBC 2016-Vol-2 PDFDocumento1.026 páginasNBC 2016-Vol-2 PDFSaurabh GuptaAinda não há avaliações

- Elastic Composite, Reinforced Lightweight Concrete (ECRLC) As A Type of Resilient Composite Systems (RCS) (Http://arxiv - Org/abs/1510.03933)Documento28 páginasElastic Composite, Reinforced Lightweight Concrete (ECRLC) As A Type of Resilient Composite Systems (RCS) (Http://arxiv - Org/abs/1510.03933)https://sites.google.com/site/newstructure1 ; https://sites.google.com/site/ecrlc1 ; Non-commercial100% (5)

- Revised Boq Civil Work For Cricket Stadium SaifaiDocumento36 páginasRevised Boq Civil Work For Cricket Stadium SaifaiGabriel Pratama SebayangAinda não há avaliações

- Creating forest sector solutions handbookDocumento63 páginasCreating forest sector solutions handbookDhany100% (1)

- Square PipeDocumento2 páginasSquare PipeWijayanto BekasiAinda não há avaliações

- Recovery of Valuable Metals From Fly Ash: A Sustainable ApproachDocumento2 páginasRecovery of Valuable Metals From Fly Ash: A Sustainable ApproachVeeranjaneyulu RayapudiAinda não há avaliações

- Maximum Spacing of PilesDocumento10 páginasMaximum Spacing of Pileskaleswara_tellakulaAinda não há avaliações

- BATCHING PLANT CALIBRATIONDocumento10 páginasBATCHING PLANT CALIBRATIONsyed sulemanAinda não há avaliações

- Comparative Analysis of Is 807:2006 With Is 807:2006 Amendment No.1Documento4 páginasComparative Analysis of Is 807:2006 With Is 807:2006 Amendment No.1Construction Engineering InfraAinda não há avaliações

- Erosion Control PlanDocumento37 páginasErosion Control Planzahrul azhaAinda não há avaliações

- 02 Polymer Modified Asphalt Emulsions Main ReportDocumento170 páginas02 Polymer Modified Asphalt Emulsions Main ReportgiamilliaAinda não há avaliações

- Sheet Pile Brochure 2022Documento8 páginasSheet Pile Brochure 2022bayzuraAinda não há avaliações

- HydraulicDocumento33 páginasHydraulicgertjaniAinda não há avaliações

- Major PPT P2-1Documento22 páginasMajor PPT P2-1Sai VamshiAinda não há avaliações

- Mass Concreting HistoryDocumento16 páginasMass Concreting HistoryTamizhan_KAinda não há avaliações

- Notes From RCC Pillai MenonDocumento71 páginasNotes From RCC Pillai MenonVaibhav SharmaAinda não há avaliações

- Concrete 1-2-4 & 1-4-8 Rate AnalsysisDocumento4 páginasConcrete 1-2-4 & 1-4-8 Rate AnalsysisMian M KhurramAinda não há avaliações

- Environmental Quality (Prescribed Activities) (Environmental Impact Assessment) Order 1987Documento9 páginasEnvironmental Quality (Prescribed Activities) (Environmental Impact Assessment) Order 1987Ahmad CendanaAinda não há avaliações

- Fly Ash PresentationDocumento28 páginasFly Ash Presentationaayushverma69100% (1)

- Continental Steel CatalogueDocumento175 páginasContinental Steel CatalogueTariq HasanAinda não há avaliações

- Nilex Woven Geotextile SpecificationsDocumento1 páginaNilex Woven Geotextile SpecificationsAbdullah BasalamahAinda não há avaliações

- 201210091700490.DEIA Tioxide Malaysia ESDocumento23 páginas201210091700490.DEIA Tioxide Malaysia ESPau Choon Hock100% (2)

- Lecture of Prof - Askar, University of Delaware, USA, March 22, 2019Documento328 páginasLecture of Prof - Askar, University of Delaware, USA, March 22, 2019madi karginAinda não há avaliações

- IRC 15-2002 Standard Specifications and Code of Practice ForDocumento66 páginasIRC 15-2002 Standard Specifications and Code of Practice ForAnkit Gupta80% (5)

- CalculationDocumento14 páginasCalculationLipika KanojiaAinda não há avaliações

- BS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFDocumento12 páginasBS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFAshraf TomizehAinda não há avaliações

- Types of Structural SteelDocumento4 páginasTypes of Structural SteelPti RaheelAinda não há avaliações

- Comparison Concrete and Asphalt PavementDocumento6 páginasComparison Concrete and Asphalt PavementJulius OgowewoAinda não há avaliações

- AHP Calculator - Example in The Lecture - 1Documento24 páginasAHP Calculator - Example in The Lecture - 1Afranur ErenAinda não há avaliações

- Soil Compaction: Pneumatic Rubber-Tired Roller Vibratory Steel-Wheeled RollerDocumento22 páginasSoil Compaction: Pneumatic Rubber-Tired Roller Vibratory Steel-Wheeled RollerSavitha PradeepAinda não há avaliações

