Escolar Documentos

Profissional Documentos

Cultura Documentos

Emergency Diesel Generators

Enviado por

jengandxb100%(1)100% acharam este documento útil (1 voto)

55 visualizações51 páginasEmergency Generator

Título original

Emergency Diesel Generators (2)

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoEmergency Generator

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

55 visualizações51 páginasEmergency Diesel Generators

Enviado por

jengandxbEmergency Generator

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 51

ACADs (08-006) Covered

1.3.2.1

4.2.7.12.19

Keywords

Emergency Diesel Generator, components, drawings.

Description

Supporting Material

NUET 230 EMERGENCY DIESEL GENERATORS

The purpose of this class is to familiarize students with Emergency

Diesel Generators.

We will use various drawings of the EMERGENCY DIESEL

GENERATORS at Fermi 2 as the primary tools to learn this system.

EMERGENCY DIESEL GENERATORS

TERMINAL OBJECTIVE

Students will understand the EMERGENCY DIESEL

GENERATORS, its major components and flowpaths

EMERGENCY DIESEL GENERATORS

ENABLING OBJECTIVES

State the purpose of the EMERGENCY DIESEL GENERATORS, including

its importance to nuclear safety.

Using a simplified diagram, identify and explain the purpose of the major

components and equipment of the EMERGENCY DIESEL

GENERATORS.

Describe the Maintenance Policies used for EDG maintenance

EMERGENCY DIESEL GENERATORS

Purposes of the EMERGENCY POWER (EAC) system

The purpose of the EDG is to provide a reliable on-site source of

AC electrical power to maintain the ability to safely shutdown the

reactor under all conditions, including a LOCA coincident with a

Loss of Offsite Power (LOP)

EMERGENCY DIESEL GENERATORS

Basic system description:

The EDGs start automatically upon receipt of LOCA and/or LOOP signal

and reach rated speed and voltage within 10 seconds. However, the EDGs

breakers will not automatically close to the plants electrical bus network

unless either a LOOP and/or loss of EDG bus voltage occurs. If a LOOP

and/or loss of EDG bus voltage occur an automatic sequencer will load the

EDGs in an orderly manner to avoid overloading and damaging the

equipment. Only the loads necessary for safe shutdown are automatically

loaded to the EDG.

The system consists of four EDG units separated into two independent

divisions. Each division containing two EDGs supplies power to the

essential loads of its respective bus. Either divisional pair is capable of

supplying loads needed for safe shutdown of the reactor. Each EDG is

supplied with its own supporting systems such that any single failure of an

EDG supporting system will not affect the remaining EDGs.

EMERGENCY DIESEL GENERATORS

EMERGENCY DIESEL GENERATORS

EMERGENCY DIESEL GENERATORS

EMERGENCY DIESEL GENERATORS

10

EMERGENCY DIESEL GENERATORS

11

EMERGENCY DIESEL GENERATORS

EDG Ventilation equipment:

Air Intake and Exhaust System - Supplies compressed air to the cylinders

for combustion, and scavenging air to remove the exhaust gases from the

previous cylinder stroke to the atmosphere

Flowpath

Air is drawn from the outside through a intake filter and silencer via the

compressor side of the turbocharger.

Major Equipment:

Intake Air Filter - The dry filter removes objects from the intake air stream

to prevent damage to the turbocharger and blower.

Intake Silencer - Reduces the noise caused by the flow of the intake air.

Turbocharger - The turbocharger pressurizes the inlet of the main blower

to increasing engine efficiency.

12

EMERGENCY DIESEL GENERATORS

13

EMERGENCY DIESEL GENERATORS

14

EMERGENCY DIESEL GENERATORS

15

EMERGENCY DIESEL GENERATORS

16

EMERGENCY DIESEL GENERATORS

17

EMERGENCY DIESEL GENERATORS

18

EMERGENCY DIESEL GENERATORS

19

EMERGENCY DIESEL GENERATORS

20

EMERGENCY DIESEL GENERATORS

21

EMERGENCY DIESEL GENERATORS

22

EMERGENCY DIESEL GENERATORS

23

EMERGENCY DIESEL GENERATORS

24

EMERGENCY DIESEL GENERATORS

Diesel engines run at higher compression pressure than

gasoline engines. Where the highest compression for most

high performance gasoline engines is close to 200 psi, diesel

runs almost 3 times that pressure. As a consequence, more

heat is generated putting extra demands on the engine cooling

system. Study shows diesel engines usually fail 50% more on

cooling related problems because it cannot stand prolong

overheating. This is why the cooling system is a high

maintenance issue.

