Escolar Documentos

Profissional Documentos

Cultura Documentos

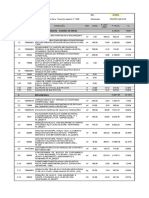

Tabela Ferro Chato Cant e Vigas

Enviado por

num fistismTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tabela Ferro Chato Cant e Vigas

Enviado por

num fistismDireitos autorais:

Formatos disponíveis

PRINCIPAIS

FORNECEDORES TABELA DE PRODUTOS

Major suppliers Product Line

Rua José Maria de Lacerda,1251-A

Cid. Industrial :: Contagem - MG :: CEP 32210-120

Tel. 31.3362.7900 :: Fax. 31. 3362.7910

www.codifer.com.br

PRODUTOS

Products

Para atender a demanda do mer- Aços em barras; Chapas grossas;

cado preenchendo os requisitos de Cantoneiras abas iguais; Chapa expandida para

acordo com a necessidade de seus Perfis H; piso;

Perfis I; Ferro chato;

clientes, a CODIFER possui uma

Tubos; Vigas “I”;

completa linha de aços para indús- Chapas finas a quente; Vigas “U”.

tria, calderaria, construção mecânica,

civil e serralheria em geral.

CODIFER offers a comprehensive Steel bars; Heavy plates;

range of steels for industrial applica- Equal angle bars; Expanded flooring

tions, boilers, mechanical construction, H-sections; plate;

I-sections; Flat bars;

civil construction and metalworking

Tubes; I-beams;

in general in order to meet its custom- Hot-rolled sheets; U-beams.

ers’ needs and quality requirements.

SERVIÇOS

Services

Com mão de obra qualificada e um alto padrão tecnológico, a CODIFER possui servi-

ços de corte e dobra sob medida, permitindo uma significativa economia. A Empresa

atua com capacidade para atender aos mais variados desenhos de peças e produtos

de seus clientes.

By employing skilled personnel and adopting excellent technological standards, CODIFER

provides customized cutting and bending services, resulting in significant savings for its

customers. It is capable of providing diversified part and product designs.

OXICORTE OXY-CUTTING

Oxicorte sob medida: Customized oxy-cutting:

- Discos; - Discs;

- Anéis; - Rings;

- Retângulos; - Rectangles;

- Cortes Especiais; - Special cuts;

- Corte de Desenhos Especiais. - Special design cuts.

PLASMA CUTTING

PLASMA Steel cutting using CNC machines for thicknesses

Corte de chapas em equipamento CNC até 2”:

up to 2”:

- Discos;

- Discs;

- Anéis;

- Rings;

- Retângulos;

- Rectangles;

- Cortes Especiais;

- Special cuts;

- Corte de Desenhos Especiais. - Special design cuts.

CORTE A FRIO COLD SHEARING

- Corte de chapas à frio até 3/8; - Cold shearing of steel plates up to 3/8”;

- Dobra de chapa até 3/8. - Plate bending up to 3/8”.

Consulte-nos sobre corte de chapas em outros We are in position of processing other steel plate grades

tipos de aço. as well.

AÇOS EM BARRAS TABELA DE BITOLAS - PERFIS I TABELA DE BITOLAS - PERFIS “H”

Steel bars Gage Table - I-Sections Gage Table - H-Sections

TABELA DE PRODUTOS Ø POL

Ø INC

Ø MM

Ø MM

Ø POL

Ø INC

Ø MM

Ø MM BITOLA MASSA LINEAR

ESPESSURA

ÁREA MASSA ESPESSURA

D BF THICKNESS H D´ BITOLA D BF H D´ ÁREA

Tabela de produtos 1/4 6.350 0.25 0.32 0.27 2 1/2 63.500 24.84 31.62 27.38

SIZE LINEAR MASS TW TF AREA LINEAR TW TF

W 150 x 13,0 13,0 148 100 4,3 4,9 138 118 16,6 Mm x kg/m Kg/m mm mm mm mm mm mm cm

5/16 7.938 0.39 0.49 0.43 2 9/16 65.088 26.10 33.22 28.78 W 150 x 18,0 18,0 153 102 5,8 7,1 139 119 23,4 W 150 x 22,5 22,5 152 152 119 139 5,8 6,6 29,0

3/8 9.525 0.56 0.71 0.62 2 5/8 66.675 27.38 34.87 30.19 W 150 x 22,5 (H) 22,5 152 152 5,8 6,6 139 119 29,0 W 150 x 29,8 29,8 157 153 118 138 6,6 9,3 38,5

W 150 x 24,0 24,0 160 102 6,6 10,3 139 115 31,5 W 150 x 37,1 37,1 162 154 119 139 8,1 11,6 47,8

