Escolar Documentos

Profissional Documentos

Cultura Documentos

PV System Design Explained

Enviado por

Humayun AhsanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PV System Design Explained

Enviado por

Humayun AhsanDireitos autorais:

Formatos disponíveis

Photovoltaic System Design

Engr. Naeem Abas Kalair

Assistant Professor

Department of Electrical

Engineering, University of

Gujrat

Long Power Down Ahead . . .

Photovoltaic System Design

Discussion Topics

Power and Energy Crisis

Photovoltaic System Design

Power & Energy Crisis

Global Cataclysm

Electric Power Crisis

Oil, Gas and Coal Reserves

Electric Power Crisis

Electric Power Crisis1

Ref 1 M. H. Khan, Missing energy targets and its repercussions, Business & Finance, Review, Daily Jang, 10-12-2007

Electric Power Crisis

Electric Power Scenario

WAPDA Supply

=

11,000 MW

Load demand

=

15,000 MW

Difference

=

4000 MW (deficit)

Annual increase

=

800-1000 MW

Economic Failure =

2017 (Deficit exceeds supply)

Catching the last bus

If we start Kalabagh Dam today then it will be ready by

20161, to maintain the current 4000MW power deficit.

Electric Power Crisis

UPS Demand Doubling Effect

Electric Power Crisis

Fossil Fuels Dependence1

Ref.1: IEA, US DOE, August 23, 2006. Retrieved on April 3, 2007

Electric Power Crisis

Renewable Energy Resources

Electric Power Crisis

Sustainable Energy Options

Technology

Present

Future

Hydropower (Capacity)

12,500 MW

>26,700 MW 1

Solar Energy

7,000 GPD (PCSIR)

1.93MWh/m 2/Y

414 KW P(>19,800AH) (DGNRER)3

Wind Power

000

700 MW by 2010 2

1: Bhasha (4500), Bunji (5400), DASU (4000), Kalabagh (3600), Kohala (1100), Patan (2800), Thakot (2800), and a

collective capacity of 2500 from Neelam, Munda, Akhori etc. Out of total available potential of 42,000 MW only 15%

has

been tapped to date. Hydro is the most viable energy option for Pakistan.

2. M. Asif. Sustainable energy options for Pakistan. RSER. DOI 10.1016/jrser.2008.04.01.

3. PCSIR Annual Report (1990), DGNRER Annual Report (1989) as reported by I. A. Raja et al in WREC 1996.

Global Energy Crisis

End of Fossil Fuels1

Oil 2022/2064

Gas 2029/2100

Coal 2150/2250

Always

(Ref.1: N. Khan et al. Natural energy sources & global power needs, RSER, Vol.12, 1959-1973, 2008)

Global Energy Crisis

Oil Peaking1

Oil peaking = 2007a

a. French study

Oil peaking = 2015b

b. USGS Report

Oil peaking = 2010c

c. WEC/IEA data

Oil peaking = 2020d

d. WEO Report 08

Ref.1: http://www.lifeaftertheoilcrash.net/peakGraph.jpg (Beyond Oil by K. Duffeyes)

Global Energy Crisis

Fossil Fuels Peaking

Fuels

Oil (2013)

Gas (2021)

Coal (2025)

Peakinga

Peakingb

Peakingc

20101/20112

20301

20251

2020-20305

20177

20256

20053/20064

2015-20218

20259

_______________________________________________

Ref.1: Energy crisis: Turning point of humanity by Rudo de Ruijter 25 June 2008.http://321energy.com

Ref.2: ASPO Report 2008

Ref.3:Simmons & Company International and Beyond Oil by K. S. Deffeyes

Ref.4:Crude oil: Supply Outlook. German Energy Watch Group headed and Chairman ARAMCO KSA.

Ref.5:CERA Report 2006, WEO Report 2008, http:en.wikipedia.org/wiki?peak_oil

Ref.6: What if coal is running out too by D Roberts, 2007, GRIST.

Ref.7: Peak oil? Peak gas may not be far behind. Energy Intelligence Group. 2007

Ref.8: High noon for natural gas by J. Darley, www.321energy.com and Get ready for another oil shock by

L. F. Ivanhoe from THE FUTURIST http:dieoff.org/page90.htm.

Ref.9: www.energybulletin.net/print/28287.

