Escolar Documentos

Profissional Documentos

Cultura Documentos

Memorial de Cálculo: Indíce de Revisões Descrição E/Ou Folhas Atingidas Rev

Enviado por

LowanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Memorial de Cálculo: Indíce de Revisões Descrição E/Ou Folhas Atingidas Rev

Enviado por

LowanDireitos autorais:

Formatos disponíveis

Nº

MEMORIAL DE CÁLCULO MC-2-22-C037311-AI1-001

CLIENTE FOLHA

Valmet Celulose, Papel e Energia Ltda 1 de 4

PROJETO

Puma II - MAQUINA DE PAPEL - MP28 -

ÁREA

34200 - MP28 - Comum - Processo (DCS) -

TÍTULO

SENGDESALUT

ENGENHARIA

TERMOELEMENTO E POÇO

CONTRATADA: Valmet Celulose, Papel e Energia Ltda

WO: 62154

FORNECEDOR: ALUTAL CONTROLES INDUSTRIAIS LTDA

RESPONSÁVEL TÉCNICO / REG. ÓRGÃO DE CLASSE: N° DOC: MC-2-22-C037311-AI1-001=C.xls

INDÍCE DE REVISÕES

REV. DESCRIÇÃO E/OU FOLHAS ATINGIDAS

0 EMISSÃO ORIGINAL / PARA COMENTÁRIOS

A ATENDENDO A COMENTÁRIOS - PARA APROVAÇÃO

B ATENDENDO A COMENTÁRIOS - PARA APROVAÇÃO

C ATENDENDO A COMENTÁRIOS - PARA APROVAÇÃO

REV. 0 REV. A REV. B REV. C REV. D REV. E REV. F REV. G REV. H

DATA 13/05/2022 15/06/2022 20/06/2022 24/06/2022

PROJETO AI1 AI1 AI1 AI1

EXECUÇÃO L.RUSSO L.RUSSO L.RUSSO L.RUSSO

VERIFICAÇÃO E.PEREIRA L.RUSSO L.RUSSO L.RUSSO

APROVAÇÃO C.LOPES C.LOPES C.LOPES C.LOPES

AS INFORMAÇÕES DESTE DOCUMENTO SÃO PROPRIEDADE DA ALUTAL, SENDO PROIBIDA A UTILIZAÇÃO FORA DA SUA FINALIDADE.

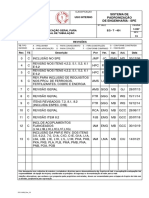

Nº REV.

MEMORIAL DE CÁLCULO MC-2-22-C037311-AI1-001 C

ÁREA FOLHA

34200 - MP28 - Comum - Processo (DCS) 2 de 4

TÍTULO

-

TERMOELEMENTO E POÇO

Wake Calc. System Em acordo com ASME PTC-19.3 TW-2016

DADOS TERMOPOÇOS

ÁREA: 34200 - MP28 - Comum - Processo (DCS)

DADOS PROCESSO: PM28_ETC_5315_Rev_0

TIPO DE CONEXÃO: SW / Flange

TOTAL DE TAGs: 80

CRITÉRIO APROVAÇÃO: ASME PTC-19.3 TW-2016

OBSERVAÇÕES:

CÁLCULO - POÇO FLANGEADO

CONFIGURAÇÃO TERMOPOÇO DADOS DE PROCESSO STATUS

Aprovado / Reprovado

Conexão ao Processo

Diâmetro Ponta - B

Diâmetro Furo - d

Diâmetro Raiz - A

Tag Identificação

Comprimento - U

Tipo de Conexão

Comprimento - T

Temperatura

Viscosidade

Velocidade

Densidade

Raio - rA

Pressão

Material

Haste

Item

mm mm mm mm mm mm °C bar m/s Kg/m³ cP

1 34217-TW-15680 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 203 12 37 4,48 0,02 Reprov.

2 34217-TW-15684 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 200 12 37 4,48 0,02 Reprov.

3 34217-TW-15685 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 160 7 31 2,51 0,01 Aprov.

4 34217-TW-15689 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 160 7 31 2,51 0,01 Aprov.

5 34217-TW-15706 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 60 8 3 1000 0,47 Aprov.

6 34217-TW-15711 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 60 8 3 1000 0,47 Aprov.

7 34217-TW-15739 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 110 8 2 972 0,26 Aprov.

8 34217-TW-15751 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 110 8 2 972 0,26 Aprov.

9 34217-TW-15771 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 120 7 34 1 0,24 Reprov.

10 34217-TW-15773 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 160 7 5 2,51 0,01 Aprov.

11 34217-TW-15780 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 203 12 37 4,48 0,02 Reprov.

12 34217-TW-15789 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 188 12 25 4,48 0,02 Aprov.

13 34217-TW-15803 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 164 12 15 0,48 0,17 Aprov.

14 34217-TW-15807 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 164 12 11 0,6 0,17 Aprov.

15 34217-TW-15810 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 164 12 10 0,7 0,17 Aprov.

16 34217-TW-15816 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 130 12 16 1 0,22 Aprov.

17 34217-TW-15823 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 150 12 10 1,4 0,19 Aprov.

18 34217-TW-15828 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 150 12 10 1,4 0,19 Aprov.

