Escolar Documentos

Profissional Documentos

Cultura Documentos

Porta Pratos Opt

Porta Pratos Opt

Enviado por

Claudio Turlher0 notas0% acharam este documento útil (0 voto)

3 visualizações5 páginasporta pratos 2

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoporta pratos 2

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

3 visualizações5 páginasPorta Pratos Opt

Porta Pratos Opt

Enviado por

Claudio Turlherporta pratos 2

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 5

kellyM

or years, [vebecnuryingto cajole

F Kelly Mehler to write an article

fornsonone ofhismany areasof

woodworking expertise: buildingens-

tom pieces that emphasize the beauty

of carefully selected hardwoods.

And Ihavenit given upon that quest

~butone of his formsisjustso appeal=

ing that I didn't want to wait for Kelly

wo be convinced in order for everyone

Lo see it So] built st vith Kelly's per-

mission, of course)

Kelly anid ts wife, Tet, workedvith

kitchen designer (and renowned Eng-

lish Anis é& Crafis furniture maker)

Nancy Hiller to desigh this plate rack.

la integrate mto their Berea, Ky., log

home’s kitchen (see “Design Process”

‘onpage 43}.

chlerePlate Rac

Add pizazz to your kitchen with contemporary curves.

Adapt for Your Aesthetics

‘While Kelly built hisplate reek in white

ak to match the rest of his family’

kitchen, I deciced on tiger maple in

part because Thada lot ig, bucin rath

because Vin not terribly fond of oak.

‘And after studying the pictures of

Kellys, alsomadesome minor chang

esto the design ofthe plate dividers by

setting mine back ¥4" from the front

sige U» ereaie an additional shadow

line —but more on that to came

Inaddition, before deaingmny plan

in SketchUp, measured the threesizes

of Louisville Stoneware plates in my

collection to makesure Lalforded sut-

ficient clearance for thein to slide in

and out of the rack, ten located my

fixed shelves accordingly.

Itsallin the Pattern

With sixsides that mustbe identical, 1

decided onpatiern routingasthe most

efficientapproach, So the frst taskwas

to create a pattern for the router bit to

follow. I used V4" plywood because it

was handy, but 14" plywood or MDF

would work as well. Ox, iFyou've no

swish to have a pattern on hand for fue

ture builds, you could cut and fair the

firstside from yourstock, and use that

toguide the pattern bit forthe remain-

ing sides

Thesidesare 11M" wide at heapex

ofthe curveand 35" in length, lcucmy

plywood to that size, then tapped in

anail at either end just sightly more

than 5" from the back edge (the sides

are5* atthe top and boxtom), and one

nail just inside the edgeat the apex of

the curve. 1 then used those to hold

a flexible metal rate in place while |

penciled inthe curve. (Note that whit

the 5" mark perfectly with my flexible

rule, the nail locations were adjusted

in increments until I found the sweet

spot)

After cutting close to iy line on

dhe band sav, I faired the curve using

aspokeshaveand sandpapes: Take the

lume to get your patiern as perfect as

possible — how close to finished your

sides are right off the router depends

upon it

‘With the paitern completed, process

your lumber, then use the pattern to

transfer the shape to the wood, regis-

tering it off the jomnted edge that will

became the back edge of each side, 1

recommend buying more wood than,

‘younced: because thereisnodecorative

clement beyond the form itselfand the

exposed joinery, youl want sufficient

amber fromwhich to choose the hest-

looking sides possible.

Again, it’s tothe band saw to cut

close to yout ots about" aways

ideal ‘Ther,

mount beartAg-guided pattern bit as

did 1. sccure the pattern beneath the

workpiece (Ldo this using holdfastac

cither end, with theedgeto be worked

hanging ofl the [rontedgeol my bench

(hen routof{ he remaining waste mov-

ing fromleft toright into thedirection

of the bits rotation), Note that it you

begin to experience tear-owt, you may

need to try climb-cutting. Andif your

band saw work was lessthan ideal and

you have an excess of waste, remove

itin a few passes (this will also reveal

where tar-outislikely occur) rather

than hogging ital off at once.

Trecommend making a few passes

on a piece of scrap first to determine

the speed at which both you and the

machine should move; getitrightand

youllhavean almost finisheready worke

plece (that is, with no burns) right off

the bit.