Unlike the gas engines, diesel engine has no electrical ignition

parts like plugs, wires and moving part like distributor rotor

which is subject to wear. These parts have a limited life and

have to be changed on regular basis.

25

EMERGENCY DIESEL GENERATORS

Since diesel engines use a lot of air, greater attention is paid to the

engine air filtration. Operators closely monitor air filter differential

pressure and ensure filter cleaning / replacement is performed when

needed. Cooling this air is also critical especially because the engine

is turbocharged. High end diesel engines are fitted with after-coolers to

cool the air from turbo charger.

26

EMERGENCY DIESEL GENERATORS

To prevent engine cylinder block scoring, avoid prolonged idle

operation of diesel engines.

The EDGs will typically be loaded within 10 minutes or less of a test

start.

27

EMERGENCY DIESEL GENERATORS

Remarks by Jeffrey S. Merrifield, Commissioner

U. S. Nuclear Regulatory Commission July 24, 2006

On August 14, 2003, I was the Acting Chairman on what I thought was

going to be just another routine day at the NRC. I had a series of

scheduled meetings that day, including a briefing on grid reliability,

where the staff discussed the trends in loss of offsite power events at

nuclear power plants. The staff informed me that the number of these

events was decreasing, which was encouraging. They also mentioned,

however, that the duration of individual events was tending to be

longer.

Around 4:00 p.m. that afternoon, Bill Travers, the EDO at that time,

came into my office and informed me that the staff was assembling in

our Operations Center in response to the automatic shutdown of

several nuclear plants in the Northeast and Midwest. At that time, we

did not know whether it was caused by multiple operational events or,

perhaps by a coordinated act of terrorism.

28

EMERGENCY DIESEL GENERATORS

As information continued to pour in the rest of the afternoon and into

the evening hours, we came to learn that nine nuclear power plants in

the U.S., as well as 11 in Canada, and a host of coal-fired power

plants had been disconnected from the grid because of electrical

instabilities, resulting in the blackout of major portions of the Northeast

and Midwest in the U.S. and parts of Canada. In fact, virtually every

power plant east of the Mississippi experienced voltage swings of

variable amplitude, though plants further from the Northeast corridor

saw only minor voltage perturbations.

By the next morning, after a long night at the Ops Center, we were

only beginning to understand the magnitude of the blackout. I

participated in several conference calls, including calls with the White

House Situation Room, to discuss the causes of the event with the

staff of the National Security Council as well as various Cabinet

members.

29

EMERGENCY DIESEL GENERATORS

As you all know, after a nuclear power plant shuts down, it cannot just

be restarted at the flip of a switch. Components in several systems

must be realigned, those systems must be walked down to confirm

their readiness, and the reactor operators must go through a checklist

before pulling control rods to restart the nuclear reaction. It typically

takes between eight and 24 hours for a reactor to restart after it trips

offline. In addition, after a station blackout event, the transmission line

operators must also ensure the grid is ready before the plant can close

its generator output breaker and resume supplying power to the grid.

There are a number of steps required to restore electrical power once

the grid has gone down. That being said, most of the nuclear power

plants were restarted within a few days and the grid returned to

normal.

30

EMERGENCY DIESEL GENERATORS

So, what caused the event? We would eventually find that poor

maintenance of transmission lines including tree trimming, lack of

sensor and relay repair or replacement, poor maintenance of control

room alarms, poor communications between load dispatchers and

power plant operators, and a lack of understanding of transmission

system interdependencies were all major contributors to the domino

effect that resulted in plant after plant tripping off line because of the

collapse of the electrical grid.

This event was truly a wake-up call for the North American

transmission system operators as well as electricity generating

companies

31

EMERGENCY DIESEL GENERATORS

WHY DOES NRC CARE ABOUT GRID STABILITY?

Nuclear power reactors must be cooled continuously, even when shut

down. The numerous pumps and valves in the reactor cooling systems

therefore must have access to electrical power at all times, even if the

normal power supply from the grid is degraded or completely lost.

As a regulator, we want to minimize the time a nuclear power plant is

subjected to a complete loss of offsite power, otherwise known as

Station Blackout. Even though plants are designed with emergency

diesel generators to supply power to pumps and valves that keep the

reactor cool when normal power is lost, we do not like to challenge

those diesel generators any more than is absolutely necessary.

The NRC was concerned about grid reliability long before the 2003

blackout event.

