Escolar Documentos

Profissional Documentos

Cultura Documentos

Interfacial Drag and The Growth of Martensite

Enviado por

Luiz Fernando VieiraTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Interfacial Drag and The Growth of Martensite

Enviado por

Luiz Fernando VieiraDireitos autorais:

Formatos disponíveis

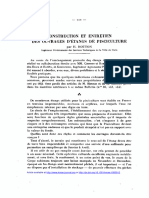

Interfacial Drag and the Growth of Martensite

F.J. S C H O E N A N D W . S. O W E N

A n e w m o d e l f o r t h e g r o w t h o f m a s s i v e - m a r t e n s i t e in F e - N i - C a l l o y s is p r e s e n t e d a n d p r e -

d i c t i o n s f r o m i t a r e c o m p a r e d w i t h the r e s u l t s o f h o t - s t a g e m e t a l l o g r a p h i c e x p e r i m e n t s o n

f i v e F e - 1 0 N i - C a l l o y s . T h e c o m p a r i s o n i n v o l v e s s i x s t e p s : 1) D e v e l o p m e n t o f a s p e c i f i c

m o d e l o f the i n t e r f a c e f o r a p a r t i c u l a r c r y s t a l l o g r a p h y . T h e s i n g l e a r r a y o f p a r a l l e l d i s l o -

c a t i o n s c a l c u l a t e d f o r t h i s i n t e r f a c e is c o m p a t i b l e in e v e r y w a y w i t h t h e r e q u i r e m e n t s o f t h e

crystallographic t h e o r i e s ; 2) c a l c u l a t i o n o f t h e e l a s t i c i n t e r a c t i o n e n e r g y b e t w e e n t h e s t r a i n

f i e l d s of d i s s o l v e d c a r b o n a t o m s i n t h e m a r t e n s i t e l a t t i c e a n d t h e s t r e s s f i e l d of t h e d i s l o c a -

t i o n a r r a y i n t h e i n t e r f a c e ; 3) d e v e l o p m e n t o f d i f f u s i o n m o d e l s f o r t h e d r a g f o r c e c r e a t e d by

t h i s i n t e r a c t i o n o n a m o v i n g i n t e r f a c e d u r i n g t h e f o r m a t i o n of t h e m a r t e n s i t e p h a s e ; 4) e s t a b -

l i s h m e n t o f a b a l a n c e of f o r c e s a t t h e m o v i n g i n t e r f a c e ; 5) p r e d i c t i o n o f g r o w t h r a t e s o f t h e

p r o d u c t ; a n d 6) c o m p a r i s o n o f t h e s e p r e d i c t i o n s w i t h the e x p e r i m e n t a l d a t a . T h e r a t e o f

g r o w t h of the p r o d u c t a n d i t s s t r o n g d e p e n d e n c e o n c a r b o n c o n c e n t r a t i o n c a n b o t h be e x p l a i n e d

i f i t i s a s s u m e d that the r a t e c o n t r o l l i n g m e c h a n i s m f o r i s o t h e r m a l g r o w t h i s t h e d r a g c a u s e d

by t h e m o v e m e n t o f C o t t r e l l a t m o s p h e r e s w i t h t h e m i g r a t i n g i n t e r f a c e . T h e Z e n e r - H i l l e r t

m o d e l f o r g r o w t h c o n t r o l by t h e d i f f u s i o n o f c a r b o n a w a y f r o m the t i p o f a g r o w i n g m a r t e n s i t e

p l a t e i s s h o w n t o be i n c o r r e c t i n p r i n c i p l e b e c a u s e i t i g n o r e s t h e g e o m e t r i c a l p r e r e q u i s i t e s

o f t h e t r a n s f o r m a t i o n . In t h e p r e s e n t m o d e l g r o w t h i s c o n t r o l l e d by t h e s i d e w i s e m o v e m e n t

o f t h e p l a n a r t r a n s f o r m a t i o n i n t e r f a c e , a n d l e n g t h g r o w t h is a g e o m e t r i c a l c o n s e q u e n c e o f t h i s

m o t i o n . T h i s v i e w i s s u p p o r t e d by t h e o b s e r v a t i o n that t h e a c t i v a t i o n e n t h a l p i e s f o r l e n g t h a n d

w i d t h g r o w t h in t h e s e a l l o y s a r e a l m o s t i d e n t i c a l . P o s s i b l e i m p r o v e m e n t s to t h e m o d e l a r e

d i s c u s s e d , and t h e i r predicted effects o n the r e s u l t s are indicated.

M A R T E N S I T I C transformations utilize t h e coopera- p a r e n t p h a s e be c o o l e d t o a t e m p e r a t u r e ( Ms) s o m e -

tive m o t i o n of m a n y a t o m s over s h o r t distances and w h a t b e l o w t h a t a t w h i c h the f r e e - e n e r g i e s of t h e

a r e t h u s c o n s i d e r e d t o be d i f f u s i o n l e s s . S i n c e m o s t o f p a r e n t a n d m a r t e n s i t e p h a s e s a r e e q u a l (To). M a n y

t h e a t o m s retain t h e i r n e a r e s t neighbors, although dif- martensitic t r a n s f o r m a t i o n s a p p e a r t o be a t h e r m a l

f e r e n t l y a r r a n g e d , a c h a n g e in s h a p e r e s u l t s f r o m t h e a n d t h e f r a c t i o n o f p a r e n t p h a s e t r a n s f o r m e d is a f u n c -

e f f e c t i v e h o m o g e n e o u s d e f o r m a t i o n of o n e p h a s e into t i o n o n l y of t h e d e g r e e o f c o o l i n g b e l o w M s . G r o w t h o f

t h e o t h e r . T h e s e two criteria--short coordinated m o v e - p l a t e s o f t h i s type of m a r t e n s i t e i s v e r y f a s t . It h a s

m e n t s of lattice a t o m s and macroscopic s h e a r or s h a p e been estimated that the interface p r e s e n t d u r i n g the

change--and t h e i r ramifications, are the b a s i s for the f o r m a t i o n o f a c i c u l a r m a r t e n s i t e in s t e e l s m o v e s w i t h

description of martensitic transformations. Marten- a v e l o c i t y o f about l0 s cm p e r sec 1 a p p r o a c h i n g t h e

s i t i c t r a n s f o r m a t i o n s o c c u r by t h e m i g r a t i o n o f d i s l o - s p e e d o f a n e l a s t i c s h e a r w a v e in t h e s o l i d . B e c a u s e

cation interfaces w h i c h b e c o m e g l i s s i l e u n d e r the ap- t h e g r o w t h is v e r y r a p i d t h e o v e r a l l k i n e t i c s o f a t h e r -

plication o f a suitable c h e m i c a l o r mechanical d r i v i n g real martensite a r e p r i m a r i l y dependent o n the n u c l e -

f o r c e . A l t h o u g h , in g e n e r a l , t h e r m a l l y a c t i v a t e d p r o c - ation frequency.

e s s e s a r e not e s s e n t i a l t o i n t e r f a c e m o v e m e n t , g r o w t h In s o m e a l l o y s , i n c l u d i n g t h o s e f i r s t r e c o g n i z e d by

of martensitic products u n d e r some conditions may K u r d j u m o v and Maximova,~ i s o t h e r m a l transformation

i n v o l v e r a t e c o n t r o l by a t o m i c m i g r a t i o n a t t h e i n t e r - o c c u r s within t h e r a n g e o f t e m p e r a t u r e - 8 0 ° to - 1 6 0 ° C .

f a c e r e q u i r i n g t h e r m a l a c t i v a t i o n . T h i s p a p e r will de- T h e k i n e t i c s of t h e s e t r a n s f o r m a t i o n s a r e c o n t r o l l e d

s c r i b e martensitic g r o w t h u n d e r such conditions. by a s t r o n g l y t e m p e r a t u r e - d e p e n d e n t n u c l e a t i o n f r e -

q u e n c y . I n c o n t r a s t , in s o m e o t h e r a l l o y s m a r t e n s i t e

KINETICS OF MARTENSITIC TRANSFORMATION f o r m s i s o t h e r m a l l y a t a r a t e c o n t r o l l e d by t h e g r o w t h

p r o c e s s . D i r e c t o b s e r v a t i o n of t h e s l o w g r o w t h of m a s -

T h e r m o d y n a m i c a l l y , m a r t e n s i t e will f o r m in a n a l l o y s i v e - m a r t e n s i t e p l a t e s a b o v e the M s t e m p e r a t u r e i n

w h e n t h e f r e e - e n e r g y o f t h e m a r t e n s i t e p h a s e is l o w e r F e - 2 8 . 8 N i h a s b e e n d e s c r i b e d by Y e o 3 w h i l e M a r d e r

than that of t h e p a r e n t p h a s e . T o n u c l e a t e t h e n e w a n d M a r d e r h a v e r e p o r t e d m u c h m o r e r a p i d g r o w t h in

p h a s e a d d i t i o n a l e n e r g y m u s t be s u p p l i e d t o o v e r c o m e F e - 2 4 . 5 N i a t a n d b e l o w t h e Ms t e m p e r a t u r e . 4 A l t h o u g h

the b a r r i e r due t o n o n c h e m i c a l t e r m s s u c h a s i n t e r - all t h e k i n e t i c f e a t u r e s o f t r a n s f o r m a t i o n in t h e s e a l -

f a c i a l a n d s t r a i n e n e r g i e s . T h i s r e q u i r e s that t h e l o y s h a v e not b e e n r e s o l v e d , t h e i n f l u e n c e of c a r b o n i s

c l e a r l y significant. T h e addition of the f i r s t s m a l l

F. J. SCHOEN, formerly with Department of Materials Science and c o n c e n t r a t i o n o f c a r b o n to a l l o y s w h i c h t r a n s f o r m to

Engineering, Cornell University,Ithaca, N.Y., is now Associate Sci- massive-martensite p r o d u c e s a l a r g e d e p r e s s i o n in

entist, Gulf General Atomic Co., San Diego, Calif. W. S. OWEN, t h e Ms t e m p e r a t u r e , s ' 6 T h i s e f f e c t c a n be r e l a t e d d i -

formerly Chairman, Department of Materials Science and Engineering,

r e c t l y t o t h e g r o w t h o f t h e p l a t e s a s s e e n by h o t - s t a g e

Cornell University,is now Dean, T h e Technological Institute, North-

western University,Evanston,Ill. m i c r o s c o p y o f t h e g r o w i n g p l a t e s in F e - 9 N i a l l o y s

This paper is based on an invited talk presented at a symposium on w i t h s m a l l a d d i t i o n s of c a r b o n . 7 S i n c e t h e e f f e c t i s

Formation of Martensite in Iron Alloys sponsored by the IMD Ferrous m u c h s t r o n g e r t h a n c a n be e x p l a i n e d by t h e c h a n g e i n

Metallurgy Committee and held at the Spring Meeting of T h e Metal- d r i v i n g f o r c e a s c a r b o n is a d d e d at a c o n s t a n t t e m p e r -

lurgical Society of AIME, May 1 9 7 0 , in Las Vegas, Nev. a t u r e , i t m u s t be c o n c l u d e d t h a t t h e r e t a r d a t i o n of

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971-2431

g r o w t h is directly r e l a t e d to t h e p r e s e n c e o f c a r b o n . known lattice s t r u c t u r e and orientation has been g i v e n

