Escolar Documentos

Profissional Documentos

Cultura Documentos

59282d3b9a986 - Terminal de Compresion

Enviado por

Linder Ibarra VilcaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

59282d3b9a986 - Terminal de Compresion

Enviado por

Linder Ibarra VilcaDireitos autorais:

Formatos disponíveis

Catálogo Geral de Produtos / General Products Catalog

TM

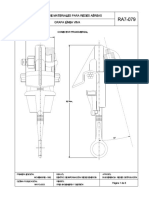

TM TM-L TM-2 TM-2L

TERMINAL À COMPRESSÃO

COMPRESSION TERMINAL

• Finalidade: Terminações de condutores de cobre.

Purpose: Copper conductors end.

Objetivo: Terminaciones de cables de cobre.

• Característica: Alta condutibilidade elétrica e resistência à corrosão. Sapata com diversas furações e ótimo contato elétrico.

Conexão por compressão.

Characteristic: High conductivity and corrosion resistance. Pad with several hole sizes and optimum electrical contact. Compression

connection.

Característica: Alta conductividad eléctrica y resistencia a la corrosión. Zapata con varios tamaños de agujeros y excelente contacto

eléctrico. Conexión por compresión.

• Aplicação: Painéis elétricos, ligações de chaves disjuntoras, motores, máquinas, barramentos, quadros de distribuição elétrica

e outras.

Application: Panels, electrical switches, engines, machines, bus bar, energy distribution boards and others.

Aplicación: Paneles, interruptores de llave, motores, máquinas, autobuses, tableros de distribución eléctrica, entre otros.

• Material: Cobre eletrolítico.

Raw material: Electrolytical copper.

Material: Cobre electrolítico.

• Acabamento: Estanhado.

Finishing: Tin plated.

Acabamiento: Estañado

• Ferramenta: AT-10, AT-60, AT-68, AY-96 e CY-96.

Tool: AT-10, AT-60, AT-68, AY-96 and CY-96.

Herramienta: AT-10, AT-60, AT-68, AY-96 y CY-96.

• Norma: NBR - 5370.

Standard: NBR - 5370.

Norma: NBR - 5370.

Terminais / Terminals

Catálogo Geral de Produtos / General Products Catalog

TM UM FURO E BARRIL CURTO

SINGLE HOLE, ONE CRIMP

Fabricado em cobre e estanhado para obtenção de

maior resistência à corrosão.

Ferramentas de Aplicação:

AT-10, AT-68, AY-96 ou similar.

Possuem vigia no barril que permite verificar a

completa inserção do cabo.

Os diâmetros interno (Di) e externo (De) do barril são

iguais para os quatro tipos de TM.

Outras bitolas e furações sob consulta.

Made of copper. Tin plated to minimize corrosion.

Recommended tools:

AT-10, AT-68, AY-96, or similar.

Hole in the back of terminal allows cable insert check.

For other gauges or hole sizes, please consult.

The internal (Di) and external (De) barrel diameters of

the four types of the Tm connector are equal.

Na utilização de condutor compacto,

Condutores

Dimensões Corrente

Ferramentas de Aplicação

*usar matriz índice IU-2.

Dim ensions Current

Conductors Application Tools

D i m e n si o n e s Corriente

Conductores Herram ientas de Aplicación

mm A Using the compact conductor, one

must use IU-2 die.

Código Alicate

Intelli Diâmetro Hidráulico Matriz Alicate Hidráulico

Parafuso Capacidade Matriz Alicate 12 t AY-96 / CY-96

Furo Alicate

C at # Área Bolt Size Capacity Mecânico AT-60 Hydraulic Recom m ended Die for Hydraulic TooL

