Escolar Documentos

Profissional Documentos

Cultura Documentos

Barras de Cereal Con Yaca Deshidratada y Harina de Semilla de Yaca

Enviado por

Karina MartinezDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Barras de Cereal Con Yaca Deshidratada y Harina de Semilla de Yaca

Enviado por

Karina MartinezDireitos autorais:

Formatos disponíveis

DOI: 10.4025/actascitechnol.v33i1.

6425

Characterization and sensorial evaluation of cereal bars with jackfruit

Calila Teixeira Santos, Renata Ferreira Bonomo, Rafael da Costa Ilhu Fontan,

Paulo Bonomo, Cristiane Martins Veloso and Gabrielle Cardoso Reis Fontan

Laboratrio de Engenharia de Processos, Universidade Estadual do Sudoeste da Bahia, Praa Primavera, 40, 45700-000,

Itapetinga, Bahia, Brazil. *Author for correspondence. E-mail: bonomorcf@pq.cnpq.br

ABSTRACT. The objective of this study was to elaborate a homemade and alternative

cereal bar using dehydrated jackfruit and seed meal as fiber source, due to the availability of

this fruit in the region, without reducing the nutritional values if comparing to those

already existent in the market. In order to evaluate the centesimal content and the

acceptance of the homemade bars, both light and traditional bars were used as reference.

The results showed that the elaborated bar presented protein values very close with

products already found in the market. However, the new bars presented higher content of

fibers. Formulations of 30 and 40% of seed meal were the ones with the best acceptance.

Keywords: functional product, Artocarpus integrifolia, nutritional value, food fiber, jackfruit.

RESUMO. Caracterizao e avaliao sensorial de barras de cereais com jaca.

Objetivou-se com o presente trabalho elaborar uma barra de cereal caseira e alternativa,

utilizando a jaca desidratada e o farelo da semente como fonte de fibras, a fim de aproveitar a

disponibilidade dessa fruta regional, sem reduzir o valor nutricional em relao s existentes

no mercado. Para avaliar a composio centesimal e aceitao das barras caseiras foram

utilizadas barras comerciais na forma light e tradicional, como parmetros de referncias. Os

resultados obtidos demonstraram que a barra formulada apresentou valores bem prximos

aos produtos comercializados no mercado no que se refere protena, mas com teores de

fibras superiores. As formulaes com 30 e 40% de teor de farelo da semente foram as que

tiveram maior aceitao.

Palavras-chave: produto funcional, Artocarpus integrifolia, valor nutricional, fibra alimentar, jaca.

Introduction

Due to the easiness of acquiring pre-prepared

and frozen food in the market, together with

several options offered by fast-foods and selfservice restaurants, the consumption of this type

of food has increased. Nowadays, eating habits

have demonstrated low ingestion of fiber, which

leads to nutritional problems (FREITAS;

MORETTI, 2006). According to few authors,

high ingestion of fiber is recommended for

intestinal treatments of adults and children. The

regular consumption of fiber is constantly

recommended by nutritionists and official food

departments (SUN-WATERHOUSE et al.,

2010). Such recommendations are based on the

fact that fiber presents certain effects responsible

for

significant

modifications

in

human

physiology,

preventing

chronic

diseases

(DREHER,

1999;

AACC,

2001).

The

consumption of fatty food, with high energetic

density and the reduction in practicing exercises

have strongly influenced nutritional problems for

Acta Scientiarum. Technology

the youth and adults worldwide. Among these

problems it is worth to point out obesity and

hypertension (BRITO et al., 2004).

Cereal bars appear due to the necessity of

having a product combining easiness and

nutritional quality, in order to either improve or

substitute snacks between meals, to complement

meals, or simply gain energy in a healthy way

(MURPHY, 2001; DUTCOSK et al., 2006;

RYLAND et al., 2010). The consumption of

cereal bars has increased mainly among young

consumers. Recent research has showed that

young adults raging from 15 to 24 years old

represent 62.5% of the consumers of cereal bars

(BRITO et al., 2004).

Food industries have sought to identify and to

attend consumers needs, considering that this is

the only way they can maintain themselves in an

increasingly

competitive

market.

The

determination of acceptance by the consumer is a

crucial part in a development and improvement

process of products. Affective tests require a team

Maring, v. 33, n. 1, p. 81-85 2011

82

composed of several participants who represent

the consumers population and/or potential

consumers. Among these most applied methods

used to measure acceptance of products is the

hedonic scale, in which consumers express their

acceptance following a pre-established scale,

which gradually varies based on terms such as like

and dislike (MORI et al., 1998; SILVA et al.,

2005).