Global Energy Crisis

Possible Ends

Fuels

End1a

End2b

Oil

Gas

Coal

20531-3

20801-3

22601-3

20704

21434

28414

End3c

21105

21505

44245

End4d

20256-7

20296-7

21638

a- Oil & Gas, b- WEO, c- USGS, d- Others

____________________________________________

1. World oil, gas and coal reserves: http://en.wikipedia.org/wiki/Fossil_fuel, 2. Natural gas reserves by country Infoplease. com, 3. Oil & Gas Journal, Vol. 103, No. 4, December 19, 2005, 4. Ch-4, Energy Supply, Table 4.2,

World Energy Outlook report, June 2008. 5- USGS World Energy Assessment Team Report Retrieved on January

18, 2007. 6. K. Deffeyes-www.princeton.edu/hubbert/current-events-06-02.html ,7. The end of fossil fuels by

L Grant, NPG, www.npg.org/forum_series/fall/04forum.htm, 8-IEA Report 2006,pp-127.

Fossil Fuels Backlash Consequences

Stop Before It Overloads!

Else!

Photovoltaic System Design

PV System Design Case

Designing a photovoltaic system for a typical

building of 10,000 square feet like UOG, Hafiz

Hayat Campus, Electrical Engineering

Department building. We want to determine the

number of solar panels, the DC batteries,

inverters or/and rotary converters to harness

solar power in a range of some 100kW loads.

Specifying substation and cable sizes to run a

personal grid system.

Photovoltaic System Design

Solar Power Availability

Photovoltaic System Design

Solar Electric Conversion

Typical 6-8kWh/m2 solar power results in 90-100We/m2

or 10We/ft2 using 12% efficiency silicon solar cells. It

means 98.95% of the incident solar light flux is wasted.

If we combine PV system with thermal system (to use

wasted heat) then hybrid system works at 50-60%

efficiency that is much better than simple PV system.

Photovoltaic Thermal (PVT) is more attractive than PV!

Photovoltaic System Design

PV System Design

To design a suitably engineered PV system, we start with

customer loads and available roof top space.

Normally roof top is enough for building electricity needs

and if not then we can consider its sun facing walls too.

Let us try to learn design procedure step by step.

Photovoltaic System Design

Case Study

To design a PV system the electrical engineer

must start from existing or intended loads to be

operated by solar electricity. Let us consider a

typical office type building using 500 fluorescent

light tubes, 300 energy savers, 200 fans, 100

exhaust fans, 50 air conditioners, 10

refrigerators, 2 water pumps, 8 televisions and 5

kettles. Let us assume conventional usage times

8 AM to 6 PM for government buildings as CIIT.

Photovoltaic System Design

Watt hour (Wh) Calculations

@10 Hrs (8AM-6PM)

Photovoltaic System Design

Watt hour (Wh) Calculations

@10 Hrs (8AM-6PM)

Photovoltaic System Design

Watt hour (Wh) Calculations

Photovoltaic System Design

Panel Energy Capacity

To compensate the power lost in wires, battery and

controller one needs to install 130Wh capacity to

meet appliance energy demand of 100Wh.

Therefore, it is recommended to multiply appliance

Wh demand by 1.3 to install the desired capacity of

the PV System panels or modules

Panel energy (capacity) = 1000,000 x 1.3Wh/day = 1,300,000 Wh/day

Photovoltaic System Design

Peak Panel Power

Environment

Panel Generation Factor (PGF)

Desert area (Baluchistan)

Coastal area (Karachi)

Cloudy area (5-7 days/month)

Cloudy area (>10 days /month)

3.86

3.43

3.00

2.57

Islamabad area does not fall under high brightness coastal areas. It is

appropriate to assume PGF = 3.00 for Islamabad (but I used 3.43). The

peak panel power @ (1Wp =3.43Wh/day) i.e. Panel Wh/day PGF

Peak panel power (Wp) = 1,300,000 3.43 = 379,009 watts

Photovoltaic System Design

PV Panel Sizing

Formula

No. of PV modules = Wp Panel Size

Panels

1. @ 200W PV panel modules = 379,009 200 = 1895

2. @100W PV panel modules = 379,009 100 = 3790

3. @75W PV panel modules

= 379,009 75

= 5054

Photovoltaic System Design

Battery Life Factor

With development in solar cell technology the cost of solar

cells is decreasing but the batteries cost is slowly increasing

due to high demand. Slow or low charging PV system,

although works, but seriously shortens the battery life span. It

is advisable to increase panel size from 20 to 30% of the

minimum capacity to increase battery life.