H ol e Mecânico

Cross Tornillo C a p a ci d a d 4t Tool D ado

Diam eter A AF L C D E M e ch a n i ca l

C ódi go Section R e co m m e n d e d Alicate

Diám etro Tool

S e cci ó n Die for M echanical Hidráulico

Agujero Alicate

mm² Tool

øF Pol. Métrico M e cá n i co Circunferencial H exag o n al

( ) D ado

Inch M etric

Pulgada M étrico

* Circum ferential

Circunferencial

H ex

Hexagonal

• TM-2,5-5 1,0-2,5 5,2 3/16 M5 18,5 4,8 7,0 5,5 10,0 1,0 41 AT-10 - - - -

TM-2,5-6 1,0-2,5 6,5 1/4 M6 18,5 4,8 8,0 5,5 10,0 1,0 41 AT-10 - - - -

• TM-6-5 4-6 5,2 3/16 M5 22,5 5,5 7,8 6,5 12,0 2,0 73 AT-10 - - - -

Ferramentas

TM-6-6 4-6 6,5 1/4 M6 23,0 5,5 9,5 6,5 12,0 2,0 73 AT-10 - - - -

• TM-10-5 10 5,2 3/16 M5 23,0 5,0 8,5 8,0 11,0 1,5 101 AT-60 / 68 IW-8 AY / CY-96 IU-8 H-8

TM-10-6 10 6,5 1/4 M6 23,0 5,0 8,5 8,0 11,0 1,5 101 AT-60 / 68 IW-8 AY / CY-96 IU-8 H-8 de Aplicação