Af you do get some burning, yout!

reed to remove it with a spokeshave

(or deep burns) or sandpaper, but try

not to change the shape of the edge

rnmuch, Ifyou do, however, mark that

iyouté using ehotbin=

= Tu

‘Shaving fair. shnp spokostiae tellomved

by endpaper as neetieds nade quick work of

fatring the pattern’ cure

(yt

side Adee me socket ‘

of theoverall build wheremtinovvatia-

ons won't be obvious,

Onto the Joinery

{considered using the Festool Domine

for loose-tenon joinery to avach the

sides to the tops and bottoms, that

would beplenty strong. Burin theend

—and for the ends —Idectded on dove-

tails ora touch ofadded visual interest

Because the force ~and a lat of it

if you have heavy dishes —is vertical,

the tails are on the sides. And so that

the line at the top and bottom of the

‘carves remained clean, I laid out hal

tailsatthe frontand back edges. Tdon't

‘now about you, but typically have

half-pins at the corners when build

ang casework, so I was sure to clearly

mark the waste to avoid cutting away

he wrong material.

Leut my dovetails by hand, tails

Jirst.and cope out che bulkof the waste

before chiseling to my baselines. You

should, of course, ext your dovetails

with whatever method you prefer.

Note thatwhile the two outside units

Pattermmaker. Aer cutting

eahick ply wont tho

‘overall and wecth of

the sides, usec afexble rule

eldn piace around three

pals ceshaw a fate curve for

my pattern

‘Rout to shape. Move 20a steady pace as you

pete oie aroun the patie, and

be sure to keep the base plate finaly en te

werkicce

ee Cacia ae

“are joined abort ie (op and bowen ~

with dovetails, the center unitis epen.

at the bottom in this design (o accom-

modave a kitchen [faucet

Alter youhave thedovetails cutand

dey-fit Jay outthelocations for the fixed

shelves. And unless your dinnerplates

are also 11" in diameter and your

salad plates are 9° in diameter, youl

need toadjust your dado locations ac-

cordingly.

Alsoconsiderany changesyoumay

Tail board. On this buik, the side pieces

get ho ca, wan a half all on eater end so

sas avin the curve te fe. aio

match tat the back,

‘wish to make to the divider subassem-

blies, With my method and dado spac-

ing, the top and bottom of the divider

subassemblies can be no more than

thick and still allow room for my

rer platestosticeinand out, Ifyou

decideon thickermaterial foryour sub

assemblies, youll need to leave sul-

ficient space both foritand to get your

platesin and out,

‘Measuring from the bottom, thelo-

cations lorthe %-wide stopped dados

on mineareat 11" and 21% on thetwo

outside units, andl ac LI" and 23%" on

the middle unit. Measuring from the

back edge, the dados are stopped at

942" I your dado locations change,

re

/

rote y

Se

SECTION ~ END UNIT

Plate Rack

26 Sides yas 35 Maple

D5 Topsbotioms Sy sa Male

2onile Mani.

D2 Adjustable shelves we Maple

Drvipex SUBASSE MES

112 Topetbarioms My 34 20 Maple

O52 Shortdivdes Mea Maple

U6 Long dividers eS Maple

* size for hap suppets: Fusing spon supports, 2d

a

confirm that the curve at that point

will accommodate a 9¥'-long dado;

your dado length may require adjust-

‘ment, I marked both the rightand let

edges of my dadosso that didn'thave

to think as much when { clamped my

simple router jigin position—because

the routerabveays rans to the right of

Trust but verify. itor

> marking the dc foe:

ens and afoang my a

fon the Gist cu Fran 4

adi ona st piece fist

twconlnn the depth of

can which

the jig, but the jig placement changes

depending onil youre workingon the

Jelt or right side of the ease. Marking

Doth sides of the dado makes tv. no-

brainer,

‘And if you decide to cut the dados

by band with a saw (bevore cleaning

outthewaste witha chisel), youlineed

31D VIEW ~ CENTER & END UNIT

DIVIDER SUBASSEMBLY

Você também pode gostar

- Cartilha AutismoDocumento11 páginasCartilha AutismoEstela AndradeAinda não há avaliações

- POP 002 Cozinha Armazenamento de AlimentosDocumento3 páginasPOP 002 Cozinha Armazenamento de AlimentosCleber GuimarãesAinda não há avaliações

- Pop LimpezaDocumento4 páginasPop LimpezaEqui Proanálise100% (1)

- Golden Ratio Nature Aesthetics and DesignDocumento13 páginasGolden Ratio Nature Aesthetics and DesignClaudio TurlherAinda não há avaliações

- Torreense - Ficha Técnica 4.1. Telha Marselha - Cálculo Do Ripado - Cálculo Da Distância Entre As RipasDocumento1 páginaTorreense - Ficha Técnica 4.1. Telha Marselha - Cálculo Do Ripado - Cálculo Da Distância Entre As RipasClaudio TurlherAinda não há avaliações

