Escolar Documentos

Profissional Documentos

Cultura Documentos

OSHA Unit 1

Enviado por

Jeremy Lim Choon Keat0 notas0% acharam este documento útil (0 voto)

50 visualizações27 páginasProfessional practice

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPTX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoProfessional practice

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPTX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

50 visualizações27 páginasOSHA Unit 1

Enviado por

Jeremy Lim Choon KeatProfessional practice

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPTX, PDF, TXT ou leia online no Scribd

Você está na página 1de 27

Occupational Safety

and Health

Unit 1 - Introduction

Gerald Victor, CEng MIMechE

Introduction to OSH

Occupational safety and health and

environmental health is the

multidisciplinary approach to the

recognition, diagnosis, treatment, and

prevention of illnesses, injuries, and other

adverse health conditions resulting from

hazardous environmental exposures in the

workplace, the home, and the community.

Challenges and opportunities for

OSH and environmental health

A middle-aged man tells his orthopedic

surgeon that he is totally disabled from

chronic back pain. Could it be due to his

many years of heavy lifting as a construction

worker?

Several members of a family who live next to

a hazardous waste site smell odors from the

site and have developed headaches, nausea,

and other symptoms. What should they do?

Challenges and opportunities for

OSH and environmental health

A pregnant woman works as a laboratory

technician. Should she change her job

because of the organic solvents to which she

and her fetus are exposed?

The wife of a former asbestos worker has

developed a pleural mesothelioma,

presumably as a result of having washed her

husbands work clothes for many years. Can

she or her family receive any compensation?

Hazardous exposures occur in both

workplaces and the general environment

Contamination of the ambient air and water near

a chemical factory, where its workers are also

exposed to hazardous substances

Application by agricultural workers of pesticides

that may contaminate surface and ground water

Accidental transport of lead, asbestos, and other

hazardous substances home on workers clothes,

shoes, skin, and hair

Exposure of workers and community residents to

hazardous wastes from an industrial facility

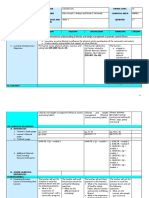

OCCUPATIONAL ACCIDENTS STATISTICS

BY SECTOR UNTIL MARCH 2015

Department of Occupational Safety

and Health , Ministry of Human

Statistics on Lung Disease in

Workplace 2001 - 2009

Department of Occupational Safety

and Health , Ministry of Human

Statistics on Job Related

Sickness 1997 - 2009

Due to injuries, workplace will

be closed for inspection

WELDING FAILURE OF A GONDOLA ARM STRUCTURE

Photo: Amusement device involved, and the broken arm with gondola on a platform

A dangerous incident involving the failure of welding on the structure of the gondola arm occurred at a theme park

in Kuala Lumpur recently. The gondola arm is one of the main components of an amusement device at the theme

park. The welding failure of the gondola arm occured when the ride was about to start, and the welding failure

caused the gondola arm to break and fall on a nearby platform. Based on the inspection done on the other gondola

arm that was still intact, cracks were observed on the welding.

To ensure the integrity of welding in good condition, the following safety measures are recommended:-

1. Daily visual inspection of welds should be carried out before the amusement ride starts operating;

2. Any cracks found should be described in detail and monitored so that cracks do not reach the critical level;

3. If cracks require repair process, the owner must ensure that the appointed welder is qualified to carry out

welding;

4. The engineer must review the welding procedure to be carried out for process improvement;

5. Non-destructive testing should be carried out on welding according to the interval recommended by the

manufacturer; and

6. Compliance with existing guidelines such as the Guidelines on the Management of Amusement Park Safety

Devices.

FIRE AND EXPLOSION OF NATURAL GAS PIPELINE IN

SARAWAK

Fire and explosion of a 36" diameter natural gas pipelines occurred

on June 10, 2014, at approximately 1.30 am. At about 5.00 am, the

fire is extinguished after fuel sources of natural gas in the pipeline

was thoroughly burned. This event does not result in any loss of life

or injury to humans (public or worker). However, the impact from the

explosion and fire formed a crater of about 10 metres in diameter

and 3 metres depth. It also caused crops surrounding area of 500

metres radius from the center of the explosion to burnt out. During

that time, there was no work activity is in progress, nor arson activity

identified.

Radius of fire estimated about 100-150 metres.