@200W PV modules = 1895 + 1895 x 25% = 2369

@100W PV modules = 3790 + 3790 x 25% = 4738

@75W PV modules = 5054 + 5054 x 25% = 6317

Photovoltaic System Design

Engineering Judgment

As a rule of thumb a solar panel of 1ft2 size produces 10

watts electricity (1ft2 = 10W). To produce 379kWmin

(200x1895) or 474kWmax (200x2369) the owner needs a

roof space of minimum 37,900ft2 (379,000/10) and

maximum 47,380ft2 (473,800/10). A combination of

minimum power (379kW) with maximum space (47,380

ft2) makes a more reliable PV system. Once we calculate

the appliance loads and peak power the area may can

be estimated from published tables.

Photovoltaic System Design

Roof Area Calculations

Power generation capacity of the solar system depends upon the

available roof space. Usually monocrystalline PV modules in bright

sunlight can produce ten watts power from 1 ft2 size solar cell. it is

recommended to start with average generation capability of 10 W/ft 2

assuming 12% efficiency as shown bellow.

Photovoltaic System Design

Roof Area Calculations

1. Based on panel generation capacity a 100kW PV system requires a

space of 10,000 ft2 .

2. A moderately adequate system considering losses (130%) may

require minimum 13,000ft2.

3. Considering PGF (3.43),100kW PV system may require about

37,900ft2 roof area.

4.

A reliable PV system adding spare capacity of 25% (20-30%) for

longer battery life reasons may require 47,380 ft2 roof space.

Photovoltaic System Design

Battery Size Calculations

A rule of thumb for battery size is to install a battery that

has at least five times as much capacity as will be

needed to operate the appliance for one day.

Multiplication factors for various types of batteries are

shown bellow.

Photovoltaic System Design

Battery Size Calculations

Multiply appliance Wh/day for battery size calculations for

various types of DC batteries as follows.

C10 battery

C100 battery

Sealed battery

Vehicle battery

= 1000,000 x 5

= 1000,000 x 6.5

= 1000,000 x 7.5

= 1000,000 x 10

=

=

=

=

5,000,000 Wh

6,500,000 Wh

7,500,000 Wh

10,000,000 Wh

Normally people use vehicle batteries for UPS in Pakistan

Photovoltaic System Design

Wh to Ah Conversions

Appliance energy demand is calculated in Watthours (Wh) but the battery capacity is given in

Ampere-hours (Ah).

To convert the appliance Wh to Ah divide the

appliance Watt-hours by the battery voltage.

Whapp V = VxIxh V = Ixh = Ah

Photovoltaic System Design

Wh to Ah Conversions

12V Battery

Appliance Ah capacity = 5000,000 12 = 416,667 Ah

24V Battery

Appliance Ah capacity = 5000,000 24 = 208,333 Ah

48V Battery

Appliance Ah capacity = 5000,000 48 = 104,166 Ah

Photovoltaic System Design

Number of Batteries

For a 12/24/48V DC PV system the number of 200Ah C10 deep

charging batteries may be estimated as follows

12V Batteries

Batteries (12V, 200 Ah) = 416,667 200 = 2084

24V Batteries

Batteries (24V, 200Ah) = 208,333 200 = 1042

48V Batteries

Batteries (48V, 200Ah) = 104,166 200 = 522

Photovoltaic System Design

Battery Capacity Issues

Previous calculations hold for C10 (deep discharge rate) batteries. If

these batteries are not available then to use C100, maintenance

free and normal vehicle starting batteries make sure to multiply the

C10 battery based capacity rating by 1.3, 1.5 and 2 as shown in

Table

Photovoltaic System Design

Battery Bank Connections

Photovoltaic System Design

Charge Controllers

The controller size should be able to allow the sum of peak

currents of the PV modules. Controllers charging capacity

for 12/24/48V PV System are given by

IC12V

IC24V

IC48V

=

=

=

Wp 12

Wp 24

Wp 48

=

=

=

379,009 12 =

379,009 24 =

379,009 48 =

31,584 A

15,792 A

7,896 A

Charge controller consists of charge and discharge control units

Photovoltaic System Design

PV System Diagram

Photovoltaic System Design

Controller Size Calculations

Motoring equipment need often 3-4 times more starting

current compared to steady state currents to keep

running. High inrush current duration 1-2 seconds.