B a i n i t e h a s b e e n variously d e s c r i b e d in t e r m s o f i t s by B u l l o u g h a n d B i l b y ,17 a n d m o d i f i e d by W i n c h e l l . TM

microstructural, k i n e t i c , o r s u r f a c e r e l i e f f e a t u r e s ,s Coherency over a substantial fraction of t h e interface

It e x h i b i t s m o r p h o l o g i c a l a n d c r y s t a l l o g r a p h i c s i m - a l l o w s t h e t r a n s f o r m a t i o n t o o c c u r by t h e c o o r d i n a t e d

ilarities to m a r t e n s i t e , a l t h o u g h s p e c i f i c c r y s t a l l o - m o v e m e n t s o f a t o m s o v e r d i s t a n c e s l e s s than t h e n o r -

g r a p h i c p a r a m e t e r s a r e d i f f e r e n t , but t h e k i n e t i c s o f mal i n t e r a t o m i c spacing. A t high t e m p e r a t u r e s r a p i d

i t s f o r m a t i o n a r e i n s h a r p c o n t r a s t t o that o f t h e c l a s - a t o m i c m o t i o n i s p o s s i b l e a n d i t m a y be s u f f i c i e n t t o

s i c a l martensite transformation. Bainite f o r m s iso- eliminate the correspondence (and h e n c e the s h a p e

t h e r m a l l y a n d s l o w l y . T h e t e m p e r a t u r e r a n g e in w h i c h c h a n g e ) by r a n d o m - w a l k d i f f u s i v e f l o w o f t h e a t o m s .

b a i n i t e f o r m s i s o f t e n d i v i d e d into two r e g i o n s o n t h e I n a n a l l o y in w h i c h o n e c o m p o n e n t is s i g n i f i c a n t l y

b a s i s of both structural and kinetic considerations, 7'9-~ m o r e m o b i l e t h a n t h e o t h e r , long-range diffusion of

w i t h u p p e r b a i n i t e , s i m i l a r in a p p e a r a n c e to m a s s i v e - one component may o c c u r d u r i n g the transformation

martensite, b e i n g f o r m e d above 350°C, and l o w e r b a i n - w h i l e the o t h e r component r e m a i n s fixed on the lattice.

i t e , a n a l o g o u s to a c i c u l a r m a r t e n s i t e , f o r m i n g b e l o w T h e t r a n s f o r m a t i o n m a y o c c u r by m a r t e n s i t i c r e a r -

350°C. Structurally, u p p e r and l o w e r bainite contain rangement o f t h e i m m o b i l e c o m p o n e n t w h i l e t h e dif-

p a r t i c l e s b e a r i n g a c r y s t a l l o g r a p h i c r e l a t i o n s h i p to f u s i n g c o m p o n e n t c a n r e s u l t in t h e s e p a r a t i o n o f a

p a r e n t a u s t e n i t e a n d b a i n i t i c f e r r i t e r e s p e c t i v e l y . 9'~° s e c o n d p h a s e . T h i s i s t h e m e c h a n i s m p r o p o s e d by

A l t h o u g h the m o s t s a t i s f a c t o r y d i s t i n c t i o n b e t w e e n C h r i s t i a n ls'16 f o r b a i n i t i c d e c o m p o s i t i o n . C l e a r l y , t h e

m a r t e n s i t e s a n d b a i n i t e s i s the o n e b a s e d o n t h e p r e s - i n t e r f a c e i s i m p o r t a n t in b a i n i t i c a s w e l l a s i n m a r t e n -

e n c e of c a r b i d e s i n b a i n i t e s , 8 it i s n o t c l e a r w h e t h e r s i t i c transformations.

c a r b i d e p r e c i p i t a t i o n is o f p r i m a r y o r s e c o n d a r y i m - T h e f o r m a l theories of the crystallography a s s u m e

p o r t a n c e t o the g r o w t h p r o c e s s . It i s c l e a r , h o w e v e r , the l a t t i c e i n v a r l a n t s h e a r t o be p r o d u c e d by f a m i l i a r

that the s l o w i s o t h e r m a l g r o w t h , c h a r a c t e r i s t i c o f deformation m o d e s . T h u s , the interface dislocations

diffusion controlled nucleation and g r o w t h t r a n s f o r m a - have a s e c o n d function: to p r o d u c e the r e q u i r e d d e f o r -

t i o n s , a n d the s h a p e d e f o r m a t i o n c h a r a c t e r i s t i c of m a t i o n w h e n t h e y a r e m o v e d . It i s c o n v e n i e n t t o a s s u m e

m a r t e n s i t i c t r a n s f o r m a t i o n s , a r e b o t h i m p o r t a n t fea- that t h e s u r f a c e d i s l o c a t i o n i s r e s o l v e d into a p a r a l l e l

t u r e s of the k i n e t i c s of b a i n i t e f o r m a t i o n . a r r a y of d i s c r e t e d i s l o c a t i o n s 19 o f a k i n d w h i c h p r o d u c e

The morphological transition from m a s s i v e - m a r t e n - t h e a p p r o p r i a t e s l i p o r t w i n n i n g . It h a s b e e n d e m o n -

site to u p p e r b a i n i t e h a s b e e n d e m o n s t r a t e d b y G o o d - s t r a t e d e l s e w h e r e2 ° ' z l that t h e d i s l o c a t i o n a r r a y r e -

e n o w a n d H e h e m a n n . ~4 A d o p t i n g the c r i t e r i o n that c a r - q u i r e d t o a c c o m m o d a t e t h e m i s f i t b e t w e e n the s t r u c -

bide particles associated with ferrite plates denotes t u r e s i s c o m p a t i b l e w i t h the a r r a y n e e d e d t o p r o d u c e

the p r e s e n c e of b a i n i t e ,s the t r a n s i t i o n in the 9 N i the appropriate lattice invariant s h e a r and thus pro-

a l l o y s o c c u r s at a b o u t 0.i w t pct c a r b o n . T h u s , t h e r e duce t h e m a r t e n s i t e s t r u c t u r e . T h a t is, t h e long-range

is a r a n g e of c o m p o s i t i o n s , at a n y g i v e n t e m p e r a t u r e s t r a i n s of the r e s o l v e d dislocation a r r a y exactly can-

of i s o t h e r m a l d e c o m p o s i t i o n of a u s t e n i t e , w i t h i n w h i c h c e l the l a t t i c e m i s m a t c h . T h e d i s l o c a t i o n s i n t h e i n t e r -

t r a n s f o r m a t i o n to m a r t e n s i t e is l i m i t e d b y s l o w iso- face a r e o f spacing h a n d lie a l o n g t h e invariant line o f

t h e r m a l g r o w t h . T h e d i s c u s s i o n w h i c h f o l l o w s is a d - t h e pure lattice deformation l. T h e b u r g e r s v e c t o r b

d r e s s e d to t h e e x p l a n a t i o n of e v e n t s c o n t r o l l i n g the o f t h e s e d i s l o c a t i o n s i s p a r a l l e l t o d 2 , t h e d i r e c t i o n of

g r o w t h of m a r t e n s i t e in this r a n g e . t h e l a t t i c e i n v a r i a n t s h e a r . If t h e l a t t i c e i n v a r i a n t

s h e a r i s a s i m p l e s h e a r a s a s s u m e d i n a l l but t h e m o s t

r e c e n t t h e o r i e s , t h e r e c a n be no c r o s s g r i d . I n t h e

T H E MARTENSITIC INTERFACE

c r y s t a l l o g r a p h i c t h e o r y f o r m u l a t i o n s by A c t o n a n d

Interfacial Structure B e v i s ,2~ a n d R o s s a n d C r o c k e r , 2 3 how e v e r , c o m p o u n d

s h e a r s a r e postulated and more complex dislocation

C h r i s t i a n ~5'~ h a s p r o p o s e d that t h e n a t u r e of t h e

a r r a y s a r e allowed. T h e p r e s e n t t r e a t m e n t is r e -

i n t e r f a c e b e t w e e n t h e p a r e n t p h a s e a n d the m a r t e n -

s t r i c t e d to t r a n s f o r m a t i o n s i n v o l v i n g a s i m p l e l a t t i c e

sitic product determines t h e growth mechanism, and invariant s h e a r .

that f o r a l l m a r t e n s i t e s the e s s e n t i a l f e a t u r e s of t h i s

interface are t h e s a m e . T h e s h a p e change c h a r a c t e r - Motion of the Interface

i s t i c of the transformation i m p l i e s some continuity

a c r o s s the interface and, consequently, this interface T h e difference b e t w e e n the free e n e r g y of the p a r e n t

m u s t be s u b s t a n t i a l l y c o h e r e n t . H o w e v e r , a c o m p l e t e l y p h a s e and the martensite provides the d r i v i n g f o r c e

c o h e r e n t p l a n e c a n e x i s t o n l y i n t h e c i r c u m s t a n c e that f o r m o v e m e n t of t h e i n t e r f a c e a n d g e n e r a t i o n o f the

t h e d e f o r m a t i o n r e l a t i n g a n y p a i r o f unit c e l l s in t h e m a r t e n s i t i c s t r u c t u r e . R e s i s t a n c e to f o r w a r d m o t i o n

two s t r u c t u r e s c o n t a i n s o n e p r i n c i p a l s t r a i n w h i c h is o f t h e i n t e r f a c e d e p e n d s o n t h e g e o m e t r y of t h e d i s l o -

z e r o . S i n c e t h i s c o n d i t i o n i s not o r d i n a r i l y m e t , t h e cations and the rate controlling m e c h a n i s m s for d e f o r -

c u r r e n t t h e o r y v i s u a l i z e s t h e m i s m a t c h t o be p e r i o d i c - m a t i o n . M o v e m e n t o f c o h e r e n t r e g i o n s i s not o p p o s e d .

a l l y c o r r e c t e d by d i s c o n t i n u i t i e s ( d i s l o c a t i o n s o r t w i n O n t h e c o n t r a r y , t h e e n e r g y r e l e a s e d by t h e s t r u c t u r a l

b o u n d a r i e s ) w h i c h e n s u r e that the s t r a i n s do not a c - c h a n g e p r o d u c e d as t h e c o h e r e n t boundary sections

cumulate over l a r g e distances. T h e interface thus con- pass through t h e c r y s t a l provides t h e f o r w a r d d r i v i n g

s i s t s of r e g i o n s of f o r c e d elastic coherence separated f o r c e for the transformation.

by r e g i o n s o f m i s f i t . I f o n l y n o n c o n s e r v a t i v e m o t i o n o f t h e i n t e r f a c e dis-

T h e m i s f i t i n the i n t e r f a c e i s b e s t d e s c r i b e d i n t e r m s l o c a t i o n s is p o s s i b l e as w i t h , f o r e x a m p l e , t h e e p i t a x i a l

of a s u r f a c e dislocation. A method for finding the b o u n d a r y d e s c r i b e d by C h r i s t i a n , 24 m o v e m e n t a t m e a s -

t e n s o r e x p r e s s i n g t h e d i s l o c a t i o n c o n t e n t o f the s u r f a c e u r a b l e s p e e d s will o c c u r o n l y at t e m p e r a t u r e s c l o s e to

dislocation between parent and martensite c r y s t a l s of t h e m e l t i n g p o i n t b e c a u s e e x t e n s i v e c l i m b o f t h e dis-

