Escolar Documentos

Profissional Documentos

Cultura Documentos

Desmopan 192

Enviado por

Ronaldo CamargoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Desmopan 192

Enviado por

Ronaldo CamargoDireitos autorais:

Formatos disponíveis

CAMPUS® Ficha de especificação

Desmopan 192 - TPU

Covestro Deutschland AG

Informação do produto

Injection molding grade

with high mechanical strength for articles subject to wear.

Application:

Shift lever balls

Roller tires

Coupling elements

Shoe heels

Propriedades mecânicas Valor Unidade Método de ensaio

Tensão em 10% de alongamento 4 MPa ISO 527-1/-2

Tensão em 100% de alongamento 9.5 MPa ISO 527-1/-2

Tensão em 300% de alongamento 17 MPa ISO 527-1/-2

Tensão na Ruptura 52 MPa ISO 527-1/-2

Deformação na Ruptura >300 % ISO 527-1/-2

Deformação permanente por compressão a 23°C 25 % ISO 815

Tempo 72 h -

Deformação permanente por compressão a 70°C, 24h 40 % ISO 815

Resistência ao rasgamento, paralelo 85 kN/m ISO 34-1

Resistência à abrasão 32 mm³ ISO 4649

Dureza Shore A 92 - ISO 48-4

Dureza Shore D 42 - ISO 48-4

Outras propriedades Valor Unidade Método de ensaio

Densidade 1230 kg/m³ ISO 1183

Last update: 2022-10-31 Source: https://www.campusplastics.com Page: 1/3

Desmopan 192 - TPU

Covestro Deutschland AG

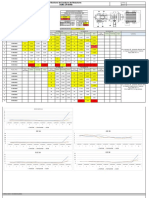

Diagrama

Viscosidade - taxa de cisalhamento Tensão de cisalhamento - taxa de cisalhamento

Viscosidade - taxa de cisalhamento Tensão de cisalhamento - taxa de cisalhamento

Desmopan 192 Desmopan 192

1E4 200 °C 1E7 200 °C

210 °C 210 °C

Tensão de cisalhamento in Pa

220 °C 220 °C

1E6

Viscosidade in Pa s

1E3

1E5

1E2

1E4

www.campusplastics.com www.campusplastics.com

1E1 1E3

1E1 1E2 1E3 1E4 1E5 1E1 1E2 1E3 1E4 1E5

Taxa de cisalhamento in 1/s Taxa de cisalhamento in 1/s

Módulo de cisalhamento dinâmico - temperatura

Módulo de cisalhamento dinâmico - temperatura

Desmopan 192

1E4 1E0

1E3

Módulo de cisalhamento in MPa

1E3 1E-1

1E2

1E2 1E-2

G" in MPa

1E1

tan d in

1E1 1E-3

1E0

1E0 1E-4

1E-1

1E-1 www.campusplastics.com

1E-2 1E-5

-100 -50 0 50 100 150 200

Temperatura in °C

Características

Processamento Disponibilidade regional

Moldagem por injeção Europa, Oriente/África

Outras informações

Moldagem por injeção

PREPROCESSING

Max. water content: 0.05 %

Max. drying temperature: 90 °C

Drying time:

Dry air dryer 1-2 h

PROCESSING

Melt temperature: 210-225 °C

Last update: 2022-10-31 Source: https://www.campusplastics.com Page: 2/3

Desmopan 192 - TPU

Covestro Deutschland AG

Mold temperature: 20-40 °C

Typical value

These values are typical values only. Unless explicitly agreed in written form, the do not constitute a binding material specification or

warranted values. Values may be affected by the design of the mold/die, the processing conditions and coloring/pigmentation of the

product. Unless specified to the contrary, the property values given have been established on standardized test specimens at room

temperature.

General

The manner in which you use and the purpose to which you put and utilize our products, technical assistance and information (whether

verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control.