19 34217-TW-15831 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 160 12 10 1,9 0,17 Aprov.

20 34217-TW-15837 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 160 12 10 2,7 0,17 Aprov.

21 34217-TW-15843 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 180 12 10 3 0,15 Aprov.

22 34217-TW-15846 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 180 12 10 3 0,15 Aprov.

23 34217-TW-15852 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 130 12 10 1 0,22 Aprov.

24 34217-TW-15855 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 150 12 10 1,6 0,19 Aprov.

25 34217-TW-15858 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 150 12 10 1,6 0,19 Aprov.

26 34217-TW-15862 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 190 12 10 4,2 0,14 Aprov.

27 34217-TW-15865 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 190 12 10 4,2 0,14 Aprov.

28 34217-TW-15868 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 100 12 10 0,6 0,28 Aprov.

29 34217-TW-15871 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 120 12 10 0,6 0,24 Aprov.

30 34217-TW-15874 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 110 12 10 0,6 0,26 Aprov.

31 34217-TW-15877 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 120 12 10 0,6 0,24 Aprov.

32 34217-TW-15896 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 170 12 2 930 0,16 Aprov.

33 34217-TW-15905 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 30 10 3 998 0,80 Aprov.

34 34217-TW-15906 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 70 10 3 983 0,41 Aprov.

35 34217-TW-15936 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 180 12 2 907 0,15 Aprov.

36 34217-TW-15951 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 60 10 3 990 0,47 Aprov.

37 34217-TW-15952 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 90 10 3 980 0,31 Aprov.

38 34217-TW-15966 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 170 10 3 943 0,16 Aprov.

39 34217-TW-15976 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 30 10 3 998 0,80 Aprov.

40 34217-TW-15977 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 60 10 3 990 0,47 Aprov.

41 34217-TW-15987 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 110 12 3 974 0,26 Aprov.

42 34217-TW-15991 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 110 12 3 974 0,26 Aprov.

Nº REV.

MEMORIAL DE CÁLCULO MC-2-22-C037311-AI1-001 C

ÁREA FOLHA

34200 - MP28 - Comum - Processo (DCS) 3 de 4

TÍTULO

-

TERMOELEMENTO E POÇO

-

Wake Calc. System Em acordo com ASME PTC-19.3 TW-2016

DADOS TERMOPOÇOS

ÁREA: 34200 - MP28 - Comum - Processo (DCS)

DADOS PROCESSO: PM28_ETC_5315_Rev_0

TIPO DE CONEXÃO: SW / Flange

TOTAL DE TAGs: 80

CRITÉRIO APROVAÇÃO: ASME PTC-19.3 TW-2016

OBSERVAÇÕES:

CONFIGURAÇÃO TERMOPOÇO DADOS DE PROCESSO STATUS

Aprovado / Reprovado

Conexão ao Processo

Diâmetro Ponta - B

Diâmetro Furo - d

Diâmetro Raiz - A

Tag Identificação

Comprimento - U

Tipo de Conexão

Comprimento - T

Temperatura

Viscosidade

Velocidade

Densidade

Raio - rA

Pressão

Material

Haste

Item

mm mm mm mm mm mm °C bar m/s Kg/m³ cP

43 34211-TW-13453 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 60 10 2,4 1000 0,47 Aprov.

44 34211-TW-13563 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 60 10 2,8 1000 0,47 Aprov.

45 34211-TW-13653 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 1,7 1000 0,47 Aprov.

46 34212-TW-13776 Flange Cônico 1" 150#RF SS316L 500 20 8 20 17 1,5 60 1,01 0 1000 0,47 Aprov.

47 34212-TW-13825 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 60 10 2,1 1000 0,47 Aprov.

48 34212-TW-13976 Flange Cônico 1" 150#RF SS316L 500 20 8 20 17 1,5 60 1,01 0 1000 0,47 Aprov.

49 34212-TW-14035 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 60 10 2,6 1000 0,47 Aprov.

50 34212-TW-14176 Flange Cônico 1" 150#RF SS316L 500 20 8 20 17 1,5 60 1,01 0 1000 0,47 Aprov.

51 34212-TW-14225 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 60 10 2,6 1000 0,47 Aprov.

52 34216-TW-15454 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 60 10 0,8 1000 0,47 Aprov.

53 34216-TW-15487 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 60 10 2 1000 0,47 Aprov.

54 34213-TW-14484 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 60 10 4 1000 0,51 Aprov.

55 34211-TW-12554 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 4,4 1000 0,51 Aprov.

56 34211-TW-12648 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 70 10 3,7 1000 0,51 Aprov.

57 34211-TW-12678 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 70 10 3,7 1000 0,51 Aprov.

58 34211-TW-13209 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 58 10 4 1000 0,51 Aprov.

59 34211-TW-13239 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 4 1000 0,51 Aprov.

60 34211-TW-13269 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 4,8 985,7 0,51 Aprov.

61 34211-TW-12809 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 3,5 985,7 0,51 Aprov.

62 34211-TW-12839 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 3,5 985,7 0,51 Aprov.

63 34211-TW-12869 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 3,5 985,7 0,51 Aprov.

64 34211-TW-12909 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 3,1 985,7 0,51 Aprov.

65 34211-TW-12939 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 70 10 3,1 985,7 0,51 Aprov.