2432-VOLUME 2 , SEPTEMBER 1971 METALLURGICAL TRANSACTIONS

y

x=--~

Fo rce

Velocity

Fig. 1---Schematic force-velocity c u r v e f o r a r a t e controlling

p r o c e s s l e a d i n g t o s t a b l e i s o t h e r m a l g r o w t h u n d e r low d r i v i n g

f o r c e a n d r a p i d u n s t a b l e g r o w t h when a c r i t i c a l driving f o r c e

is exceeded.

l o c a t i o n s is n e c e s s a r y . A t t h e s e t e m p e r a t u r e s diffu-

sive flow w o u l d wipe out t h e s h a p e change. M a n y mar-

Z ~ sheor

tensitic t r a n s f o r m a t i o n s o c c u r at low temperatures

( d o w n t o 4 ° K ) ,25 a n d , c l e a r l y , m o t i o n o f t h e i n t e r f a c e F i g . 2--Schematic d i a g r a m i l l u s t r a t i n g the important f e a t u r e s

m u s t be c o n s e r v a t i v e . T h e n e c e s s a r y g e o m e t r i c a l of the interface.

c o n d i t i o n f o r c o n s e r v a t i v e m o t i o n is t h a t t h e b u r g e r s

v e c t o r o f t h e i n t e r f a c e d i s l o c a t i o n s d o e s n o t l i e i n the

i n t e r f a c e a n d h e n c e t h e y r e s u l t o n l y in a n e f f e c t i v e

i n t e r f a c e . A l t h o u g h r e s i s t a n c e to d i s l o c a t i o n m o t i o n l o w e r i n g o f t h e d r i v i n g f o r c e f o r the t r a n s f o r m a t i o n .

will i n c r e a s e as t h e magnitude o f t h e b u r g e r s v e c t o r

i s i n c r e a s e d , t h e r e i s r e a l l y no n e c e s s i t y f o r the dis-

l o c a t i o n s i n t h e i n t e r f a c e t o be o f t h e t y p e r e q u i r e d f o r A M O D E L FOR T H E G R O W T H O F A P L A T E

conventional deformation of a single-phase material. OF MASSIVE-MARTENSITE

T h e c r y s t a l g e o m e t r y of t h e t r a n s f o r m a t i o n m a y d i c t a t e Specific Interface

the selection of a b u r g e r s vector l a r g e r than that re-

q u i r e d for m i n i m u m elastic self-energy of t h e d i s l o - T h e i n t e r f a c e is i l l u s t r a t e d in Fig. 2 . T h e a s s i g n -

cations. m e n t of specific variants of the crystallographic pa-

In a n e a r l i e r d i s c u s s i o n , O w e n , S c h o e n , a n d S r i n i - r a m e t e r s r e q u i r e s complete crystallographic c h a r a c -

v a s a n2° p o i n t e d o u t that r a p i d g r o w t h o f m a r t e n s i t e terization (habit p l a n e , orientation relationship, t h e

p l a t e s in s o m e a l l o y s a n d s l o w g r o w t h in o t h e r s i m - e l e m e n t s a n d m a g n i t u d e of l a t t i c e i n v a r i a n t s h e a r ,

p l i e s that t h e a p p l i e d f o r c e - v e l o c i t y r e l a t i o n s h i p d e - a n d so f o r t h ) o f a p a r t i c u l a r t r a n s f o r m a t i o n . A s

s c r i b i n g m o t i o n o f the i n t e r f a c e i s o f t h e f o r m i l l u s - t h e s e p a r a m e t e r s c a n o t a l l be p r o p e r l y a s c e r t a i n e d

t r a t e d s c h e m a t i c a l l y in Fig. 1. T h e r e l a t i o n s h i p must f o r m a s s i v e - m a r t e n s i t e , it is n e c e s s a r y to fit a s e l f -

contain an instability. In a c i c u l a r martensite, the i n s t a - c o n s i s t e n t set o f c r y s t a l l o g r a p h i c p a r a m e t e r s ob-

b i l i t y o c c u r s b e c a u s e t h e n u c l e a t i o n of t r a n s f o r m a t i o n t a i n e d through application of the f o r m a l crystallo-

twins, p a r t o f t h e g r o w t h s t a g e , is a m o r e difficult s t e p g r a p h i c t h e o r y to t h e available e x p e r i m e n t a l d a t a f o r

t h a n t h e i r subsequent p r o p a g a t i o n . T h e g r o w t h o f m a s - t h e t r a n s f o r m a t i o n . It h a s b e e n s h o w n p r e v i o u s l y 2° t h a t

sive-martensite, h o w e v e r , c a n n o t i n v o l v e t h i s type of the m e a s u r e d crystallographic p a r a m e t e r s for m a s s i v e -

i n s t a b i l i t y s i n c e t h e s u b s t r u c t u r e i n g e n e r a l d o e s not m a r t e n s i t e a r e in g o o d a g r e e m e n t w i t h a t h e o r e t i c a l set

c o n t a i n i n t e r n a l t w i n n i n g , 26-28 a n d t h e l a t t i c e i n v a r i a n t p r o p o s e d by W e c h s l e r , R e a d , a n d L i e b e r m a n .29 T a b l e I

s h e a r i s a s s u m e d t o o c c u r by s l i p . T h e s u g g e s t i o n s h o w s all o f t h e p e r t i n e n t crystallographic p a r a m e t e r s

that a force-velocity c u r v e containing an instability d e s c r i b i n g t h e interface. For t h e particular crystallog-

c o u l d a r i s e in m a s s i v e - m a r t e n s i t e s a s a r e s u l t of t h e r a p h y c h o s e n t h e d i s l o c a t i o n s i n t h e i n t e r f a c e do not

interaction of the interface s t r e s s f i e l d with the have a f a m i l i a r bcc b u r g e r s vector. However, t h e y m a y

s t r a i n f i e l d s of d i s s o l v e d c a r b o n a t o m s h a s b e e n dis- be d i s s o c i a t e d into t w o s e t s e a c h h a v i n g i d e n t i c a l s p a c -

c u s s e d e a r l i e r .2° A m o r e d e t a i l e d q u a n t i t a t i v e m o d e l ing and t h e low e n e r g y (lll)c~ t y p e b u r g e r s vector. F o r

w i l l be e x p l o r e d i n t h e s u b s e q u e n t s e c t i o n s o f t h i s t h e c a l c u l a t i o n s to follow, t h i s c o n s i d e r a t i o n i s i r r e l e -

p a p e r . T h e m o d e l predicts a slow s t a b l e g r o w t h when v a n t s i n c e t h e s t r e s s f i e l d s a r e not a f f e c t e d by d i s s o c i a -

t h e d r i v i n g f o r c e is s m a l l , a n d r a p i d u n s t a b l e m o t i o n t i o n . I f t h e p o s s i b i l i t y of u n e q u a l s p a c i n g o f t w o s e t s of

w h e n a c r i t i c a l d r i v i n g f o r c e is exceeded. d i s l o c a t i o n s i n t h e h a b i t p l a n e i s a l l o w e d , t h e n a wide

F o r c e s s u c h a s the P e i e r l s s t r e s s o f t h e b c c s t r u c - v a r i e t y of c r y s t a l l o g r a p h i e s , s o m e o f w h i c h g i v e h a b i t

t u r e ( i f t h e t e m p e r a t u r e is l o w e n o u g h ) , t h e s t r e n g t h p l a n e s v e r y n e a r { 1 1 1 } 7 a r e o b t a i n e d . T h i s is t h e i n -

o f the f c c s t r u c t u r e ( t a k i n g into a c c o u n t t h e w o r k h a r d - terfacial description of the Acton and Bevis,22 and R o s s

e n i n g due t o a c c o m m o d a t i o n ) , a n d o t h e r i m p e d i m e n t s a n d C r o c k e r23 g e n e r a l i z e d c r y s t a l l o g r a p h i c t h e o r i e s

t o d i s l o c a t i o n m o t i o n s h o u l d be c o n s i d e r e d i n d e t e r - allowing multiple lattice invariant s h e a r s . T h e p r e s e n t

mining t h e o v e r a l l b a l a n c e o f f o r c e s at t h e interface. a u t h o r s a r e c u r r e n t l y e x p l o r i n g i n d e t a i l t h e u s e of

To a f i r s t approximation, however, t h e s e a r e c o n s e r - t h e s e t h e o r i e s in e x p l a i n i n g t h e m e a s u r e d c r y s t a l l o -

v a t i v e f o r c e s w h i c h do not d e p e n d o n t h e v e l o c i t y o f g r a p h i c p a r a m e t e r s o f m a s s i v e - m a r t e n s i t e . 3°

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971-2433

1.0

Table I. Complete Crystallographic Chracterization

of the Massive-Martensite Interface O

0.8[ u2

Habit Plane (P0 (-0.653 0.480 0.586)~ II 450"C

(-0,861 -0.170 0.480)=

0.6

Plane of Lattice lnvariant

Shear (P2) (001)~,

T

Shear Direction (d2) [lrll~ 0.4

O

Invariant Line (/) [0.481 0.583 0.655]= u2

Flux Vector (V) [-0.169 --0.794 -0.584]=

in eV

0.2

Magnitude ofLattice =+-9

Invariant Shear (m2) 0.284 (8.1 deg.)

cos/3(/'b) 0.875

cos • (y' p~) 0.974

Distance between the Dislocations -0.2

in the Interface (h) 14.68A

Orientation Relationship

Axis (u) -0.4

0.195 I

0.97413, -0.6

Angle (0) 44.37 deg

Assumed Correspondence -0.8

ccC

? -3.77

-I,O t

O 1.0 2.0 3.0

(2 •

Q = T X

(b) h

1.0

1.0

0.8

450*C

0

0.8 u3

0.6

450*C

0.6

0.4

0

Ul

in eV 0.4

o2 r /-x: u;

in eV

0.2

-0.2

~=O

-0.2

-0.4

-0.6

-0.4

-0.6

-0.8

- 1.0 -0.8 t"

0 1.0 2.0 3.0

(2 •

(1 =/rx -I.0 I I I

(a) b 0 1.0 2.0 3.0

Ct •

Fig. 3--Calculated interaction e n e r g y as a function of the co- Q;TX

ordinates c~ and X for c a r b o n i n (a) [100]a s i t e s , (b) [010]a h

s i t e s , and (c) [ 0 0 1 ]~ s i t e s . (c)