- 3.6 Abstract .................. 7 3.7 Technical Specification of Each Layer ..8Documento38 páginas3.6 Abstract .................. 7 3.7 Technical Specification of Each Layer ..8Abhay JainAinda não há avaliações

- Sludge processing steps and dewateringDocumento21 páginasSludge processing steps and dewateringShubham BansalAinda não há avaliações

- Erosion and Sediment Control for Reservoir Sedimentation from Agricultural Activities in HighlandsNo EverandErosion and Sediment Control for Reservoir Sedimentation from Agricultural Activities in HighlandsAinda não há avaliações

- Efficient Fly Ash Handling with High Concentration Slurry Density SystemDocumento4 páginasEfficient Fly Ash Handling with High Concentration Slurry Density SystemGirish BhagchandaniAinda não há avaliações

- Ash HandlingDocumento30 páginasAsh Handlingrmm99rmm99100% (2)

- 3221technological Options For Removal of Fly Ash at TPPs in IndiaDocumento4 páginas3221technological Options For Removal of Fly Ash at TPPs in Indiarmm99rmm99100% (1)

- M24L40Documento7 páginasM24L40Andenet AshagrieAinda não há avaliações

- Sewage Treatment Plant Design ProjectDocumento30 páginasSewage Treatment Plant Design Projectgk mAinda não há avaliações

- NB O&M Brochure 01sept2020Documento10 páginasNB O&M Brochure 01sept2020srigirisetty208Ainda não há avaliações

- 5C1. Coal Ash Generation Process and Application FieldsDocumento2 páginas5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Ainda não há avaliações

- Arar 33kV Cable Sizing ReportDocumento9 páginasArar 33kV Cable Sizing Reportsrigirisetty208Ainda não há avaliações

- 330MW Shrinagar Project Technical Data SheetDocumento4 páginas330MW Shrinagar Project Technical Data Sheetsrigirisetty208Ainda não há avaliações

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataDocumento2 páginas330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Ainda não há avaliações

- Fire Detection and Alarm System Design Basis DocumentDocumento12 páginasFire Detection and Alarm System Design Basis Documentsrigirisetty208Ainda não há avaliações

- Boiler Tube Failures Due To Improper CommissioningDocumento21 páginasBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanAinda não há avaliações

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocumento3 páginas4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Ainda não há avaliações

- Care and Maintenance of CFB Boilers Refractory FailureDocumento6 páginasCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZAinda não há avaliações

- 4.19 - Instrumentation and ControlDocumento2 páginas4.19 - Instrumentation and Controlsrigirisetty208Ainda não há avaliações

- 330MW Shrinagar Project Technical Data SheetDocumento4 páginas330MW Shrinagar Project Technical Data Sheetsrigirisetty208Ainda não há avaliações

- 4.11 - Bypass Channel - Automatic GateDocumento1 página4.11 - Bypass Channel - Automatic Gatesrigirisetty208Ainda não há avaliações

- HZL Crane EssentialsparesDocumento2 páginasHZL Crane Essentialsparessrigirisetty208Ainda não há avaliações

- 4.17 - Powerhouse - Powerhouse CraneDocumento3 páginas4.17 - Powerhouse - Powerhouse Cranesrigirisetty208Ainda não há avaliações

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineDocumento2 páginas4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208Ainda não há avaliações

- Sch-3A 14-Perfor GuartDocumento5 páginasSch-3A 14-Perfor Guartsrigirisetty208Ainda não há avaliações

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocumento3 páginas4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Ainda não há avaliações

- 4.5 - Dam and Spillway - ElevatorDocumento2 páginas4.5 - Dam and Spillway - Elevatorsrigirisetty208Ainda não há avaliações

- Quality Assurance Plan for 2x150 MW Coal Power PlantDocumento1 páginaQuality Assurance Plan for 2x150 MW Coal Power Plantsrigirisetty208Ainda não há avaliações

- HZL Chs EssentialsparesDocumento6 páginasHZL Chs Essentialsparessrigirisetty208Ainda não há avaliações

- SCH 3A.17 Q.a.assessmentDocumento1 páginaSCH 3A.17 Q.a.assessmentsrigirisetty208Ainda não há avaliações

- HZL Ahs EssentialsparesDocumento8 páginasHZL Ahs Essentialsparessrigirisetty208Ainda não há avaliações

- 150 MW Coal Fired Power Plant Construction Equipment ListDocumento2 páginas150 MW Coal Fired Power Plant Construction Equipment Listsrigirisetty208Ainda não há avaliações

- BFP Drawings PDFDocumento42 páginasBFP Drawings PDFsrigirisetty208Ainda não há avaliações

- SCH 3A.9 Places of Mfg.Documento1 páginaSCH 3A.9 Places of Mfg.srigirisetty208Ainda não há avaliações

- BFP DrawingsDocumento42 páginasBFP Drawingssrigirisetty208Ainda não há avaliações

- SCH 3A.11 SparesDocumento3 páginasSCH 3A.11 Sparessrigirisetty208Ainda não há avaliações

- Equipment Supply by BidderDocumento6 páginasEquipment Supply by Biddersrigirisetty208100% (2)