Jackfruit (Artocarpus integrifolia), is originally

from Asia and it has acclimated well in Brazil. It is

a fruit rich in carbohydrates, complex B vitamins,

and minerals (RAHMAN et al., 1999;

JAGADEESH et al., 2007, SOUZA et al., 2009).

Jackfruit is freshly consumed, and it can be

processed to candies, sweeties, frozen pulps,

juices, among others. Its seed can be consumed

baked or used in culinary to develop several

menus. Nowadays, there are studies concerning

the use of seed meal for preparing cookies,

sweeties, and bread as an alternative source of

carbohydrate.

The shortage of low-cost products with high

nutritional value has gathered researches to seek

for alternative protein sources which attend to

matters concerning low production costs.

Due to its different flavor, jackfruit can

become an innovator ingredient of cereal bars,

which offers an exotic flavor, and an increase in

its nutritional quality. Also, it can be used for

reducing production costs due to its low cost.

Therefore, the objective of this study it to

elaborate a homemade and alternative cereal bar

of jackfruit without reducing nutritional values

comparing to those already available for

consumers.

Material and methods

Jackfruit was obtained in the free market of

Itapetinga and region. They were opened and seeds

were selected. The last were washed in water in

order to remove fiber, dried at room temperature,

and ground. Further, the product was stored in

plastic recipients at room temperature. Jackfruit pulp

with 75.4% (wet basis) of moisture was dried in a

trail drier at 65C with an air velocity of 1.5 m s-1,

for 6 hours, until a moisture content near to 20%

(wet basis), and then it was submitted to grounding.

Three formulations of cereal bars were tested, with a

variation only in relation to dehydrated jackfruit

Acta Scientiarum. Technology

Santos et al.

seed meal, respectively 50:50, 60:40 and 70:30 for

formulations I, II and III. These relationships were

used to verify the influence of seed meal

concentration on product acceptance. Cereal bars

were prepared according to the formulation

presented in Table 1.

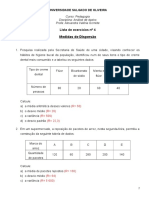

Table 1. Final formulation of jackfruit cereal bars.

Formulations (g 100 g-1)

I

II

III

25.5 g

25.5 g

25.5 g

14 g

14 g

14 g

2.5 g

2.5 g

2.5 g

10 g

10 g

10 g

10 g

10 g

10 g

19 g

22.8 g

26.6 g

19 g

15.2 g

11.4 g

Ingredient

Sugar

Glucose syrup

Vegetable fat

Fine oat

Thick oat

Dehydrated Jackfruit

Seed meal

Elaboration of bars

The ingredients were mixed manually in a plastic

recipient for 20 minutes approximately, until

obtaining homogeneous mass. Furthermore, the

mass was put on aluminum trays covered with

aluminum paper and submitted to the oven at

110C for 15 minutes. After cooling, bars were cut,

wrapped with flexible film and let at rest until

analyses. Cereal bars were produced in the morning

and sensorial analyses carried out in the afternoon at

the same day. The Figure 1 shows the production of

different cereal bars.

Jack

Dehydration

fruit

Grinding

Toasting Seed meal

Dry ingredients

Mixture

Glucose syrup

Homogenize

Shape

Heating

Colling

Cut

Packing

Figure 1. Scheme of elaboration of cereal bars.

Maring, v. 33, n. 1, p. 81-85, 2011

Cereal bars with jackfruit

Proximate analysis

Dehydrated jackfruit, seed meal and cereal bars

were submitted to physical chemical analyses for

protein determination (Kjeldahl method), fat

(Soxhlet method), ash content, and moisture

content in a oven at 105C, as described by AOAC

(1996) and determination of pure fiber in accordance

to the method described by Silva and Queiroz (2002).

Samples of 50 g by repetition were used to analyses,

conduced in triplicate each one.

Sensory analysis

Samples of each formulation of cereal bars

were evaluated by 60 non-trained testers ranging

from 18 to 50 years old, of both sexes. Acceptance

test was conducted in individual cabins under

light bulb, at the Laboratory of Sensory Analysis

located at the Southwest Bahia State University.

Samples of cereal bars were presented to

testers under room temperature, in a three digit

code. The order of presentation was randomly

established by the design of a table of numbers.