TM-10-8 10 8,5 5/16 M8 27,6 7,0 12,0 8,0 15,0 1,5 101 AT-60 / 68 IW-8 AY / CY-96 IU-8 H-8

• TM-16-5 16 5,2 3/16 M5 28,0 6,0 11,3 10,0 13,5 2,0 137 AT-60 / 68 IW-5 AY / CY-96 IU-5 H-5

TM-16-6 16 6,5 1/4 M6 28,0 6,0 11,3 10,0 13,5 2,0 137 AT-60 / 68 IW-5 AY / CY-96 IU-5 H-5

TM-16-8 16 8,5 5/16 M8 28,0 6,0 11,3 10,0 13,5 2,0 137 AT-60 / 68 IW-5 AY / CY-96 IU-5 H-5

• TM-25-6 25 6,5 1/4 M6 32,0 6,0 12,9 11,0 15,5 2,2 182 AT-60 / 68 IW-4 AY / CY-96 IU-4 H-4

TM-25-8 25 8,5 5/16 M8 32,0 6,0 12,9 11,0 15,5 2,2 182 AT-60 / 68 IW-4 AY / CY-96 IU-4 H-4

TM-25-10 25 10,5 3/8 M10 34,0 8,0 15,5 11,0 18,0 2,2 182 AT-60 / 68 IW-4 AY / CY-96 IU-4 H-4 AT-10

TM-35-6 35 6,5 1/4 M6 36,0 8,0 15,0 12,0 17,5 2,4 226 AT-60 / 68 IW-4 AY / CY-96 IU-2 H-2

• TM-35-8 35 8,5 5/16 M8 36,0 8,0 15,0 12,0 17,5 2,4 226 AT-60 / 68 IW-4 AY / CY-96 IU-2 H-2

TM-35-10 35 10,5 3/8 M10 36,0 8,0 15,0 12,0 17,5 2,4 226 AT-60 / 68 IW-4 AY / CY-96 IU-2 H-2

TM-50-6 50 6,5 1/4 M6 42,5 9,0 18,0 16,0 19,5 2,7 275 AT-60 / 68 IW-1 AY / CY-96 IU-25 ** H-25

TM-50-8 50 8,5 5/16 M8 42,5 9,0 18,0 16,0 19,5 2,7 275 AT-60 / 68 IW-1 AY / CY-96 IU-25 ** H-25

• TM-50-10 50 10,5 3/8 M10 42,5 9,0 18,0 16,0 19,5 2,7 275 AT-60 / 68 IW-1 AY / CY-96 IU-25 ** H-25

TM-50-13 50 13,0 1/2 M12 42,5 9,0 18,0 16,0 19,5 2,7 275 AT-60 / 68 IW-1 AY / CY-96 IU-25 ** H-25

AT-68

TM-70-8 70 8,5 5/16 M8 46,0 10,0 20,3 16,5 22,0 3,0 353 AT-60 / 68 IW-26 AY / CY-96 IU-26 H-26

• TM-70-10 70 10,5 3/8 M10 46,0 10,0 20,3 16,5 22,0 3,0 353 AT-60 / 68 IW-26 AY / CY-96 IU-26 H-26

TM-70-13 70 13,8 1/2 M12 46,0 10,0 20,3 16,5 22,0 3,0 353 AT-60 / 68 IW-26 AY / CY-96 IU-26 H-26

TM-95-8 95 8,5 5/16 M8 49,0 10,0 24,0 17,5 22,0 3,0 430 AT-60 / 68 IW-27 AY / CY-96 IU-27 H-27

• TM-95-10 95 10,5 3/8 M10 49,0 10,0 24,0 17,5 22,0 3,0 430 AT-60 / 68 IW-27 AY / CY-96 IU-27 H-27

TM-95-13 95 13,8 1/2 M12 49,0 10,0 24,0 17,5 22,0 3,0 430 AT-60 / 68 IW-27 AY / CY-96 IU-27 H-27

TM-120-8 120 8,5 5/16 M8 65,0 13,3 27,0 25,5 29,5 3,3 500 AT-60 / 68 IW-29 AY / CY-96 IU-29 H-29

• TM-120-10 120 10,5 3/8 M10 65,0 13,3 27,0 25,5 29,5 3,3 500 AT-60 / 68 IW-29 AY / CY-96 IU-29 H-29

TM-120-13 120 13,8 1/2 M12 65,0 13,3 27,0 25,5 29,5 3,3 500 AT-60 / 68 IW-29 AY / CY-96 IU-29 H-29

TM-120-17 120 17,5 5/8 M16 65,0 13,3 27,0 25,5 29,5 3,3 500 AT-60 / 68 IW-29 AY / CY-96 IU-29 H-29

TM-150-10 150 10,5 3/8 M10 67,0 13,0 30,0 24,0 29,5 3,6 577 - - AY / CY-96 IU-30 H-30

• TM-150-13 150 13,8 1/2 M12 67,0 13,0 30,0 24,0 29,5 3,6 577 - - AY / CY-96 IU-30 H-30 CY-96

TM-150-17 150 17,5 5/8 M16 67,0 13,0 30,0 24,0 29,5 3,6 577 - - AY / CY-96 IU-30 H-30

TM-185-10 185 10,5 3/8 M10 68,5 13,5 32,4 26,0 29,5 3,8 661 - - AY / CY-96 IU-31 H-31

• TM-185-13 185 13,8 1/2 M12 68,5 13,5 32,4 26,0 29,5 3,8 661 - - AY / CY-96 IU-31 H-31

TM-185-17 185 17,5 5/8 M16 68,5 13,5 32,4 26,0 29,5 3,8 661 - - AY / CY-96 IU-31 H-31

TM-240-10 240 10,5 3/8 M10 80,5 17,0 38,0 29,0 35,0 4,8 781 - - AY / CY-96 IU-34 H-34

• TM-240-13 240 13,8 1/2 M12 80,5 17,0 38,0 29,0 35,0 4,8 781 - - AY / CY-96 IU-34 H-34

TM-240-17 240 17,5 5/8 M16 80,5 17,0 38,0 29,0 35,0 4,8 781 - - AY / CY-96 IU-34 H-34