The discharge controller minimum current capacity

should be equal to the sum of amperes from all lights

heater appliances times 1.5, plus the amperes from all

appliances with motors times 3-4.

Photovoltaic System Design

Controller Size Calculations

Appliance Loads

Lights/heater loads

Motor type loads

=

=

224,000Wh/day 10

676,000Wh/day 10

=

=

22.4 kW

67.6 kW

Steady State Currents (12V DC System)

Active load currents

Reactive load currents

Controller capacity (A)

=

=

=

22,400 12

67,600 12

1867 + 5633

= 1867 A

= 5633 A

= 7500 A

Peak Transient Currents

Active load currents

Reactive load currents

Controller capacity (A)

= 1867 x 1.5

= 5617 x 3

= 2800 + 16,899

=

=

=

2800 A

16,899 A

19,699 A

Photovoltaic System Design

Controller Size Calculations

If all loads are not running at same time then discharge

controller of minimum capacity of 7500A can be used.

If all loads are going to operate simultaneously then

maximum size controller of 19,699A must be used.

It is more economical and reliable to install multiple

charge/discharge controllers at different circuits.

Photovoltaic System Design

Inverter Selection

There are four types of inverters. All of them are

expensive but square wave is cheaper than modified

square wave inverter that is relatively cheaper than

PWM inverter which is cheaper than sine wave inverter.

Photovoltaic System Design

Harmonics Limits

According to IEEE 929-2000, EN 61727 (EU) and IEC

61000-3-2 standards the full load current THD be less

than 5% and the voltage THD be less than 2% for

harmonic spectra up to 49th harmonic.

It means squaring waves inverters output can not be

interfaced with utility without adequate installation of

harmonic filters. Another costly requirement.

Only PWM and sinewave inverters qualify but expensive.

Photovoltaic System Design

Power Electronics Limitations

High voltage and current rating semiconductor devices

are very costly. First issue is to find the high rating

devices and the second is to afford to buy it.

Photovoltaic System Design

Static Inverters vs. Rotary Converters?

To help sustainable energy culture manufacturers have already started

designing12-96V DC battery powered solar lights, solar fans, solar washing

machines, solar refrigerators, solar air conditions and solar water pumping

systems.

For example, Sanyo manufactures DC inverter air conditioners from 300 to

2000 Watts. A Malaysian company has introduced 12 V @ 8A and 24V @ 4

A DC air conditioners of 300 watts cooling capacities. A Chinese company

has introduced 5000-18000 BTU capacity 24/48V batter operated 1000

watts DC air conditioners. 24-400V DC inputted 5-200kVA inverters are

available in market.

If the owner does not want to change the existing appliance and wiring then

he/she may go for DC to AC inverters or DC Motor-AC Generator sets. A

12/24/48V DC motor can easily drive a generator to produce sinusoidal

voltage at desired frequency. Rotary converter is also called MG set.

Photovoltaic System Design

PV Cable Sizing

IEEE 1526 (Recommended practice for testing the

performance of stand-alone photovoltaic systems) and

NEC 2002 (National electrical code/wiring methods)

recommend the total voltage drop in feeder and branch

circuits be less than 5% (4.2% for 0.5V drop in 12V DC

system), with the drop in either feeder or branch circuit

limited to no more than 3% (2.1% for 0.5V drop in 24V

DC system).

Photovoltaic System Design

PV Cable Sizing

NEC recommended /kft (Ohms/1000 ft) are shown in Table

Photovoltaic System Design

PV Cable Sizing

If L is the distance from source to load and VS is the

source (battery) voltage then percent voltage drop

(%VD) in the wire is given by

The circuit resistance /kft becomes

Photovoltaic System Design

PV Cable Sizing

Wire sizes of 50-watt filament lamp and 500-watt electric

iron located at distance of 20 m from a 12V DC battery

may be calculated as follows

I(75W bulb) = P/ V

= 75/12

= 6.250 A

I(500w iron) = P/ V

= 500/12

= 41.67 A

Photovoltaic System Design

PV Cable Sizing

For 0.96 (6.25A) and 0.144 (41.67A) /kft values

NEC Std recommends to use wire size # 8 for 50-watt

lamp and the wire size # 0 for 500-watt electric iron.