This incident caused by the release of gas from the pipeline through a welded joint between two pipes. This failure was due

to the low strain capacity of the girth weld at joint that was subjected to external loading (such as soil movement and vibration

loads by heavy vehicle). Fracture at the weld joint was resulting from welding defects and flaws. Type of consumables

(electrodes) used, expertise of welders and welding technique implemented caused this condition to happen. These inherent

defects have not been identified and translated effectively through Non-Destructive Test (NDT) performed on respective

welded joint.

From the results of the investigation made on these events, emphasis on the integrity of the welding should be given,

particularly for welding works of the underground gas pipeline. Therefore, attentions to the following point must be

considered:

Preparation of a thorough and accurate Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR)

should consider all the elements requiredby the respective welding design code.

The welding work carried out should be effectively and thoroughly supervised in ensuring compliance with welding

techniques, procedures and materials used as specified in the provided WPS and PQR.

A competent person must interpret and evaluate accurately and transparently the results of the non-destructive tests of

welding conducted.

The effectiveness and usability of a detection system of gas relief from underground gas pipelines and its control measures

over such events should be provided and monitored from time to time.

Terms of Definition

What is Safety?

What is Hazard?

What is Risk?

What is Accident?

What is Incident?

What is Safety?

Control of Accidental Loss

Injury

Illness

Damage to anything in the occupational or

external environment

In the past, safety is defined

as:

freedom from injuries

What is Hazard?

The potential to cause harm, including ill

health and injury, damage to property, plant

products or environment, production losses

or liabilities

What is Risk?

The likelihood that a specified undesired

event will occur due to the realization of a

hazard by, or during work activities or by

the products and services created by work

activities.

What is Accident?

Undesired event that results in unintended

harm or damage to people, property,

environment, and/or loss of

process/production

In the past, accident is

defined as :

An undesired event resulted in

harm to people

What is Incident?

An event which could or does result in

unintended harm or damage

In the past, incident is

defined as:

Near accident or a near miss

3 Basic Steps of Workplace

Safety

Hazard Identification

Knowing the things and actions that may lead to

accidents

Hazard Evaluation / Assessment

Being able to judge the risk of each hazard

Hazard Control

Finding ways to reduce or get rid of each hazard

Safety Management Systems

are now seen as investment as they

reduce costs and increase productivity

and profits

Classification of Hazards

Physical

Chemical

Biological

Mechanical and Ergonomic

Psycho-social

Hazards in Workplace

Chemical Hazards Physical Hazards

Mechanical/fire

Gases/vapour

Electrical/radiation

Dust Ergonomic

Fume Noise/vibration

Acid/Alkali Working at high/low

temp or pressure

Psycho Social Biological Hazards

Sexual harassment Bacteria/virus/spora

Family problem Dust plants

Work pressure

When workers are injured,

there is loss and costs:

Direct costs include:

Cost of medical treatment, benefit cost to workers

Indirect costs include:

Cost of property damage

Equipment damage

Loss of productive work time

Investigation time

Hiring and training replacement workers

Loss of profits

3 Levels of Loss Control:

Loss Control describes as actions to prevent

injury to people, damage to property and loss of

productivity and profit. 3 levels of control are:

1. Engineering controls

2. Administrative controls

Management supports and encourages safe work

practices

3. Basic / Point of Contact Controls

Personal protective equipment, etc.

Safety Management

System

In the past safety was said to be freedom

from injuries

Safety programs now focus on:

What management does

How workers do their work

Safety and Health Management Systems are

designed to prevent:

Loss due to injuries

Loss due to production

Damage to property

A problem solving approach to safety

Safety Management

System

The focus on safety moved away from

worker to management

This way of viewing safety becomes a

safety management system a problem

solving approach to safety

ACT 514 OSHA General duties of

employers (clause 15)

ACT 514 OSHA General duties of

employees (clause 24)

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- R.4.1 Macquarie University IOL - IELTS Academic Reading - Practice Test 1 - QuestionsDocumento12 páginasR.4.1 Macquarie University IOL - IELTS Academic Reading - Practice Test 1 - QuestionsIrfan AhmedAinda não há avaliações

- Safety Data Sheet Quorum Red Ii: Section 1. Product and Company IdentificationDocumento11 páginasSafety Data Sheet Quorum Red Ii: Section 1. Product and Company IdentificationMauricio Camarena100% (1)

- Case Study EsrdDocumento4 páginasCase Study EsrdSTEPHANIE JOSUEAinda não há avaliações

- Spars Pandemic Scenario (1) (01 38)Documento38 páginasSpars Pandemic Scenario (1) (01 38)YuliayAngel NavarroAinda não há avaliações