VIGAS “I” 7/16 11.113 0.76 0.97 0.84 2 11/16 68.263 28.70 36.55 31.67

W 150 x 29,8 (H) 29,8 157 153 6,6 9,3 138 118 38,5 W 200 x 35,9 35,9 201 165 161 181 6,2 10,2 45,7

I-beams 1/2 12.700 0.99 1.27 1.10 2 3/4 69.850 30.05 38.27 33.14 W 150 x 37,1 (H) 37,1 162 154 8,1 11,6 139 119 47,8 W 200 x 46,1 46,1 203 203 161 181 7,2 11,0 58,6

9/16 14.288 1.26 1.60 1.39 2 13/16 71.438 31.44 40.02 34.22 W 200 x 15,0 15,0 200 100 4,3 5,2 190 170 19,4 W 200 x 53,0 53,0 204 207 161 181 11,3 11,3 68,1

W 200 x 19,3 19,3 203 102 5,8 6,5 190 170 25,1 W 200 x 71,0 71,0 216 206 161 181 10,2 17,4 91,0

PERFIL ESPESSURA DA ALMA PESO 5/8 15.875 1.55 1.98 1.71 2 7/8 73.025 32.85 41.82 36.22 W 200 x 22,5 22,5 206 102 6,2 8,0 190 170 29,0 W 250 x 62,0 62,0 246 256 201 225 10,5 10,7 79,6

SHAPE WEB THICKNESS WEIGHT 11/16 17.463 1.88 2.39 2.07 2 15/16 74.613 34.29 43.66 37.81 W 200 x 26,6 26,6 207 133 5,8 8,4 190 170 34,2 W 250 x 73,0 73,0 253 254 201 225 8,6 14,2 92,7

Pol. | Inch Pol. | Inch mm | mm Kg/m | Kg/m 3/4 19.050 2.24 2.85 2.46 3 76.200 35.77 45.54 39.43 W 200 x 31,3 31,3 210 134 6,4 10,2 190 170 40,3 W 250 x 80,0 80,0 256 255 201 225 9,4 15,6 101,9

W 200 x 35,9 (H) 35,9 201 165 6,2 10,2 181 161 45,7 HP 250 x 85,0 85,0 254 260 201 225 14,4 14,4 108,5

0.170 4.32 8.45 13/16 20.638 2.26 3.34 2.89 3 1/8 79.375 38.81 49.41 42.79 W 200 x 41,7 (H) 41,7 205 166 7,2 11,8 181 157 53,5

3 X 2 3/8 W 250 x 89,0 89,0 260 256 201 225 10,7 17,3 113,9

0.251 6.38 9.68 7/8 22.225 3.04 3.87 3.35 3 1/4 82.550 41.88 53.44 46.34 W 200 x 46,1 (H) 46,1 203 203 7,2 11,0 181 161 58,6 HP 310 x 79,0 79,0 299 306 245 277 11,0 11,0 100,0

W 200 x 52,0 (H) 52,0 206 204 7,9 12,6 181 157 66,9 HP 310 x 93,0 93,0 303 306 245 277 13,1 13,1 119,2

0.190 4.83 11.40 15/16 23.813 3.49 4.45 3.85 3 3/8 85.725 45.27 57.63 49.98

4 X 2 5/8 HP 200 x 53,0 (H) 53,0 204 207 11,3 11,3 181 161 68,1 W 310 x 97,0 97,0 308 305 245 277 9,9 15,4 123,6

0.253 6.43 12.70 1 25.400 3.97 5.06 4.38 3 1/2 88.900 48.68 61.98 53.74 W 200 x 59,0(H) 59,0 210 205 9,1 14,2 182 158 76,0 W 310 x 107,0 107,0 311 306 245 277 10,9 17,0 136,4

0.210 5.53 14.80 1 1/16 26.988 4.49 5.71 4.95 3 5/8 92.075 52.22 66.49 57.66 W 200 x 71,0 (H) 71,0 216 206 10,2 17,4 181 161 91,0 HP 310 x 110,0 110,0 308 310 245 277 15,4 15,5 141,0

5X3 W 200 x 86,0 (H) 86,0 222 209 13,0 20,6 181 157 110,9

0.347 8.81 18.20 1 1/8 28.575 5.03 6.40 5.55 3 3/4 95.250 55.88 71.15 61.69 W 310 x 117,0 117,0 314 307 245 277 11,9 18,7 149,9

W 250 x 17,9 17,9 251 101 4,8 5,3 240 220 23,1 HP 310 x 125,0 125,0 312 312 245 277 17,4 17,4 159,0

