Escolar Documentos

Profissional Documentos

Cultura Documentos

JSA

Enviado por

mike cams0 notas0% acharam este documento útil (0 voto)

403 visualizações8 páginasTítulo original

JSA.ppt

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

403 visualizações8 páginasJSA

Enviado por

mike camsDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 8

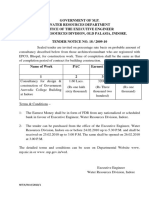

JOB SAFETY

ANALYSIS (JSA)

PROPER JOB ANALYSIS

AND PROCEDURES

JOB SAFETY ANALYSIS

DEFINED AS THE SYSTEMATIC

EXAMINATION OF A JOB TO IDENTIFY ALL

LOSS EXPOSURES PRESENT WHILE THE

JOB IS BEING DONE

LOSS EXPOSURES ARE DUE TO HAZARDS

PRESENT IN DOING THE JOB

THE AIM IS TO USE THESE INFORMATION

TO DEVELOP STANDARD JOB

PROCEDURES (SJPs) OR SOPs,

INCORPORATING THE NECESSARY

CONTROLS

OCCUPATION – POSITION TITLE COVERING ALL

WORK ACTIVITIES THAT AN EMPLOYEE

WHO HOLDS THAT TITLE PERFORMS

JOB - ALSO REFERRED TO AS TASKS; A

DEFINITE SEQUENCE OF STEPS OR

ACTIVITIES THAT AN EMPLOYEE

ENGAGES TO PERFORM WORK

ASSIGNMENT WITHIN AN OCCUPATION

PROPER JOB PROCEDURES – A TOOL FOR TEACHING

THE MOST SYTEMATIC WAY TO DO A CRITICAL JOB

CONSISTENTLY WITH MAXIMUM EFFICIENCY

PROPER JOB ANALYSIS – A SYSTEMATIC

INVESTIGATION OF THE BASIC ELEMENTS OF

WORKER’S JOB – QUALITY, PRODUCTION AND SAFETY

STEPS OF JOB SAFETY ANALYSIS

1. Identify all jobs by occupation / position

2. Determine critical jobs

2.1 Identify loss exposures / hazards

2.2 Evaluate criticality / significance by assessing the

risks for each hazard (use RA matrix)

2.3 Identify controls (general in nature)

3. Analyze critical jobs

3.1 Break down the job into orderly sequence of steps

or activities

3.2 Identify hazards for each step or activity

3.3 Conduct the efficiency check (PEME)

3.3 Identify and develop hazard controls required

4. Write the standard job procedure

EQUIPMENT

PEOPLE

PRODUCTION

COSTS

QUALITY

SAFETY

ENVIRONMENT MATERIAL

Efficiency Check Review

People: rules and regulations, PPE, number

of people doing the job, utilization

Equipment: proper tools, hand vs. power

tools, utilization, tools availability

Material: substitution, wastage, recycling, less

costly

Environment: housekeeping, improve

conditions, junk, unnecessary aspects

Some Guidelines

Operations: 15 – 30 jobs / task

5 – 10 critical jobs

Maintenance: 2 to 3X more

15 – 30 critical jobs

Use of JSAs:

Induction / Orientation

Instruction

Inspections

Observations

Safety Talks

Investigation

Skill training

Hazard assessment

Enhanced supervision

SUCCESS FACTORS

JSA shown to be vital to the prevention

and control of accidents

Time-consuming, thus need adequate

time and personnel commitment

Team approach is necessary

Training for those involved is required

Você também pode gostar

- Safe Work Procedure A Complete Guide - 2020 EditionNo EverandSafe Work Procedure A Complete Guide - 2020 EditionAinda não há avaliações

- Behavior-based safety A Clear and Concise ReferenceNo EverandBehavior-based safety A Clear and Concise ReferenceAinda não há avaliações

- Certified Health And Safety Consultant A Complete Guide - 2020 EditionNo EverandCertified Health And Safety Consultant A Complete Guide - 2020 EditionAinda não há avaliações

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakNo EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakNota: 5 de 5 estrelas5/5 (1)

- Health and Safety Officer: Passbooks Study GuideNo EverandHealth and Safety Officer: Passbooks Study GuideAinda não há avaliações

- (Alex) Accident Investigation PDFDocumento224 páginas(Alex) Accident Investigation PDFbongAinda não há avaliações

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNo EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsAinda não há avaliações

- GC 2 - Past Questions With Answers (4) - 1Documento308 páginasGC 2 - Past Questions With Answers (4) - 1mohamed ishaqAinda não há avaliações

- Basic Hse TrainingDocumento33 páginasBasic Hse Trainingnsankar71100% (3)