Therefore, it is imperative that you test our products, technical assistance, information and recommendations to determine to your own

satisfaction whether our products, technical assistance and information are suitable for your intended uses and applications. This

application-specific analysis must at least include testing to determine suitability from a technical as well as health, safety, and

environmental standpoint. Such testing has not necessarily been done by Covestro.

Unless we otherwise agree in writing, all products are sold strictly pursuant to the terms of our standard conditions of sale which are

available upon request. All information and technical assistance is given without warranty or guarantee and is subject to change without

notice. It is expressly understood and agreed that you assume and hereby expressly release us from all liability, in tort, contract or

otherwise, incurred in connection with the use of our products, technical assistance, and information. Any statement or recommendation

not contained herein is unauthorized and shall not bind us. Nothing herein shall be construed as a recommendation to use any product in

conflict with any claim of any patent relative to any material or its use. No license is implied or in fact granted under the claims of any

patent.

Medical Grades

Only Covestro products that are designated as “Medical Grade”may be used in medical devices or intermediates of medical devices. The

designation as “Medical Grade” does not mean that Covestro or anyone else has determined that the product is suitable for use in any

particular Medical Application. Except when Covestro has expressly agreed in writing to the sale of these products for such applications,

Covestro products designated as “Medical Grade” shall not be considered candidates for any Medical Applications in: (a) cosmetic,

reconstructive or reproductive implants, (b) other body implants, (c) applications involving contact with or storage of human tissue, blood or

other bodily fluids for longer than 30 days, or (d) applications involving contact for longer than 24 hours with circulating blood, tissue, bone

or dentin.

For further information on the use of Covestro products in Medical Applications, please request from your sales support contact our

Guidance document: GUIDANCE ON USE OF COVESTRO PRODUCTS IN A MEDICAL APPLICATION.

plastics.covestro.com

Last update: 2022-10-31 Source: https://www.campusplastics.com Page: 3/3

Você também pode gostar

- FT - Vulkem 350 NF-SL - 345 - 346 LVDocumento7 páginasFT - Vulkem 350 NF-SL - 345 - 346 LVJuliana DiasAinda não há avaliações

- Texaco MeropaDocumento2 páginasTexaco MeropaRicardo Crispim da SilvaAinda não há avaliações

- Volkswagen Worker 17220 PDFDocumento4 páginasVolkswagen Worker 17220 PDFJailton Santos100% (2)

- Volkswagen Worker 17220Documento4 páginasVolkswagen Worker 17220jairoarchanjo100% (2)

- TA Resfriadores para Oleo 2020 v3Documento2 páginasTA Resfriadores para Oleo 2020 v3lilicaAinda não há avaliações

- Catálogo de O-Rings para Industria de Moldes 2020 - OnlineDocumento44 páginasCatálogo de O-Rings para Industria de Moldes 2020 - OnlineJoão MatosAinda não há avaliações

- MONIT - ctrl.TECNOLOGICO - Rev.00 - 21 Fev A 20 Mar - Calda - Injeção de ConsolidaçãoDocumento15 páginasMONIT - ctrl.TECNOLOGICO - Rev.00 - 21 Fev A 20 Mar - Calda - Injeção de Consolidaçãoluciano vieira VieiraAinda não há avaliações

- Ficha Técnica - Geomembrana de Polietileno de Alta Densidade Alvatech 5002Documento1 páginaFicha Técnica - Geomembrana de Polietileno de Alta Densidade Alvatech 5002Jose Araujo PepsAinda não há avaliações

- tc407 003Documento6 páginastc407 003Paulo SilvaAinda não há avaliações

- Ref. No. Descrição Ref. No. Descrição: Binários de Aperto (1) 34,5 3,5 NM Binários de Aperto 120 NM 45Documento30 páginasRef. No. Descrição Ref. No. Descrição: Binários de Aperto (1) 34,5 3,5 NM Binários de Aperto 120 NM 45Juarez Geronimo Da SilvaAinda não há avaliações

- Verion 2011 - e BombasDocumento51 páginasVerion 2011 - e Bombasjeferson clecioAinda não há avaliações