66 34211-TW-13029 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 70 10 2,8 985,7 0,51 Aprov.

67 34205-TW-10821 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 30 10 2,9 998 0,8 Aprov.

68 34206-TW-10930 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 50 10 3,2 998 0,55 Aprov.

69 34206-TW-10941 Socket Weld Cônico 3/4" SW SS316L 125 100 6,6 19 16 1,5 40 10 3,2 998 0,65 Aprov.

70 34206-TW-11011 Socket Weld Cônico 3/4" SW SS316L 75 100 6,6 19 16 1,5 30 10 1,8 998 0,8 Aprov.

71 34206-TW-11331 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 30 10 37 1,225 0,02 Aprov.

72 34226-TW-24672.1 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 600 0,04 N/C

73 34226-TW-24672.2 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 600 0,04 N/C

74 34206-TW-11336 Socket Weld Cônico 3/4" SW SS316L 100 100 6,6 19 16 1,5 60 10 11 1225 N/C

75 34226-TW-23962 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 40 1,5 1530 N/C

76 34226-TW-24762 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 40 1,5 1530 N/C

77 34227-TW-25152 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 150 2,4 1104 200 N/C

78 34227-TW-26923 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 80 1000 1 N/C

79 34227-TW-25158 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 150 2,4 1104 200 N/C

80 34227-TW-26857 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 50 2 1200 400 N/C

81 34227-TW-26838 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 55 1000 N/C

82 34227-TW-25516 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 40 N/C

83 34227-TW-25166 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 19 16 1,5 100 1075 N/C

NOTAS

1. N/C = Não calculado devido a falta de dados de processo e/ou devido a não ser necessário cálculo.

Nº REV.

MEMORIAL DE CÁLCULO MC-2-22-C037311-AI1-001 C

ÁREA FOLHA

34200 - MP28 - Comum - Processo (DCS) 4 de 4

TÍTULO

-

TERMOELEMENTO E POÇO

-

Wake Calc. System Em acordo com ASME PTC-19.3 TW-2016

DADOS TERMOPOÇOS

ÁREA: 34200 - MP28 - Comum - Processo (DCS)

DADOS PROCESSO: PM28_ETC_5315_Rev_0

TIPO DE CONEXÃO: SW / Flange

TOTAL DE TAGs: 80

CRITÉRIO APROVAÇÃO: ASME PTC-19.3 TW-2016

OBSERVAÇÕES:

SOLUÇÕES PARA OS POÇOS REPROVADOS

CONFIGURAÇÃO TERMOPOÇO DADOS DE PROCESSO STATUS

Aprovado / Reprovado

Conexão ao Processo

Diâmetro Ponta - B

Diâmetro Furo - d

Diâmetro Raiz - A

Tag Identificação

Comprimento - U

Tipo de Conexão

Comprimento - T

Temperatura

Viscosidade

Velocidade

Densidade

Raio - rA

Pressão

Material

Haste

Item

mm mm mm mm mm mm °C bar m/s Kg/m³ cP

1 34217-TW-15680 Socket Weld Reto 3/4" SW SS316L 105 100 6,6 21 21 1,5 203 12 37 4,48 0,02 Aprov.

2 34217-TW-15684 Socket Weld Reto 3/4" SW SS316L 105 100 6,6 21 21 1,5 200 12 37 4,48 0,02 Aprov.

9 34217-TW-15771 Socket Weld Cônico 3/4" SW SS316L 150 100 6,6 20 17 1,5 120 7 34 1 0,24 Aprov.

11 34217-TW-15780 Socket Weld Reto 3/4" SW SS316L 105 100 6,6 21 21 1,5 203 12 37 4,48 0,02 Aprov.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15680 Reference #: -

Process Operating Conditions

Process Fluids: SMP - Vapor saturado, média pressão

Max Temperature (T) 203 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 37 m/s

Fluid Density: 4,48 Kg/m^3

Fluid Viscosity: 0,0159298 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 48,38 m/s Von Mises Stress (Root): 96,82 psi

Bending Stress at VIR (So.max) 24441,17 psi

Peak oscill. bending stress (So.max) 169,58 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 218766

Process Connection: Socket-Weld Frequency must be below: 366,39 [Hz] Strouhal # (Ns): 0,1949

Stem Style: Straight Installed Natural Freq (fnc): 915,97 [Hz] Scruton # (Nsc): 7,96

Thermowell Material: 316L Strouhal Frequency (fs): 343,4 [Hz] Freq Ratio (fs/fnc):0,37

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5092,66psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 205mm

Unsupported Length (U): 105mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 21mm Oscillating Stress (psi) PASS 169,58

Tip Diameter (B): 21mm Steady-State Stress (psi) PASS 284,079

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 343,40

Calculated U Length : 117,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15684 Reference #: -

Process Operating Conditions

Process Fluids: SMP - Vapor saturado, média pressão

Max Temperature (T) 200 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 37 m/s

Fluid Density: 4,48 Kg/m^3

Fluid Viscosity: 0,0157971 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 48,34 m/s Von Mises Stress (Root): 96,82 psi

Bending Stress at VIR (So.max) 24406,57 psi

Peak oscill. bending stress (So.max) 169,62 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 220604

Process Connection: Socket-Weld Frequency must be below: 366,39 [Hz] Strouhal # (Ns): 0,195

