Escolar Documentos

Profissional Documentos

Cultura Documentos

Non Traditional Machining Processes by Arshad Habib Khan

Enviado por

Arshad Habib KhanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Non Traditional Machining Processes by Arshad Habib Khan

Enviado por

Arshad Habib KhanDireitos autorais:

Formatos disponíveis

NON TRADITIONAL MACHINING PROCESSES

Presented By-

Arshad Habib Khan Mechanical Engineering M H Saboo Siddik College

Introduction

Rapid growth in the development of harder materials. These materials find application in aerospace, nuclear industries, etc. Machining harder materials by traditional method is difficult. Non traditional concept was emerged in 1960 This method uses some form of energy for metal machining.

TRADITIONAL V/S NON TRADITIONAL

Traditional Old method Tool & work are in contact Machinability depends on hardness Simple shapes Excessive too wear Large cutting force High material removal Less expensive Non Tradional New method No contact Hardness of the workpiece is immaterial Complex shapes Less tool wear No cutting force Low material removal expensive

CLASSIFICATION

MATERIAL APPLICATION

PROCESS SELECTION

Capital cost Tooling cost Consumed power cost Metal removal rate (efficiency) Wear of tooling

ULTRA SONIC MACHINING (USM)

The term ULTRASONIC is used to describe a vibratory wave of a frequency(above 16 Hz) Ultrasonic Transducer is used. Electrical energy is converted into mechanical vibrations Piezo-electric effect is utilized Tool is vibrating at 20-30 kHz

Construction & working

Pros & Cons

Pros Metal removal cost is low Stress free Good surface finish upto 0.02 to 0.8 microns Good accuracy upto +/0.07mm Extremely hard materials can be machined Cons Initial cost is high Power consumption is high Soft materials are difficult to machine Not suitable for heavy metal removal

ABRASIVE JET MACHINING (AJM)

It is a finishing process Focus high speed stream of abrasive particles Used for machining delicate or very hard materials Produces no heat damage to work piece surface Produces a taper in deep cut.

Construction & working

Consists of a power supply & mixer, ehaust hood a and gas or water supply. The nozzle can be held or mounted in a fixture for automatic operation.

Applications of AJM

Paint removal Cleaning Cutting soft materials Pocket milling Drilling Turning Textile, leather industry

WATER JET MACHINING (WJM)

Uses a high velocity jet of water. Mixture of water and abrasives. It finds the appliocation in industries from mining to aerospace.

ELECTRO CHEMICAL MACHINING

Electro chemical process Used for mass production For extremely hard materials

ELECTRO-DISCHARGE MACHINING(EDM)

Thermo Electric Type Spark erosion Material removal due to thermal energy of the spark Electrically conductive materials

Construction &working of EDM

Spark machining or Spark erosion Material is removed by rapidly recurring current discharges between two electrodes Separated by a die electric fluid

TYPES OF EDM

Sinker EDM

Wire EDM

LASER BEAM MACHINING(LBM)

LIGHT AMPLIFICATION STIMULATED EMISSION OF RADIATION. It is a cutting technology uses laser to cut material

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 7 Plumbing Max FajardopdfDocumento175 páginas7 Plumbing Max FajardopdfEmere James P. TagoonAinda não há avaliações

- Powder 1Documento84 páginasPowder 1Nyanda MadiliAinda não há avaliações

- Submitted By:-Jatin GargDocumento26 páginasSubmitted By:-Jatin GargNANDHINI NAinda não há avaliações

- Beneficiation of AvocadoDocumento10 páginasBeneficiation of AvocadoJUANAinda não há avaliações

- D 6797 - 02 Rdy3otcDocumento3 páginasD 6797 - 02 Rdy3otcJuan GutierrezAinda não há avaliações

- NCH Tech Sheet Deox ThailandDocumento1 páginaNCH Tech Sheet Deox Thailandson.brbAinda não há avaliações

- Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForDocumento16 páginasSteel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForAlejandro Valdés RojasAinda não há avaliações

- Chapter 1 Technology and DevelopmentDocumento46 páginasChapter 1 Technology and DevelopmentKeep ThrowAinda não há avaliações

- Design and Fabrication of Portable Rotating Machinery Fault SimulatorDocumento48 páginasDesign and Fabrication of Portable Rotating Machinery Fault SimulatorAdib Fikri0% (1)

- Chapter 4 Forming and ShapingDocumento147 páginasChapter 4 Forming and Shapingquan quanAinda não há avaliações

- Frictional Losses in Circular PipeDocumento5 páginasFrictional Losses in Circular PipeVrushiket PatilAinda não há avaliações

- DRM Wha B PDFDocumento31 páginasDRM Wha B PDFBryan JohnsonAinda não há avaliações

- SCN0046 P410 MSZDocumento2 páginasSCN0046 P410 MSZCristian ChiruAinda não há avaliações

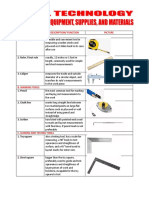

- Tool/ Equipment Description/ Function Picture A. Measuring ToolsDocumento13 páginasTool/ Equipment Description/ Function Picture A. Measuring ToolsNicolas AntiguaAinda não há avaliações

- NORSOK N 004 d3 E3Documento276 páginasNORSOK N 004 d3 E3Nils Antoine Freund100% (1)

- Ped Asme ComparisionDocumento31 páginasPed Asme ComparisionJose A ManciniAinda não há avaliações

- CountryProfile ProductMetadataforSectorDocumento232 páginasCountryProfile ProductMetadataforSectorMeenakshi JaikrishnanAinda não há avaliações

- MBA E4b - 360-Prateek Thakur - GCSA (02-04-20)Documento3 páginasMBA E4b - 360-Prateek Thakur - GCSA (02-04-20)Prateek SinghAinda não há avaliações

- Limites AceitesDocumento3 páginasLimites AceitesAdrian OcampoAinda não há avaliações

- Gear Reference PDFDocumento15 páginasGear Reference PDFXuan Phuong HuynhAinda não há avaliações

- High Voltage Transformer: InstructablesDocumento6 páginasHigh Voltage Transformer: InstructablespinoAinda não há avaliações

- Unit V Mass Transfer PDFDocumento11 páginasUnit V Mass Transfer PDFArivazhagan SundaraganesanAinda não há avaliações

- Rf00025-Quantitative Fractography and Modelling of FatiguDocumento14 páginasRf00025-Quantitative Fractography and Modelling of Fatiguzixin chenAinda não há avaliações

- E FT 6Documento1 páginaE FT 6Phil YianAinda não há avaliações

- Salmson Pompen NeoSys LRL-JRL PDFDocumento20 páginasSalmson Pompen NeoSys LRL-JRL PDFAbdulSattarAinda não há avaliações

- MITSUBOSHI - Timing BeltDocumento142 páginasMITSUBOSHI - Timing BeltAnonymous jW9BkgbQmE67% (3)

- ComponentsDocumento39 páginasComponentskarthikv83Ainda não há avaliações

- Manual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Documento2 páginasManual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Harry RamzaAinda não há avaliações

- Document 1Documento6 páginasDocument 1LaurenceFabialaAinda não há avaliações

- Damp Proof - PIS PDFDocumento2 páginasDamp Proof - PIS PDFArun KumarAinda não há avaliações