- Ficha Tecnica Gpps 525Documento1 páginaFicha Tecnica Gpps 525alvich17Ainda não há avaliações

- Tecnil - UniflonDocumento29 páginasTecnil - Uniflonlucascabralveiga39Ainda não há avaliações

- Eletroduto-Roscavel-13 CoflexDocumento5 páginasEletroduto-Roscavel-13 CoflexKaren PaolaAinda não há avaliações

- Tabela EletricistaDocumento2 páginasTabela EletricistaMarceloMeirellesAinda não há avaliações

- JPEREIRA02Documento1 páginaJPEREIRA02JefersonAinda não há avaliações

- 3 - Densit Wearflex HT Altas TemperaturasDocumento2 páginas3 - Densit Wearflex HT Altas TemperaturasIvo Nunes de OliveiraAinda não há avaliações

- Bakelite PF 51Documento3 páginasBakelite PF 51Rodrigo GhiroAinda não há avaliações

- DNER-EM364-97 Alcatrão para Pavimentação PDFDocumento3 páginasDNER-EM364-97 Alcatrão para Pavimentação PDFAntonio Jose PauloAinda não há avaliações

- Bombas Centrifugas SENAI e Planos de SelagemDocumento70 páginasBombas Centrifugas SENAI e Planos de SelagemLuis ReisAinda não há avaliações

- Resina Poliester Arazyn 4.7Documento2 páginasResina Poliester Arazyn 4.7Humberto BogazAinda não há avaliações

- Technical Specifications PT PT TEC05210044 2123Documento1 páginaTechnical Specifications PT PT TEC05210044 2123fiviloversAinda não há avaliações

- 2.ensaio Universal de FlexãoDocumento19 páginas2.ensaio Universal de FlexãoJoana AlmeidaAinda não há avaliações

- Linha TADocumento1 páginaLinha TACelio CostaAinda não há avaliações

- 3129-1989 - Talhas de Corrente Com Acionamento Motorizado - EnsaiosDocumento3 páginas3129-1989 - Talhas de Corrente Com Acionamento Motorizado - EnsaiosVilsonBorgesAinda não há avaliações

- Tabelas Eletrica IndustrialDocumento8 páginasTabelas Eletrica IndustrialcarlosmarciosfreitasAinda não há avaliações

- Tabela Do Eletricista - FinalDocumento2 páginasTabela Do Eletricista - Finalnewpec0% (1)

- Catálogo Motores TecmafDocumento8 páginasCatálogo Motores TecmafJean CarlosAinda não há avaliações

- 2023 01 13 167361555663c158c44bd7c.cleanedDocumento2 páginas2023 01 13 167361555663c158c44bd7c.cleanedAdriel da Silva GamaAinda não há avaliações

- 337-1987 - Líquidos Orgânicos Voláteis - Determinação Da Faixa de DestilaçãoDocumento12 páginas337-1987 - Líquidos Orgânicos Voláteis - Determinação Da Faixa de DestilaçãoVilsonBorgesAinda não há avaliações

- Sem 39 Monitoreo Tem - Vibr de ReductoresDocumento2 páginasSem 39 Monitoreo Tem - Vibr de Reductoreskenny arturo cainicela alvinoAinda não há avaliações

- Modelo 6 X 36 WS AACIDocumento9 páginasModelo 6 X 36 WS AACIlaertetito92Ainda não há avaliações

- Thomas Poli 2018Documento69 páginasThomas Poli 2018Thomas CarmonaAinda não há avaliações

- Ipiflex Li EP - 250619Documento2 páginasIpiflex Li EP - 250619joaquim pedro thomazelli de castroAinda não há avaliações

- Dimensionam. de Engrenagens Cilíndricas Com Dentes Retos-1Documento10 páginasDimensionam. de Engrenagens Cilíndricas Com Dentes Retos-1Marcio ChiaratoAinda não há avaliações