The section was conducted presenting three

samples of cereal bars corresponding to three

formulations varying in their seed meal content

and dehydrates jackfruit in 50/50 (formulation I),

40/60 (formulation II) and 30/70 (formulation

III), monadically presented. The hedonic scale

was structured in nine points, which the

minimum grade corresponded to the term

extremely disliked and the highest grade

corresponded to the term extremely liked. The

following characteristics were evaluated by the

tester: global impression, aroma, flavor, color, and

texture.

Statistical analysis

In order to test the differences among the

formulation, the Analysis of Variance (ANOVA)

was conducted. Data obtained from the sensorial

analysis were evaluated using the Analysis of

Variance (ANOVA), comparing averages using

Duncans test at 10% probability, using the

statistic software SAEG v 8.1 (RIBEIRO

JUNIOR, 2001).

Results and Discussion

Characterization of the raw-material and cereal bars

The values of protein, lipids, ashes and moisture

content of the three formulations found in this work

Acta Scientiarum. Technology

83

were not different among themselves. Results of

centesimal content of elaborated cereal bars, as well

as dehydrated jackfruit and seed meal are shown in

Table 2. The formulations of cereal bars presented

in an average 4.8 and 4.6% of protein, a desirable

value if compared to values found in the market

(which average values range from 3.0 to 4.0%). Seed

meal presented a considerable protein value (4.61%)

taking into account that it is a residual.

Formulations I, II and III contain, in percentages,

proteins from FJ (seed meal) + JD (dehydrated

jackfruit) of 76.76%, 75.43 and 72.17%, in dry

bases. According to the results shown in Table 2,

one verifies that the selection of fruit and seed

meal as a protein source is adequate, because

dehydrated jackfruit and seed meal contributes to

75% of the protein content of this cereal bar, and

the rest was from the oat. Brito et al. (2004), once

formulating cereal bars, obtained higher protein

values (6.27 g 100 g-1) if compared to those

obtained in this study (4.8 and 4.6 g 100 g -1). This

may be explained by the use of oat formulation

and corn starch cookies, which probably had more

influence in the total protein content of the bar if

compared to seed meal and dehydrated jackfruit

used in the formulations of this study. Lipid

content in bars I, II and III, if compared to bars of

other authors (BRITO et al., 2004; FREITAS;

MORETTI, 2006) was high. This was probably

due to the amount of hydrogenated fat (2.5 g 100

g-1) used in these formulations. The objective of

this addition was to avoid water addition in order

to promote uniformity, due to the fact that water

could promote rehydration of jackfruit, which is

not interesting if concerning the final texture of

the bar. According to Mattos and Martins (2000),

the value found for fibers (among 4.10 and 4.60 g

100 g-1) allows to classify homemade cereal bars as

a product of moderate fiber content.

Comparing portions of the product (25 g-1) with

brands found in the market, as described in Table 3,

it may be observed that the lipid value found in this

study is close to the ones commercially used.

Regarding carbohydrate and fiber contents,

elaborated bars presented a lower carbohydrate

content and higher fiber content if compared to

other bars. This fact may be explained by the

addition of seed meal, which has high total fiber

content (24.4 g 100 g-1) and low carbohydrate

content (3.76 g 100 g-1).

Maring, v. 33, n. 1, p. 81-85, 2011

84

Santos et al.

Table 2. Approximate centesimal content (% wet base) of jackfruit cereal bar.

Dehydrated jackfruit

271.18

2.730.03

1.940.02

2.470.03

19.830.09

63.43

9.600.30

Caloric value (kcal 100 g-1)

Protein (Nx6.25)

Fat

Ash

Moisture

Carbohydrate*

Fiber

Seed meal

242.88

4.610.04

0.800.007

12.120.09

54.310.10

3.76

24.400.25

Formulation I

419.06

4.800.035

8.680.04

1.590.03

21.020.09

42.50

4.600.09

Formulation II

414.85

4.600.029

6.220.03

1.380.029

21.400.08

44.10

4.100.09

Formulation III

413.21

4.600.03

7.810.03

1.560.025

20.260.10

45.40

4.500.08

*Calculated by difference.

Table 3. Centesimal content of Formulations I, II and III of

cereal bars and commercial bars (D (light) and E (traditional)).

I

10.625

2.17

1.21

1.15

Carbohydrate (g)

Fat (g)

Protein (g)

Fiber (g)

II

11.025

1.56

1.15

1.03

III

11.350

1.95

1.15

1.13

D*

19.000

1.00

1.00

1.00

E*

17.000

4.00

1.00

1.00

and C are among 7 and 9, which indicates

moderately liked and extremely liked.