Photovoltaic System Design

Future Scope

Photovoltaic System Design

Thank You

Você também pode gostar

- Photovoltaic Standards - PV SystemsDocumento2 páginasPhotovoltaic Standards - PV SystemsSolar - Marketing/CELAinda não há avaliações

- 400-kW Grid Connected Solar PV System: Technical and Commercial ProposalDocumento6 páginas400-kW Grid Connected Solar PV System: Technical and Commercial ProposalGulshana GajjuAinda não há avaliações

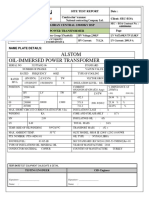

- SITE TEST REPORT: Step & Touch Voltage Test: Contractor: SSEM Contract No:1453/00Documento3 páginasSITE TEST REPORT: Step & Touch Voltage Test: Contractor: SSEM Contract No:1453/00Humayun AhsanAinda não há avaliações

- Interlocking Scheme Transmission Dept PDFDocumento40 páginasInterlocking Scheme Transmission Dept PDFSergio Henrique F. CArniettoAinda não há avaliações

- Wind Power in Power SystemsNo EverandWind Power in Power SystemsThomas AckermannNota: 3 de 5 estrelas3/5 (1)

- 09 PV Sam Pvsyst Performance Yield ComparisonDocumento19 páginas09 PV Sam Pvsyst Performance Yield Comparisonrajuwithualways100% (1)

- Sheikh A. Solar PV System Design Guide For Beginners... 2021Documento105 páginasSheikh A. Solar PV System Design Guide For Beginners... 2021Juan Carlos CastroAinda não há avaliações

- Grid-Connected PV System Design Guidlines 1-1Documento24 páginasGrid-Connected PV System Design Guidlines 1-1Sindhu sri100% (1)

- Photovoltaic NEC Code Practices2005Documento143 páginasPhotovoltaic NEC Code Practices2005Roberto Capdevila GriñoAinda não há avaliações

- Technical Expert To PVDocumento36 páginasTechnical Expert To PVSe SamnangAinda não há avaliações

- Solar Pat Checklist 111Documento6 páginasSolar Pat Checklist 111Buddhisagar BastolaAinda não há avaliações

- PV Online Brochure en Final 3Documento40 páginasPV Online Brochure en Final 3HAMDI100% (1)

- Solar Design EngineerDocumento2 páginasSolar Design EngineerImtiaz AhmedAinda não há avaliações

- Solar Power System CalculationDocumento10 páginasSolar Power System Calculationmanohar_033100% (1)

- Solfest Test Answer Key PDFDocumento6 páginasSolfest Test Answer Key PDFsalem BEN MOUSSAAinda não há avaliações

- Frequently Asked Questions On Solar PowerDocumento30 páginasFrequently Asked Questions On Solar Powergantasri8Ainda não há avaliações

- Photovoltaic System DesignDocumento21 páginasPhotovoltaic System DesignMuhammad Amusa100% (1)

- RFP App A Solar Technical SpecificationDocumento50 páginasRFP App A Solar Technical SpecificationarunghandwalAinda não há avaliações

- Stand Alone PV System ComponentDocumento142 páginasStand Alone PV System Componentbedilu77Ainda não há avaliações

- Design of A Large Scale Solar PV SystemDocumento309 páginasDesign of A Large Scale Solar PV SystemArianit Zeqiri67% (3)

- Solar PV Minigrid Systems - Design, Installation, Operation & Maintenance Guidelines HandbookDocumento162 páginasSolar PV Minigrid Systems - Design, Installation, Operation & Maintenance Guidelines HandbookDwipen BoruahAinda não há avaliações

- 1 MW Soalr Power Plant Project ReportDocumento44 páginas1 MW Soalr Power Plant Project ReportmattAinda não há avaliações

- Solar Training at ONGC, DehradhunDocumento54 páginasSolar Training at ONGC, DehradhunParveen ChoudharyAinda não há avaliações