0.230 5.84 18.50 1 3/16 30.163 5.60 7.14 6.18 3 7/8 98.425 60.67 75.98 65.88 W 250 x 22,3 22,3 254 102 5,8 6,9 240 220 28,9

6 X 3 3/8 W 360 x 110 110,0 360 256 288 320 11,4 19,9 140,6

0.343 8.71 22.00 1 1/4 31.750 6.21 7.91 6.85 4 101.600 63.58 80.96 W 250 x 25,3 25,3 257 102 6,1 8,4 240 220 32,6

W360 x 122 122,0 363 257 288 320 13,0 21,7 155,3

W 250 x 28,4 28,4 260 102 6,4 10,0 240 220 36,6

1 5/16 33.338 6.85 8.72 7.55 4 1/4 107.950 71.78 91.39 W 250 x 32,7 32,7 258 146 6,1 9,1 240 220 42,1

1 3/8 34.925 7.51 9.57 8.29 4 3/8 111.125 76.06 96.85 W 250 x 38,5 38,5 262 147 6,6 11,2 240 220 49,6

W 250 x 44,8 44,8 266 148 7,6 13,0 240 220 57,6

VIGAS “U” 1 7/16 36.513 8.21 10.46 9.06 4 1/2 114.300 80.47 102.46

W 250 x 62,0 (H) 62,0 246 256 10,5 10,7 225 201 79,6

U-beams 1 1/2 38.100 8.94 11.39 9.86 4 3/4 120.650 89.66 114.16 W 250 x 73,0 (H) 73,0 253 254 8,6 14,2 225 201 92,7

1 9/16 39.688 9.70 12.35 10.70 5 127.000 99.80 126.50 W 250 x 80,0 (H) 80,0 256 255 9,4 15,6 225 201 101,9

W 250 x 85,0 (H) 85,0 254 260 14,4 14,4 225 201 108,5

CARACTERÍSTICAS TÉCNICAS PERFIS “I” E “H”

PERFIL ESPESSURA DA ALMA PESO 1 5/8 41.275 10.49 13.36 11.57 5 1/4 133.350 109.50 139.50

W 250 x 89,0 (H) 89,0 260 256 10,7 17,3 225 201 113,9

SHAPE WEB THICKNESS WEIGHT 1 11/16 42.863 11.32 14.41 12.48 5 1/2 139.700 120.20 153.10 W 205 x 101,0 (H) 101,0 264 257 11,9 19,6 225 201 128,7 Perfis Açominas produzidos no sistema universal de laminação a quente, utilizando

Pol. | Inch Pol. | Inch mm | mm Kg/m | Kg/m 1 3/4 44.450 12.17 15.50 13.42 5 3/4 146.050 131.40 167.20 W 250 x 115,0 (H) 115,0 269 259 13,5 22,1 225 201 146,1

W 310 x 21,0 21,0 303 101 5,1 5,7 292 272 27,2

quatro cilindros no mesmo plano;

0.170 4.32 6.11 1 13/16 46.038 13.06 16.62 14.40 6 152.400 143.10 182.50

3 X 1 1/2 W 310 x 23,8 23,8 305 101 5,6 6,7 292 272 30,7

0.258 6.55 7.44 1 7/8 47.625 13.97 17.79 15.41 6 1/4 158.750 155.20 197.80 W 310 x 28,3 28,3 309 102 6,0 8,9 291 271 36,5 Padrões e especificações de acordo com a Norma ASTM, com ampla variedade de

0.180 4.57 7.95 1 15/16 49.213 14.92 18.99 16.45 6 1/2 158.750 167.90 213.50 W 310 x 32,7 32,7 313 102 6,6 10,8 291 271 42,1 bitolas, de 6 a 24 polegadas (de 150 mm a 600 mm);

4 X 1 5/8 W 310 x 38,7

0.247 6.27 9.30 38,7 310 165 5,8 9,7 291 271 49,7

2 50.800 15.90 20.24 17.53 6 3/4 171.450 181.10 231.00 W 310 x 44,5 44,5 313 166 6,6 11,2 291 271 57,2

0.200 5.08 12.20 Produzidos em diferentes especificações - ASTM A 36, A 572 GRAU 50, A 588 e

6X2 2 1/16 52.388 16.91 21.51 18.64 7 177.800 194.70 248.10 W 310 x 52,0 52,0 317 167 7,6 13,2 291 271 67,0

0.314 7.98 15.60 HP 310 x 79,0 (H) 79,0 299 306 11,0 11,0 277 245 100,0 outros;