32

EMERGENCY DIESEL GENERATORS

On August 12, 1999, while the Callaway plant (in Missouri) was offline

in a maintenance outage, the plant saw the offsite power supply

voltage fall below minimum requirements for a 12-hour period. The

voltage drop they observed was caused by peak levels of electrical

loading and the transport of large amounts of power on the grid

adjacent to Callaway. The licensee noted that the deregulated

wholesale power market contributed to conditions where higher grid

power flows were likely to occur in the area near Callaway. Alliant

Energy had to spend ten's of millions of dollars to install new

transformers with automatic tap changers to keep voltage above

minimum requirements, and capacitor banks to improve the reactive

power (volt-amps reactive, or VARs) factor in the Callaway switchyard.

33

EMERGENCY DIESEL GENERATORS

As a result of deregulation, many electric utilities were split into electric

generating companies and transmission and distribution companies. Thus,

nuclear power plants now must rely on outside entities to maintain the

switchyard voltage within acceptable limits. Over time, some transmission

companies have become less sensitive to the potential impacts that grid

voltage can have on nuclear plant operations. A big part of our risk-informed

regulatory strategy depends on plants having access to reliable offsite

power. We assume that there will be very few times when a plant will be

subjected to a total loss of offsite power, and when such condition exists it

will be for a relatively short period of time (hours or days rather than weeks).

Our strategy of allowing more on-line maintenance to be performed on

certain important safety equipment such as the emergency diesel

generators makes sense as long as the risk of a plant trip remains very low

during the period of time that equipment is out of service. This philosophy

relies on the fact that a total loss of offsite power is a rare occurrence that

will be corrected in a short period of time.

END OF NRC COMMENTS

34

EMERGENCY DIESEL GENERATORS

Engine Construction

Cylinder Block - A "shock qualified," precision-welded steel

block designed for structural rigidity and a design life

exceeding 40 years. Dry block construction eliminates

leakage and extends frame life. Large access openings at

five levels in the engine improve maintenance.

Turbocharging - High-efficiency turbocharging and pulse

manifolding improves cylinder scavenging, thereby

improving efficiency and lowering emissions. Optional TurboBlower Series design provides fast-starting and high-load

acceptance capability, ideal for combination emergency

stand-by and peak shaving applications.

35

EMERGENCY DIESEL GENERATORS

Engine Construction

Cylinder Liners - Two pistons inside the cylinder liner form

the combustion space, eliminating cylinder heads, valves,

and associated hardware. Compared to other engine

designs, Opposed Piston engines have less than half the

moving parts.

Pistons, Bearings, and Connecting Rods - Upper and lower

piston assemblies may be removed from the lower

crankcase, simplifying maintenance procedures. Connecting

rods are forged from high-tensile-strength alloy steel. Due to

the Opposed Piston's two-stroke cycle design and

conservative operating speed (900 and 1000 rpm),

aluminum alloy main and rod bearing life is extended.

36

EMERGENCY DIESEL GENERATORS

In a nutshell, a synchroscope

is a device used in AC

electrical power systems that

indicates the degree to which

two sources of power (power

systems, generators, bus ties,

etc.) are synchronized with

each other. Synchroscopes

measure and display the

differences in frequency

(speed) and time phase

between the two power

sources. This photo shows

two sources in synch, each

with matched voltages, in this

case a 13,800 volt main bus

circuit and a generator.

37

EMERGENCY DIESEL GENERATORS

Concerning the start up of a US *60HZ AC generator (*60HZ= 3600rpm); if

the generator is turning at a lower frequency than the circuit that it is to be

connected to, the synchroscope indicator will spin continually on the slow

side, in a counterclockwise direction, until the speed of the generator is

increased. The slower the speed, the faster the indicator will spin and the

brighter the indicating lights, on either side of the scope, will illuminate. If

the generator is running on the fast side of the synchroscope, the indicator

will spin continually in the clockwise direction, indicating that the generator

speed must be decreased. Ideally the station operator adjusts the generator

speed (frequency) until the indicator reaches the '12 oclock' point, showing

that it is running at precisely the same frequency as the circuit it is being

connected to. With this, and matching voltages on both sides, the generator

circuit breaker is closed and the generator is placed in service.