- An Approximate DESIGN of A 100MW Solar P PDFDocumento7 páginasAn Approximate DESIGN of A 100MW Solar P PDFVinod BabhaleAinda não há avaliações

- Part 4 - Solar Systems Greater Than 425 KWPDocumento26 páginasPart 4 - Solar Systems Greater Than 425 KWPganesamoorthy1987Ainda não há avaliações

- PV Site Selection Survey 6Documento6 páginasPV Site Selection Survey 6Luis ShamanAinda não há avaliações

- 2 Performance Test On Solar Photovoltaic PanelDocumento3 páginas2 Performance Test On Solar Photovoltaic PanelManish VankudreAinda não há avaliações

- Solar Power Plant Design Interconnection 201104Documento20 páginasSolar Power Plant Design Interconnection 201104Amit PathaniaAinda não há avaliações

- TH - EnglishDocumento87 páginasTH - EnglishBacamarteAinda não há avaliações

- Manual Guide For PVDocumento40 páginasManual Guide For PVRahmawati AgustinAinda não há avaliações

- Designing of PV 2Documento55 páginasDesigning of PV 2ashrafrazi100% (1)

- Questions Answers - Photo Voltaic Training Session 1Documento6 páginasQuestions Answers - Photo Voltaic Training Session 1Fernando Nuno100% (1)

- 9AKK107492A3277 Photovoltaic Plants - Technical Application PaperDocumento158 páginas9AKK107492A3277 Photovoltaic Plants - Technical Application PaperJanitha HettiarachchiAinda não há avaliações

- DPR 5MW Sahil Energy Kadiri 1Documento58 páginasDPR 5MW Sahil Energy Kadiri 1Vamsi Krishna SivadiAinda não há avaliações

- Solar Professor-NABCEP-IV Curve PDFDocumento10 páginasSolar Professor-NABCEP-IV Curve PDFSami Al-aminAinda não há avaliações

- Design of A Residential PV Power SystemDocumento37 páginasDesign of A Residential PV Power SystemAsad UllahAinda não há avaliações

- Floating Solar PlantDocumento2 páginasFloating Solar PlantSuhagPatelAinda não há avaliações

- Stand Alone PV System Design Using PVSystDocumento15 páginasStand Alone PV System Design Using PVSystRaam Perumal100% (11)

- Solar Radiation CalculationDocumento43 páginasSolar Radiation Calculationbharathscds0% (1)

- HVDC ReportDocumento3 páginasHVDC ReportSueja MalligwadAinda não há avaliações

- PV Perfromance in Solar FinancingDocumento29 páginasPV Perfromance in Solar FinancingjgravisAinda não há avaliações

- Best Practices in Solar PV Systems Operation and MaintenanceDocumento99 páginasBest Practices in Solar PV Systems Operation and MaintenancesrichanderAinda não há avaliações

- PV System DesignDocumento96 páginasPV System DesignSourabh Banerjee100% (3)

- PV System DesignDocumento36 páginasPV System DesignRaymond LinguajeAinda não há avaliações

- Solar Panels: DeployableDocumento8 páginasSolar Panels: DeployableRajib ChowdhuryAinda não há avaliações

- Helioscope User ManualDocumento38 páginasHelioscope User ManualbenignoAinda não há avaliações

- Pvtrin Checklist Practical Tips On PV Installations enDocumento22 páginasPvtrin Checklist Practical Tips On PV Installations enyavuz772100% (1)

- Solar PV System GuideDocumento29 páginasSolar PV System Guidecatersolar100% (15)

- Solar Substation ProposalDocumento42 páginasSolar Substation ProposalNitishPaudel100% (1)

- Light Emitting DiodeDocumento21 páginasLight Emitting DiodeDeepak YadavAinda não há avaliações

- Design Document v2Documento17 páginasDesign Document v2api-533235687Ainda não há avaliações

- First Solar 2014 Annual Report Bookmark - FinalDocumento188 páginasFirst Solar 2014 Annual Report Bookmark - FinalFabián OrccónAinda não há avaliações

- Design of A Solar PV SystemDocumento46 páginasDesign of A Solar PV SystemGokulAinda não há avaliações

