Escolar Documentos

Profissional Documentos

Cultura Documentos

Artigo Alumina

Enviado por

Marília Rosato0 notas0% acharam este documento útil (0 voto)

11 visualizações8 páginasAlumina e mulita

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAlumina e mulita

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

11 visualizações8 páginasArtigo Alumina

Enviado por

Marília RosatoAlumina e mulita

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 8

5

Structural oxides I:

Al,O3 and mullite

5.1 INTRODUCTION TO ALUMINA,

Some useful properties of alumina are its high melting temperature,

‘chemical resistance, electrical resistance and hardness (Gitzen, 1970),

Alumina is to the ceramic industry what steel is to the metallurgical

industry and is the most widely used ceramic. Alumina powder is

produced cheaply in massive quantities. A diverse range of types of

alumina ceramic exist with a concomitant range of properties. The

major markets for alumina-based materials on a weight basis are

refractories (50%), abrasives (20%), whitewares and spark plugs (15%),

and engineering ceramics (10%). Aluminas are used in a variety of

applications ranging from the calcined bauxite anti-skid road dressin

Jumps in some refractory and building applications to m-sized ci

aluminate cements used in monolithic refractories down to the sub-

micron aluminas produced, for example by sol-gel routes. Figure 5.1

shows the diversity of products formed from aluminas. Included in the

igure are

5.2 ALUMINA POWDER PRODUCTION

5.2.1 Mineral sources

‘Alumina occurs abundantly

‘which are the essential cons

Bauxite is an impure mixture o

ture, most often as impure hydroxides

‘of bauxite ores (Gitzen, 1970)

ibbsite AI(OH), = «-Al,05,3H,0,

256 LAL

100% a-AlzO5 whereas

crystallite size, may also

lly y. This may cause dit

The Bayer process produces highh-aggregated powders which mi

be milled 1 release theultimate particles and so enable high ps

ensies and reduced porosity in the gren formed sate Te evel

of powder morphology can be controlled. during, pred

Calation so that the fetes can be wsed to facta breakup.

introduce substantial amounts of contamination from the milling media.

‘areful control of the Bayer process and caleination/milling conditions

iminas of up to 99.99% purity

indicates typical chemical analyses of the main forms

tain about

SSwt% Na,O which degrades many proper

‘causing deterioration

ja alumina, Table 5.2 indica

1 of calcined Bayer alumina powders (Maczura et

., 1992).

‘Low soda alumina is produced by using:

low soda gibbsite prepared by adjusting the Bayer process precipi

ion condi

Spark plugs

2. washing alumi

followed by fui

3. adding chiorine,

may give low green density and poor sintering. Reactive powders

require low soda but high surface area. Table 5.3 (Southern, 1991)

illustrates the effect of these variables on sintered density for several

alumina powders, powder 3 being the most reactive, Reactive alumina

powders are used in those applications requiring the best high-

temperature mechanical behaviour such as in ZTA (section 9.3.2) and

SiC-reinforced alumina CMCs (section 9.3.3).

5.2.3 Fused and tabular refractory grades

to large

shaped crystals occurs. The recrystallized alumina is in the massive

state and tabular alumina crystals are hard and dense with good

thermal conductivity and high crushing strength. A wide range of

(0 >2004m), hexagonal, elongated tablet-

Alumina Powder Production 263,

‘Table 5.4 Properties of tabular and fused akamina

Tabular Fused

White Brown

>9 29 955

o.1-0.02 o.01-0.05 12

0-03 003-015 01s.

0.02-0.36 002-05 °

TiO, o.ot-0.02 26

MgO 045

Bulk density 3.56 3.86 32

3 3 1

2050 2000

6 6

85 8S

particle sizes (25jzm to 6mm) are made by crushing and grading the

tabular alumina. Table 5.4 lists useful properties of tabular and fused

alumina, Tabular aluminas are used extensively in alumina~graphite

refractories (Chapter 8), and in low-cement and ultra low cement

castable mixes

ist produced in 1909 as an abrasive. In the

ich is mixed, charged and melted in an electric arc

furnace using graphite electrodes with a removable, water-cooled, stee!

shell, The fused refractory grain is massive and requires crushing and

milling to obtain the desired siz alumina is produced in two

forms: white and brown (Table 5.4). White fused alumina (WFA) is

‘made from calcined Bayer alumina and different grades are avai

based on differences in alkali contents. The grain

and, as an abrasive, superior

removal of impurities as ferrosilicon. The impurities

‘melting temperature by about

than WEA and has superior wear resistank

00 eructuras Urades I: AlO3 and

5.3 ALUMINA POLYMORPHS AND CRYSTAL STRUCTURES

5.3.1 Transition aluminas

Many proceses such a the oxidation of aluminium metal andthe for

mation of alumina by heating gost or vapour deposited aera

ous akumina thin fs involve the formation of ntermedate metocheg

alumina phases, These tansiion. phases are denoted ae ye

tt, 5, @ and x and ate of parcalar importance ‘teva

their use as catalysts or catalyst supports. The sequence of annie!