2434-VOLUME 2, SEPTEMBER 1971 METALLURGICAL TRANSACTIONS

T h e Interaction Between the Interface h i g h . T h i s s i t u a t i o n was q u a n t i t a t i v e l y f i r s t a n a l y z e d

and D i s s o l v e d C a r b o n A t o m s by S c h o e c k a n d S e e g e r33 f o r i n t e r a c t i o n w i t h a s i n g l e

dislocation. O n t h e o t h e r h a n d , at high t e m p e r a t u r e s

T h e s y m m e t r i c a l s t r e s s t e n s o r (a) o f t h e d i s l o c a t i o n

o r l o w d i s l o c a t i o n v e l o c i t i e s (low v e l o c i t i e s o f i n t e r -

a r r a y 2° r e l a t i v e t o a n o r t h o n o r m a l b a s i s i n t h e i n t e r -

face propagation), extensive diffusion of c a r b o n over

f a c e (p}, y , l ) a n d the s t r a i n t e n s o r (E) o f t h e t e t r a g o n a l

l o n g d i s t a n c e s is p o s s i b l e in t h e t i m e in w h i c h a l a b e l e d

d i s t o r t i o n o f a c a r b o n a t o m i n e a c h of the t h r e e o c t a -

c a r b o n a t o m i s i n f l u e n c e d by t h e s t r e s s f i e l d o f t h e

h e d r a l i n t e r s t i c e s o f the b c c s t r u c t u r e r e f e r r e d t o t h i s

interface. This effect w a s originally a n a l y z e d for a

s a m e b a s i s21 h a v e b e e n s e t o u t e a r l i e r . T h e e l a s t i c

s i n g l e dislocation, ignoring redistribution of c a r b o n

interaction e n e r g y between the dislocation a r r a y and a

a m o n g t h e / - s i t e s , by C o t t r e l l a n d B i l b y34 a n d C o t t r e l l

d i s s o l v e d c a r b o n a t o m n e a r t h e i n t e r f a c e is

a n d J a s w o n .31 I t i s a p p r o p r i a t e l y k n o w n a s t h e C o t t r e l l

u : - ( ~ , c)a~ interaction. The S n o e k and Cottrell m o d e l s a r e each

s i m p l i f i e d v e r s i o n s of t h e d r a g p h e n o m e n o n . I n a n y r e a l

and

situation, t h e c a r b o n a t o m s m a y simultaneously s e l e c t

u = u l i f £1 > e2 = ca, c a r b o n a t o m i n [ 1 0 0 ~ s i t e [1] / - s i t e s a n d diffuse o v e r d i s t a n c e s g r e a t e r t h a n o n e

a t o m i c spacing.

u = u2 i f e2 > E~ = c a , c a r b o n a t o m i n [010]c~ s i t e

Martensite f o r m s a s an o r d e r e d s t r u c t u r e of c a r b o n

u = u3 i f Ea > (~ = ¢~, c a r b o n a t o m i n [ 0 0 1 ] a s i t e in a d i s t o r t e d bcc l a t t i c e as a d i r e c t c o n s e q u e n c e o f

t h e g e o m e t r y of t h e t r a n s f o r m a t i o n . T h e d i s t o r t i o n

w h e r e a a is t h e l a t t i c e p a r a m e t e r o f t h e m a r t e n s i t e .

m a k e s t h e unit cell tetragonal. T h e c a r b o n a t o m s a r e

T h e s e i n t e r a c t i o n e n e r g i e s m u s t be c o r r e c t e d f o r t h e

all in i d e n t i c a l / - s i t e s , t h e p a r t i c u l a r s i t e b e i n g d e t e r -

e n e r g y r e s u l t i n g f r o m t h e i n t e r a c t i o n o f the l o n g - r a n g e

m i n e d by t h e s e l e c t e d v a r i a n t o f t h e B a i n c o r r e s p o n d -

s t r e s s f i e l d s of the dislocations, w h i c h exactly c a n c e l

the l a t t i c e m i s m a t c h b e t w e e n t h e a u s t e n i t e a n d m a r t e n - e n c e . All t h e calculations d i s c u s s e d here a s s u m e d t h e

c a r b o n a t o m s in t h e m a r t e n s i t e s t r u c t u r e a r e l o c a t e d

s i t e s t r u c t u r e s , w i t h t h e s t r a i n f i e l d due t o t h e c a r b o n

i n s i t e 3 , ( T a b l e I). A s t h e i n t e r f a c e m o v e s , t h e c a r b o n

a t o m s . T h e i n t e r a c t i o n e n e r g y u~ r e s u l t s . V a l u e s o l u }

a t o m s j u m p to t h e e n e r g e t i c a l l y m o s t f a v o r a b l e p o s i -

a s a function o f t h e distance X within t h e interface a n d

tions. D u r i n g the time r e q u i r e d for the j u m p , the r e -

a p e r p e n d i c u l a r to it were c a l c u l a t e d u s i n g a n IBM

l a x a t i o n t i m e , t h e i n t e r f a c e m o v e s a s h o r t d i s t a n c e so

3 6 0 / 6 5 c o m p u t e r . T h e r e s u l t s a r e p l o t t e d in F i g . 3 f o r

that t h e i n t e r s t i t i a l s a r e no l o n g e r i n m i n i m u m e n e r g y

t h e e x a c t c r y s t a l l o g r a p h i c p a r a m e t e r s in T a b l e I . F o r

p o s i t i o n s c o r r e s p o n d i n g to t h e n e w p o s i t i o n o f t h e i n -

each of the t h r e e p o s s i b l e positions of the c a r b o n atom

in t h e unit cell t h e i n t e r a c t i o n e n e r g y a p p r o a c h e s z e r o t e r f a c e . T h e r e s u l t i s that t h e c a r b o n j u m p i n g i s n o t

e x a c t l y in p h a s e w i t h t h e i n s t a n t a n e o u s l o w e n e r g y

a t a = ~ . That i s , t h e e n e r g y g o e s t o z e r o a t a d i s t a n c e

configurations of the s y s t e m and an e n e r g y dissipation

f r o m t h e i n t e r f a c e e q u a l t o t h e d i s t a n c e b e t w e e n the dis-

o c c u r s c a u s i n g a drag on the interface. For the i n t e r -

l o c a t i o n s ( 1 4 . 6 8 A ) . A t a g r e a t e r d i s t a n c e t h e r e i s no

f a c e to m o v e , t h e f o r c e p u s h i n g t h e i n t e r f a c e must

preference a m o n g the interstitial s i t e s . For c a r b o n

supply enough e x t r a e n e r g y to o v e r c o m e t h i s d i s s i p a -

a t o m s l y i n g i n t h e s h e a r p l a n e X = 0 , u~ a n d u~ a p p r o a c h

t i o n . F o r t h e p a r t i c u l a r c o n d i t i o n s o f i n t e r e s t h e r e it

a l a r g e n e g a t i v e , a n d u~ a l a r g e p o s i t i v e , v a l u e a s a

h a s b e e n s h o w n t h a t t h e d r a g f o r c e p r o d u c e d by t h e

approaches z e r o . T h e s e represent the e n e r g y of inter-

S n o e k i n t e r a c t i o n is q u i t e i n s i g n i f i c a n t w h e n c o m p a r e d

a c t i o n w i t h t h e c o r e a n d t h e c u r v e s s h o u l d be c u t off a t

s o m e a p p r o p r i a t e value as t h e assumption o f l i n e a r t o t h a t p r o d u c e d by t h e C o t t r e l l i n t e r a c t i o n a n d h e n c e

o n l y t h e l a t t e r w i l l be c o n s i d e r e d . T h e d e t a i l s o f b o t h

e l a s t i c i t y , as well a s t h e s t r e s s f i e l d f o r m u l a t i o n itself,

c a l c u l a t i o n s a r e d e s c r i b e d e l s e w h e r e .35

b e c o m e s u n t e n a b l e . T h e c h o i c e o f a c o r e l i m i t is a dif-

ficult p r o b l e m . P h y s i c a l l y , it is e x p e c t e d t h a t t h e i n t e r -

s t i t i a l a t o m s n e a r the c o r e w i l l be v e r y t i g h t l y b o u n d Cottrell Drag M o d e l

a n d will o f f e r v e r y l i t t l e r e s i s t a n c e to m o t i o n o f t h e

i n t e r f a c e d i s l o c a t i o n s . 3~ In t h e s e c i r c u m s t a n c e s the L o n g - r a n g e diffusion o f c a r b o n to t h e b o u n d a r y is

p e r m i t t e d i n t h e C o t t r e l l m o d e l a n d it i s c o n s i d e r e d

i n t e r a c t i o n o p p o s i n g m o t i o n w o u l d t h e n be w i t h i n t e r -

t h a t a n y p o s i t i o n (x, y ) t h e c a r b o n a t o m i s s i t t i n g i n

stitial a t o m s at s o m e distance away f r o m t h e boundary.

In t h e c a l c u l a t i o n s t o f o l l o w , t h e r e a s o n a b l e c o r e c u t - t h e s i t e o f m i n i m u m u~ a s d e f i n e d by t h e d a t a i n F i g .

3 . T h e concentration profile a r o u n d the moving b o u n d -

off v a l u e of b/2 i s u s e d . T h e s u i t a b i l i t y of t h i s c h o i c e

a r y i s o b t a i n e d by a s s u m i n g that s o l u t e a t o m s i n a

w i l l be e x a m i n e d w h e n t h e t h e o r e t i c a l p r e d i c t i o n s a r e

s m a l l r e g i o n b e h i n d the interface a c q u i r e a velocity

c o m p a r e d with experimental r e s u l t s .

r e l a t i v e t o t h e b o u n d a r y i n t h r e e w a y s : 31

T h e i n t e r a c t i o n e n e r g y u~ i s d e p e n d e n t o n b o t h the 1) A n E i n s t e i n d r i f t v e l o c i t y due t o t h e s t r e s s

xy coordinate position behind the interface, and the gradient

d i r e c t i o n of t h e t e t r a g o n a l d i s t o r t i o n o f t h e c a r b o n

a t o m , d e s c r i b e d by t h e p a r a m e t e r i . T h e e n e r g y of the D Ou'

c r y s t a l m a y be r e d u c e d by o n e o f t w o p r o c e s s e s . T h e YD - k T Ox [2]

/ - s i t e m a y be c h a n g e d a t a c o n s t a n t x a n d y , o r d i f f u - w h e r e D is t h e diffusion c o e f f i c i e n t a n d u ' is t h e m i n -

sion over m a n y atomic distances m a y take p l a c e , with imum interaction e n e r g y u~,

t h e most favorable / - s i t e probably b e i n g c h o s e n at a n y 2) a d i f f u s i o n v e l o c i t y c a u s e d by t h e c o n c e n t r a t i o n

particular x and y . Reorganization of c a r b o n a m o n g g r a d i e n t s s e t up by t h e s e g r e g a t i o n i n t h e s t r e s s f i e l d

e n e r g e t i c a I l y f a v o r a b l e / - s i t e s (the S n o e k i n t e r a c t i o n ) ~2

Dac

r e q u i r e s o n l y o n e a t o m i c j u m p a n d t h i s is t h e m o r e vC - c ~x [3]

p r o b a b l e o c c u r r e n c e i f the t e m p e r a t u r e i s l o w o r i f t h e

v e l o c i t y of t h e d i s l o c a t i o n s c a u s i n g t h e i n t e r a c t i o n i s a s s u m i n g a d i l u t e solution, and

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971-2435

~D I ~ Diffusion Coefficient profil@

2 LJ ~ O'~'x~h/8 ~ D = 3V2D L

D I k h,0 <-"x(-h - - D =('~"~)° D L " D L

I

DLI •

\ ~

(2

....--

~,o h/8 h

~8 Fig. 4--Temperature dependence of the

E J c a l c u l a t e d p a r a m e t e r s a , c~/B2 , and/3

2 u s e d in the determination of the C o t t r e l l

g.e interaction. T h e a s s u m e d d i f f u s i o n co-

Cln efficient p r o f i l e i s g i v e n in the i n s e t .