- Solar Modules Cleaning GuidelinesDocumento2 páginasSolar Modules Cleaning GuidelinesCNP WEBAinda não há avaliações

- MR Nilesh Jaiswal: Engineering, Procurement & Construction (EPC)Documento9 páginasMR Nilesh Jaiswal: Engineering, Procurement & Construction (EPC)Dhruv ChaudharyAinda não há avaliações

- Malang Project12000Ah - vc9 ReportDocumento4 páginasMalang Project12000Ah - vc9 ReportEgavania ZerlindaAinda não há avaliações

- 3D Photovoltaic Devices Complete Self-Assessment GuideNo Everand3D Photovoltaic Devices Complete Self-Assessment GuideAinda não há avaliações

- Solar Panel Improvement: 1950–2016: For Solar, by Solar, to SolarNo EverandSolar Panel Improvement: 1950–2016: For Solar, by Solar, to SolarAinda não há avaliações

- Off Grid Photovoltaic SystemDocumento7 páginasOff Grid Photovoltaic Systemggabi307Ainda não há avaliações

- 11.Eng-Solar Energy Solution To Fuel Dilemma-Arwa WafiqDocumento10 páginas11.Eng-Solar Energy Solution To Fuel Dilemma-Arwa WafiqImpact JournalsAinda não há avaliações

- Tribhuvan University IOE, Pashchimanchal CampusDocumento38 páginasTribhuvan University IOE, Pashchimanchal CampusDilkumari ShreeshAinda não há avaliações

- Walker PV TechnologyDocumento53 páginasWalker PV TechnologyaakashtrivediAinda não há avaliações

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocumento2 páginasTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- Lor Ri 16-Rp 94f-2 6rp2Documento2 páginasLor Ri 16-Rp 94f-2 6rp2Humayun AhsanAinda não há avaliações

- P442 Test ProcedureDocumento6 páginasP442 Test ProcedureHumayun AhsanAinda não há avaliações

- Transformer Test FormatDocumento31 páginasTransformer Test FormatHumayun Ahsan100% (3)

- Sec - Eoa Contract No: 4400003814 Sheet No: 1 of 5Documento4 páginasSec - Eoa Contract No: 4400003814 Sheet No: 1 of 5Humayun AhsanAinda não há avaliações

- LCC Schematics 380kvDocumento59 páginasLCC Schematics 380kvHumayun AhsanAinda não há avaliações

- CT Secondary InjectionDocumento2 páginasCT Secondary InjectionHumayun AhsanAinda não há avaliações

- Electrical Engineer: Employment Experience EducationDocumento1 páginaElectrical Engineer: Employment Experience EducationHumayun AhsanAinda não há avaliações

- HV EngineeringDocumento132 páginasHV EngineeringHumayun AhsanAinda não há avaliações

- Grid Connected PV SystemDocumento9 páginasGrid Connected PV SystemHumayun AhsanAinda não há avaliações

- Difference B/W Pure Sinewave and Squarewave InverterDocumento9 páginasDifference B/W Pure Sinewave and Squarewave InverterHumayun Ahsan100% (2)

- Basic Signals: ProgramDocumento2 páginasBasic Signals: ProgramHumayun AhsanAinda não há avaliações

- Overhead Conductor TypesDocumento5 páginasOverhead Conductor TypesHumayun AhsanAinda não há avaliações

- B.SC Curriculum (Revised 2012) UogDocumento47 páginasB.SC Curriculum (Revised 2012) UogHumayun AhsanAinda não há avaliações

- Transmission Lines: Power Carrying Capacity in PakistanDocumento3 páginasTransmission Lines: Power Carrying Capacity in PakistanHumayun AhsanAinda não há avaliações

- Buck Converter: DC To DC Converter Switched-Mode Power Supply Transistor DiodeDocumento9 páginasBuck Converter: DC To DC Converter Switched-Mode Power Supply Transistor DiodeHumayun AhsanAinda não há avaliações

- Ssignment Itle: E - Z M D E E U G, GDocumento1 páginaSsignment Itle: E - Z M D E E U G, GHumayun AhsanAinda não há avaliações

- M Eng 8086Documento148 páginasM Eng 8086Suleman Mirza100% (3)

- Synchronous Motor and Asynchronous MotorDocumento3 páginasSynchronous Motor and Asynchronous MotorMOHANAKIRANAAinda não há avaliações