2 1/8 53.975 17.95 22.85 19.79 7 1/2 190.500 223.80 285.00

0.220 5.59 17.10 HP 310 x 93,0 (H) 93,0 303 308 13,1 13,1 277 245 119,2

8 X 2 1/4 2 3/16 55.563 19.02 24.21 20.97 8 203.200 254.60 324.00 W 310 x 97,0 (H) 97,0 308 305 9,9 15,4 277 245 123,6 Abas paralelas e retilíneas;

0.303 7.70 20.50 2 1/4 57.150 20.12 25.62 22.19 8/1/2 215.900 287.40 365.90 W 310 x 107,0 (H) 107,0 311 306 10,9 17,0 277 245 136,4

0.240 6.10 22.70 2 5/16 58.338 21.25 27.06 23.44 9 228.600 322.10 410.20 HP 310x110,0 (H) 110,0 308 310 15,4 15,5 277 245 141,0 Menor massa linear (kg/m);

10 X 2 5/8 W 310 x 117,0 (H) 117,0 314 307 11,9 18,7 277 245 149,9

0.379 9.63 29.80 2 3/8 60.325 22.42 28.54 24.72 9 1/2 241.300 359.00 457.10 HP 310 x 125,0 (H) 125,0 312 312 17,4 17,4 277 245 159,0 Vigas inteiriças, sem tensões localizadas.

0.280 7.11 30.70 2 7/16 61.913 23.61 30.06 26.03 10 254.000 397.00 506.50 W 360 x 32,9 32,9 349 127 5,8 8,5 332 308 42,1

12 X 3

0.387 9.83 37.20 W 360 x 39,0 39,0 353 128 6,5 10,7 332 308 50,2

W 360 x 44,0 44,0 352 171 6,9 9,8 332 308 57,7

W 360 x 51,0 51,0 355 171 7,2 11,6 332 308 64,8

CHAPAS GROSSAS W 360 x 57,8 57,8 358 172 7,9 13,1 332 308 72,5

Heavy plates W 360 x 64,0 64,0 347 203 7,7 13,5 320 288 81,7

TECHNICAL DATA fl Hfl AND IflSECTIONS

CANTONEIRAS ABAS IGUAIS

W 360 x 72,0 72,0 350 204 8,6 15,1 320 288 91,3

Equal angle bars ESPESSURA MM KG/M2 W 360 x 79,0 79,0 354 205 9,4 16,8 320 288 101,2 Açominas sections produced by the universal hot rolling technology using four rolls in

THICKNESS MM KG/M2 W 360 x 91,0 (H) 91,0 353 254 9,5 16,4 320 288 115,9

W 360 x 101,0 (H) 101,0 357 255 10,5 18,3 320 286 129,5

the same plane;

1/4 6.30 49.39

TAM. W 360 x 110,0 (H) 110,0 360 256 11,4 19,9 320 288 140,6

CHAPAS FINAS 5 / 16 8.00 62.72 Specifications according to ASTM standards, with a wide range of sizes – from 6 to 24

POL. W 360 x 122,0 (H) 122,0 363 257 13,0 21,7 320 288 155,3

5/8 3/4 7/8 1 1 1/4 1 1/2 1 3/4 2 2 1/2 3 4 5 6 3/8 9.50 74.48

SIZE À QUENTE 1/2 12.50 98.00 W 410 x 38,8 38,8 399 140 6,4 8,8 381 357 50,3 inches (150 – 600 mm);

INCH Hot-rolled sheets 5/8 16.00 125.44 W 410 x 46,1 46,1 403 140 7,0 11,2 381 357 59,2

1/8 0.71 0.88 1.04 1.20 1.53 1.85 2.18 2.46 1.27

3/4 19.00 149.00 W 410 x 53,0 53,0 403 177 7,5 10,9 381 357 68,4 Sections produced to different specifications: ASTM A 36, A 572 GRADE 50, A 588,

Nº MM KG/M2 7/8 22.40 175.84 W 410 x 60,0 60,0 407 178 7,7 12,8 381 357 76,2

3/16 1.73 2.22 2.70 3.19 3.66 4.64 5.59 W 410 x 67,0 67,0 410 179 8,8 14,4 381 357 86,3 among others;

NO. MM KG/M2 1 25.00 196.00

14 1.90 15.20 1 1/8 28.57 226.20 W 410 x 75,0 75,0 413 180 9,7 16,0 381 357 95,8

1/4 2.28 2.86 3.51 4.16 4.79 6.08 7.35 9.93

W 410 x 85,0 85,0 417 181 10,9 18,2 381 357 108,6 Straight and parallel flange bars;