E~ 4 /3

/o~

2 /32

-2 I I I I I

1.20 1.30 1.40 1.50 1.60 1.70

I000/r (°K)

3) a v e l o c i t y due t o the m o t i o n of t h e b o u n d a r y , --v. in Fe-I0 Ni-C alloys is the interaction of dissolved

The velocity of the boundary, VR, relative to the group interstitial solutes with the moving interface, there

of solute atoms is are additional processes which may contribute to the

retardation of growth by interracial action. Since the

D 3u' D 8c

VR = k T Ox c Ox [4] magnitudes of these drag forces are to a first approx-

imation all independent of the velocity of the interface

T h e c a l c u l a t i o n of the c o n c e n t r a t i o n p r o f i l e a r o u n d the it is convenient to take the net forward driving force

b o u n d a r y a n d the r e s u l t a n t d r a g f o r c e f o l l o w s f r o m t h e as the difference between the free-energy of the trans-

s o l u t i o n o f E q . [4] s u b j e c t t o t h e a p p r o p r i a t e b o u n d a r y formation and the constant retarding forces. Then the

conditions and the imposition of the continuity condi- rate of forward motion of the interface is assumed to

tions (O/Ox)(cvR) = 0 . An approximate solution for the be that at whichthe velocity-dependent frictional re-

d r a g f o r c e F c , f i t t i n g a l l v e l o c i t y r e g i m e s , i s 36 tarding force is just balanced by the net driving force.

The forward driving force for the transformation,

Fc OlYCo [~] Fig. 6, has been calculated for the alloys under con-

1 + ~2v2 sideration from the recent correlation of thermody-

where --U' namic variables for Fe-Ni-C alloys by Rao, Russell,

h h,2 oxp( ) 1 and Winchell.37 This will be considered as the total

ot : NvkT

h ~; f D(x) ~y ax [6] energy available to move the interface against all im-

h/2 pediments to the transformation from austenite to

and martensite of the same composition. In carbon-free

h h/2 (OU,~2 materials, the predominant force retarding the forward

ot _ Nv

[7]

~32 hkT / f \ax/ dy dx

h/2

w h e r e Nv i s t h e n u m b e r o f c a r b o n a t o m s i t e s i n the i 300 ~ At( omc Froction.05.C075.02805010

s t r u c t u r e , k is B o l t z m a n ' s c o n s t a n t , T is t h e a b s o l u t e

t e m p e r a t u r e , a n d co i s t h e bulk c a r b o n c o n c e n t r a t i o n

i n the a l l o y .

U s i n g t h e interaction e n e r g y profiles previously

calculated, and t h e reasonable diffusion coefficient 200

p r o f i l e s h o w n i n t h e i n s e t of F i g . 4 , t h e p a r a m e t e r s o t

a n d /3 w e r e o b t a i n e d by n u m e r i c a l i n t e g r a t i o n . T h e

r e s u l t s o f t h e c a l c u l a t i o n a r e s h o w n a s a f u n c t i o n of

r e c i p r o c a l t e m p e r a t u r e in Fig. 4 . F o r c e - v e l o c i t y a

r~ I00

c u r v e s a r e r e a d i l y computed from this information u_'.'

a n d a r e s h o w n , f o r 4 5 0 ° C a n d the c a r b o n l e v e l s e m -

p l o y e d in t h e e x p e r i m e n t a l a s p e c t s o f t h i s i n v e s t i g a -

t i o n , in Fig. 5.

00 2 4 6 8 I0 12 14 16 18 20 22 24I

Velocity, v in 10-2mrn/sec

B a l a n c e o f F o r c e s at t h e Interface

Fig. 5---Calculated force-velocity curves for the Cottrell inter-

A l t h o u g h it is a s s u m e d h e r e t h a t t h e c o n t r o l l i n g action of carbon atoms with the massive-martensite boundary

m e c h a n i s m in t h e i s o t h e r m a l f o r m a t i o n o f m a r t e n s i t e at 450°C for various carbon levels.

2436-VOLUME 2 , SEPTEMBER 1971 METALt.URGICALTRANSACT1ONS

I00

-50C

-40C

-500 x

=o I0

O

E

-2oc E

o E

C

?, -IOO

>, (.9

LL

Atom Fro¢tion 0

a~

0 Corbon

R~.= 0

Xc

3

.ooo5 2 RT= 5 0 , 0 0 0psi RT= 25,000psi

+1oo .0028

.005

.oo75

.01

+200 I I I I i I

5oo 600 700 8oo 900 IOOO IlOO

T e m p e r a t u r e , *K

Fig. 6--Variation with t e m p e r a t u r e of the d r i v i n g f o r c e for the .I I ! I I I

m a r t e n s i t e transformation, A F ~ ' ~ , for s e v e r a l F e - 1 0 N i - C 0 .002 .004 .006 .008 .010

alloys, a s c a l c u l a t e d from the thermodynamic m o d e l of Rao, Atom Fraction Carbon, Xc

R u s s e l l , and Winehell. T h e points O a r e the Ms t e m p e r a t u r e s

d e t e r m i n e d experimentally i n the p r e s e n t investigation. Fig. 7--Predicted w i d t h g r o w t h r a t e s at 450°C a s a function of

c a r b o n content on the b a s i s of the Cottrell d r a g g r o w t h c o n t r o l

m o d e l a s s u m i n g v a r i o u s v a l u e s of the a u s t e n i t e r e s i s t a n c e t o

m o t i o n of the m a r t e n s i t i c i n t e r f a c e i s t h e r e s i s t a n c e transformation.

to m o t i o n o f t h e t r a n s f o r m a t i o n d i s l o c a t i o n s t h r o u g h

t h e p a r e n t a u s t e n i t e . It i s n o w w i d e l y h e l d that i t i s l e n g t h a n d w i d t h g r o w t h of a p l a t e s h o u l d be r e l a t e d i n

the p l a s t i c , r a t h e r t h a n e l a s t i c , p r o p e r t i e s o f t h e aus- t h a t l e n g t h g r o w t h is r e a l l y a g e o m e t r i c a l c o n s e q u e n c e

t e n i t e w h i c h a r e i m p o r t a n t in d e t e r m i n i n g t h e k i n e t i c s o f g r o w t h in t h e w i d t h d i r e c t i o n . H e n c e t h e a c t i v a t i o n

o f m a r t e n s i t i c t r a n s f o r m a t i o n . 3s-4° In v i e w o f t h e e x - e n t h a l p i e s f o r g r o w t h in t h e l e n g t h a n d w i d t h d i r e c t i o n s

t r e m e p l a s t i c d e f o r m a t i o n o f a u s t e n i t e due t o a c c o m - s h o u l d be i d e n t i c a l .

m o d a t i o n i n f r o n t o f a g r o w i n g m a r t e n s i t e p l a t e ,41 a n d P r e d i c t e d g r o w t h r a t e s of the martensitic p r o d u c t

t h e high effective s t r a i n r a t e u n d e r w h i c h this d e f o r - f o r m e d i s o t h e r m a l l y in t h e F e - 1 0 N i - C a l l o y s at 4 5 0 ° C

m a t i o n o c c u r s ,2x i t i s p o s s i b l e that the a u s t e n i t e r e - o n t h e b a s i s of t h e C o t t r e [ 1 d r a g f o r c e - v e l o c i t y r e l a -

s i s t a n c e t o t r a n s f o r m a t i o n i s s u b s t a n t i a l . M a g e e~8 a n d tionships, the f o r w a r d d r i v i n g f o r c e for transformation,

S c h o e n 21 h a v e r e a c h e d t h e c o n c l u s i o n that t h i s s t r e n g t h and the a s s u m e d v a l u e s of austenite lattice r e s i s t a n c e

is o f t h e o r d e r o f 4 0 , 0 0 0 psi u n d e r t h e c o n d i t i o n s in t o t r a n s f o r m a t i o n a r e g i v e n i n F i g . 7 . I t i s not p o s s i b l e

q u e s t i o n b u t , b e c a u s e of t h e u n c e r t a i n t i e s i n v o l v e d i n t o p r e d i c t t h e m a g n i t u d e of t h e t e m p e r a t u r e d e p e n d e n c e

t h e s e e s t i m a t e s , v a r i o u s v a l u e s of t h e a u s t e n i t e l a t t i c e of t h e s e g r o w t h r a t e s b e c a u s e the calculations d e p e n d

r e s i s t a n c e b e t w e e n 0 a n d 5 0 , 0 0 0 psi were a s s u m e d in sensitively o n t h e exact net f o r w a r d d r i v i n g f o r c e and

the c a l c u l a t i o n s . i t s t e m p e r a t u r e d e p e n d e n c e . T h i s f o r c e is, in t u r n ,

s t r o n g l y a f f e c t e d by t h e e x a c t v a l u e a n d t e m p e r a t u r e

dependence of the unknown austenite lattice r e s i s t a n c e

G r o w t h Rate Predictions

to t r a n s f o r m a t i o n .

P r e d i c t i o n s o f m a r t e n s i t i c g r o w t h r a t e s on t h e b a s i s

o f t h e kinetic m o d e l w e r e made a s s u m i n g t h a t t h e

EXPERIMENTAL RESULTS

g r o w t h o f t h e p l a t e i s d e t e r m i n e d by the v e l o c i t y of a

uniform planar interface of infinite e x t e n t . C l a r i f i c a - A s y s t e m a t i c s e r i e s o f e x p e r i m e n t s d e s i g n e d to de-

tion o f t w o p o i n t s r e l a t i n g t o t h e g e o m e t r y of g r o w t h t e r m i n e the r a t e s of length and w i d t h g r o w t h of m a r t e n -

i s n e c e s s a r y . T h e f i r s t i s that t h e a c t u a l d i r e c t i o n o f s i t i c p l a t e s f o r m e d i s o t h e r m a l l y in f i v e h i g h - p u r i t y

m o t i o n of t h e i n d i v i d u a l d i s l o c a t i o n s i s not p a r a l l e l t o F e - 1 0 N i - C a l l o y s w a s p e r f o r m e d by h o t - s t a g e m e t a l -

t h e n o r m a l to t h e habit p l a n e . T h e g r o w t h r a t e s r e f l e c t l o g r a p h y . T h e a l l o y c o m p o s i t i o n s a r e g i v e n i n T a b l e II.

t h i s d i f f e r e n c e . T h e a c t u a l d i r e c t i o n of m o t i o n o f t h e M e a s u r e m e n t s w e r e made d i r e c t l y f r o m p r o j e c t e d e n -

d i s l o c a t i o n s n i s n o r m a l t o the d i s l o c a t i o n l i n e l , a n d l a r g e m e n t s o f s i n g l e f r a m e s of 8 m m c i n e f i l m s t a k e n

lies in t h e slip p l a n e p2. F o r t h e p r e s e n t g e o m e t r y d u r i n g t h e t r a n s f o r m a t i o n . ~z

n = [-0.763 ~).460 0.460]a. Secondly, s i n c e the con- M a n y p l a t e s w e r e s e e n to d e v e l o p f u l l y a s individual

t r o l l i n g m e c h a n i s m f o r m a r t e n s i t i c g r o w t h is t h o u g h t p l a t e s , but s o m e g r e w i n g r o u p s o f c l o s e l y - s p a c e d

t o be the m o v e m e n t o f a p l a n a r , s e m i c o h e r e n t , g l i s s i l e p a r a l l e l p l a t e s or " s h e a v e s " . Length g r o w t h m e a s u r e -

interface between the parent and product s t r u c t u r e s , m e n t s w e r e p o s s i b l e on b o t h t y p e s o f s t r u c t u r e s , but

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971-2437

Table II. Chemical Analysis of Alloys, Wt Pct

Code C Mn P S Si Ni Cr Mo Cu V A1

m

57 0.010 0.01 0.002 0.006 0.01 10.3 0.01 0.01 0.003 0.01 0.003

58 0.056 0,01 0.002 0.006 0.01 10.2 0.01 0.01 0.003 0.01 0.003

59 0 .I0 0,01 0.002 0.006 0.01 10.2 0.01 0.01 0.001 0.01 0.003

60 0.15 0.01 0.002 0.006 0.01 10.2 0.01 0.01 0.003 0.01 0.006

61 0.20 0.01 0.002 0.007 0.01 10.2 0.01 0.01 0.003 0.01 0.005

Note: Bars above values indicate the amounts are less than percentage shown.