- Descritivo Técnico - TCCDocumento4 páginasDescritivo Técnico - TCCClaudio TurlherAinda não há avaliações

- Tetpor AirDocumento4 páginasTetpor AirClaudio TurlherAinda não há avaliações

- Edifício Time - Apto 1308Documento1 páginaEdifício Time - Apto 1308React TeenAinda não há avaliações

- Cálculo de Área ResidencialDocumento3 páginasCálculo de Área ResidencialLayz DiasAinda não há avaliações

- Ebook Monte Sua Cozinha V 01Documento38 páginasEbook Monte Sua Cozinha V 01VirginiaAinda não há avaliações

- Manual Bosch Lava Roupa Komfort Klasse 1000Documento17 páginasManual Bosch Lava Roupa Komfort Klasse 1000Sergio Koji Sakamoto60% (5)

- Lista Enxoval de CasaDocumento5 páginasLista Enxoval de CasaMikaely FernandaAinda não há avaliações

- LTS12 GabineteDocumento3 páginasLTS12 GabineteRodrigo VictorAinda não há avaliações

- Esmerilhadeira Bosch GWS 21-180Documento1 páginaEsmerilhadeira Bosch GWS 21-180Paulo HackAinda não há avaliações

- Vocabulário de Casa e CômodosDocumento2 páginasVocabulário de Casa e CômodosPriscilaAinda não há avaliações

- Det. Marcenaria Cozinha - Projeto Modelo DpagDocumento3 páginasDet. Marcenaria Cozinha - Projeto Modelo DpagLucas PereiraAinda não há avaliações

- Projeto André E Shayra Área MolhadaDocumento81 páginasProjeto André E Shayra Área MolhadaFelipe Rissatto BravoAinda não há avaliações

- Novo Catálogo de Produtos Royal PrestigeDocumento27 páginasNovo Catálogo de Produtos Royal Prestigesaymon2Ainda não há avaliações

- Manual WDQX13Documento28 páginasManual WDQX13Thiago CamargoAinda não há avaliações

- Texto ExpositivoDocumento2 páginasTexto ExpositivoCristina CostaAinda não há avaliações

- NBR 6178 Out 1993 Lavanderia IndustrialDocumento5 páginasNBR 6178 Out 1993 Lavanderia IndustrialdferrierosAinda não há avaliações

- Manual de Instruções - LBU 15Documento24 páginasManual de Instruções - LBU 15Adair Moreira100% (1)

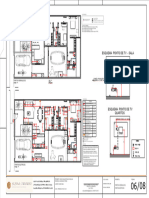

- 06 R1 Exe Arq Hidro e Tomadas Ricardo Maia ScarqDocumento1 página06 R1 Exe Arq Hidro e Tomadas Ricardo Maia ScarqElionaiØnîî-chânAinda não há avaliações

- Planilhas de HigienizaçãoDocumento9 páginasPlanilhas de Higienizaçãodeise.rufattoAinda não há avaliações

- Ferro Com Caldeira PHILIPS GC793330 PerfectCare - Pesquisa GoogleDocumento1 páginaFerro Com Caldeira PHILIPS GC793330 PerfectCare - Pesquisa GoogleGuidaAinda não há avaliações

- Manual - Cafeteira Eletrica 100 L - RodriaçoDocumento11 páginasManual - Cafeteira Eletrica 100 L - RodriaçoJoao VictorAinda não há avaliações

- Lista Do Chá de Casa NovaDocumento2 páginasLista Do Chá de Casa NovaTatiana Seixas TavaresAinda não há avaliações

- 19-11-2021 - CotasDocumento1 página19-11-2021 - CotasPaulo Henrique RaposoAinda não há avaliações

- Tabela de Potência Dos Eletrodomésticos! - Mundo Da ElétricaDocumento2 páginasTabela de Potência Dos Eletrodomésticos! - Mundo Da ElétricaJeremias ReisAinda não há avaliações

- Laudo VistoriaDocumento1 páginaLaudo VistoriaCamilo VenturiAinda não há avaliações

- Limpeza Do Forno Josper.Documento2 páginasLimpeza Do Forno Josper.Silvana RochaAinda não há avaliações

- Sorteio de Culto de MulheresDocumento5 páginasSorteio de Culto de MulheresHaylla e Havylla santosAinda não há avaliações

- Death House IDocumento8 páginasDeath House IResenhante PaiAinda não há avaliações

- Dicas para Preparar Produtos de LimpezaDocumento2 páginasDicas para Preparar Produtos de LimpezaMarcos ViniciusAinda não há avaliações