13 2.25 18.00 1 1/4 31.50 247.27

5/16 4.26 5.05 5.88 7.49 9.10 12.37 W 460 x 52,0 52,0 450 152 7,6 10,8 381 404 66,6

12 2.65 21.20 1 1/2 37.50 294.37

3/8 6.93 8.86 10.80 14.60 18.30 22.20 11 3.00 24.00 1 3 /4 44.45 348.50

W 460 x 60,0 60,0 455 153 8,0 13,3 428 404 76,2 Lowest linear mass (kg/m);

W 460 x 68,0 68,0 459 154 9,1 15,4 428 404 87,6

1/2 11.45 14.00 19.10 24.10 29.20 10 3.35 26.80 2 50.00 392.00

9 3.75 30.00 2 1 /2 63.00 494.55

W 460 x 74,0 74,0 457 190 9,0 14,5 428 404 94,9 One-piece beams, without localized stresses.

W 460 x 82,0 82,0 460 191 9,9 16,0 428 404 104,7

8 4.25 34.00 3 75.00 588.10

W 460 x 89,0 89,0 463 192 10,5 17,7 428 404 114,1

7 4.50 36.00 3 1/2 88.90 697.80

W 460 x 97,0 97,0 466 193 11,4 19,0 428 404 123,4

FERRO CHATO 3/16 4.75 38.00 4 100.00 784.00

W 460 x 106,0 106,0 469 194 12,6 20,6 428 404 135,1

Flat bars W 530 x 66,0 66,0 525 165 8,9 11,4 502 478 83,6

W 530 x 72,0 72,0 524 207 9,0 10,9 502 478 91,6 PERFIS “I” E “H” H- and I-Sections Y

CHAPA EXPANDIDA PARA PISO W 530 x 74,0 74,0 529 166 9,7 13,6 502 478 95,1

DIM | DIM 1/12 5/8 3/4 7/8 1 1 1/4 1 1/2 1 3/4 2 2 1/2 3 4 W 530 x 82,0 82,0 528 209 9,5 13,3 501 477 104,5 d = Height

1/8 0.32 0.40 0.48 0.56 0.63 0.72 0.87 1.11 1.27 Expanded flooring plate d = altura

R

W 530 x 85,0 85,0 535 166 10,3 16,5 502 478 107,7 d’ = altura livre da alma d’ = Free web height

3/16 0.48 0.59 0.71 0.83 0.95 1.19 1.42 1.66 1.90 W 530 x 92,0 92,0 533 209 10,2 15,6 502 478 117,6 h = altura interna h = Inside height d

1/4 0.59 0.74 0.95 1.11 1.27 1.58 1.90 2.22 2.53 3.17 3.80 5.07 ESPESSURA DIM./MM MALHA PESO/M2 W 530 x 101,0 101,0 537 210 10,9 17,4 502 470 130,0 b’f = largura da aba b’f = Flange width

5/16 1.20 1.40 1.58 1.98 2.38 2.80 3.17 3.96 4.75 6.33 THICKNESS DIM./MM THICKNESS WEIGHT W 530 x 109,0 109,0 539 211 11,6 18,8 501 469 139,7 d X

3/8 1.42 1.66 1.90 2.38 2.85 3.32 3.80 4.75 5.70 7.60 5/16 / 8.00 2.000 x 1.000 34 x 133 31,5 kg W 610 x 101,0 101,0 603 228 10,5 14,9 573 541 130,3 tf = espessura da aba tf = Flange thickness

1/2 1.90 2.22 2.53 3.17 3.80 4.42 5.06 6.33 7.60 10.13 1 / 4 / 6.35 1.500 x 3.000 45 x 100 15,0 kg W 610 x 113,0 113,0 608 228 11,2 17,3 573 541 145,3 h

tw = espessura da alma tw = Web thickness tw

5/8 3.16 3.95 4.75 5.39 6.33 7.92 9.50 12.67 1 / 46 / 35 1.000 x 2.000 45 x 100 15,0 kg W 610 x 125,0 125,0 612 229 11,9 19,6 573 541 160,1 R = Transition radius

R = raio de concordância

3/4 3.80 4.75 5.70 6.65 7.60 9.50 11.40 15.19 3 / 16 / 4.75 1000 x 2.000 45 x 100 7,5 kg W 610 x 140,0 140,0 617 230 13,1 22,2 573 541 179,3 tf

7/8 8.86 10.87 13.28 17.71 1 8 / 3.00 1.000 x 2.000 20 x 50 7,6 kg W 610 x 155,0 155,0 611 324 12,7 19,0 573 541 198,1 bf