18,OO0

m e a n i n g f u l w i d t h g r o w t h d a t a c o u l d be o b t a i n e d only ©

PRESENT STUDY

f r o m p l a t e s g r o w i n g in i s o l a t i o n . )6,OOO (~ &HI - LENGTH GROWTH

I s o t h e r m a l g r o w t h in t h e l e n g t h a n d w i d t h d i r e c t i o n s [] AHw - WIDTH GROWTH

IR,O00

took p l a c e a t a c o n s t a n t r a t e , a l t h o u g h c o n s i d e r a b l e

s c a t t e r f r o m p l a t e to p l a t e was o b s e r v e d . A s p r e v i o u s l y 12,ODD

r e c o g n i z e d 7'4a'44 t h i s s c a t t e r i s m o r e t h a n c a n be a c - • LENGTH GROWTH ACTIVATION 46 [] (

ENERGIES REPORTED BY GOODENOW

c o u n t e d f o r by e x p e r i m e n t a l u n c e r t a i n t y . A l l p l a t e s

i n c r e a s e d in size at s l o w t e m p e r a t u r e - d e p e n d e n t r a t e s

B.OOO E

u n t i l s t o p p e d by i m p i n g e m e n t w i t h a n o t h e r p l a t e o r a n

J

a u s t e n i t e g r a i n b o u n d a r y . It i s i m p o r t a n t t o n o t e that 6,000 O ~ . / /

t h i c k e n i n g o f p l a t e s c o n t i n u e d a t the s a m e r a t e a f t e r / i

/

•

g r o w t h i n t h e l e n g t h d i r e c t i o n h a d s t o p p e d by i m p i n g e - q,ooo

.I I •

m e n t . S p e i c h 43 a n d G o o d e n o w a n d H e h e m a n n45 o b s e r v e d .I "I []

/

a s i m i l a r effect d u r i n g the growth of l o w e r bainite.

,,000

• 11-11~

T h e i n f l u e n c e o f t e m p e r a t u r e o n the l e n g t h a n d w i d t h O

g r o w t h of the isothermally f o r m e d martensitic product ATOH FRACTION CARBON, Xc X 103

in t h e Fel0 N i - 0 . 2 C a l l o y is shown in Fig. 8 . T h e l i n e s Fig. 9--Activation enthalpies for g r o w t h a s a function of c a r b o n

through the data points are l e a s t - s q u a r e s l i n e s . For content i n F e - 1 0 Ni-C a l l o y s .

e a c h of t h e a l l o y s i n v e s t i g a t e d , t h e g r o w t h r a t e s d e -

T h e experimentally d e t e r m i n e d activation enthalpies

c r e a s e a p p r o x i m a t e l y l i n e a r l y w i t h the r e c i p r o c a l o f

f o r l e n g t h a n d w i d t h g r o w t h , A H l a n d ~xHw r e s p e c t i v e l y ,

the absolute reaction temperature over the entire t e m -

p e r a t u r e r a n g e investigated. T h e length g r o w t h rate a r e p l o t t e d i n F i g . 9 f o r the f i v e a l l o y s u s e d i n t h e i n -

v e s t i g a t i o n . T h e a c t i v a t i o n e n t h a l p i e s a r e s e e n t o be

w a s approximately an o r d e r of magnitude g r e a t e r t h a n

the w i d t h g r o w t h r a t e o v e r a l l t e m p e r a t u r e s a n d c o m - s i m i l a r f o r l e n g t h a n d w i d t h g r o w t h in t h e s a m e a l l o y ,

a n d t h e r e is a n i n c r e a s e in t h e t e m p e r a t u r e depend-

p o s i t i o n s studied.

e n c e of g r o w t h a s t h e c a r b o n c o n t e n t i s i n c r e a s e d . A t

h i g h e r c a r b o n concentrations the activation enthalpies

A l l o y 61 Fe-IONi-.20C a r e h i g h e r t h a n t h o s e r e p o r t e d by G o o d e n o w 46 f o r 9 N i

1.0 s t e e l s , a l s o p l o t t e d i n F i g . 9 . T h e r e a s o n f o r t h e dis-

4~0oc 3~0oc

c r e p a n c y i s not k n o w n .

F i g . 10 s h o w s t h e e x p e r i m e n t a l l y d e t e r m i n e d l e n g t h

0 a n d w i d t h g r o w t h r a t e s at v a r i o u s t e m p e r a t u r e s ,

0

q)

E

....>.o 0

0

0 0 0

plotted a s a function of c a r b o n content. The data of

G o o d e n o w , M a t a s , a n d H e h e m a r m 7 a n d G o o d e n o wa6 f o r

l e n g t h g r o w t h in t h e 9 N i s t e e l s a r e i n c l u d e d to i l l u s -

t r a t e t h e excellent agreement between t h e two s e t s o f

E o

m O. m e a s u r e m e n t s . Both the length and width-growth r a t e s

bI d e c r e a s e s h a r p l y a s c a r b o n i s a d d e d t o the F e - 1 0 N i

e" b a s e . T h e g r o w t h r a t e is r e d u c e d a p p r o x i m a t e l y two

o r d e r s of m a g n i t u d e f o r a n i n i t i a l a d d i t i o n o f o n l y a b o u t

d 0 . 1 wt p c t C . T h e e f f e c t o f t e m p e r a t u r e o n t h e s e c u r v e s

r e f l e c t s t h e i n c r e a s e in a c t i v a t i o n e n t h a l p y w i t h i n -

O

rY c r e a s i n g c a r b o n c o n c e n t r a t i o n in t h e a l l o y s . T h e

e- g r o w t h r a t e at a g i v e n temperature d e c r e a s e s very

l i t t l e w i t h i n c r e a s e in c a r b o n c o n c e n t r a t i o n in e x c e s s

~0

(.9 o f a p p r o x i m a t e l y 0.1 wt p c t C . T h i s i n i t i a l s t r o n g d e -

c r e a s e in g r o w t h r a t e a n d t h e w e a k e r d e p e n d e n c y as

m o r e c a r b o n is a d d e d is in e x c e l l e n t a g r e e m e n t w i t h

the qualitative predictions of the m o d e l .

l I I I I

1.30 1.40 1.50 1.60 DISCUSSION

VT(°K) x 1o3

GrowthGeometry

Fig. 8--Temperature dependence of the length and w i d t h g r o w t h

r a t e s of the isothermally f o r m e d m a r t e n s i t i c p r o d u c t in a l l o y T h e g e o m e t r i c a l m o d e l f o r t h e g r o w t h of a p l a t e o f

61. m a r t e n s i t e m a y be c o m p a r e d w i t h t h e o b s e r v a t i o n s o f

2438 VOLUME 2 , SEPTEMBER 1971 METALLURGICAL TRANSACTIONS

IOOC

FILLED P O I N T S INDICATE EXTRAPOLATIONS

OPEN P O I N T S REPRESENT ACTUAL GROWTH Predicted b y Z e n e r - H i l l e r t

10 MEASUREMENTS m o d e l - corrected C u r v e f o r

w i d t h g r o w t h f r o m Ref. 7 - 4 0 0 ° C

'ql' [] • PRESENT STUDY Present Study

O A GOODENOW, MATAS, AND .\ Predicted from Cottrell drag

HEHEMANN AND GOODENOW I00 model for various values of the

\ oustenite resistance to trons-

~ formation - 450eC

~ ~ 0 Experimental - 450°C

1.0 ~ , N ~ T H

E

E I0

:E %

(.9

_z 450oc

R), = 0

.~

..,.,

o.i

£ R ¥ = 5 0 , 0 0 0 psi R T = 2 5 , 0 0 0 psi

p- o o

L9

o

0.oi - ~ 5°°C

~ 0 0 °C

o o Experimental

[] 45oOc

I J I I I .OI I I I I I

0 2 4 6 8 I0 12 0 002 .004 .006 008 .010

Atom Fraction Carbon, Xc

ATOM FRACTION CARBON, X C X 10 3

Fig. l l - - C o m p a r i s o n of experimental a n d theoretically c a l c u -

Fig. 10--Experimentally d e t e r m i n e d c a r b o n concentration d e - l a t e d w i d t h g r o w t h r a t e s for F e - 1 0 Ni-C a l l o y s a t 450°C. T h e

pendence of length and width g r o w t h r a t e s of the i s o t h e r m a l calculations u s i n g the Z e n e r - H i l l e r t m o d e l for length g r o w t h

transformation p r o d u c t in F e - 1 0 Ni-C a l l o y s at v a r i o u s have b e e n r e d u c e d t o w i d t h g r o w t h by a f a c t o r 1/10 j u s t i f i e d

temperatures. by the experimental r e s u l t s .

plate g r o w t h and the experimentally d e t e r m i n e d activa- d i c t i o n s b a s e d o n t h e h y p o t h e s i s that t h i s s i n g l e p r o c -

t i o n e n t h a l p i e s . T h e p r i m a r y h y p o t h e s i s that w i d t h e s s i s c o n t r o l l e d by t h e C o t t r e l l i n t e r a c t i o n o f c a r b o n

g r o w t h i s the i m p o r t a n t p r o c e s s i n p l a t e g r o w t h i s a t o m s w i t h t h e m o v i n g i n t e r f a c e w i l l n o w be c o m p a r e d

s t r o n g l y s u p p o r t e d by t h e o b s e r v a t i o n that p l a t e s c o n - with the experimental data.

t i n u e t o g r o w in t h e w i d t h d i r e c t i o n e v e n a f t e r l e n g t h

g r o w t h h a s b e e n s t o p p e d . T h i s w o u l d a l s o be p o s s i b l e

Kinetics of G r o w t h

i f l e n g t h a n d w i d t h g r o w t h w e r e c o n t r o l l e d by s e p a r a t e

p r o c e s s e s , but it c e r t a i n l y i s not p o s s i b l e i f , a s i n t h e T h e p r e d i c t i o n s of w i d t h g r o w t h a s a f u n c t i o n o f c a r -