Stem Style: Straight Installed Natural Freq (fnc): 915,97 [Hz] Scruton # (Nsc): 7,96

Thermowell Material: 316L Strouhal Frequency (fs): 343,6 [Hz] Freq Ratio (fs/fnc):0,38

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5092,66psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 205mm

Unsupported Length (U): 105mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 21mm Oscillating Stress (psi) PASS 169,62

Tip Diameter (B): 21mm Steady-State Stress (psi) PASS 284,079

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 343,60

Calculated U Length : 117,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15685 Reference #: -

Process Operating Conditions

Process Fluids: SLP - Vapor saturado, baixa pressão

Max Temperature (T) 160 °C

Max Pressure (P): 7 Bar

Fluid Velocity (v): 31 m/s

Fluid Density: 2,51 Kg/m^3

Fluid Viscosity: 0,0142608 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 21,59 m/s Von Mises Stress (Root): 82,23 psi

Bending Stress at VIR (So.max) 5987,31 psi

Peak oscill. bending stress (So.max) 257,5 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 87468

Process Connection: Socket-Weld Frequency must be below: 404,53 [Hz] Strouhal # (Ns): 0,1882

Stem Style: Tapered Installed Natural Freq (fnc): 505,67 [Hz] Scruton # (Nsc): 13,07

Thermowell Material: 316L Strouhal Frequency (fs): 364,57 [Hz] Freq Ratio (fs/fnc):0,72

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 250mm

Unsupported Length (U): 150mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 257,49

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 194,039

Tip Thickness (t): 6,3mm Pressure (psi) PASS 101,527

Fillet (Root): 1,5mm Frequency (Hz) PASS 364,56

Calculated U Length : 162,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15689 Reference #: -

Process Operating Conditions

Process Fluids: SLP - Vapor saturado, baixa pressão

Max Temperature (T) 160 °C

Max Pressure (P): 7 Bar

Fluid Velocity (v): 31 m/s

Fluid Density: 2,51 Kg/m^3

Fluid Viscosity: 0,0142608 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 21,59 m/s Von Mises Stress (Root): 82,23 psi

Bending Stress at VIR (So.max) 5987,31 psi

Peak oscill. bending stress (So.max) 257,5 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 87468

Process Connection: Socket-Weld Frequency must be below: 404,53 [Hz] Strouhal # (Ns): 0,1882

Stem Style: Tapered Installed Natural Freq (fnc): 505,67 [Hz] Scruton # (Nsc): 13,07

Thermowell Material: 316L Strouhal Frequency (fs): 364,57 [Hz] Freq Ratio (fs/fnc):0,72

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 250mm

Unsupported Length (U): 150mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 257,49

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 194,039

Tip Thickness (t): 6,3mm Pressure (psi) PASS 101,527

Fillet (Root): 1,5mm Frequency (Hz) PASS 364,56

Calculated U Length : 162,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15706 Reference #: -

Process Operating Conditions

Process Fluids: WWC - Água morna

Max Temperature (T) 60 °C

Max Pressure (P): 8 Bar

Fluid Velocity (v): 3 m/s

Fluid Density: 1000 Kg/m^3

Fluid Viscosity: 0,466 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 28115384,6153846 psi

Allowable Stress (S) / Fatigue Limit (Sf): 16700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 39,03 m/s Von Mises Stress (Root): 134,6 psi

Bending Stress at VIR (So.max) 3502072,85 psi

Peak oscill. bending stress (So.max) 208,35 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 102960

Process Connection: Socket-Weld Frequency must be below: 388,06 [Hz] Strouhal # (Ns): 0,1886

Stem Style: Tapered Installed Natural Freq (fnc): 970,15 [Hz] Scruton # (Nsc): 0,03

Thermowell Material: 316L Strouhal Frequency (fs): 35,37 [Hz] Freq Ratio (fs/fnc):0,04

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 6096,41psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 117018,23psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 208,34

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 263,663

Tip Thickness (t): 6,3mm Pressure (psi) PASS 116,031

Fillet (Root): 1,5mm Frequency (Hz) PASS 35,37

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15711 Reference #: -

Process Operating Conditions

Process Fluids: WWC - Água morna

Max Temperature (T) 60 °C

Max Pressure (P): 8 Bar

Fluid Velocity (v): 3 m/s

Fluid Density: 1000 Kg/m^3

Fluid Viscosity: 0,466 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 28115384,6153846 psi

Allowable Stress (S) / Fatigue Limit (Sf): 16700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 39,03 m/s Von Mises Stress (Root): 134,6 psi

Bending Stress at VIR (So.max) 3502072,85 psi

Peak oscill. bending stress (So.max) 208,35 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 102960

Process Connection: Socket-Weld Frequency must be below: 388,06 [Hz] Strouhal # (Ns): 0,1886

Stem Style: Tapered Installed Natural Freq (fnc): 970,15 [Hz] Scruton # (Nsc): 0,03

Thermowell Material: 316L Strouhal Frequency (fs): 35,37 [Hz] Freq Ratio (fs/fnc):0,04

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 6096,41psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 117018,23psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 208,34