Furthermore, more than 25% of the grades

concerning flavor of the three formulations were

among this same grade interval.

*Composition of labels.

The grades given by testers concerning sensorial

preference is shown in Table 4. The three

formulations presented a good sensory acceptance,

in a general standpoint. However, texture sensation

caused by the combination of the ingredients

obtained lower averages of sensory preference.

Frequency (%)

Sensory analysis

Table 4. Averages of grades given by testers for sensorial preferences

of jackfruit cereal bars.1

Formulation

III

II

I

Aroma

Color

Taste

Texture

6.9 a

6.5 a

5.9 b

6.9a

6.6a

6.1b

7.1a

6.8a

5.9b

6.6a

6.3ab

5.7b

Global

Impression

7.1a

6.8ab

6.3 b

Means, in the same column, followed by the same letter are not significantly different

(Duncans test, p > 0.1).

Concerning sensory characteristics: global

impression and texture, formulation II obtained

intermediary average, which did not significantly

differed (p > 0.1) from Formulations III

(30% of seed meal) and I (50% of seed meal).

Regarding color and aroma, Formulation III,

with a lower content of seed meal (30%) obtained

the best averages (6.9 and 6.9, respectively), but it

did not significantly differed (p > 0.1) from

Formulation II which contained 40% of seed meal.

Considering taste, Formulation III obtained the

highest grade, 7.1, but it did not significantly

differed (p > 0.1) from Formulation II. Formulation

1 which contains 50% of dehydrated jackfruit and

50% of seed meal presented lower preference grades

if compared to the others.

Figure 2 shows the frequency of grades for the

following characteristics: Global Impression and

Flavor, due to the relevance of these characteristics,

from the three formulation of jackfruit cereal bar. It

is possible to verify that 30% of the grades

concerning Global Impression for formulations B

Acta Scientiarum. Technology

Hedonic scale score

Figure 2. Distribution of grade frequencies for global impression

and taste of the three formulations of jackfruit cereal bar.

Conclusion

Based on the obtained results we can conclude

that the cereal bar elaborated from seed meal of

jackfruit and dehydrated jackfruit satisfactorily

attends nutritional values if compared to other in the

market. Concerning sensorial characteristics,

formulations containing 30 and 40% of seed meal of

jackfruit were preferred by testers. Regarding

nutritional value, the variation of seed meal and

dehydrated jackfruit content did not present

significant differences. However, if considering the

testers acceptance, the best formulation is the one

which contains 40% of seed meal and 60% of

dehydrated jackfruit, due to the use of higher

amount of seed meal. Moreover, this formulation

did not differ from formulations containing 30% of

seed meal and 60% of dehydrated jackfruit.

Acknowledgements

The authors would like to thank the Bahia

State Research Fund Agency (Fapesb) and CNPq

for their financial support.

Maring, v. 33, n. 1, p. 81-85 2011

Cereal bars with jackfruit

References

AACC-American Association of Cereal Chemists. The

definition of dietary fibre. Cereal Foods World, v. 46,

n. 3, p. 112-129, 2001.

AOAC-Association of Official Analytical Chemists.

Official methods of analysis. 16th ed. Gaithersburg,

1996.

BRITO, I. P.; CAMPOS, J. M.; SOUZA, T. F. L.;

WAKIYAMA, C.; AZEREDO, G. A. Elaborao e

avaliao global de barra de cereais caseira. Boletim

CEPPA, v. 22, n. 1, p. 35-50, 2004.

DREHER, M. Food sources and uses of dietary fibre. In:

CHO, S. S. (Ed.). Complex carbohydrates in foods.

New York: Marcel Dekker, 1999. p. 385-394.

DUTCOSKY, S. D.; GROSSMANN, M. V. E.; SILVA,

S. S. F. R.; WELSCH, A. K. Combined sensory

optimization of a prebiotic cereal product using

multicomponent mixture experiments. Food Chemistry,

v. 98, n. 4, p. 630-638, 2006.

FREITAS, D. G. C.; MORETTI, R. H. Caracterizao e

avaliao sensorial de barra de cereais funcional de alto

teor protico e vitamnico. Cincia e Tecnologia de

Alimentos, v. 26, n. 2, p. 318-324, 2006.