TM-300-13 300 13,8 1/2 M12 91,5 19,0 41,5 33,0 40,0 4,8 902 - - AY / CY-96 IU-36 H-36 AY-96

• TM-300-17 300 17,5 5/8 M16 91,5 19,0 41,5 33,0 40,0 4,8 902 - - AY / CY-96 IU-36 H-36

TM-300-20 300 20,5 3/4 M20 91,5 19,0 41,5 33,0 40,0 4,8 902 - - AY / CY-96 IU-36 H-36

TM-400-13 400 13,8 1/2 M12 101,5 19,0 47,0 38,0 42,0 5,3 1085 - - AY / CY-96 IU-40 H-40

• TM-400-17 400 17,5 5/8 M16 101,5 19,0 47,0 38,0 42,0 5,3 1085 - - AY / CY-96 IU-40 H-40

TM-400-20 400 20,5 3/4 M20 101,5 19,0 47,0 38,0 42,0 5,3 1085 - - AY / CY-96 IU-40 H-40

• TM-500-17 500 17,5 5/8 M16 109,0 19,0 52,0 43,0 45,0 5,1 1253 - - AY / CY-96 IU-44 H-44

TM-500-20 500 20,5 3/4 M20 109,0 19,0 52,0 43,0 45,0 5,1 1253 - - AY / CY-96 IU-44 H-44

TM-500-26 500 26,5 1 M26 109,0 19,0 52,0 43,0 45,0 5,1 1253 - - AY / CY-96 IU-44 H-44

• TM-630-17 630 17,5 5/8 M16 125,0 22,5 61,2 50,5 51,0 6,3 1454 - - - - -

TM-630-20 630 20,0 3/4 M20 125,0 22,5 61,2 50,5 51,0 6,3 1454 - - - - -

TM-630-26 630 26,5 1 M26 125,0 22,5 61,2 50,5 51,0 6,3 1454 - - - - -

Você também pode gostar

- Projetos De Eletrônica Industrial Usando O ArduinoNo EverandProjetos De Eletrônica Industrial Usando O ArduinoAinda não há avaliações

- Terminais TMDocumento2 páginasTerminais TMMateus Alencar MartinsAinda não há avaliações

- Item 20Documento2 páginasItem 20Fernando Pedra ScherederAinda não há avaliações

- Catalogo IntelliDocumento52 páginasCatalogo IntelliEver Angel Nieto SalazarAinda não há avaliações

- Nortel IntelliDocumento52 páginasNortel IntelliTiagohowpy RamosAinda não há avaliações

- Hidrômetro Multijato Mecânico - Classe C PDFDocumento4 páginasHidrômetro Multijato Mecânico - Classe C PDFAngel Febrero CanaviriAinda não há avaliações

- Cerello - Catalogo - 2006 PDFDocumento86 páginasCerello - Catalogo - 2006 PDFluiziriasAinda não há avaliações

- Material para Red AereaDocumento8 páginasMaterial para Red AereastephanyderekAinda não há avaliações

- Ficha ElectrotécnicaDocumento2 páginasFicha ElectrotécnicaNatalinoandradeAinda não há avaliações

- FT Clamper Mobi BoxDocumento2 páginasFT Clamper Mobi BoxFabio L do CarmoAinda não há avaliações

- Cabo Drain WireDocumento1 páginaCabo Drain WireBruno BambinetiAinda não há avaliações

- Disjuntor Caixa Moldada - WegDocumento68 páginasDisjuntor Caixa Moldada - WegAlan KennedeAinda não há avaliações

- WEG - Catálogo - Disjuntores Caixa MoldadaDocumento68 páginasWEG - Catálogo - Disjuntores Caixa MoldadaJavierAinda não há avaliações

- Fusível NEOZED (Retardado)Documento7 páginasFusível NEOZED (Retardado)angeloAinda não há avaliações

- Nexans Cabos EP DRY 105 MT 8-7-15 KVDocumento5 páginasNexans Cabos EP DRY 105 MT 8-7-15 KVmarcelogcruzAinda não há avaliações

- Switch DeslizanteDocumento9 páginasSwitch DeslizanteEnzo SánchezAinda não há avaliações

- Disjuntores em Caixa MoldadaDocumento64 páginasDisjuntores em Caixa Moldadaromildo ferreiraAinda não há avaliações

- Coai - Brushes For Electrical Machines: Máquinas EléctricasDocumento6 páginasCoai - Brushes For Electrical Machines: Máquinas EléctricasBruno Carlos Alves PinheiroAinda não há avaliações