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 263,663

Tip Thickness (t): 6,3mm Pressure (psi) PASS 116,031

Fillet (Root): 1,5mm Frequency (Hz) PASS 35,37

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15739 Reference #: -

Process Operating Conditions

Process Fluids: SCP - Condensado, bombeado

Max Temperature (T) 110 °C

Max Pressure (P): 8 Bar

Fluid Velocity (v): 2 m/s

Fluid Density: 972 Kg/m^3

Fluid Viscosity: 0,259 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 37,09 m/s Von Mises Stress (Root): 63,24 psi

Bending Stress at VIR (So.max) 3074107,9 psi

Peak oscill. bending stress (So.max) 89,94 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 120042

Process Connection: Socket-Weld Frequency must be below: 384,5 [Hz] Strouhal # (Ns): 0,1893

Stem Style: Tapered Installed Natural Freq (fnc): 961,25 [Hz] Scruton # (Nsc): 0,03

Thermowell Material: 316L Strouhal Frequency (fs): 23,67 [Hz] Freq Ratio (fs/fnc):0,02

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5183,78psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 89,94

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 188,833

Tip Thickness (t): 6,3mm Pressure (psi) PASS 116,031

Fillet (Root): 1,5mm Frequency (Hz) PASS 23,67

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15751 Reference #: -

Process Operating Conditions

Process Fluids: SCP - Condensado, bombeado

Max Temperature (T) 110 °C

Max Pressure (P): 8 Bar

Fluid Velocity (v): 2 m/s

Fluid Density: 972 Kg/m^3

Fluid Viscosity: 0,259 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 37,09 m/s Von Mises Stress (Root): 63,24 psi

Bending Stress at VIR (So.max) 3074107,9 psi

Peak oscill. bending stress (So.max) 89,94 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 120042

Process Connection: Socket-Weld Frequency must be below: 384,5 [Hz] Strouhal # (Ns): 0,1893

Stem Style: Tapered Installed Natural Freq (fnc): 961,25 [Hz] Scruton # (Nsc): 0,03

Thermowell Material: 316L Strouhal Frequency (fs): 23,67 [Hz] Freq Ratio (fs/fnc):0,02

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5183,78psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 89,94

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 188,833

Tip Thickness (t): 6,3mm Pressure (psi) PASS 116,031

Fillet (Root): 1,5mm Frequency (Hz) PASS 23,67

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15771 Reference #: -

Process Operating Conditions

Process Fluids: SLP - Vapor saturado, baixa pressão

Max Temperature (T) 120 °C

Max Pressure (P): 7 Bar

Fluid Velocity (v): 34 m/s

Fluid Density: 1 Kg/m^3

Fluid Viscosity: 0,2374 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 21,13 m/s Von Mises Stress (Root): 40,53 psi

Bending Stress at VIR (So.max) 2084,71 psi

Peak oscill. bending stress (So.max) 147,31 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 2457

Process Connection: Socket-Weld Frequency must be below: 424,83 [Hz] Strouhal # (Ns): 0,2113

Stem Style: Tapered Installed Natural Freq (fnc): 531,04 [Hz] Scruton # (Nsc): 33,34

Thermowell Material: 316L Strouhal Frequency (fs): 422,62 [Hz] Freq Ratio (fs/fnc):0,80

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5430,11psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 250mm

Unsupported Length (U): 150mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 20mm Oscillating Stress (psi) PASS 147,31

Tip Diameter (B): 17mm Steady-State Stress (psi) PASS 148,267

Tip Thickness (t): 6,3mm Pressure (psi) PASS 101,527

Fillet (Root): 1,5mm Frequency (Hz) PASS 422,61

Calculated U Length : 162,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15773 Reference #: -

Process Operating Conditions

Process Fluids: SLP - Vapor saturado, baixa pressão

Max Temperature (T) 160 °C

Max Pressure (P): 7 Bar

Fluid Velocity (v): 5 m/s

Fluid Density: 2,51 Kg/m^3

Fluid Viscosity: 0,0142608 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 45,16 m/s Von Mises Stress (Root): 24,15 psi

Bending Stress at VIR (So.max) 11799,53 psi

Peak oscill. bending stress (So.max) 1,46 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 14108

Process Connection: Socket-Weld Frequency must be below: 810,94 [Hz] Strouhal # (Ns): 0,197

Stem Style: Tapered Installed Natural Freq (fnc): 1013,67 [Hz] Scruton # (Nsc): 13,07

Thermowell Material: 316L Strouhal Frequency (fs): 61,56 [Hz] Freq Ratio (fs/fnc):0,06

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,46

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 116,35

Tip Thickness (t): 6,3mm Pressure (psi) PASS 101,527

Fillet (Root): 1,5mm Frequency (Hz) PASS 61,55

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15780 Reference #: -

Process Operating Conditions

Process Fluids: SMP - Vapor saturado, média pressão

Max Temperature (T) 203 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 37 m/s

Fluid Density: 4,48 Kg/m^3

Fluid Viscosity: 0,0159298 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 48,38 m/s Von Mises Stress (Root): 96,82 psi

Bending Stress at VIR (So.max) 24441,17 psi

Peak oscill. bending stress (So.max) 169,58 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 218766

Process Connection: Socket-Weld Frequency must be below: 366,39 [Hz] Strouhal # (Ns): 0,1949

Stem Style: Straight Installed Natural Freq (fnc): 915,97 [Hz] Scruton # (Nsc): 7,96