JAGADEESH, S.; REDDY, L. B. S.; SWAMY, G. S. K.;

GORB, K.; RAGHAVAN, G. S. V. Chemical composition

of jackfruit (Artocarpus heterophyllus) selections of Western

Ghats of India. Food Chemistry, v. 102, n. 1, p. 361-365,

2007.

MATTOS, L. L.; MARTINS, I. S. Consumo de fibras

alimentares em populao adulta. Revista de Sade

Pblica, v. 34, n. 1, p. 50-55, 2000.

MORI, E. E. M.; YOTSUYANAGI, K.; FERREIRA, V. L. F.

Anlise sensorial de goiabadas de marcas comerciais. Cincia

e Tecnologia de Alimentos, v. 18, n. 1, p. 105-110, 1998.

MURPHY, O. Non-polyol low-digestible carbohydrates:

Acta Scientiarum. Technology

85

food applications and functional benefits. British Journal

of Nutrition, v. 85, suppl. 1, p. 47-53, 2001.

RAHMAN, M. A.; NAHAR, N.; JABBAR, M. A.;

MOSIHUZZAMAN, M. Variation of carbohydrate

composition of two forms of fruit from jack tree

(Artocarpus heterophyllus) with maturity and climatic

conditions. Food Chemistry, v. 65, n. 1, p. 91-97, 1999.

RIBEIRO JNIOR, J. I. Anlises estatsticas no

SAEG. Viosa: UFV, 2001.

RYLAND, D.; VAISEY-GENSER, M.; ARNTFIELD, S.

D.; MALCOLMSON, L. J. Development of a nutritious

acceptable snack bar using micronized flaked lentils, Food

Research International, v. 43, n. 2, p. 642-649, 2010.

SILVA, A. F.; MINIM, V. P. R.; RIBEIRO, M. M. Anlise

sensorial de diferentes marcas comerciais de caf (Coffea

arabica L.) orgnico. Cincia e Agrotecnologia, v. 29,

n. 6, p. 1224-1230, 2005.

SILVA, D. J; QUEIROZ, A. C. Anlise de Alimentos:

mtodos qumicos e biolgicos. Viosa: UFV, 2002.

SOUZA, T. S.; CHAVES, M. A.; BONOMO, R. C. F.;

SOARES, R. D.; PINTO, E. G.; COTA, I. R.

Desidratao osmtica de frutculos de jaca (Artocarpus

integrifolia L.): aplicao de modelos matemticos. Acta

Scientiarum. Technology, v. 31, n. 2, p. 225-230, 2009.

SUN-WATERHOUSE,

D.;

TEOH,

A.;

MASSAROTTO, C.; WIBISONO, R.; WADHWA, S.

Comparative analysis of fruit-based functional snack bars.

Food Chemistry, v. 119, n. 4, p. 1369-1379, 2010.

Received on February 27, 2009.

Accepted on November 18, 2009.

License information: This is an open-access article distributed under the terms of the

Creative Commons Attribution License, which permits unrestricted use, distribution,

and reproduction in any medium, provided the original work is properly cited.

Maring, v. 33, n. 1, p. 81-85, 2011

Você também pode gostar

- Bioactive Compounds of Jaboticaba (Plinia sp.)No EverandBioactive Compounds of Jaboticaba (Plinia sp.)Ainda não há avaliações

- 94-Texto Do Artigo-659-1-10-20191218Documento16 páginas94-Texto Do Artigo-659-1-10-20191218Artur MktAinda não há avaliações

- 16288-Texto Do Artigo-62959-72452-10-20220216Documento7 páginas16288-Texto Do Artigo-62959-72452-10-2022021603ctadriveAinda não há avaliações

- Métodos de Conservação de Frutos Na Pós-ColheitaDocumento9 páginasMétodos de Conservação de Frutos Na Pós-ColheitaLid SantosAinda não há avaliações

- TCC NutriçãoDocumento22 páginasTCC NutriçãoAlexia 97Ainda não há avaliações

- Avaliação Sensorial de Docinho Elaborado Com Polpa e Casca de BananaDocumento6 páginasAvaliação Sensorial de Docinho Elaborado Com Polpa e Casca de Bananadilzinha9006Ainda não há avaliações

- Banana Flour Spouted BedDocumento7 páginasBanana Flour Spouted BedMarcelo LopesAinda não há avaliações

- Resumo ExpandidoDocumento3 páginasResumo ExpandidoBruno CostaAinda não há avaliações

- Artigo 1 - Porphyra Tenera Ciências Biológicas Artigo CientíficoDocumento6 páginasArtigo 1 - Porphyra Tenera Ciências Biológicas Artigo CientíficoClarisse LealAinda não há avaliações