- SCH 3A.12 Special Tools &tacklesDocumento3 páginasSCH 3A.12 Special Tools &tacklessrigirisetty208Ainda não há avaliações

- Guaranteed DataDocumento2 páginasGuaranteed Datasrigirisetty208Ainda não há avaliações

- TOS 1st QuarterDocumento8 páginasTOS 1st QuarterDesire T. SamillanoAinda não há avaliações

- Evidence of Evolution Lab AnalysisDocumento4 páginasEvidence of Evolution Lab AnalysisDiego GuardadoAinda não há avaliações

- Chapter 6 Work and EnergyDocumento9 páginasChapter 6 Work and Energybmz00000Ainda não há avaliações

- RBP 2023 3 04Documento14 páginasRBP 2023 3 04reisvictoria1529Ainda não há avaliações

- Redox ReactionsDocumento44 páginasRedox ReactionsAnanthakrishnan Tinneveli VAinda não há avaliações

- Landslide, Slope Failure, Timor-Leste, Multivariate Statistical AnalysisDocumento212 páginasLandslide, Slope Failure, Timor-Leste, Multivariate Statistical Analysishopffer2008Ainda não há avaliações

- Bernoulli Chapter 3 PDFDocumento45 páginasBernoulli Chapter 3 PDFMirrovshan SagdullaevAinda não há avaliações

- Recycling ResearchDocumento4 páginasRecycling ResearchZahid ChandiaAinda não há avaliações

- Assessment Criteria On Sustainable Rating Tools Used in Asian CountriesDocumento12 páginasAssessment Criteria On Sustainable Rating Tools Used in Asian CountriesTseng Chong MingAinda não há avaliações

- Flood Susceptibility Mapping Using Gis-Ahp of Kuala KraiDocumento12 páginasFlood Susceptibility Mapping Using Gis-Ahp of Kuala Kraibambang cahyonoAinda não há avaliações

- CHM131 - Chapter 5 - The Gases StateDocumento54 páginasCHM131 - Chapter 5 - The Gases StateLeo PietroAinda não há avaliações

- املجم 11Documento7 páginasاملجم 11nawafAinda não há avaliações

- Utilization of Bioslurryfrom Biogas PlanDocumento4 páginasUtilization of Bioslurryfrom Biogas Planshubham agarwalAinda não há avaliações

- BiodiversityDocumento19 páginasBiodiversityGill0% (1)

- Rock Forming Minerals: RocksDocumento3 páginasRock Forming Minerals: RocksUche S OsigweAinda não há avaliações

- An Introduction To The Principles of Pavement Drainage: Course No: C02-048 Credit: 2 PDHDocumento25 páginasAn Introduction To The Principles of Pavement Drainage: Course No: C02-048 Credit: 2 PDHManfredi Di MaitaAinda não há avaliações

- Schneider - Power Factor CorrectionDocumento100 páginasSchneider - Power Factor CorrectionErica BeasleyAinda não há avaliações

- Aspen Plus DEPG Model PDFDocumento23 páginasAspen Plus DEPG Model PDFGodstandAinda não há avaliações

- SM 57Documento373 páginasSM 57Calin Kidzor50% (2)

- (EPRI) Effect of Flexible Operation On Boiler Components - Theory and Practice - Vol.1 - Fundamentals (3002001180, 2013)Documento172 páginas(EPRI) Effect of Flexible Operation On Boiler Components - Theory and Practice - Vol.1 - Fundamentals (3002001180, 2013)Kunhee MoonAinda não há avaliações

- Question Paper Grade 5 6 PDFDocumento14 páginasQuestion Paper Grade 5 6 PDFSufian HijazAinda não há avaliações

- Integrated Cement Orient Cement ChittapurDocumento38 páginasIntegrated Cement Orient Cement Chittapurdurgesh25Ainda não há avaliações

- Summer Test CH 3 and 5 2012 NewDocumento7 páginasSummer Test CH 3 and 5 2012 NewIvetty EstepanAinda não há avaliações

- DPE Broceure 2Documento4 páginasDPE Broceure 2Debabrata SinghAinda não há avaliações

- AP Bio - Semester 1 Review Cheat Sheet: by ViaDocumento2 páginasAP Bio - Semester 1 Review Cheat Sheet: by ViaTrisha GarciaAinda não há avaliações

- CONCEPTUAL-FRAMEWORK - With - ReferenceDocumento2 páginasCONCEPTUAL-FRAMEWORK - With - ReferenceGacias RJAinda não há avaliações

- Structure and Bonding Updated 2Documento82 páginasStructure and Bonding Updated 2jadabrown542Ainda não há avaliações

- Carnicom Institute Research-2002Documento132 páginasCarnicom Institute Research-2002Anonymous i71HvPXAinda não há avaliações

- Rock Cycle Worksheet: Name Use Your Book and Your Rock LabsDocumento4 páginasRock Cycle Worksheet: Name Use Your Book and Your Rock LabsBhawana SinghAinda não há avaliações

- The developmental project (Unit 1Documento3 páginasThe developmental project (Unit 1SKAinda não há avaliações