aluminas that form is strongly dependent onthe sang maternl aon

as formed. For example i the starting materia fs bookie

) formed from solution or amorphous lumina then the me

probable sequence sy -» 8» 8a. However, the stare na

I ghbsite, wAIOHy then the soquence may incde te et

= 0 — even though Boehmite fo formed prior f0 7, Digpor

another polymorph of AIO(OH) transforms dell 1 ALOe Re

tion of the transiton aluminas from hydrted compounds soc

ied by development of a highly porous powder micrstnseer

{Wilson 1979)

‘The transition aluminas have pasty disordered crystal structures ll

based on a close-packed oxygen subatice with Varying testa

aluminium configurations. As equim i approached the stacey

become more ordered forming. hexagonal cxygen sublatice ont

Sable walumina i formed. Table 5.5 Ists coptllogaphi inter

mation forthe tansition aluminas bu since few ofthese inernedice

aluminas have been subjected to sngle-aystal XRD examination the

fable incomplete

The rst structures ofthe transition alumina are characterized by

the maintenance of an approximately fc anion sublatice

197) While isted a8 cuble in Table 53 ‘alumina hes

tecagonally-distorted defect spinel stuctre (about O95, hed

ton varying with heat uestmend Balumina has tttagonal seper

structure with one unit cell parameter tripled with the ation vaca

thought te ordered on the vtahedal ste o

monocinc with space group Adi but’

and often twinned, Eta cube apne!

5.3.2 @-Alumina

Unlike the transition aluminas the crystal structure of «alumina

(termed corundum in mineral form and sapphire as the single crystal)

is well known. (Sapphire is a misnomer since sapphire is «Al

containing Ti** conferring, the characteristic blue colour. Ruby is a \

Table 5.5 Crystallographic data for transition aluminas

Delta (8) ‘Theta (@) Kappa te) deta) Epson Ce)

Chi)

Eta)

Gamma)

Hexagonal

Péame

55

9.028

5.62

2.906

179

Monoclinic Orthorhombic

Adm

103.74

Tetragonal

7.983

8

i

i

ae Bie

: pos

HuLik

26-31

16-394 37-1462 4978s

4875344900

10-425

JCPDS* card no,

powder XRD peak positions and intensities for most known mated

suchas space groups, densily and reactive indices.

ion Standards, Ist the

*JCPDS, the Joint Committe on Powder Dirac

‘The cards also list much other useful information|

and Mullite

for ALO,

Crystal Space group Lattice pr ycpps

ster @ bc aard No,

Rhomb. RB «4.7559 — 12991 10-173

ontaining CP* impurity responsible forthe red colour.) Crystal

the hexagonal structural

1¢ close-packed directions lie alo

collated useful crystallographic an¢

Microstructures and Prop

ior)

led circles are Al, open circles are

ices (after Kronberg, 1957)

54 ALUMINA CERAMIC FABRICATION ROUTES,

MICROSTRUCTURES AND PROPERTIES

High density, high-alumina ceramics can be categorized as (a) those

densified wit the aid of aliquid by viscous flow

there is essentially no liquid phase and sintering

In the following sections we will cover ge

id the resulting properties. Solid

ly pure (>99,7 wt % AlO3) requiring

careful processing. They are used in

requiring good mechanical properties

very pure starting powders

the most demanding applic

Você também pode gostar

- Processamento de Termoplasticos PDFDocumento429 páginasProcessamento de Termoplasticos PDFRicardo Coletto100% (4)

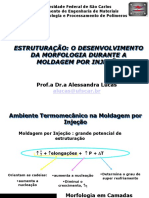

- A Cristalização e a Morfologia na Moldagem por InjeçãoDocumento51 páginasA Cristalização e a Morfologia na Moldagem por InjeçãoMarília RosatoAinda não há avaliações

- Introdução à FundiçãoDocumento96 páginasIntrodução à FundiçãoMarília RosatoAinda não há avaliações

- Metalurgia ExtrativaDocumento10 páginasMetalurgia ExtrativaMarília RosatoAinda não há avaliações

- Resolução de Exercícios - .Guidorizzi Volume 3Documento82 páginasResolução de Exercícios - .Guidorizzi Volume 3Renan Ottersbach65% (17)

- Termoquímica - Até Entalpia de CombustãoDocumento1 páginaTermoquímica - Até Entalpia de CombustãoMarília RosatoAinda não há avaliações

- Relatório: ESTUDO DO MOMENTO DE INÉRCIA DE SISTEMAS DISCRETOS PELO MÉTODO CIENTÍFICODocumento10 páginasRelatório: ESTUDO DO MOMENTO DE INÉRCIA DE SISTEMAS DISCRETOS PELO MÉTODO CIENTÍFICOMarília RosatoAinda não há avaliações

- Macetes e Propriedades Da Tabela PerDocumento1 páginaMacetes e Propriedades Da Tabela PerMarília RosatoAinda não há avaliações