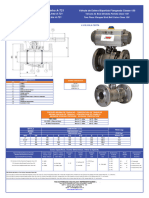

- Valvula Esferica BipartidaDocumento2 páginasValvula Esferica Bipartidaservices.purchase2Ainda não há avaliações

- Certificado Fita de VedaçãoDocumento1 páginaCertificado Fita de VedaçãopaulomattusAinda não há avaliações

- SDFDocumento10 páginasSDFPVelozoAinda não há avaliações

- REG - Ensaios Argamassa Basica FMDocumento5 páginasREG - Ensaios Argamassa Basica FMEdson Ferreira do NascimentoAinda não há avaliações

- Folder Painel Caract TecnicasDocumento1 páginaFolder Painel Caract TecnicascaduAinda não há avaliações

- Detalle de Refuerzo VIGA - TIPICADocumento1 páginaDetalle de Refuerzo VIGA - TIPICACésar Julián González GamboaAinda não há avaliações

- The Study of Heat-Mass Transfer Characteristics and Multi-Objective Optimization On Electric Arc FurnaceDocumento12 páginasThe Study of Heat-Mass Transfer Characteristics and Multi-Objective Optimization On Electric Arc FurnaceDaiara Budi AlvesAinda não há avaliações

- Linha 15 TonDocumento4 páginasLinha 15 TonCristyan GabrielAinda não há avaliações

- DB 717 PTDocumento26 páginasDB 717 PTehferreiraAinda não há avaliações

- Catálogo - Cabos Navais PANNAV PN de Baixa Tensão 0,6:1kV - Pan ElectricDocumento1 páginaCatálogo - Cabos Navais PANNAV PN de Baixa Tensão 0,6:1kV - Pan ElectricStephano FigueiredoAinda não há avaliações

- Ficha Tecnica Super Tauro Sintetico PT BR tcm82-206055Documento2 páginasFicha Tecnica Super Tauro Sintetico PT BR tcm82-206055assessorinterno2Ainda não há avaliações

- Válvulas Offshore - Qualificação de Válvulas - Alexandre Migoranço - Rev - 00Documento103 páginasVálvulas Offshore - Qualificação de Válvulas - Alexandre Migoranço - Rev - 00albertofilho6Ainda não há avaliações

- Folder Válvulas TAGDocumento12 páginasFolder Válvulas TAGRonesAinda não há avaliações

- 2014 Empanques Geral WEBDocumento20 páginas2014 Empanques Geral WEBVicit GrupoAinda não há avaliações

- Ar 260Documento2 páginasAr 260Lucas MouraAinda não há avaliações

- Ensaio de Torção e Compressão - Ressistencia Dos MateriaisDocumento6 páginasEnsaio de Torção e Compressão - Ressistencia Dos Materiaishemilly.klestyAinda não há avaliações

- NBR 09240 - 1986 - Proteção Catódica PDFDocumento5 páginasNBR 09240 - 1986 - Proteção Catódica PDFMarcos SerrãoAinda não há avaliações

- Fispq Intertuf 262 Kha 062Documento4 páginasFispq Intertuf 262 Kha 062Flaviana Ribeiro O MoreiraAinda não há avaliações

- Veb C150-300Documento2 páginasVeb C150-300cvfAinda não há avaliações

- Ficha EMDDocumento2 páginasFicha EMDAndreArmaniniAinda não há avaliações

- Valvula de Descarga Hiter.86pDocumento2 páginasValvula de Descarga Hiter.86pMCDANIELAinda não há avaliações

- CHECELTAMC15 - Celta 1 - 4 8V - Valores de Torques Do MotorDocumento1 páginaCHECELTAMC15 - Celta 1 - 4 8V - Valores de Torques Do MotorAllexandro L OliveiraAinda não há avaliações

- Celesc TransformadoresDocumento47 páginasCelesc TransformadoresFabio CollaçoAinda não há avaliações

- Pisos Cerâmicos Antiderrapantes E/ou Antideslizantes?No EverandPisos Cerâmicos Antiderrapantes E/ou Antideslizantes?Ainda não há avaliações