- hsg129 PDFDocumento138 páginashsg129 PDFmanimeczAinda não há avaliações

- EHS Handbook FINAL 2013-12-11Documento8 páginasEHS Handbook FINAL 2013-12-11Erica LindseyAinda não há avaliações

- OSHA Fire SafetyDocumento20 páginasOSHA Fire SafetyrpbpaAinda não há avaliações

- Contractor Safety Proceduresv1 1Documento27 páginasContractor Safety Proceduresv1 1Bambang Setyo Utomo100% (1)

- Unit 01 ETUET-1-0005-1-3: Understand Occupational Health and SafetyDocumento56 páginasUnit 01 ETUET-1-0005-1-3: Understand Occupational Health and Safetyshaista100% (1)

- Principles of Accident PreventionDocumento72 páginasPrinciples of Accident PreventionShaikh IbrahimAinda não há avaliações

- Toolbox Talk: Nik Hanisah Binti Nik Aziz HSE Executive 017-9149022/011-11315135Documento10 páginasToolbox Talk: Nik Hanisah Binti Nik Aziz HSE Executive 017-9149022/011-11315135Still SatAinda não há avaliações

- GC2 IGC Examiners' Report May - July 2014Documento10 páginasGC2 IGC Examiners' Report May - July 2014johnmason246100% (1)

- NEBOSH International Diploma: Unit IaDocumento19 páginasNEBOSH International Diploma: Unit IaRouf AhmadAinda não há avaliações

- Ohs Legal - Ohsa Act 1994Documento1 páginaOhs Legal - Ohsa Act 1994Nurul HidayahAinda não há avaliações

- Module 1 - Osh and Bosh FrameworkDocumento5 páginasModule 1 - Osh and Bosh FrameworkJohn Ray CuevasAinda não há avaliações

- COSH Catalogue 2019-2020Documento13 páginasCOSH Catalogue 2019-2020ShahzaibUsmanAinda não há avaliações

- Workplace Exposure To Vibration in Europe: An Expert ReviewDocumento12 páginasWorkplace Exposure To Vibration in Europe: An Expert Reviewrajesh kumarAinda não há avaliações

- ADH Municipality Health Safety Codes of Practice For Construction Projects Part 1 PDFDocumento116 páginasADH Municipality Health Safety Codes of Practice For Construction Projects Part 1 PDFjohnknight000100% (1)

- Construction Safety GuideDocumento38 páginasConstruction Safety GuideJustina RodriguezAinda não há avaliações

- HSW Book ExtractDocumento10 páginasHSW Book ExtractSammie WilliamsAinda não há avaliações

- Hazard Control GuideDocumento6 páginasHazard Control GuideImran KhanAinda não há avaliações

- What Is The Difference Between Jha and JsaDocumento2 páginasWhat Is The Difference Between Jha and JsaSalvacion JaroAinda não há avaliações

- Reasons For Managing Health and SafetyDocumento3 páginasReasons For Managing Health and SafetybrightAinda não há avaliações

- HSE PlanDocumento14 páginasHSE PlankbonairAinda não há avaliações

- Part 1 - Personal Details and Declaration IGC3 NEBOSHDocumento9 páginasPart 1 - Personal Details and Declaration IGC3 NEBOSHEngi SaifAinda não há avaliações

- Electrical SafetyDocumento191 páginasElectrical SafetyMartin UribeAinda não há avaliações

- Fall ProtectionDocumento71 páginasFall ProtectionFairuz AthallahAinda não há avaliações

- IGC2Documento49 páginasIGC2KashifPervez100% (4)

- HSE Manual Unlimited EnergyDocumento74 páginasHSE Manual Unlimited Energysangar sabirAinda não há avaliações

- Health and Safety at Work SlidesDocumento195 páginasHealth and Safety at Work SlidesZulfiqar Hyder100% (2)

- By: Mr. Eros G. ZuñigaDocumento60 páginasBy: Mr. Eros G. ZuñigarorieAinda não há avaliações

- IGC2 Element 7 Chemical BiologicalDocumento68 páginasIGC2 Element 7 Chemical BiologicalAlaa100% (1)

- NEBOSH NCC Exam Paper 9Documento3 páginasNEBOSH NCC Exam Paper 9Joel CummingsAinda não há avaliações

- Day 1 Checklist-GLS-OSH (Guideinaccom)Documento21 páginasDay 1 Checklist-GLS-OSH (Guideinaccom)mike camsAinda não há avaliações

- EPR PlanDocumento19 páginasEPR Planpaolo sangalangAinda não há avaliações

- Chapter 1 - Safety and Health Manager (Ferrer and Rellores)Documento3 páginasChapter 1 - Safety and Health Manager (Ferrer and Rellores)Evan Charl Moraleda100% (1)