- Disjuntores e Interruptores de Cargas em Caixa Moldada BT - Compact MERLIN GERIN de 80 A 1250ADocumento331 páginasDisjuntores e Interruptores de Cargas em Caixa Moldada BT - Compact MERLIN GERIN de 80 A 1250Aluizpauloneto4226Ainda não há avaliações

- Fusíveis Ar e GL/GG Tipo NH Contato Faca e Flush End: Proteção Adequada para ADocumento32 páginasFusíveis Ar e GL/GG Tipo NH Contato Faca e Flush End: Proteção Adequada para ALê BarbosaAinda não há avaliações

- Catalogo KRJ BrasilDocumento5 páginasCatalogo KRJ Brasiltoro chircaAinda não há avaliações

- Ficha Electrotecnica EstaleiroDocumento2 páginasFicha Electrotecnica EstaleiroAntonio Regne M CantoAinda não há avaliações

- Cabos de Elevadores para Aplicacoes Padrao 2011 08 PTDocumento8 páginasCabos de Elevadores para Aplicacoes Padrao 2011 08 PTengenharia Elevadores CasteloAinda não há avaliações

- Motores de Corrente Contínua: DNF / DCF Dns / DcsDocumento8 páginasMotores de Corrente Contínua: DNF / DCF Dns / DcsThiago Soares MartinsAinda não há avaliações

- IOM Wall Mounted 50BWDocumento24 páginasIOM Wall Mounted 50BWJuliano MorasAinda não há avaliações

- Catálogo 2021 22 (1) - Force Line CompletoDocumento55 páginasCatálogo 2021 22 (1) - Force Line CompletoMariana Pereira SinzimbraAinda não há avaliações

- Aula - 10 Cat - Logo - Fus - Veis - para - Sistemas - FotovoltaicosDocumento2 páginasAula - 10 Cat - Logo - Fus - Veis - para - Sistemas - FotovoltaicosNAILTON JOSE DE OLIVEIRAAinda não há avaliações

- WEG Alternadores Sincronos Linha G Plus 50013799 Catalogo Portugues BRDocumento36 páginasWEG Alternadores Sincronos Linha G Plus 50013799 Catalogo Portugues BRVinicius Silva MartinsAinda não há avaliações

- Descrição: Tm-2L - Terminal de Cobre À Compressão (Dois Furos / Barril Longo)Documento2 páginasDescrição: Tm-2L - Terminal de Cobre À Compressão (Dois Furos / Barril Longo)Gidione Bispo VieiraAinda não há avaliações

- Descrição: Tm-2L - Terminal de Cobre À Compressão (Dois Furos / Barril Longo)Documento2 páginasDescrição: Tm-2L - Terminal de Cobre À Compressão (Dois Furos / Barril Longo)leoactmAinda não há avaliações

- Carbinox Eletroduto PDFDocumento12 páginasCarbinox Eletroduto PDFglobaldisAinda não há avaliações

- Chint Power SystemsDocumento2 páginasChint Power SystemsLuis Felipe AguirreAinda não há avaliações

- Manual Bombas - Multiestagio - MR - HM - HuDocumento4 páginasManual Bombas - Multiestagio - MR - HM - HuRafael CossolinoAinda não há avaliações

- Cnc-Ombr-Mat-18-0124-Edce - AnexosDocumento29 páginasCnc-Ombr-Mat-18-0124-Edce - AnexosMARCELO BARBOSA DE SOUSA alu.ufc.brAinda não há avaliações

- Forceline Catálogo de ProdutosDocumento57 páginasForceline Catálogo de ProdutosDirceuAinda não há avaliações

- Projecto de Postos de Transformação: (5 Parte - Dimensionamento Do Transformador E Suas Protecções)Documento4 páginasProjecto de Postos de Transformação: (5 Parte - Dimensionamento Do Transformador E Suas Protecções)Joaquim SamuelAinda não há avaliações

- Aumento de Produtividade e Economia de Energia Com Inversores de Frequencia e Soft StartersDocumento36 páginasAumento de Produtividade e Economia de Energia Com Inversores de Frequencia e Soft StarterslucianocostaAinda não há avaliações