- Daily Lesson Log on Lifestyle and Weight ManagementDocumento8 páginasDaily Lesson Log on Lifestyle and Weight ManagementNoel Isaac Maximo100% (2)

- Blood Gas Analysis Ppt-3Documento32 páginasBlood Gas Analysis Ppt-3Kresna Dharma SuryanaAinda não há avaliações

- ColaDocumento4 páginasColaJeremy Lim Choon KeatAinda não há avaliações

- Test 2 SolutionDocumento6 páginasTest 2 SolutionJeremy Lim Choon KeatAinda não há avaliações

- Difference Between Isotropic and Orthotropic in Material Science Both the Term Isotropic in North Atrophic Are Related to Mechanical and Thermal Properties Along the Three Directions but There Exists a Distinct Difference bDocumento1 páginaDifference Between Isotropic and Orthotropic in Material Science Both the Term Isotropic in North Atrophic Are Related to Mechanical and Thermal Properties Along the Three Directions but There Exists a Distinct Difference bJeremy Lim Choon KeatAinda não há avaliações

- PP Hirarc ProjectDocumento4 páginasPP Hirarc ProjectJeremy Lim Choon KeatAinda não há avaliações

- Enthalpies of GasesDocumento17 páginasEnthalpies of GasesJeremy Lim Choon KeatAinda não há avaliações

- Estimating Total Project Time JeremyDocumento2 páginasEstimating Total Project Time JeremyJeremy Lim Choon KeatAinda não há avaliações

- Script Jeremy Estimating Project TimeDocumento1 páginaScript Jeremy Estimating Project TimeJeremy Lim Choon KeatAinda não há avaliações

- HIRARC GuideLine From DOSHDocumento34 páginasHIRARC GuideLine From DOSHMohd Hadri50% (2)

- Barred VibrationDocumento1 páginaBarred VibrationJeremy Lim Choon KeatAinda não há avaliações

- Presentation AprilDocumento2 páginasPresentation AprilJeremy Lim Choon KeatAinda não há avaliações

- Q4Documento1 páginaQ4Jeremy Lim Choon KeatAinda não há avaliações

- EDP - Jan 2016 - Project Briefing - 15 Jan 16Documento7 páginasEDP - Jan 2016 - Project Briefing - 15 Jan 16Jeremy Lim Choon KeatAinda não há avaliações

- Module02 Brainstorming WorksheetDocumento2 páginasModule02 Brainstorming WorksheetJeremy Lim Choon KeatAinda não há avaliações

- Technology in Product DevelopmentDocumento2 páginasTechnology in Product DevelopmentJeremy Lim Choon KeatAinda não há avaliações

- BoilerDocumento5 páginasBoilerJeremy Lim Choon KeatAinda não há avaliações

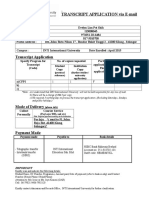

- Online Transcript Application FormDocumento2 páginasOnline Transcript Application FormJeremy Lim Choon KeatAinda não há avaliações

- Bmegi PlanDocumento1 páginaBmegi PlanJeremy Lim Choon KeatAinda não há avaliações

- Fluid Mechanics ExperimentDocumento13 páginasFluid Mechanics ExperimentJeremy Lim Choon KeatAinda não há avaliações

- 19th INTIMA Activity Proposal GK 1Documento5 páginas19th INTIMA Activity Proposal GK 1Jeremy Lim Choon KeatAinda não há avaliações

- MEE3223 - Assignment 2Documento2 páginasMEE3223 - Assignment 2Ihsan Samoh เพี่อนดีดีAinda não há avaliações

- Egr4202 Operations and Quality Management - Course StructureDocumento5 páginasEgr4202 Operations and Quality Management - Course StructureJeremy Lim Choon KeatAinda não há avaliações

- Book 40 Bikes for Event at RM5/hourDocumento1 páginaBook 40 Bikes for Event at RM5/hourJeremy Lim Choon KeatAinda não há avaliações

- Sponsor BrandDocumento1 páginaSponsor BrandJeremy Lim Choon KeatAinda não há avaliações

- KenamaticsDocumento1 páginaKenamaticsJeremy Lim Choon KeatAinda não há avaliações

- Exercise 5Documento2 páginasExercise 5Jeremy Lim Choon KeatAinda não há avaliações

- Solid Mechanics Chapter 2 ExercisesDocumento2 páginasSolid Mechanics Chapter 2 ExercisesJeremy Lim Choon KeatAinda não há avaliações