1 12.66 15.19 20.26 1 / 1.55 1.000 x 2000 12 x 25 3,6 kg W 610 x 174,0 174,0 616 325 14,0 21,6 573 541 222,8

Você também pode gostar

- Apresentação Engemecal Construções Metálicas LTDADocumento15 páginasApresentação Engemecal Construções Metálicas LTDAengemecalAinda não há avaliações

- Catalogo 2020Documento62 páginasCatalogo 2020Engekeep Departamento EstruturalAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauWalace LanesAinda não há avaliações

- Portafolio Todo LáminaDocumento42 páginasPortafolio Todo LáminaINGENIERIA JFBAinda não há avaliações

- C2-Bandejamentos (Piso e Aparente)Documento24 páginasC2-Bandejamentos (Piso e Aparente)Larisa AlvesAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdaujoaoluiizzAinda não há avaliações

- 17 06 201117 53tubulacoesindustriais Fundamentos 130801190914 Phpapp01 PDFDocumento373 páginas17 06 201117 53tubulacoesindustriais Fundamentos 130801190914 Phpapp01 PDFPaulo Ricardo SouzaAinda não há avaliações

- CATÁLOGO ESCADAS 2017-v4.ptDocumento28 páginasCATÁLOGO ESCADAS 2017-v4.ptvicente hilaAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauMarivaldo de SouzaAinda não há avaliações

- Apresentação Gon PetroDocumento22 páginasApresentação Gon Petrorickvs91Ainda não há avaliações

- Catalago DaganDocumento60 páginasCatalago DaganFrederock Assis LeiteAinda não há avaliações

- RDG - Catalogo PRD 2022Documento11 páginasRDG - Catalogo PRD 2022rangel limaAinda não há avaliações

- FFD PAM 2008Documento84 páginasFFD PAM 2008Catarina SilvaAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauMagno Luiz BritoAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauDouglas VitorAinda não há avaliações

- Cabos de Elevadores para Aplicacoes Padrao 2011 08 PTDocumento8 páginasCabos de Elevadores para Aplicacoes Padrao 2011 08 PTengenharia Elevadores CasteloAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauQualidade LagotelaAinda não há avaliações

- ProdutosDocumento3 páginasProdutosDouglas GonçalvesAinda não há avaliações

- Produtos EletromecânicoDocumento5 páginasProdutos EletromecânicoAlto TorqueAinda não há avaliações

- Catalogo Cedisa 2023Documento64 páginasCatalogo Cedisa 2023Ronaldo RIBEIRO FERNANDESAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauGilney PalharesAinda não há avaliações

- Catalogo Barras e PerfisDocumento8 páginasCatalogo Barras e PerfisricardomendesecvAinda não há avaliações

- Apresentação Raio Serviços - EscopoDocumento3 páginasApresentação Raio Serviços - EscopoFelipe SantosAinda não há avaliações

- Catalogo UsiminasDocumento72 páginasCatalogo UsiminasAnderson SantosAinda não há avaliações

- Catalogo Chumbadores INDUFIX PDFDocumento34 páginasCatalogo Chumbadores INDUFIX PDFVitor Folador GonçalvesAinda não há avaliações

- C1-Bandejamentos (Áereo)Documento36 páginasC1-Bandejamentos (Áereo)Larisa AlvesAinda não há avaliações

- Estruturas MetálicasDocumento35 páginasEstruturas MetálicastvieiracruzAinda não há avaliações

- Catalogo Barras e Perfis GerdauDocumento20 páginasCatalogo Barras e Perfis GerdauWellington LimaAinda não há avaliações

- Catalogo Barras e PerfisDocumento8 páginasCatalogo Barras e PerfisjoaoluiizzAinda não há avaliações

- PerfisaDocumento12 páginasPerfisaAntónio NôroAinda não há avaliações

- Perfis Soldados USIMECDocumento16 páginasPerfis Soldados USIMECOsvaldo Junges BomfimAinda não há avaliações

- Catalogo Barras e PerfisDocumento8 páginasCatalogo Barras e PerfisWalace LanesAinda não há avaliações

- APOSTILA CURSO PHB ONGRID v.2.9 01-2020Documento306 páginasAPOSTILA CURSO PHB ONGRID v.2.9 01-2020Einstein Salomão De Oliveira100% (1)

- Catalogo Multiaços 2005Documento10 páginasCatalogo Multiaços 2005Lucas XavierAinda não há avaliações

- Catalogo SataCompletoDocumento70 páginasCatalogo SataCompletoalessandroAinda não há avaliações

- Catalogo SCADocumento7 páginasCatalogo SCAPaulo Gracindo JuniorAinda não há avaliações