- Hidrômetro Unijato Magnético Classe BDocumento4 páginasHidrômetro Unijato Magnético Classe BJuan Carlos Troche FernandezAinda não há avaliações

- WEG Disjuntores em Caixa Moldada DW 50009825 Catalogo PT PDFDocumento64 páginasWEG Disjuntores em Caixa Moldada DW 50009825 Catalogo PT PDFWendel GonçalvesAinda não há avaliações

- WEG Disjuntores em Caixa Moldada DW 50009825 Catalogo Portugues BRDocumento56 páginasWEG Disjuntores em Caixa Moldada DW 50009825 Catalogo Portugues BRMarcelo SouzaAinda não há avaliações

- Aula 13 EletrodutosDocumento10 páginasAula 13 EletrodutosTECCON Tecnologia em Concreto, Aço e SoloAinda não há avaliações

- Catalogo Enerpac - Chaves de Torque PDFDocumento12 páginasCatalogo Enerpac - Chaves de Torque PDFSalatiel MarquesAinda não há avaliações

- WEG Solucoes para Propulsao Tracao Eletrica 50042550 Catalogo Portugues BR PDFDocumento24 páginasWEG Solucoes para Propulsao Tracao Eletrica 50042550 Catalogo Portugues BR PDFAnderson AntunesAinda não há avaliações

- ED ES 2006 Relatorio Cabo 240Documento11 páginasED ES 2006 Relatorio Cabo 240DCT ProjetosAinda não há avaliações

- LimniDB CAPDocumento2 páginasLimniDB CAPFelipe Alfredo JahnAinda não há avaliações

- Ar CondicionadoDocumento6 páginasAr CondicionadoWill F AlvesAinda não há avaliações

- Ape 21Documento60 páginasApe 21jolinoraidias100% (1)

- Terminais de Conexão Olhal RTDocumento2 páginasTerminais de Conexão Olhal RTDaniel RoyoAinda não há avaliações

- Cont at Ores e Disjuntores GEDocumento12 páginasCont at Ores e Disjuntores GEpirugfAinda não há avaliações

- Cartilha Ligacao NovaDocumento12 páginasCartilha Ligacao NovaRenato Prazeres100% (2)

- PR-004 Rev6Documento20 páginasPR-004 Rev6Gésseca NatáliaAinda não há avaliações

- 81215M Position 07-2021 PorDocumento19 páginas81215M Position 07-2021 PorCristovao RendecaoAinda não há avaliações

- Sensores IndutivosDocumento4 páginasSensores IndutivosVictor Jorge SilvaAinda não há avaliações

- Aula 7 Dimensionamento I - Correntes de ElosDocumento29 páginasAula 7 Dimensionamento I - Correntes de ElosEdmilson Lima100% (2)

- Iom 50TJN-370 G-A-09 (256.10.088)Documento28 páginasIom 50TJN-370 G-A-09 (256.10.088)Flavio RicAinda não há avaliações

- Holmatro Rescue Tools Portugese 0208 PDFDocumento24 páginasHolmatro Rescue Tools Portugese 0208 PDFleonard farahAinda não há avaliações

- CDR Intense 2020Documento8 páginasCDR Intense 2020Itacio SantosAinda não há avaliações

- Descritivo TC500SDocumento1 páginaDescritivo TC500SRenato OliveiraAinda não há avaliações

- Aulas de QuimicaDocumento9 páginasAulas de QuimicaMarcus David Santos Da SilvaAinda não há avaliações

- Aula 3 - Ligações InteratômicasDocumento38 páginasAula 3 - Ligações InteratômicasThadilla SouzaAinda não há avaliações

- Fórmulas QuímicasDocumento4 páginasFórmulas QuímicasCarlosAinda não há avaliações

- Cafeteira - Philips-Walita - RI7546Documento3 páginasCafeteira - Philips-Walita - RI7546Saulo SouzaAinda não há avaliações

- Trabalho I - HistologiaDocumento2 páginasTrabalho I - HistologiaVALÉRIA SOARESAinda não há avaliações