- Document 2Documento10 páginasDocument 2Cíntia AgustoniAinda não há avaliações

- Arevalo-Pinedo Et Al 2013Documento8 páginasArevalo-Pinedo Et Al 2013Ana Claudia Hertel PereiraAinda não há avaliações

- 1981 6723 BJFT 20 E2016119Documento8 páginas1981 6723 BJFT 20 E2016119AngeloDeLaRamaAinda não há avaliações

- Biosaude, Gerente Da Revista, 24339-109024-1-CEDocumento7 páginasBiosaude, Gerente Da Revista, 24339-109024-1-CERosyleide PereiraAinda não há avaliações

- 2003 - Cultivo e Composição Cogumelo Do Sol - C Shibata - 12pgDocumento12 páginas2003 - Cultivo e Composição Cogumelo Do Sol - C Shibata - 12pgRichard G. WuestefeldAinda não há avaliações

- A Viabilidade Financeira de Produzir Alimentos Orgânicos para ADocumento17 páginasA Viabilidade Financeira de Produzir Alimentos Orgânicos para ASerli AndradeAinda não há avaliações

- Barbara 2003Documento256 páginasBarbara 2003Babs LoprettoAinda não há avaliações

- Produção de Milho HidropônicoDocumento6 páginasProdução de Milho HidropônicoAlexandre BarretoAinda não há avaliações

- Análise de Leites Fermentados ComercializadosDocumento16 páginasAnálise de Leites Fermentados ComercializadosAndré de LimaAinda não há avaliações

- PDF - Débora Santos DantasDocumento72 páginasPDF - Débora Santos DantasAdrian Orihuela JaroAinda não há avaliações

- 1177-Texto Do Artigo-4251-1-10-20190905Documento8 páginas1177-Texto Do Artigo-4251-1-10-20190905katiuciuaAinda não há avaliações

- Fluxograma Sorvete de SojaDocumento9 páginasFluxograma Sorvete de SojaANTONIO CARLOSAinda não há avaliações

- Harina de ResiduosDocumento9 páginasHarina de ResiduosJulieth Orduña OrtegaAinda não há avaliações

- Aceitabilidade de SnacksDocumento9 páginasAceitabilidade de SnacksTaymara SantosAinda não há avaliações

- Desidratação de Batata-Doce para Fabricação de FarinhaDocumento9 páginasDesidratação de Batata-Doce para Fabricação de Farinhaogb65625Ainda não há avaliações

- Development of A Breakfast Cereal UsingDocumento5 páginasDevelopment of A Breakfast Cereal UsingManoj SahuAinda não há avaliações

- TCC Caroline Prado GeddaDocumento12 páginasTCC Caroline Prado GeddaDííh GarciaAinda não há avaliações

- Cópia de ProjetoprontoparasubmeteraoCEPVANUZADocumento16 páginasCópia de ProjetoprontoparasubmeteraoCEPVANUZAAllan de azevedoAinda não há avaliações

- Artigo Aula IDocumento11 páginasArtigo Aula IbrendaanazcobenitesAinda não há avaliações

- Nutrição e FertilidadeDocumento28 páginasNutrição e FertilidadeGabriela GussoAinda não há avaliações

- BLPC12122022Documento74 páginasBLPC12122022fehabreu157Ainda não há avaliações

- Analise de Mercado Da Batata Doce Chips Assada No Micro OndasDocumento13 páginasAnalise de Mercado Da Batata Doce Chips Assada No Micro OndasJoão SegattoAinda não há avaliações

- Artigo Final - Aquila-1Documento25 páginasArtigo Final - Aquila-1Daniel SalesAinda não há avaliações

- Souza 2021 - Artigo TCCDocumento9 páginasSouza 2021 - Artigo TCCWeysser Felipe Cândido de SouzaAinda não há avaliações

- Uniformizacao Da Mistura de Ração Total para Vacas LeiterasDocumento14 páginasUniformizacao Da Mistura de Ração Total para Vacas LeiterasGustavo BolsoniAinda não há avaliações

- Elaboração de Granola Com Adição de Polpa E Casta-Nha de Bacuri para Consumo Com IogurteDocumento18 páginasElaboração de Granola Com Adição de Polpa E Casta-Nha de Bacuri para Consumo Com IogurtePedro Gomes LeandroAinda não há avaliações