Thermowell Material: 316L Strouhal Frequency (fs): 343,4 [Hz] Freq Ratio (fs/fnc):0,37

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5092,66psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 205mm

Unsupported Length (U): 105mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 21mm Oscillating Stress (psi) PASS 169,58

Tip Diameter (B): 21mm Steady-State Stress (psi) PASS 284,079

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 343,40

Calculated U Length : 117,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15789 Reference #: -

Process Operating Conditions

Process Fluids: SMP - Vapor saturado, média pressão

Max Temperature (T) 188 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 25 m/s

Fluid Density: 4,48 Kg/m^3

Fluid Viscosity: 0,0152691 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 65,35 m/s Von Mises Stress (Root): 47,25 psi

Bending Stress at VIR (So.max) 24524,78 psi

Peak oscill. bending stress (So.max) 37,42 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 117493

Process Connection: Socket-Weld Frequency must be below: 635,57 [Hz] Strouhal # (Ns): 0,1892

Stem Style: Tapered Installed Natural Freq (fnc): 1588,91 [Hz] Scruton # (Nsc): 7,33

Thermowell Material: 316L Strouhal Frequency (fs): 295,65 [Hz] Freq Ratio (fs/fnc):0,19

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4271,14psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 37,42

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 220,72

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 295,64

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15803 Reference #: -

Process Operating Conditions

Process Fluids: SMP/SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 164 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 15 m/s

Fluid Density: 0,48 Kg/m^3

Fluid Viscosity: 0,16928 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 37,35 m/s Von Mises Stress (Root): 41,39 psi

Bending Stress at VIR (So.max) 1542,58 psi

Peak oscill. bending stress (So.max) 2,61 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 681,3

Process Connection: Socket-Weld Frequency must be below: 811,04 [Hz] Strouhal # (Ns): 0,2129

Stem Style: Tapered Installed Natural Freq (fnc): 1013,8 [Hz] Scruton # (Nsc): 68,40

Thermowell Material: 316L Strouhal Frequency (fs): 199,6 [Hz] Freq Ratio (fs/fnc):0,20

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 2,61

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,461

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 199,59

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15807 Reference #: -

Process Operating Conditions

Process Fluids: SMP/SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 164 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 11 m/s

Fluid Density: 0,6 Kg/m^3

Fluid Viscosity: 0,16928 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,83 m/s Von Mises Stress (Root): 41,37 psi

Bending Stress at VIR (So.max) 2697,38 psi

Peak oscill. bending stress (So.max) 0,96 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 632,86

Process Connection: Socket-Weld Frequency must be below: 1285,8 [Hz] Strouhal # (Ns): 0,2124

Stem Style: Tapered Installed Natural Freq (fnc): 1607,25 [Hz] Scruton # (Nsc): 54,00

Thermowell Material: 316L Strouhal Frequency (fs): 146 [Hz] Freq Ratio (fs/fnc):0,09

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 0,96

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,478

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 146,00

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15810 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 164 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 0,7 Kg/m^3

Fluid Viscosity: 0,16928 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,78 m/s Von Mises Stress (Root): 41,36 psi

Bending Stress at VIR (So.max) 3117,72 psi

Peak oscill. bending stress (So.max) 0,92 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 666,17

Process Connection: Socket-Weld Frequency must be below: 1285,8 [Hz] Strouhal # (Ns): 0,2127

Stem Style: Tapered Installed Natural Freq (fnc): 1607,24 [Hz] Scruton # (Nsc): 46,64

Thermowell Material: 316L Strouhal Frequency (fs): 132,97 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 0,91

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,452

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 132,96

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15816 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 130 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 16 m/s

Fluid Density: 1 Kg/m^3

Fluid Viscosity: 0,2178 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,75 m/s Von Mises Stress (Root): 41,41 psi

Bending Stress at VIR (So.max) 4458,75 psi

Peak oscill. bending stress (So.max) 3,39 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1186,1

Process Connection: Socket-Weld Frequency must be below: 1285,77 [Hz] Strouhal # (Ns): 0,2159

Stem Style: Tapered Installed Natural Freq (fnc): 1607,21 [Hz] Scruton # (Nsc): 32,57

Thermowell Material: 316L Strouhal Frequency (fs): 215,93 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 3,39

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,983

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 215,92

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15823 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 150 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1,4 Kg/m^3

Fluid Viscosity: 0,1864 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,63 m/s Von Mises Stress (Root): 41,38 psi

Bending Stress at VIR (So.max) 6203,43 psi

Peak oscill. bending stress (So.max) 1,83 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1210

Process Connection: Socket-Weld Frequency must be below: 1285,74 [Hz] Strouhal # (Ns): 0,216

Stem Style: Tapered Installed Natural Freq (fnc): 1607,17 [Hz] Scruton # (Nsc): 23,32

Thermowell Material: 316L Strouhal Frequency (fs): 135,01 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,83

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,027

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 135,00

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15828 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 150 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1,4 Kg/m^3

Fluid Viscosity: 0,1864 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,63 m/s Von Mises Stress (Root): 41,38 psi

Bending Stress at VIR (So.max) 6203,43 psi

Peak oscill. bending stress (So.max) 1,83 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1210