- IGC2 QuestionsDocumento58 páginasIGC2 QuestionsSumesh Kodannur0% (1)

- Workers' Participation in ManagementDocumento37 páginasWorkers' Participation in ManagementPiyush ParmarAinda não há avaliações

- Safe Systems of Work 2Documento23 páginasSafe Systems of Work 2Vincent Uchenna Nwankwo50% (2)

- Role of Safety Professional in Construction IndustryDocumento30 páginasRole of Safety Professional in Construction IndustryKiranSivakumarAinda não há avaliações

- Confined Space Hazards AwarenessDocumento27 páginasConfined Space Hazards AwarenessNoor Fadilah Printis100% (1)

- Hearing Conservation Training: Environmental Health and Safety University of TennesseeDocumento54 páginasHearing Conservation Training: Environmental Health and Safety University of TennesseeMG NandanAinda não há avaliações

- Risk Assessment RatingDocumento6 páginasRisk Assessment Ratingmike camsAinda não há avaliações

- Top Safety Measures at Construction SitesDocumento3 páginasTop Safety Measures at Construction Sitesananthu.uAinda não há avaliações

- Hotworks and Welding SafetyDocumento21 páginasHotworks and Welding SafetyprokjongAinda não há avaliações

- Manual HandlingDocumento5 páginasManual HandlingImad A KhanAinda não há avaliações

- ILO COnvention 155Documento7 páginasILO COnvention 155Shashikala Kollipara100% (1)

- Day 2 Hazard Identification, Assesment & ControlDocumento39 páginasDay 2 Hazard Identification, Assesment & Controlmike cams86% (7)

- Day 3 Fire Exit DrillDocumento20 páginasDay 3 Fire Exit Drillmike camsAinda não há avaliações

- Day 1 Introduction To OSH NewDocumento88 páginasDay 1 Introduction To OSH Newmike cams85% (20)

- Day 3 Safety Inspections (Handout)Documento5 páginasDay 3 Safety Inspections (Handout)mike cams100% (1)

- Day 3 PPE (Handout)Documento10 páginasDay 3 PPE (Handout)mike camsAinda não há avaliações

- Day 4 Motivating For OSHDocumento67 páginasDay 4 Motivating For OSHmike cams100% (1)

- Day 1 Introduction To OSHDocumento69 páginasDay 1 Introduction To OSHmike camsAinda não há avaliações

- Day 3 Job Hazard Analysis (Handout)Documento6 páginasDay 3 Job Hazard Analysis (Handout)mike camsAinda não há avaliações

- Day 2 Occupational Health HazardsDocumento62 páginasDay 2 Occupational Health Hazardsmike cams100% (2)

- Day 5 Safety ProgramDocumento7 páginasDay 5 Safety Programmike cams100% (1)

- Day 3 Personal Protective Equipment (PPE)Documento18 páginasDay 3 Personal Protective Equipment (PPE)mike cams100% (1)

- Day 3 Risk Management in High Rise BuildingDocumento5 páginasDay 3 Risk Management in High Rise Buildingmike camsAinda não há avaliações

- Day 1 Checklist-GLS-OSH (Guideinaccom)Documento21 páginasDay 1 Checklist-GLS-OSH (Guideinaccom)mike camsAinda não há avaliações

- Day 2 Materials Handling, Storage & DisposalDocumento48 páginasDay 2 Materials Handling, Storage & Disposalmike camsAinda não há avaliações

- Day 2 Electrical HazardsDocumento47 páginasDay 2 Electrical Hazardsmike camsAinda não há avaliações

- Day 2 Machine SafetyDocumento26 páginasDay 2 Machine Safetymike cams100% (1)

- Day 1 Fundamentals of Safety ManagementDocumento20 páginasDay 1 Fundamentals of Safety Managementmike cams100% (2)

- Day 1 DO 57-04 EditedDocumento17 páginasDay 1 DO 57-04 Editedmike camsAinda não há avaliações

- Day 1 Health and Safety CommitteeDocumento23 páginasDay 1 Health and Safety Committeemike cams100% (1)

- Risk Assessment RatingDocumento6 páginasRisk Assessment Ratingmike camsAinda não há avaliações

- Day 1 Basic Occupational Safety & HealthDocumento5 páginasDay 1 Basic Occupational Safety & Healthmike camsAinda não há avaliações

- Career Testing Since 1997Documento11 páginasCareer Testing Since 1997mike camsAinda não há avaliações