38

EMERGENCY DIESEL GENERATORS

39

EMERGENCY DIESEL GENERATORS

40

EMERGENCY DIESEL GENERATORS

41

EMERGENCY DIESEL GENERATORS

42

EMERGENCY DIESEL GENERATORS

43

EMERGENCY DIESEL GENERATORS

44

EMERGENCY DIESEL GENERATORS

45

EMERGENCY DIESEL GENERATORS

46

EMERGENCY DIESEL GENERATORS

EDG Governor

Electric

Actuator

47

EMERGENCY DIESEL GENERATORS

EDG

Centrifugal

Governor

48

EMERGENCY DIESEL GENERATORS

49

EMERGENCY DIESEL GENERATORS

TERMINAL OBJECTIVE

Students will understand the EMERGENCY DIESEL

GENERATORS, its major components and flowpaths

50

EMERGENCY DIESEL GENERATORS

ENABLING OBJECTIVES

State the purpose of the EMERGENCY DIESEL GENERATORS, including

its importance to nuclear safety.

Using a simplified diagram, identify and explain the purpose of the major

components and equipment of the EMERGENCY DIESEL

GENERATORS.

Describe the Maintenance Policies used for EDG maintenance

51

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- How To Start An Oil Change BusinessDocumento24 páginasHow To Start An Oil Change BusinessjengandxbAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- QuickServe Online - (4915540) QSX15 Owners ManualDocumento4 páginasQuickServe Online - (4915540) QSX15 Owners ManualjengandxbAinda não há avaliações

- K38 - Cylinder Head InstallationDocumento3 páginasK38 - Cylinder Head InstallationjengandxbAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- K38 Front Gear Housing Tightining ProcedureDocumento1 páginaK38 Front Gear Housing Tightining ProcedurejengandxbAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- QuickServe Online - (3666422) ICON™ Idle Control SystemDocumento18 páginasQuickServe Online - (3666422) ICON™ Idle Control Systemjengandxb100% (1)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDocumento2 páginasQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- QuickServe Online - (5411406) Fluids For Cummins® Products Service ManualDocumento7 páginasQuickServe Online - (5411406) Fluids For Cummins® Products Service Manualjengandxb100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Single Piece Piston Kit Installation InstructionDocumento1 páginaSingle Piece Piston Kit Installation InstructionjengandxbAinda não há avaliações

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Documento7 páginasPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbAinda não há avaliações

- CentinalDocumento2 páginasCentinaljengandxb0% (1)

- K38, K50, Owners ManualDocumento3 páginasK38, K50, Owners ManualjengandxbAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- QuickServe Online - (4021539) QST30 Service ManualDocumento7 páginasQuickServe Online - (4021539) QST30 Service Manualjengandxb33% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Documento7 páginasPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Preparatory Steps: Dual-PistonDocumento4 páginasPreparatory Steps: Dual-PistonjengandxbAinda não há avaliações

- QSK78 Owners Manual PDFDocumento17 páginasQSK78 Owners Manual PDFjengandxb100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- QSK78 Troubleshooting and Repair Manual PDFDocumento4 páginasQSK78 Troubleshooting and Repair Manual PDFjengandxbAinda não há avaliações

- Remove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)Documento2 páginasRemove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)jengandxbAinda não há avaliações

- Fault Code 113: Electronic Step Timing Control (STC) CircuitDocumento2 páginasFault Code 113: Electronic Step Timing Control (STC) CircuitjengandxbAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- ECM TroubleshootingDocumento27 páginasECM Troubleshootingjengandxb100% (4)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Cummins K-50 Performance PartsDocumento10 páginasCummins K-50 Performance Partsjengandxb100% (1)

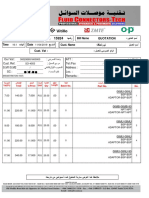

- Pay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationDocumento3 páginasPay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationjengandxbAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- QSK78 Troubleshooting and Repair ManualDocumento4 páginasQSK78 Troubleshooting and Repair Manualjengandxb0% (1)

- General Information: Industrial EnginesDocumento17 páginasGeneral Information: Industrial EnginesjengandxbAinda não há avaliações

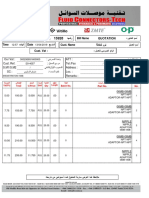

- Pay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationDocumento3 páginasPay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationjengandxbAinda não há avaliações

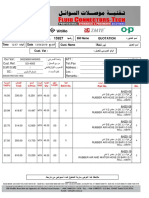

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocumento6 páginasPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbAinda não há avaliações

- En TN004-Dead Bus SynchronizingDocumento6 páginasEn TN004-Dead Bus SynchronizingAlain AounAinda não há avaliações

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocumento3 páginasPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbAinda não há avaliações