Z e n e r - H i l l e r t m o d e l ,7'47 l e n g t h g r o w t h i s t h e r a t e - bon content calculated on-the b a s i s of the Cottrell drag

c o n t r o l l i n g p r o c e s s a n d width g r o w t h is m e r e l y a g e o - m o d e l for t h e F e - 1 0 Ni-C a l l o y s at 450°C a r e p l o t t e d

m e t r i c c o n s e q u e n c e o f t h i s g r o w t h . If t w o s e p a r a t e w i t h t h e m e a s u r e d r a t e s in Fig. 11. F o r p u r p o s e s o f

p r o c e s s e s e x i s t f o r l e n g t h a n d w i d t h g r o w t h , it i s c o m p a r i s o n , r a t e s of t h i c k e n i n g a t 4 0 0 ° C d e r i v e d7 f r o m

h i g h l y u n l i k e l y that t h e y a r e so s i m i l a r a s t o h a v e the t h e Z e n e r - H i l l e r t d i f f u s i o n c o n t r o l m o d e l47 a r e p l o t t e d

s a m e a c t i v a t i o n e n e r g y , as has been d e m o n s t r a t e d e x - also in Fig. 11. T h i s m o d e l p r e d i c t s r a t e s o f g r o w t h

p e r i m e n t a l l y , Fig. 9. T h e a c t i v a t i o n e n e r g y p r e d i c t e d in t h e l e n g t h d i r e c t i o n . T o o b t a i n t h e r a t e s o f b r o a d e n -

by t h e Z e n e r - H i l l e r t m o d e l i s a c o n t i n u o u s f u n c t i o n o f i n g u s e d i n F i g . 11 t h e r a t e s o f l e n g t h e n i n g w e r e d i -

t h e reaction temperature w h i c h b e c o m e s negative at v i d e d by 1 0 . T h e e x p e r i m e n t a l j u s t i f i c a t i o n f o r u s i n g

high t e m p e r a t u r e s . T h e f a c t o r c o n t r o l l i n g g r o w t h is t h i s f a c t o r w a s g i v e n e a r l i e r in t h i s p a p e r . T h e r a t e s

a s s u m e d t o be the r a t e a t w h i c h c a r b o n c a n be t r a n s - o f g r o w t h p r e d i c t e d by t h e p r e s e n t m o d e l a r e o n e o r

p o r t e d t h r o u g h a u s t e n i t e a w a y f r o m t h e tip o f t h e two o r d e r s o f magnitude f a s t e r t h a n t h o s e m e a s u r e d

g r o w i n g p l a t e . It i s d i f f i c u l t t o s e e how a p l a t e g r o w i n g e x p e r i m e n t a l l y , t h e m a g n i t u d e of t h e d i s p r e p a n c y d e -

in t h i s w a y c o u l d undergo a s h a p e c h a n g e . T h u s , t h e p e n d i n g o n t h e c h o s e n v a l u e o f the a u s t e n i t e r e s i s t a n c e

geometrical and structural r e q u i r e m e n t s and the fact t o t r a n s f o r m a t i o n . T h e g r o w t h r a t e s p r e d i c t e d by t h e

t h a t l e n g t h a n d w i d t h g r o w t h h a v e b e e n f o u n d to h a v e Z e n e r - H i l l e r t m o d e l a r e a b o u t t h r e e o r d e r s of m a g -

a l m o s t identical activation enthalpies are s t r o n g evi- n i t u d e too l a r g e . T h e p r e s e n t i n t e r f a c e c o n t r o l m o d e l

d e n c e against t h e Zener-Hillert m o d e l a n d favoring b e t t e r p r e d i c t s the s t e e p d r o p i n g r o w t h r a t e f o r t h e

t h e a s s u m p t i o n of a s i n g l e g r o w t h c o n t r o l l i n g p r o c e s s initial s m a l l addition of c a r b o n . Both m o d e l s p r e d i c t

h y w i d t h m o v e m e n t of t h e i n t e r f a c e . Q u a n t i t a t i v e p r e - a m a r k e d d e c r e a s e i n t h e r a t e o f c h a n g e of g r o w t h r a t e

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971 2439

~ RT=O

R),=25,000psi

l i o n si n v o l v e d i n t h e c a l c u l a t i o n o f t h e i n t e r a c t i o n

[3 Ry.50,OOOpsi energy relationships, and t h e i r s u b s e q u e n t manipulation

Atom Fraction C

(Width growth rote .005 ,0075 ~

extropOloted to MS)'1 0005 0028 ~ - - - - " ' ~ in t h e t h e o r y . M o s t o f t h e a p p r o x i m a t i o n s a n d l i m i t a -

t i o n s in t h e p r e s e n t d r a g m o d e l a r e t h e s a m e as t h o s e

d

p r e v i o u s l y e n c o u n t e r e d in m o d e l s d e v e l o p e d f o r s i n g l e

dislocation-interstitial interactions. T h e most i m p o r t -

E Experimentol ~.X>~' a n t o f t h e s e a r e t h e use o f a continuum m o d e l , t h e a s -

R •Predi

.0~00, o ~ f . o . _ . I ~~ - ~ > -

g_ ctions s u m p t i o n o f i s o t r o p i c l i n e a r e l a s t i c i t y in r e g i o n s o f

g high s t r e s s ( n e a r t h e individual d i s l o c a t i o n s in t h e

a

b o u n d a r y ) a n d h i g h s t r a i n (the d i s p l a c e m e n t s o f t h e

,J m a t r i x a t o m s defining an o c c u p i e d octahedral i n t e r -

stitial site), t h e neglect of interaction b e t w e e n n e i g h -

b o r i n g c a r b o n a t o m s , t h e n e g l e c t of the p o s s i b i l i t y o f

1.20

I

1.30 I,/0 1.50 I./0 170 saturation effects, and the assumption of a constant

1OO(3/r I ' K ) diffusion c o e f f i c i e n t n e a r t h e boundary. Some r e f i n e -

Fig. 12--Comparison of experimental and theoretical v a l u e s m e n t s of the s i n g l e dislocation-interstitial interaction

of the p a r a m e t e r s c~ and/3 u s i n g different a s s u m e d v a l u e s of m o d e l h a v e b e e n a t t e m p t e d but n o n e o f t h e s e a r e s u f f i -

the austenite r e s i s t a n c e t o transformation. c i e n t l y d e v e l o p e d to w a r r a n t i n c l u s i o n in t h e p r e s e n t

model.

w i t h i n c r e a s e in c a r b o n c o n t e n t a b o v e about 0 . 0 0 5 T h e g r o w t h r a t e s p r e d i c t e d by t h e d r a g m o d e l a r e

a t o m f r a c t i o n , but n e i t h e r m o d e l p r e d i c t s t h e o b s e r v e d a f f e c t e d m o s t by t h e c o r e c u t - o f f v a l u e s e l e c t e d . B o t h

r a t e of c h a n g e w h i c h i s a l m o s t z e r o . It i s p r o b a b l e , the v a l u e s of the interaction e n e r g y and the s h a p e of

h o w e v e r , t h a t a t 4 5 0 ° C , the p r o d u c t i n a l l o y s c o n t a i n i n g diffusion coefficient profiles have a m a j o r effect o n t h e

m o r e than 0 . 0 0 5 a t o m f r a c t i o n o f c a r b o n i s b a i n i t i c , a s r e s u l t s b e c a u s e together they d e t e r m i n e the r e g i o n of

d e f i n e d in the f i r s t p a r t o f t h i s p a p e r , a n d the t r a n s - interaction within which drag originates. A n e x a m i n a -

formation mechanism involves some interaction of the t i o n o f the i n t e g r a n d s of t h e a a n d /3 p a r a m e t e r s , E q s .

interface dislocations with c a r b i d e particles. [6] a n d [7], r e v e a l s t h e r e l a t i v e c o n t r i b u t i o n s . A t b o t h

B e c a u s e t h e p r e d i c t e d g r o w t h r a t e s d e p e n d in a c o m - high a n d l o w v e l o c i t i e s it is n e c e s s a r y to d i s t i n g u i s h

p l e x w a y o n the c a l c u l a t e d a a n d /3 p a r a m e t e r s o f t h e b e t w e e n t h e a s s u m p t i o n that t h e d i f f u s i o n c o e f f i c i e n t

Cottrell interaction, a c l e a r e r a s s e s s m e n t of the m o d e l p r o f i l e r i s e s s t e e p l y to a high v a l u e n e a r t h e b o u n d a r y ,

m a y be o b t a i n e d by c o n s i d e r i n g e a c h o f t h e s e p a r a m - a n d the a s s u m p t i o n t h a t t h e d i f f u s i o n c o e f f i c i e n t p r o f i l e

e t e r s separately. T h u s , determination of the experi- i s s h a l l o w , r e a c h i n g a p e a k v a l u e a t t h e b o u n d a r y not

m e n t a l v a l u e s o f a a n d fl, a n d t h e i r c o m p a r i s o n w i t h m u c h d i f f e r e n t f r o m t h e l a t t i c e diffusion c o e f f i c i e n t in

the c a l c u l a t e d p a r a m e t e r s , w i l l g i v e a b e t t e r u n d e r - the a b s e n c e o f i n t e r a c t i o n . F o r l o w v e l o c i t i e s , t h e

standing of t h e p o s s i b l e s o u r c e s of discrepancy be- prevailing situation d u r i n g slow isothermal g r o w t h ,

tween the theoretical and experimental g r o w t h r a t e s . t h e c o n t r i b u t i o n t o t h e d r a g i s (e- u z k T - 1 ) / 1 9 , F i g . 1 3 .

It i s a s s u m e d i n the m o d e l that t h e Ms t e m p e r a t u r e i s If t h e d i f f u s i o n c o e f f i c i e n t i s e v e r y w h e r e s h a l l o w , a s

the t e m p e r a t u r e a t w h i c h t h e n e t f o r w a r d d r i v i n g f o r c e t h e p r o f i l e c h o s e n in t h e p r e s e n t c a l c u l a t i o n s ( i n s e t o f

for the transformation e x c e e d s the m a x i m u m height Fig. 4 ) , t h e n t h e d r a g c o m e s f r o m r e g i o n s c l o s e to t h e

in t h e f o r c e - v e l o c i t y r e l a t i o n s h i p d e s c r i b i n g t h e r a t e d i s l o c a t i o n s i n the b o u n d a r y , a s s h o w n s c h e m a t i c a l l y

c o n t r o l l i n g p r o c e s s . T h u s , a t the M s t e m p e r a t u r e , t h e a n d o n e - d i m e n s i o n a l l y i n F i g . 1 3 ( a ) . In t h i s s i t u a t i o n ,

force-velocity c u r v e d e s c r i b i n g the Cottrell drag the choice of core cut-off b e c o m e s critical. On the

m e c h a n i s m h a s a h e i g h t e q u a l t o the n e t f o r w a r d f o r c e o t h e r h a n d , i t i s p o s s i b l e that t h e d i f f u s i o n c o e f f i c i e n t

available to o v e r c o m e f r i c t i o n a l d r a g p r o c e s s e s , a n d is m u c h e n h a n c e d n e a r t h e i n t e r f a c e d i s l o c a t i o n s be-

t h e v e l o c i t y of t h e m a x i m u m ( a d j u s t e d by t h e a p p r o - c a u s e the l a r g e s t r e s s e s c r e a t i n g a t o m i c a r r a n g e m e n t s

p r i a t e g e o m e t r i c a l f a c t o r s ) s h o u l d c o i n c i d e w i t h that f a r f r o m e q u i l i b r i u m . T h i s s i t u a t i o n m a y c a u s e the

d e t e r m i n e d e x p e r i m e n t a l l y by e x t r a p o l a t i o n t o Ms of diffusion c o e f f i c i e n t to rise s e v e r a l o r d e r s o f m a g n i -

d a t a d e t e r m i n e d a t h i g h e r t e m p e r a t u r e s . [3 i s t h e tude n e a r t h e b o u n d a r y . T h e d r a g will t h e n o r i g i n a t e

r e c i p r o c a l of t h i s g r o w t h r a t e . E x p e r i m e n t a l v a l u e s at s o m e distance f r o m t h e boundary, Fig. 13(b).