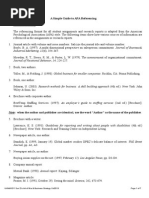

- A Simple Guide To APA Referencing - Oct13Documento7 páginasA Simple Guide To APA Referencing - Oct13Jeremy Lim Choon KeatAinda não há avaliações

- 2007 KeyDocumento1 página2007 KeyJeremy Lim Choon KeatAinda não há avaliações

- Speaking Sample Test 4 - MedicineDocumento1 páginaSpeaking Sample Test 4 - MedicineNaim KırbeciAinda não há avaliações

- Myasthenia Gravis NCPDocumento1 páginaMyasthenia Gravis NCPCzarina0% (1)

- Script TBDocumento10 páginasScript TBMelrhean GraceAinda não há avaliações

- Interventions For Treating Post-Extraction Bleeding (Review)Documento28 páginasInterventions For Treating Post-Extraction Bleeding (Review)Marcela GarciaAinda não há avaliações

- Collection, Transportation, Treatment & Disposal of Laboratory WasteDocumento51 páginasCollection, Transportation, Treatment & Disposal of Laboratory WasteYuresh TwayanaAinda não há avaliações

- Volunteer nurse seeks hands-on trainingDocumento5 páginasVolunteer nurse seeks hands-on trainingMary Sol Reyes BatayolaAinda não há avaliações

- Spooner Pachana (2006)Documento11 páginasSpooner Pachana (2006)CagolindaAinda não há avaliações

- AntibioticsDocumento21 páginasAntibioticsJerry ArockeAinda não há avaliações

- A Survey of Employee EngagementDocumento31 páginasA Survey of Employee EngagementToni Krispin0% (1)

- Pengaruh Kompres Dingin Terhadap Penurunan Nyeri Persalinan Kala I Pada Ibu Bersalin Di Wilayah Kerja Puskesmas Batu Aji Kota Batam TAHUN 2018Documento5 páginasPengaruh Kompres Dingin Terhadap Penurunan Nyeri Persalinan Kala I Pada Ibu Bersalin Di Wilayah Kerja Puskesmas Batu Aji Kota Batam TAHUN 2018Arisa CaAinda não há avaliações

- Download ebook Current Diagnosis Treatment Obstetrics Gynecology 12Th Edition Pdf full chapter pdfDocumento67 páginasDownload ebook Current Diagnosis Treatment Obstetrics Gynecology 12Th Edition Pdf full chapter pdfbeth.hao417100% (25)

- Drug Reflection PaperDocumento3 páginasDrug Reflection Paperapi-489846183Ainda não há avaliações

- Rituximab Tullus Kjeil 2021Documento9 páginasRituximab Tullus Kjeil 2021Carmen MunteanAinda não há avaliações

- Katz Et Al. - 2018 - Changes in Subcutaneous Abdominal Fat Thickness Following High-Intensity Focused Electro-MagneticDocumento2 páginasKatz Et Al. - 2018 - Changes in Subcutaneous Abdominal Fat Thickness Following High-Intensity Focused Electro-MagneticNicolas FarkasAinda não há avaliações

- Factsheet: Tacrolimus Ointment (Protopic®)Documento4 páginasFactsheet: Tacrolimus Ointment (Protopic®)Ivan LinAinda não há avaliações

- Classroom Nutritional Status ReportDocumento2 páginasClassroom Nutritional Status ReportEden PingliAinda não há avaliações

- Vitamin KDocumento456 páginasVitamin KSamy AbdelazizAinda não há avaliações

- JSA-070 Desert Road TripDocumento4 páginasJSA-070 Desert Road TripMoaatazz NouisriAinda não há avaliações

- Out-And-Included - July16Documento31 páginasOut-And-Included - July16Navin JollyAinda não há avaliações

- Antimaleria Drug ModelsDocumento33 páginasAntimaleria Drug ModelsMehari AsratAinda não há avaliações

- Frequently Asked Questions On The RH BillDocumento15 páginasFrequently Asked Questions On The RH BillMulat Pinoy-Kabataan News Network100% (2)

- Chiro Case Study Week 2Documento6 páginasChiro Case Study Week 2api-479754549Ainda não há avaliações

- Nature's Role in Reducing Mental FatigueDocumento9 páginasNature's Role in Reducing Mental FatigueCrăciun RalucaAinda não há avaliações

- Nutrition Support in Adults NICE Guideline PDFDocumento54 páginasNutrition Support in Adults NICE Guideline PDFnewtypeAinda não há avaliações