- Auto WorksDocumento2 páginasAuto Worksmike camsAinda não há avaliações

- MKT624 - Final Term Quiz Master File SolvedDocumento69 páginasMKT624 - Final Term Quiz Master File SolvedAzeem AhmadAinda não há avaliações

- Ikea Presentation PDFDocumento21 páginasIkea Presentation PDFBharat Gourav DashAinda não há avaliações

- Fundamentals of Cooperatives PresentationDocumento110 páginasFundamentals of Cooperatives PresentationRiverside High SchoolAinda não há avaliações

- Venga Tu ReinoDocumento2 páginasVenga Tu ReinoOmar camacho HernandezAinda não há avaliações

- Up To Date CVDocumento4 páginasUp To Date CViqbal1439988Ainda não há avaliações

- Accounts Agreed ValuesDocumento35 páginasAccounts Agreed ValuesJay Raphael TrioAinda não há avaliações

- Kgfs ModelDocumento24 páginasKgfs ModelgautamojhaAinda não há avaliações

- IMECS 2016 Full PapersDocumento779 páginasIMECS 2016 Full PapersCristin PasatAinda não há avaliações

- IMNU HimasnhuPatel Anand Rathi Internship ReportDocumento57 páginasIMNU HimasnhuPatel Anand Rathi Internship ReportHimanshu Patel33% (3)

- The Supply Chain Management Concept 1aDocumento20 páginasThe Supply Chain Management Concept 1aMRK466100% (1)

- Jennifer Wong - MKT 393 Final Draft 1Documento20 páginasJennifer Wong - MKT 393 Final Draft 1api-705120250Ainda não há avaliações

- Safety Audit - Regional District of Okanagan-SimilkameenDocumento105 páginasSafety Audit - Regional District of Okanagan-SimilkameenJoe FriesAinda não há avaliações

- 4.2 Marketing PlanningDocumento30 páginas4.2 Marketing Planningnacho narroAinda não há avaliações

- HRM CHAPTER 10 Changes in Personnel StatusDocumento8 páginasHRM CHAPTER 10 Changes in Personnel StatusBen joe CajigalAinda não há avaliações

- Presidential Decree No 442Documento10 páginasPresidential Decree No 442Eduardo CatalanAinda não há avaliações

- Chapter 1 EnterprDocumento11 páginasChapter 1 EnterprSundas FareedAinda não há avaliações

- Asian Development Bank: Project Completion ReportDocumento34 páginasAsian Development Bank: Project Completion ReportsanthoshkumarkrAinda não há avaliações

- Justification Letter SampleDocumento2 páginasJustification Letter SampleDinapuanNgLangaw100% (1)

- PIMCO COF IV Marketing Deck - Israel - 03232023 - 5732Documento64 páginasPIMCO COF IV Marketing Deck - Israel - 03232023 - 5732moshe2mosheAinda não há avaliações

- 10-1 - Developing An Effective Business PlanDocumento21 páginas10-1 - Developing An Effective Business PlanZameer AbbasiAinda não há avaliações

- Customer Service ExampleDocumento27 páginasCustomer Service ExampleSha EemAinda não há avaliações

- Strategic Business Managegent Case Study of FIRST DIRECT BANK by SADIQ YUSUF YABODocumento12 páginasStrategic Business Managegent Case Study of FIRST DIRECT BANK by SADIQ YUSUF YABOsadiq yusuf100% (6)

- Resume Frank Rothaermel - Strategic Management Chapter 4Documento4 páginasResume Frank Rothaermel - Strategic Management Chapter 4Dani YustiardiAinda não há avaliações

- SAP ComponentsDocumento7 páginasSAP ComponentsFahad QuadriAinda não há avaliações

- Hola-Kola ComputationsDocumento7 páginasHola-Kola ComputationsKristine Nitzkie SalazarAinda não há avaliações

- Analysis of Logistic Department Through Supply Chain ManagementDocumento6 páginasAnalysis of Logistic Department Through Supply Chain ManagementGRD JournalsAinda não há avaliações

- TCS India Process - Separation KitDocumento25 páginasTCS India Process - Separation KitT HawkAinda não há avaliações

- Ayurvedic Medical College - IndoreDocumento2 páginasAyurvedic Medical College - IndoresalemmanojAinda não há avaliações

- Assignment 2023 For BPOI - 105 (005) (DBPOFA Prog)Documento1 páginaAssignment 2023 For BPOI - 105 (005) (DBPOFA Prog)Pawar ComputerAinda não há avaliações

- Blockholder Trading, Market E Ciency, and Managerial MyopiaDocumento35 páginasBlockholder Trading, Market E Ciency, and Managerial MyopiamkatsotisAinda não há avaliações