o f the p a r a m e t e r a w e r e o b t a i n e d u s i n g t h e v a l u e s o f K o l i w a d a n d J o h n s o n 4s h a v e s h o w n r e c e n t l y that t h e

the overall free e n e r g y of transformation and experi- s t r e s s e f f e c t a l t e r s b o t h t h e c h e m i c a l p o t e n t i a l of the

m e n t a l l y d e t e r m i n e d Ms t e m p e r a t u r e s , F i g . 6 , E q . [5], i n t e r s t i t i a l a n d the a c t i v a t i o n b a r r i e r f o r a d i f f u s i o n a l

a n d t h e a s s u m e d v a l u e s of t h e a u s t e n i t e l a t t i c e r e s i s t - j u m p . T h e f i r s t o f t h e s e e f f e c t s i s a r e s u l t o f the p o s i -

a n c e to t r a n s f o r m a t i o n . T h e o r e t i c a l a n d e x p e r i m e n t a l tion dependent interaction e n e r g y and has been c o n s i d -

p a r a m e t e r s a r e c o m p a r e d in Fig. 12. T h e p r e s e n t e r e d in t h e p r e s e n t a n a l y s i s . T h e s e c o n d e f f e c t , w h i c h

d r a g m o d e l , w i t h a c o r e c u t - o f f of b / 2 a n d the d i f f u - h a s not b e e n t a k e n into a c c o u n t , c o u l d be v e r y i m p o r t -

s i o n c o e f f i c i e n t p r o f i l e g i v e n in t h e i n s e t o f Fig. 4 , a n t b e c a u s e o f s m a l l c h a n g e in t h e a c t i v a t i o n b a r r i e r

underestimates a by a b o u t o n e o r d e r o f m a g n i t u d e a n d f o r d i f f u s i o n h a s a l a r g e e f f e c t o n the d i f f u s i o n c o e f f i -

/3 by t w o t o t h r e e o r d e r s of m a g n i t u d e . T h e e x p e r i - c i e n t . H o w e v e r , t h e e x t e n t to w h i c h t h e a c t i v a t i o n b a r -

m e n t a l t e m p e r a t u r e d e p e n d e n c e o f b o t h a a n d {3 i s r i e r i s a f f e c t e d i s not y e t c l e a r . B o s m a n e t a l J9 a n d

c l o s e t o that p r e d i c t e d by t h e m o d e l . B a s s a n d L a z a r u s 5° w e r e u n a b l e t o f i n d a m e a s u r a b l e

T h e s o u r c e s of d i s c r e p a n c y b e t w e e n t h e o r y a n d effect of hydrostatic p r e s s u r e on the mobility of c a r b o n

e x p e r i m e n t m a y n o w be e x a m i n e d . T h e o v e r a l l r e s u l t s i n a - i r o n . T h i s s u g g e s t s t h a t t h e e f f e c t d i s c u s s e d by

a r e r e l a t i v e l y i n s e n s i t i v e t o v a r i a t i o n s i n the c r y s t a l - K o l i w a d a n d J o h n s o n m a y be s m a l l i n t h i s s y s t e m .

lographic p a r a m e t e r s . However, the calculated q u a n - Reducing t h e core cut-off l i m i t i n c r e a s e s both a and

t i t i e s a a n d ~3 a r e e x t r e m e l y s e n s i t i v e t o t h e a s s u m p - /3, F i g . 1 4 . E x c e l l e n t a g r e e m e n t b e t w e e n p r e d i c t e d

2440 V O L U M E 2, S E P T E M B E R 1971 METALLURGICAL TRANSACTIONS

16 l

x

.o a~-X ot b

/ ~ (I)

14

u

,¢{

2

I0 g (1)

8 ~ - ~ b (II)

o,

I I I I

/

EXPERIHENTAL THEORET I CAL

a /x R~ = 0 1 C O R E CUT-OFF (D PROFILE)

O Ry = 2 5 , 0 0 0 PSI / ~ Y l

[] Ry = 50,000 PSI O D

Bo x x

q

B 0 0

<> b

L

-t

e

o ~ (i)

a.

2

~ _b ( 1 )

2

3- - g

0

(a) (b) ._i b (ii)

-2 l i - I r - - - - T- - 4

Fig. 13--The c o n t r i b u t i o n s t o c a r b o n drag at l o w velocities

from various p a r t s of the atmosphere shown schematically l .40 l. 5 0 l .60 1.70

for t w o c a s e s : (a) relatively l i t t l e enhancement of diffusion 1000/T (°K)

near the boundary, and (b) g r e a t l y enhanced diffusivity i n a

r e g i o n c l o s e r t o the boundary than the regions of h i g h i n t e r - Fig. 14--Effect of various assumptions of core cut-off limit

action energy. T o p c u r v e s h o w s interaction e n e r g y ; m i d d l e and diffusion coefficient profile on the calculated Cottrell

c u r v e , diffusion coefficient profile; b o t t o m c u r v e , contribu- drag parameters (x and/3.

t i o n s t o drag--all as functions of distance from the boundary.

l o g r a p h i c i n v e s t i g a t i o n o f the k i n e t i c s o f g r o w t h i n f i v e

and experimental values of the ot parameter are ob- F e - 1 0 Ni-C alloys over a r a n g e of temperatures and

tained if a core cut-off value of 3b/8 is selected and c a r b o n contents.

the diffusion coefficient profile in Fig. 4 is assumed.

ACKNOWLEDGMENTS

A cut-off at 3b/8 is reasonable, The predicted value

of 13, however, falls approximately one order of mag- T h e a u t h o r s g r a t e f u l l y a c k n o w l e d g e the B e t h l e h e m

nitude below the experimental value of /3. The assump- S t e e l C o r p o r a t i o n f o r f u r n i s h i n g the a l l o y s u s e d i n t h i s

tion of a steep diffusion coefficient profile, rising as i n v e s t i g a t i o n a n d the M a t e r i a l s S c i e n c e C e n t e r a t

e -u/kT, drops the predicted values of the ~ and /3 pa- C o r n e l l U n i v e r s i t y for financial support u n d e r contract

rameters by approximately 5 orders of magnitude. S D - 6 8 . O n e o f the a u t h o r s r e c e i v e d p a r t i a l s u p p o r t

Thus, by the selection of a suitable diffusion profile f r o m the N a t i o n a l S c i e n c e F o u n d a t i o n , c o n t r a c t G K -

and a reasonable cut-off, agreement is obtained be- 23985.

tween the predictions of the model and the experimental

data whichis encouraging if allowance is made for the R E F E R E N CE S

many approximations whichhave been unavoidably in- 1. R. F. Bunshah and R. F. Mehh Trans. AIME, 1953, vol. 125, p. 125.

corporated into the model. 2, G. V. Kurdjumov and O. P. Maximova: Dokl. Acad. Nauk. SSSR, 1948, vol.

61, p. 83.

3. R. B. G. Yeo: Trans. ASM, 1964, vol. 57, p. 48.

SUMMARY 4. J. M. Marder and A. R. Marder: Trans. ASM, 1969, vol. 62, p. 1.

5. W. S. Owen, E. A. Wilson, and T. Bell: High-Strength Materials, V. Zackay, ed.,

A q u a n t i t a t i v e m o d e l b a s e d o n the e l a s t i c i n t e r a c t i o n p. 167, Wiley, New York, 1965.

o f the s t r a i n f i e l d s o f d i s s o l v e d c a r b o n a t o m s i n the 6. M. M. Rao and P. G. Winchell: Trans. TMS-AIME, 1967, vol. 239, p. 956.

m a r t e n s i t e l a t t i c e w i t h the s t r e s s f i e l d o f the m o v i n g 7. R. H. Goodenow, S. J. Matas, and R. F. Hehemann: Trans. TMS-AIME, 1963,

vol. 227, p. 651.

t r a n s f o r m a t i o n i n t e r f a c e d i s l o c a t i o n a r r a y has b e e n

8. H. I. Aaronson: The Mechanism o f Phase Transformations in Crystalline

c o n s t r u c t e d f o r the s l o w i s o t h e r m a l g r o w t h of m a s s i v e - Solids, Iron Steel Inst. MonographNo. 33, p. 270, 1968.

m a r t e n s i t e i n F e - 1 0 Ni-C a l l o y s . T h e m o d e l , c o n s i d - 9. D. N. Shackleton and P. M. Kelly: The PhysicalProperties o f Martensite and

e r i n g C o t t r e l l a t m o s p h e r e f o r m a t i o n and the r e s u l t a n t Bainite, Iron Steel Inst. Special Report 93, p. 93, 1965, and Acta Met., 1968,

d r a g o n the i n t e r f a c e , s a t i s f i e s a l l o f the r e q u i r e m e n t s vol. 16, p. 609.

10. G. R. Srinivasan and C. M. Wayman: Acta. Met., 1968, voL 16, p. 609.

o f the f o r m a l c r y s t a l l o g r a p h i c t h e o r i e s a n d p r e d i c t s

11. K. J. Irving and F. P. Pickering:J. Iron Steellnst., 1958, vol. 188, p. 101,

the k i n e t i c s o f g r o w t h a s a f u n c t i o n of c a r b o n c o n t e n t 12. P. Vasudevan, L. W. Graham and H. J. Axon: J. Iron Steellnst., 1958, vol.

and temperature. T h e s e predictions c o m p a r e f a v o r - 190, p. 386.

ably w i t h the r e s u l t s o f a s y s t e m a t i c h o t - s t a g e m e t a l - 13. S. V. Radcliffe and E. C. Rollason: J. Iron Steellnst., 1959, vol. 191, p. 56.

METALLURGICAL TRANSACTIONS VOLUME 2 , SEPTEMBER 1971-2441

14. R. H. Goodenow and R. F. Hehemann: Trans. TMS-AIME, 1965, vol. 233, 33. G. Schoeck and A. Seeger,Acta. Met., 1959, vol. 7, p. 469.

p. 1777. 34. A. H. Cottrell and B. A. Bilby: Proc. Phys. Soc., 1949,vol. 62, p. 49.

15. J. W. Christian: The Theory o f Transformations in Metals and Alloys, Chap. 35. F. J. Schoen and W. S. Owen: unpublished research, April, 1971.

XXI, Pergamon, New York, 1965. 36. J. W. Cahn: Acta. Met., 1962, vol. 10, p. 789.

16. J. W.Christian: The PhysicalProperties o fMartensite and Bainite, Iron Steel 37. M. M. Rao, R. J. Russell and P. G. Winchell: Trans. TMS-AIME, 1962, vol.

Inst. Special Report 93, p. 1, 1965. 239, p. 634.

17. R. Bullough and B. A. Bilby: Proc. Phys. Soe., 1956, vol. 69, p. 1276. 38. C. L. Magee: Ph.D. Thesis, Carnegie Institute of Technology, 1966.

18. P. G. Wincheli: Purdue University, Lafayette, Indiana, private communication, 39. A. J. Goldman and W. D. Robertson: Acta. Met., 1965, vol. 13, p . 391.

1968. 40. E. Breinan: Ph.D. Thesis, Rensselaer Polytechnic Institute, 1967.

19. F. C. Frank: ActaMet., 1953, vol. 1, p. 15. 41. F. J. Schoen and W. S. Owen: Metallography, 1970, vol. 3, p. 473.

20JW. S. Owen, F. J. Schoen and G. R. Srinivasan:Phase Transformations, p. 157, 42. S. Dash and N. Brown: Acta. Met., 1966, vol. 14, p. 595.

A.S.M., Cleveland, 1970. 43. G. R. Speich: Decomposition o f Austenite byDiffusional Processes, V.

21. F. J. Schoen: Ph.D. Thesis, Cornell University, 1970. Zackay and H. I. Aaronson, eds., p. 353, Interscience, New York, 1963.