- Potencial de Utilização de Ora-Pro-Nóbis em Iogurtes FuncionaisDocumento20 páginasPotencial de Utilização de Ora-Pro-Nóbis em Iogurtes FuncionaisLaiza AndradeAinda não há avaliações

- 2 1 Descricao Do EventoDocumento10 páginas2 1 Descricao Do EventoRenan Luiz Brambilla Gracino de OliveiraAinda não há avaliações

- 55° CBQ - Pão Enriquecido Com Farinha de Açaí Da Amazônia - Como Estratégia de Estudo de Alimentos PDFDocumento5 páginas55° CBQ - Pão Enriquecido Com Farinha de Açaí Da Amazônia - Como Estratégia de Estudo de Alimentos PDFEloi MenezesAinda não há avaliações

- Acidez em AlimentosDocumento13 páginasAcidez em AlimentosgedeoliAinda não há avaliações

- Teor de Carotenoides em Polpas de Acerola Congeladas: Carotenoids in Frozen Acerola PulpsDocumento4 páginasTeor de Carotenoides em Polpas de Acerola Congeladas: Carotenoids in Frozen Acerola PulpsBrian FrossardAinda não há avaliações

- Produção Artesanal Da Pasta de Soja MissôDocumento6 páginasProdução Artesanal Da Pasta de Soja Missôcarlos.quaglio2857Ainda não há avaliações

- 995 3059 1 PB 3Documento10 páginas995 3059 1 PB 3Patrícia da Conceição AlvesAinda não há avaliações

- Contexto Da AlimentaçãoDocumento99 páginasContexto Da Alimentaçãobrenda_bbAinda não há avaliações

- 766 2485 1 PBDocumento11 páginas766 2485 1 PBLimber Castro ChinoAinda não há avaliações

- Benefícios Do Caroço Do AbacateDocumento10 páginasBenefícios Do Caroço Do AbacateAdriene Pereira JoseAinda não há avaliações

- Aproveitamento Do Residuo de Acerola PDFDocumento8 páginasAproveitamento Do Residuo de Acerola PDFalexsandra_souzaAinda não há avaliações

- Pecuaria Organica Leiteira - WebDocumento40 páginasPecuaria Organica Leiteira - WebGiovana BragaAinda não há avaliações

- Kefir de Água e Leite - Composição Físico-Química em Diferentes SubstratosDocumento7 páginasKefir de Água e Leite - Composição Físico-Química em Diferentes SubstratosfabiowalligatorAinda não há avaliações

- Jordana Trindade Paz - 2021Documento41 páginasJordana Trindade Paz - 2021Babugi Ernesto Antonio ObraAinda não há avaliações

- APPCC Doce de LeiteDocumento17 páginasAPPCC Doce de LeiteGraziela BarrosAinda não há avaliações

- Caracterização Farinha de InhameDocumento5 páginasCaracterização Farinha de InhameJoice CorreiaAinda não há avaliações

- Manual AppccDocumento17 páginasManual AppccLilian RizzoAinda não há avaliações

- Avaliação Da Composição e Dos Parâmetros Tecnológicos de Farinhas Produzidas A Partir de Subprodutos AgroindustriaisDocumento8 páginasAvaliação Da Composição e Dos Parâmetros Tecnológicos de Farinhas Produzidas A Partir de Subprodutos AgroindustriaisAgnelli Holanda OliveiraAinda não há avaliações

- Impacto Da Substituicao Da Farinha de TrigoDocumento62 páginasImpacto Da Substituicao Da Farinha de TrigowelnunesAinda não há avaliações

- 54 DB 4 Eab 0 CF 233119 BC 5 CB 88Documento17 páginas54 DB 4 Eab 0 CF 233119 BC 5 CB 88Patrícia da Conceição AlvesAinda não há avaliações

- Detecção de Proteinas em Alimentos Atraves Do Teste BiuretoDocumento7 páginasDetecção de Proteinas em Alimentos Atraves Do Teste BiuretoUEGMORRINHOSAinda não há avaliações

- Agriculturas Alternativas - UM ESTUDO DE CASO SOBRE A AGRICULTURADocumento77 páginasAgriculturas Alternativas - UM ESTUDO DE CASO SOBRE A AGRICULTURAGustavo AyresAinda não há avaliações

- Trabalho BromatologiaDocumento5 páginasTrabalho Bromatologiamarcoslouro.medicinaAinda não há avaliações

- Liofilização Artigo Não Tão BomDocumento8 páginasLiofilização Artigo Não Tão Bomthais.costa.santosAinda não há avaliações