- Suspensao Pneumatica H400 V6Documento1 páginaSuspensao Pneumatica H400 V6Ronaldo CamargoAinda não há avaliações

- TSW 6008 A PretoDocumento1 páginaTSW 6008 A PretoRonaldo CamargoAinda não há avaliações

- Suspensao Pneumatica S400 V6Documento1 páginaSuspensao Pneumatica S400 V6Ronaldo CamargoAinda não há avaliações

- Suspensao Pneumatica Quadro AutodirecionalDocumento1 páginaSuspensao Pneumatica Quadro AutodirecionalRonaldo CamargoAinda não há avaliações

- Clarividência - Charles Leadbater PDFDocumento80 páginasClarividência - Charles Leadbater PDFTiago Lopes100% (1)

- A Porta Aberta - Peter BrookDocumento34 páginasA Porta Aberta - Peter BrookAureliano Lopes100% (4)

- Texto Definitivo Do Doente Imaginario - PortuguesDocumento44 páginasTexto Definitivo Do Doente Imaginario - PortuguesVictor Luvizotto Rodrigues100% (6)

- Resumo o Doente Imaginario MoliereDocumento2 páginasResumo o Doente Imaginario MoliereRonaldo CamargoAinda não há avaliações

- Idec Orcamento DomesticoDocumento48 páginasIdec Orcamento DomesticoAugusto JordãoAinda não há avaliações

- R - e - Rafael Francisco KoppeDocumento42 páginasR - e - Rafael Francisco KoppeRonaldo CamargoAinda não há avaliações

- LubrizolDocumento31 páginasLubrizolRonaldo CamargoAinda não há avaliações

- Susan Sontag Contra A InterpretacaoDocumento43 páginasSusan Sontag Contra A InterpretacaoLu ChiAinda não há avaliações

- Ebook Convenia - Como Cuidar Da Sade Mental e Emocional Dos ColaboradoresDocumento23 páginasEbook Convenia - Como Cuidar Da Sade Mental e Emocional Dos ColaboradoresRonaldo CamargoAinda não há avaliações

- Mas-Tin Converted by AbcdpdfDocumento53 páginasMas-Tin Converted by AbcdpdfRonaldo CamargoAinda não há avaliações

- Palestra AnsiedadeDocumento10 páginasPalestra AnsiedadeRonaldo CamargoAinda não há avaliações

- Catalogo Interplast - 5 Edicao 3Documento139 páginasCatalogo Interplast - 5 Edicao 3Ronaldo CamargoAinda não há avaliações

- Cena LobotomiaDocumento2 páginasCena LobotomiaRonaldo CamargoAinda não há avaliações

- Mil Platôs Vol. 1 PDFDocumento94 páginasMil Platôs Vol. 1 PDFPaulo VictorAinda não há avaliações

- A - Tolerâncias Dimensionais e Acabamentos SuperficiaisDocumento26 páginasA - Tolerâncias Dimensionais e Acabamentos Superficiaisdm_spawn100% (1)

- 2022-10-04 - ArcelorMittal - 50S-RA - Soldável - AR.r01Documento7 páginas2022-10-04 - ArcelorMittal - 50S-RA - Soldável - AR.r01Giuliano QuirogaAinda não há avaliações

- Aula 3 - Cubos de Roda e RolamentosDocumento44 páginasAula 3 - Cubos de Roda e RolamentosJoão SoaresAinda não há avaliações

- PPM 3BDocumento25 páginasPPM 3BIcaro OliveiraAinda não há avaliações

- Significado Numero Dos FiosDocumento11 páginasSignificado Numero Dos FiosGabrielAinda não há avaliações

- OPERAÇÕES UNITÁRIAS II AULA 13 - EVAPORADORES E CONGELAMENTO. Profa. Dra. Milena Martelli TosiDocumento9 páginasOPERAÇÕES UNITÁRIAS II AULA 13 - EVAPORADORES E CONGELAMENTO. Profa. Dra. Milena Martelli TosiRaquel FernandesAinda não há avaliações