- Catálogo DenverDocumento9 páginasCatálogo DenverEdson LaranjeiraAinda não há avaliações

- Catalogo SomarDocumento32 páginasCatalogo SomarGiovani Farias100% (3)

- Catálogo - Caixa para Rolamento (Mancais) - HENFELDocumento56 páginasCatálogo - Caixa para Rolamento (Mancais) - HENFELr_freireAinda não há avaliações

- Catálogo Aços Especiais - AutomotivoDocumento8 páginasCatálogo Aços Especiais - AutomotivoCarlos MequiliniAinda não há avaliações

- Catalogo de ProdutosDocumento56 páginasCatalogo de ProdutosAntónio AlmeidaAinda não há avaliações

- Catalogo BarrasPerfis PDFDocumento8 páginasCatalogo BarrasPerfis PDFEngenheiro Stefan ObermarkAinda não há avaliações

- Catálogo Construção Civil Tuper PDFDocumento19 páginasCatálogo Construção Civil Tuper PDFFernandoAinda não há avaliações

- Catálogo Casa Do AçoDocumento4 páginasCatálogo Casa Do AçoLucas de MedeirosAinda não há avaliações

- Apresentação Ficha Tecnica de Aço 2 PDFDocumento68 páginasApresentação Ficha Tecnica de Aço 2 PDFFrancisco SousalimaAinda não há avaliações

- Aços Contrução MecanicaDocumento68 páginasAços Contrução MecanicaOdilonAinda não há avaliações

- Catalogo Barras e PerfisDocumento8 páginasCatalogo Barras e PerfisMarivaldo de SouzaAinda não há avaliações

- Catalogo Tubos Pretos e GalvanizadosDocumento5 páginasCatalogo Tubos Pretos e GalvanizadosAlejandra Antezana EspadaAinda não há avaliações

- 04.05.0071 - Manilha para Cabo de Aco Zincado Din82101aDocumento1 página04.05.0071 - Manilha para Cabo de Aco Zincado Din82101acoutoAinda não há avaliações

- Barras e Perfis Catalogo PDFDocumento8 páginasBarras e Perfis Catalogo PDFNathan LeonardoAinda não há avaliações

- Co 15 - Guarda Corpo Tubular PDFDocumento5 páginasCo 15 - Guarda Corpo Tubular PDFLeonardo SilveiraAinda não há avaliações

- IRWIN - Catálogo de Alicates e Chaves (47 PGS)Documento47 páginasIRWIN - Catálogo de Alicates e Chaves (47 PGS)mcelllAinda não há avaliações

- Apresentação WTR FundiçãoDocumento5 páginasApresentação WTR FundiçãoRebeca MORAESAinda não há avaliações

- Portfolioalcede 2018Documento16 páginasPortfolioalcede 2018Everton FernandesAinda não há avaliações

- Catálogo Somar - Standard PDFDocumento32 páginasCatálogo Somar - Standard PDFGilbertoAinda não há avaliações

- Cat礚ogo Oficial Equipamentos 03.23Documento59 páginasCat礚ogo Oficial Equipamentos 03.23Pr. Reinaldo BarbosaAinda não há avaliações

- CAT%c3%81LOGO+TRIF%c3%81SICO WebDocumento8 páginasCAT%c3%81LOGO+TRIF%c3%81SICO WebRafael BruxelAinda não há avaliações

- Artigo Classe de Porcas e ParafusosDocumento16 páginasArtigo Classe de Porcas e Parafusosnum fistismAinda não há avaliações

- Exercício 03 - Tensões - ResolvidoDocumento6 páginasExercício 03 - Tensões - Resolvidonum fistismAinda não há avaliações

- RODEX Correntes GERALDocumento36 páginasRODEX Correntes GERALnum fistismAinda não há avaliações

- Catálogo de Aços (Diadema Triaço) 05.2017Documento12 páginasCatálogo de Aços (Diadema Triaço) 05.2017num fistismAinda não há avaliações

- Catalogo Fixacao Mecanica PDFDocumento9 páginasCatalogo Fixacao Mecanica PDFRicardo Argentton FicanhaAinda não há avaliações

- Novo Actros 2648 6x4 S MetalicaDocumento2 páginasNovo Actros 2648 6x4 S Metalicanum fistismAinda não há avaliações

- Axor 1933 4x2 Cavalo MecanicoDocumento2 páginasAxor 1933 4x2 Cavalo Mecaniconum fistismAinda não há avaliações

- Linha Tombadores - JoscilDocumento3 páginasLinha Tombadores - Joscilnum fistismAinda não há avaliações