- Modelo Relatorio QuimicaDocumento8 páginasModelo Relatorio QuimicaHiel OliveiraAinda não há avaliações

- Aspectos Macroscópicos II PROENEMDocumento3 páginasAspectos Macroscópicos II PROENEMThays BrandãoAinda não há avaliações

- Sequencia - Didatica UFABCDocumento8 páginasSequencia - Didatica UFABCJacques SouzaAinda não há avaliações

- Gases e Termodinamica para EEAR CFS1 2022 BDocumento8 páginasGases e Termodinamica para EEAR CFS1 2022 BJúlia GabrielaAinda não há avaliações

- Aços FerramentasDocumento7 páginasAços FerramentasFelipe AugustoAinda não há avaliações

- 6ano Atividadeciencias 06 11Documento2 páginas6ano Atividadeciencias 06 11GENYFER POLINE NERI DE SOUZAAinda não há avaliações

- Diagrama de Fases Fe Fe3CDocumento18 páginasDiagrama de Fases Fe Fe3CFlavianoAinda não há avaliações

- Virex Detergente - FISPQDocumento10 páginasVirex Detergente - FISPQMurilo PucineliAinda não há avaliações

- FISPQ Alphasyn T 32 (BR-PT)Documento13 páginasFISPQ Alphasyn T 32 (BR-PT)Tamara ScarpiniAinda não há avaliações

- Ecologia Química de Abelhas BrasileirasDocumento138 páginasEcologia Química de Abelhas BrasileirasMBAinda não há avaliações

- 2° Simulado IquimicaDocumento10 páginas2° Simulado IquimicaVinícius Borges Dos AnjosAinda não há avaliações

- 1 Trimestral - Questões Analítico - 8 AnoDocumento7 páginas1 Trimestral - Questões Analítico - 8 AnoJéssica MoraesAinda não há avaliações

- Riscos Ocupacionais Devido Aos Agentes QuímicosDocumento27 páginasRiscos Ocupacionais Devido Aos Agentes QuímicosJuliaAinda não há avaliações

- Manual Técnico Do Cimento Resinoso Dual Allcem Da FGMDocumento22 páginasManual Técnico Do Cimento Resinoso Dual Allcem Da FGMKarla de Oliveira MirandaAinda não há avaliações

- Exercícios - ELVDocumento4 páginasExercícios - ELVTayla LuizaAinda não há avaliações

- Falha de Materiais Devido À Fluência e À FadigaDocumento5 páginasFalha de Materiais Devido À Fluência e À FadigaFabien Lisias Alcantara DelebosseAinda não há avaliações

- Bula Amilase - ANALISADocumento2 páginasBula Amilase - ANALISAPaulo LauarAinda não há avaliações

- Solução Hemostatica Tópica - BiodinamicaDocumento3 páginasSolução Hemostatica Tópica - BiodinamicaLeonardo SoaresAinda não há avaliações

- Atividades de Quimica Prop. Gerais Da MatériaDocumento7 páginasAtividades de Quimica Prop. Gerais Da MatériamatheusAinda não há avaliações

- AULA PRATICA 1 - MicrotecnicaDocumento3 páginasAULA PRATICA 1 - MicrotecnicaJéssica N. CostaAinda não há avaliações

- Penq0763 DDocumento91 páginasPenq0763 DJosé FernandesAinda não há avaliações

- Aula7-Ni CompressedDocumento29 páginasAula7-Ni CompressedMarcio LuizAinda não há avaliações

- Relatório 5 Analítica - Marina de Freitas GuerraDocumento5 páginasRelatório 5 Analítica - Marina de Freitas GuerraMarina GuerraAinda não há avaliações

- Diluição de SoluçõesDocumento15 páginasDiluição de SoluçõesLucas Ribeiro Secondary.Ainda não há avaliações

- Aula 02 Fisica e Leis Do MergulhoDocumento27 páginasAula 02 Fisica e Leis Do MergulhoPaulo OliveiraAinda não há avaliações