Process Connection: Socket-Weld Frequency must be below: 1285,74 [Hz] Strouhal # (Ns): 0,216

Stem Style: Tapered Installed Natural Freq (fnc): 1607,17 [Hz] Scruton # (Nsc): 23,32

Thermowell Material: 316L Strouhal Frequency (fs): 135,01 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,83

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,027

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 135,00

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15831 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 160 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1,9 Kg/m^3

Fluid Viscosity: 0,1736 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 38,78 m/s Von Mises Stress (Root): 41,46 psi

Bending Stress at VIR (So.max) 6593,65 psi

Peak oscill. bending stress (So.max) 4,49 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1756,8

Process Connection: Socket-Weld Frequency must be below: 810,97 [Hz] Strouhal # (Ns): 0,2126

Stem Style: Tapered Installed Natural Freq (fnc): 1013,71 [Hz] Scruton # (Nsc): 17,24

Thermowell Material: 316L Strouhal Frequency (fs): 132,88 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 4,49

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 200,67

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 132,88

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15837 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 160 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 2,7 Kg/m^3

Fluid Viscosity: 0,1736 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 39,64 m/s Von Mises Stress (Root): 41,55 psi

Bending Stress at VIR (So.max) 9788,08 psi

Peak oscill. bending stress (So.max) 6,38 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 2495

Process Connection: Socket-Weld Frequency must be below: 810,93 [Hz] Strouhal # (Ns): 0,2112

Stem Style: Tapered Installed Natural Freq (fnc): 1013,66 [Hz] Scruton # (Nsc): 12,14

Thermowell Material: 316L Strouhal Frequency (fs): 132,02 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 6,37

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 201,842

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 132,02

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15843 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 180 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 3 Kg/m^3

Fluid Viscosity: 0,153 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 39,78 m/s Von Mises Stress (Root): 41,6 psi

Bending Stress at VIR (So.max) 10965,42 psi

Peak oscill. bending stress (So.max) 7,09 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 3149,2

Process Connection: Socket-Weld Frequency must be below: 801,85 [Hz] Strouhal # (Ns): 0,2099

Stem Style: Tapered Installed Natural Freq (fnc): 1002,31 [Hz] Scruton # (Nsc): 10,92

Thermowell Material: 316L Strouhal Frequency (fs): 131,18 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4271,14psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 7,09

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 202,288

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 131,18

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15846 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 180 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 3 Kg/m^3

Fluid Viscosity: 0,153 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 39,78 m/s Von Mises Stress (Root): 41,6 psi

Bending Stress at VIR (So.max) 10965,42 psi

Peak oscill. bending stress (So.max) 7,09 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 3149,2

Process Connection: Socket-Weld Frequency must be below: 801,85 [Hz] Strouhal # (Ns): 0,2099

Stem Style: Tapered Installed Natural Freq (fnc): 1002,31 [Hz] Scruton # (Nsc): 10,92

Thermowell Material: 316L Strouhal Frequency (fs): 131,18 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4271,14psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 7,09

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 202,288

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 131,18

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15852 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 130 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1 Kg/m^3

Fluid Viscosity: 0,2178 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 58,75 m/s Von Mises Stress (Root): 41,37 psi

Bending Stress at VIR (So.max) 4458,75 psi

Peak oscill. bending stress (So.max) 1,31 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 741,34

Process Connection: Socket-Weld Frequency must be below: 1285,77 [Hz] Strouhal # (Ns): 0,2135

Stem Style: Tapered Installed Natural Freq (fnc): 1607,21 [Hz] Scruton # (Nsc): 32,57

Thermowell Material: 316L Strouhal Frequency (fs): 133,43 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,31

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,701

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 133,42

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15855 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 150 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1,6 Kg/m^3

Fluid Viscosity: 0,1864 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 60,63 m/s Von Mises Stress (Root): 41,38 psi

Bending Stress at VIR (So.max) 7539,96 psi

Peak oscill. bending stress (So.max) 2,08 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1375

Process Connection: Socket-Weld Frequency must be below: 1285,72 [Hz] Strouhal # (Ns): 0,213

Stem Style: Tapered Installed Natural Freq (fnc): 1607,15 [Hz] Scruton # (Nsc): 20,52

Thermowell Material: 316L Strouhal Frequency (fs): 133,12 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 2,08

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,183

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 133,12

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15858 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 150 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 1,6 Kg/m^3

Fluid Viscosity: 0,1864 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27000000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 12700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 60,63 m/s Von Mises Stress (Root): 41,38 psi

Bending Stress at VIR (So.max) 7539,96 psi

Peak oscill. bending stress (So.max) 2,08 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 1375

Process Connection: Socket-Weld Frequency must be below: 1285,72 [Hz] Strouhal # (Ns): 0,213

Stem Style: Tapered Installed Natural Freq (fnc): 1607,15 [Hz] Scruton # (Nsc): 20,52

Thermowell Material: 316L Strouhal Frequency (fs): 133,12 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4636,19psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 88989,91psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 2,08

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 199,183

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 133,12

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15862 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 190 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 4,2 Kg/m^3

Fluid Viscosity: 0,1442 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 65,81 m/s Von Mises Stress (Root): 41,5 psi

Bending Stress at VIR (So.max) 23360,3 psi

Peak oscill. bending stress (So.max) 5,46 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 4674,4