- TCC de Fibras 2l ProfaanitaDocumento13 páginasTCC de Fibras 2l ProfaanitaLucimara ChagasAinda não há avaliações

- Variaveis Aleatórias Bidimensionais AulaDocumento18 páginasVariaveis Aleatórias Bidimensionais AulaDavid VenacioAinda não há avaliações

- E Statistic ADocumento8 páginasE Statistic AFabricio MagnelliAinda não há avaliações

- Lista 1 - Probabilidade IIDocumento2 páginasLista 1 - Probabilidade IIgazAinda não há avaliações

- Lista 4 DadosDocumento2 páginasLista 4 DadosMatheus SoaresAinda não há avaliações

- Planejamento Experimental - ExercícioDocumento20 páginasPlanejamento Experimental - ExercícioFSFAinda não há avaliações

- Competencias Habilidades Matematicas Enem PDFDocumento6 páginasCompetencias Habilidades Matematicas Enem PDFEder SoaresAinda não há avaliações

- Questões para Testes - 2º PeríodoDocumento8 páginasQuestões para Testes - 2º PeríodoHelena Vaz Domingos100% (3)

- Caderno de Prova: Manejo e Conservação Do Solo e Da ÁguaDocumento24 páginasCaderno de Prova: Manejo e Conservação Do Solo e Da ÁguaManoel da Encarnação CoutinhoAinda não há avaliações

- Apostila de Hidrologia Civil 2017Documento136 páginasApostila de Hidrologia Civil 2017Danielle Manzoli50% (2)

- Textos de Apoio - Assimetria e Concentracao PDFDocumento11 páginasTextos de Apoio - Assimetria e Concentracao PDFattackcairoAinda não há avaliações

- ConfiabilidadeDocumento128 páginasConfiabilidadeNicolas De NadaiAinda não há avaliações

- 8867-20 60KV PT 019Documento2 páginas8867-20 60KV PT 019BGP10Ainda não há avaliações

- Tutorial Statistix (2010)Documento53 páginasTutorial Statistix (2010)Aldenir AlvesAinda não há avaliações

- Simul Enem Up 2012 Marcelo RenatoDocumento6 páginasSimul Enem Up 2012 Marcelo RenatoMarcelo Renato Moreira BaptistaAinda não há avaliações

- Apostila Statistica 6Documento85 páginasApostila Statistica 6Igor Assis100% (1)

- INE7002ListaInf PDFDocumento4 páginasINE7002ListaInf PDFHORUS_KHANAinda não há avaliações

- Apostila de Introdução À ProbabilidadeDocumento5 páginasApostila de Introdução À ProbabilidadeElanã Farias GomesAinda não há avaliações

- Apostila Do Software Past para Ecologia PDFDocumento22 páginasApostila Do Software Past para Ecologia PDFDouglasAlbrechtAinda não há avaliações

- Lista1 TeoriadeErrosDocumento4 páginasLista1 TeoriadeErrosBruno VictorAinda não há avaliações

- Resumo de Fundamentos de MatemáticaDocumento59 páginasResumo de Fundamentos de MatemáticaRodrigo NairAinda não há avaliações

- Lista Exercicios Previsao DemandaDocumento3 páginasLista Exercicios Previsao DemandaJonathan MendesAinda não há avaliações

- Lista de Exercícios Econometria - UFMGDocumento5 páginasLista de Exercícios Econometria - UFMGAnna Carol OliveiraAinda não há avaliações

- 2 AtividadeDocumento3 páginas2 AtividadeBen JhonsonAinda não há avaliações

- Tarefa 1 - Curva BanheiraDocumento11 páginasTarefa 1 - Curva BanheiraFábia FrancoAinda não há avaliações

- Lista de Exercícios para Prova II - 2o Bimestre de 2015 - 1o Ano - Matemática C - ProfDocumento3 páginasLista de Exercícios para Prova II - 2o Bimestre de 2015 - 1o Ano - Matemática C - Proffernandoabel01Ainda não há avaliações

- Exercícios (Lista 02)Documento4 páginasExercícios (Lista 02)valdicleyAinda não há avaliações

- Curva Idf RondoniaDocumento13 páginasCurva Idf RondoniaJolival JúniorAinda não há avaliações

- STP GloriaDocumento21 páginasSTP GloriaGloria GonçalvesAinda não há avaliações

- Apostila Estatística IIDocumento75 páginasApostila Estatística IIDudah SlotaAinda não há avaliações