- SMK0965F: Switching Regulator ApplicationsDocumento8 páginasSMK0965F: Switching Regulator ApplicationsFale MensAinda não há avaliações

- Installation Instructions - M210E-Cz Conventional Zone Interface ModuleDocumento4 páginasInstallation Instructions - M210E-Cz Conventional Zone Interface ModuleProstě ZanekAinda não há avaliações

- Coupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Documento1 páginaCoupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Carlos HerreraAinda não há avaliações

- Vacon NXP Grid Converter ARFIFF03V164 Manual DPD01599C UK - V001Documento185 páginasVacon NXP Grid Converter ARFIFF03V164 Manual DPD01599C UK - V001hunt huntAinda não há avaliações

- Kqe7004 - Mid Sem Test - 2019 - 231119Documento5 páginasKqe7004 - Mid Sem Test - 2019 - 231119Shoaib SadikAinda não há avaliações

- Metoda Budeanu PDFDocumento10 páginasMetoda Budeanu PDFPaduretz KeepsakeAinda não há avaliações

- Epcos Thyristor ModuleDocumento6 páginasEpcos Thyristor ModuleSanthosh OsAinda não há avaliações

- Ampliful MarcelDocumento15 páginasAmpliful MarcelDanut StanciuAinda não há avaliações

- General Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionDocumento11 páginasGeneral Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionrvasilevaAinda não há avaliações

- Toshiba Injection MouldingDocumento11 páginasToshiba Injection MouldingR.Ranjan PradhanAinda não há avaliações

- Omron PDFDocumento16 páginasOmron PDFIgnacio NashAinda não há avaliações

- HTLS DDW ACEF 2015 16 June 2015Documento19 páginasHTLS DDW ACEF 2015 16 June 2015Sube OhAinda não há avaliações

- TRAX Manual enDocumento58 páginasTRAX Manual enJack Duff100% (3)

- Pyram Pyram Pyram Pyram D DSP D DSP D DSP - T T T TDocumento38 páginasPyram Pyram Pyram Pyram D DSP D DSP D DSP - T T T TAndersonAinda não há avaliações

- Semiconductors: Thyristor Modules Thyristor/Diode ModulesDocumento4 páginasSemiconductors: Thyristor Modules Thyristor/Diode ModulesTeknotama Inti Medindo PTAinda não há avaliações

- QuoteDocumento4 páginasQuoteRahul Rajan KulkarniAinda não há avaliações

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocumento2 páginasHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- Commander SK: Getting Started GuideDocumento52 páginasCommander SK: Getting Started GuideAshraf E. YacoubAinda não há avaliações

- Centre Tapped Transformer SpecificationsDocumento4 páginasCentre Tapped Transformer SpecificationsALNATRON GROUPSAinda não há avaliações

- Relay Setting Phojal SubstationDocumento108 páginasRelay Setting Phojal SubstationSanjay Kaushal100% (2)

- Iec TS 62257-7-2008Documento18 páginasIec TS 62257-7-2008Yassine BecharAinda não há avaliações

- Tabela de VaristoresDocumento15 páginasTabela de VaristoresMarcioAndradeAinda não há avaliações

- Excerpt From: Electricity InformationDocumento7 páginasExcerpt From: Electricity InformationCarlosAinda não há avaliações

- Standard+installations+électriques Version+du+28-06-2016 ENDocumento17 páginasStandard+installations+électriques Version+du+28-06-2016 ENGrego NefalinoAinda não há avaliações

- PA CIGRE-2014 A Deeper Insight Into Fault Location On Long Submarine Power Cables ENDocumento10 páginasPA CIGRE-2014 A Deeper Insight Into Fault Location On Long Submarine Power Cables ENUsman AliAinda não há avaliações

- Easy Wind Speed Meter WSMDocumento4 páginasEasy Wind Speed Meter WSMJune BugAinda não há avaliações

- Panelboard and Switchboard PDFDocumento32 páginasPanelboard and Switchboard PDFGerardo M. James BravoAinda não há avaliações

- 1250 WWWWWWWWWWWWWWWWWWWWWWDocumento1 página1250 WWWWWWWWWWWWWWWWWWWWWWchalaAinda não há avaliações