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocumento3 páginasPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Main Bearing Torque K50Documento1 páginaMain Bearing Torque K50jengandxb100% (1)

- 11111Documento3 páginas11111jengandxbAinda não há avaliações

- Leyte Geothermal Power Progressive Employees UnionDocumento3 páginasLeyte Geothermal Power Progressive Employees Unionaags_06Ainda não há avaliações

- Green Buildings, Energy EfficiencyDocumento7 páginasGreen Buildings, Energy EfficiencyAbu Talha FarooqiAinda não há avaliações

- Design 8 ConsheetDocumento7 páginasDesign 8 ConsheetEryl David BañezAinda não há avaliações

- Schedule of Loads PDFDocumento5 páginasSchedule of Loads PDFmae_morano81% (27)

- Sugar ManufacturingDocumento55 páginasSugar Manufacturingamrialifa100% (3)

- 988B Diagrama ElectricoDocumento4 páginas988B Diagrama ElectricoMaquinaria Pesada ServisAinda não há avaliações

- RippleTankSE Key PDFDocumento10 páginasRippleTankSE Key PDFYesi Setyo Ningrum100% (1)

- Vista Vista Ar Tech Data Sheet MalarkeyDocumento2 páginasVista Vista Ar Tech Data Sheet MalarkeyHoeAinda não há avaliações

- of Gatorade..Documento29 páginasof Gatorade..Jay ThakkarAinda não há avaliações

- PE Electromagnetic Pump Unit PE GB T1101 01-02-182Documento4 páginasPE Electromagnetic Pump Unit PE GB T1101 01-02-182li geneAinda não há avaliações

- Force and Types of Forces Muscular Mechanical Gravitational Magnetic Frictional Static Electric ForceDocumento3 páginasForce and Types of Forces Muscular Mechanical Gravitational Magnetic Frictional Static Electric ForceJasvinder Singh67% (3)

- Siemens IEC61850Documento2 páginasSiemens IEC61850g-bearAinda não há avaliações

- Assignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsDocumento61 páginasAssignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsHarshil JainAinda não há avaliações

- Centrifugal Compressor TutorialDocumento31 páginasCentrifugal Compressor TutorialJackjinnAinda não há avaliações

- Eurocode 8-1-3Documento18 páginasEurocode 8-1-3joaoAinda não há avaliações

- 20146501.pdf Ga75vsdDocumento34 páginas20146501.pdf Ga75vsdCHATEAUVIEUX Patrick100% (1)

- "Enron Energy Scandal": Assignment ONDocumento11 páginas"Enron Energy Scandal": Assignment ONDarshan GohilAinda não há avaliações

- Cloud Point of Diesel Fuel: Application NoteDocumento2 páginasCloud Point of Diesel Fuel: Application Noteanilkumar995472Ainda não há avaliações

- Samuel FrimpongDocumento14 páginasSamuel Frimpongdunlut pelemAinda não há avaliações

- Waterjet 2008 CondensedDocumento12 páginasWaterjet 2008 Condensedkaniappan sakthivelAinda não há avaliações

- Definition of Terms - Plumbing2Documento15 páginasDefinition of Terms - Plumbing2Gels GenovaAinda não há avaliações

- 2018 - Integrated Annual ReportDocumento205 páginas2018 - Integrated Annual ReportazshpAinda não há avaliações

- Teikin Catalog Vol 18-Automotive FiatDocumento6 páginasTeikin Catalog Vol 18-Automotive FiatJuan Esteban Ordoñez BonillaAinda não há avaliações

- G7Documento21 páginasG7Maame Ama FrempongAinda não há avaliações

- EPIV ValvesDocumento2 páginasEPIV ValvesstomakosAinda não há avaliações

- Datasheet Noise FilterDocumento2 páginasDatasheet Noise FilternellyyulitasariiAinda não há avaliações

- Hazardous Area Classification: Codes of Practice and StandardsDocumento13 páginasHazardous Area Classification: Codes of Practice and StandardsborrowmanaAinda não há avaliações

- Synchronous Machines Question BankDocumento10 páginasSynchronous Machines Question BankelecenggAinda não há avaliações

- Product Data Sheet: Motor - M40 - Sepam Series 40Documento2 páginasProduct Data Sheet: Motor - M40 - Sepam Series 40Akriti AgrawalAinda não há avaliações

- DPI - Jul-Aug 16Documento59 páginasDPI - Jul-Aug 16ratninp9368Ainda não há avaliações