- Elementos Do Estilo Tipografico. Versao 4.0 PDFDocumento12 páginasElementos Do Estilo Tipografico. Versao 4.0 PDFP.h. DiazAinda não há avaliações

- Apostila Historia 3 Ano 4 Bimestre ProfessorDocumento36 páginasApostila Historia 3 Ano 4 Bimestre ProfessorTricia Carnevale100% (4)

- Fullstack Master - DevPlenoDocumento13 páginasFullstack Master - DevPlenohelderlmcAinda não há avaliações

- Planilha de Orçamento - Modelo 1 (Version 1) (Version 1)Documento2 páginasPlanilha de Orçamento - Modelo 1 (Version 1) (Version 1)Felipe SiqueiraAinda não há avaliações

- Mascaras em DBEditsDocumento7 páginasMascaras em DBEditsAdriano Vieira da Silva0% (1)

- E-Book Turismo SertanejoDocumento276 páginasE-Book Turismo SertanejoIngrid SantosAinda não há avaliações

- Apostila 1 Parte PDFDocumento40 páginasApostila 1 Parte PDFw2ttec developerAinda não há avaliações

- Caelum HTML Css JavascriptDocumento286 páginasCaelum HTML Css JavascriptRodrigo SantosAinda não há avaliações

- IT 22 CBMBA - 2016 Sistemas de Hidrantes e de Mangotinhos para Combate A Incendio PDFDocumento35 páginasIT 22 CBMBA - 2016 Sistemas de Hidrantes e de Mangotinhos para Combate A Incendio PDFiuricarloAinda não há avaliações

- Lei 14300 Geracao DistribuidaDocumento15 páginasLei 14300 Geracao DistribuidaPRO-W ENGENHARIAAinda não há avaliações

- Sempre É Uma Companhia - QuizizzDocumento4 páginasSempre É Uma Companhia - QuizizzEduarda FernandesAinda não há avaliações

- Importaaao de ConfiguraaaoDocumento3 páginasImportaaao de Configuraaaomatheus martinsAinda não há avaliações

- Pinos Up Tsi 2016Documento1 páginaPinos Up Tsi 2016Fabio EletrotecAinda não há avaliações

- Como Elaborar Um CanvasDocumento1 páginaComo Elaborar Um Canvassuzana samuelAinda não há avaliações

- Controle Geral de Extintores e HidrantesDocumento8 páginasControle Geral de Extintores e HidrantesMario Lucio OliveiraAinda não há avaliações

- Processamento de Imagens Digitais - GonzalezDocumento264 páginasProcessamento de Imagens Digitais - GonzalezFelipe Lopes100% (2)

- Boleto 928605Documento1 páginaBoleto 928605paulomsnbAinda não há avaliações

- Trabalho ArquiteturaDocumento12 páginasTrabalho ArquiteturaThiago RodriguesAinda não há avaliações

- Aula 3 - Construção de Interfaces Gráficas de Usuário Com VBADocumento33 páginasAula 3 - Construção de Interfaces Gráficas de Usuário Com VBAWeslei FelixAinda não há avaliações

- Menalda Andre PDFDocumento75 páginasMenalda Andre PDFCelestinaAinda não há avaliações

- Relatorio Resistencia EletricaDocumento13 páginasRelatorio Resistencia Eletricavander_lilson06Ainda não há avaliações

- Pro GibbDocumento13 páginasPro GibbMesquita Divino NunesAinda não há avaliações

- Tecnologia Da Informação JurídicaDocumento101 páginasTecnologia Da Informação JurídicaJeane Pâmela RubimAinda não há avaliações

- 2015 Fiat Freemont 105251Documento452 páginas2015 Fiat Freemont 105251Flavio CorleoneAinda não há avaliações

- Monografia de Gustavo A Almeida Neves TCCII - EstácioDocumento90 páginasMonografia de Gustavo A Almeida Neves TCCII - EstácioGustavo Alves Almeida NevesAinda não há avaliações

- Apontamentos de Estruturas MetálicasDocumento207 páginasApontamentos de Estruturas MetálicasAlbano Viveiros100% (1)

- Trator Trator BH BH 145 145 GIII GiiiDocumento2 páginasTrator Trator BH BH 145 145 GIII GiiiWashington SAinda não há avaliações

- AVEng-CV - Engenheiro - Perito Judicial - Rev1Documento2 páginasAVEng-CV - Engenheiro - Perito Judicial - Rev1Fernando Alves da Silva100% (1)

- Guimarães Cidade Visível #1Documento122 páginasGuimarães Cidade Visível #1Paulo PintoAinda não há avaliações

- STC6 PortfolioDocumento19 páginasSTC6 PortfolioGonçalo Romão100% (1)