- Catálogo Escavadeira DX 140 LC PDFDocumento12 páginasCatálogo Escavadeira DX 140 LC PDFGabriely Murilo75% (4)

- Vol 1 - PARTE II - T3 - Resultantes Tangencial e CentrípetaDocumento25 páginasVol 1 - PARTE II - T3 - Resultantes Tangencial e Centrípetaconde cosmopolitaAinda não há avaliações

- Laudo de Conformidade Técnica Eletromecânico de Veículo - Placa Epu 6564 - Caminhão ApoioDocumento14 páginasLaudo de Conformidade Técnica Eletromecânico de Veículo - Placa Epu 6564 - Caminhão Apoiomtm1234100% (4)

- Motor de Passo Nema 23 Torque 15 00 KGFCM Corrente 3 00 A Dat I000389 2Documento4 páginasMotor de Passo Nema 23 Torque 15 00 KGFCM Corrente 3 00 A Dat I000389 2wagnermeneAinda não há avaliações

- Checape CarroDocumento4 páginasChecape CarroLeandro AtivistaAinda não há avaliações

- Acoplamento VoithDocumento12 páginasAcoplamento Voithguidd1Ainda não há avaliações

- Aparadotor TramontiniDocumento15 páginasAparadotor TramontiniDiego Roberto Bonatto100% (1)

- Elementos de Fixacao Chavetas - Aula 10 - WordDocumento32 páginasElementos de Fixacao Chavetas - Aula 10 - WordDASILVAERICK53Ainda não há avaliações

- Programa Estruturas de Betão IDocumento3 páginasPrograma Estruturas de Betão IEmerson ChissamaAinda não há avaliações

- Apresentação Hidráulica 3a Aula - 2013.1 HidrodinamicaDocumento30 páginasApresentação Hidráulica 3a Aula - 2013.1 HidrodinamicaTstAdriano100% (1)

- Escoamentos Uniformes em CanaisDocumento6 páginasEscoamentos Uniformes em CanaisRenato De Marchi Vieira Dos SantosAinda não há avaliações

- Aula 1 Motores Eletricos-IntroducaoDocumento13 páginasAula 1 Motores Eletricos-IntroducaorodolfoloveraAinda não há avaliações

- Dinâmica Do Corpo RigidoDocumento107 páginasDinâmica Do Corpo RigidoUemerson CoelhoAinda não há avaliações

- Aula 12 Sistema HidráulicoDocumento3 páginasAula 12 Sistema HidráulicojefersonAinda não há avaliações

- 9 Ficha de Fisica ClasseDocumento3 páginas9 Ficha de Fisica Classeneilover100% (1)

- Cs533E, Cs533E XT, Cp533E: Compactadores Vibratórios de SoloDocumento12 páginasCs533E, Cs533E XT, Cp533E: Compactadores Vibratórios de SoloRogeana RibeiroAinda não há avaliações

- Manual de Servico Facilita 2868Documento135 páginasManual de Servico Facilita 2868andersondelgadogomesAinda não há avaliações

- Manual Migflex 160 BV 2vDocumento35 páginasManual Migflex 160 BV 2veduardocasarim1604Ainda não há avaliações

- Ondas PDFDocumento4 páginasOndas PDFRui FernandesAinda não há avaliações

- AULA 06 - Edifícios em Concreto Armado - 050423Documento13 páginasAULA 06 - Edifícios em Concreto Armado - 050423Mikael TobiasAinda não há avaliações

- P09 - Momento de InérciaDocumento4 páginasP09 - Momento de InérciaJuan SilvaAinda não há avaliações

- Agrale VolareDocumento6 páginasAgrale VolareSetor De ComprasAinda não há avaliações

- Carga Térmica - Renovação e Infiltração 2017Documento19 páginasCarga Térmica - Renovação e Infiltração 2017Jose Gomes100% (1)

- Egys90clp 513701340Documento4 páginasEgys90clp 513701340Jenifer MoraisAinda não há avaliações