Process Connection: Socket-Weld Frequency must be below: 635,58 [Hz] Strouhal # (Ns): 0,207

Stem Style: Tapered Installed Natural Freq (fnc): 1588,94 [Hz] Scruton # (Nsc): 7,80

Thermowell Material: 316L Strouhal Frequency (fs): 129,36 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4271,14psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 5,46

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 201,311

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 129,36

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15865 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 190 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 4,2 Kg/m^3

Fluid Viscosity: 0,1442 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 26400000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 11700 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 65,81 m/s Von Mises Stress (Root): 41,5 psi

Bending Stress at VIR (So.max) 23360,3 psi

Peak oscill. bending stress (So.max) 5,46 psi

Frequency

Thermowell Configuration Frequency Limit: 0,40 Reynolds # (Re): 4674,4

Process Connection: Socket-Weld Frequency must be below: 635,58 [Hz] Strouhal # (Ns): 0,207

Stem Style: Tapered Installed Natural Freq (fnc): 1588,94 [Hz] Scruton # (Nsc): 7,80

Thermowell Material: 316L Strouhal Frequency (fs): 129,36 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 4271,14psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 81982,83psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 5,46

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 201,311

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 129,36

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15868 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 100 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 0,6 Kg/m^3

Fluid Viscosity: 0,2825 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 37,85 m/s Von Mises Stress (Root): 41,37 psi

Bending Stress at VIR (So.max) 2005,89 psi

Peak oscill. bending stress (So.max) 1,44 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 344,75

Process Connection: Socket-Weld Frequency must be below: 818,51 [Hz] Strouhal # (Ns): 0,206

Stem Style: Tapered Installed Natural Freq (fnc): 1023,14 [Hz] Scruton # (Nsc): 54,00

Thermowell Material: 316L Strouhal Frequency (fs): 128,73 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5183,78psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,43

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,77

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 128,73

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15871 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 120 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 0,6 Kg/m^3

Fluid Viscosity: 0,2374 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 37,75 m/s Von Mises Stress (Root): 41,37 psi

Bending Stress at VIR (So.max) 1995,1 psi

Peak oscill. bending stress (So.max) 1,44 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 410,24

Process Connection: Socket-Weld Frequency must be below: 818,51 [Hz] Strouhal # (Ns): 0,2082

Stem Style: Tapered Installed Natural Freq (fnc): 1023,14 [Hz] Scruton # (Nsc): 54,00

Thermowell Material: 316L Strouhal Frequency (fs): 130,13 [Hz] Freq Ratio (fs/fnc):0,13

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5183,78psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 200mm

Unsupported Length (U): 100mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 1,43

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,77

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 130,13

Calculated U Length : 112,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information

Customer: Valmet Celulose, Papel e Energia Ltda Analyst: - Date : 20/06/2022

Tag Numbers: 34217-TW-15874 Reference #: -

Process Operating Conditions

Process Fluids: SCM - Vapor / Condensado (dupla fase)

Max Temperature (T) 110 °C

Max Pressure (P): 12 Bar

Fluid Velocity (v): 10 m/s

Fluid Density: 0,6 Kg/m^3

Fluid Viscosity: 0,259 centipoise

Thermowell Material Properties

Density (Pm): 0,29 lb/in^3

Elastic Modulus, E(T): 27500000 psi

Allowable Stress (S) / Fatigue Limit (Sf): 14200 psi/5400 psi

Stress (Support Plane)

In-Line Reson. Velocity(VIR): 59,57 m/s Von Mises Stress (Root): 41,36 psi

Bending Stress at VIR (So.max) 2765,8 psi

Peak oscill. bending stress (So.max) 0,79 psi

Frequency

Thermowell Configuration Frequency Limit: 0,80 Reynolds # (Re): 376,03

Process Connection: Socket-Weld Frequency must be below: 1297,65 [Hz] Strouhal # (Ns): 0,2071

Stem Style: Tapered Installed Natural Freq (fnc): 1622,07 [Hz] Scruton # (Nsc): 54,00

Thermowell Material: 316L Strouhal Frequency (fs): 129,46 [Hz] Freq Ratio (fs/fnc):0,08

Process Pipe Size 3/4" (1.05" Dia)

Internal Thread: 1/2" NPT Pressure

Flange Material: Not Applicable Allowable Stem Pressure(Pc): 5183,78psi

Bore Size: 6,6mm Allowable Tip Pressure(Pt): 99500,53psi

Overall Length (L): 175mm

Unsupported Length (U): 75mm Thermowell Rating

Shielded Length (Lo): 36,5mm Status Value

Root Diameter (Q): 19mm Oscillating Stress (psi) PASS 0,79

Tip Diameter (B): 16mm Steady-State Stress (psi) PASS 198,374

Tip Thickness (t): 6,3mm Pressure (psi) PASS 174,046

Fillet (Root): 1,5mm Frequency (Hz) PASS 129,46

Calculated U Length : 87,7mm

The thermowell design has PASSED the wake frequency calculation

“These well design calculations are based on the ASME PTC 19.3 TW-2016 formulas. The results of these calculations should only be used as a

guide for thermowell design. Alutal does not guarantee the performance of a specific well design obtained from the use of these calculations”.

Report Information