Escolar Documentos

Profissional Documentos

Cultura Documentos

Grdu Eg Seg 07 001 - A2

Enviado por

cadilson.albertoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Grdu Eg Seg 07 001 - A2

Enviado por

cadilson.albertoDireitos autorais:

Formatos disponíveis

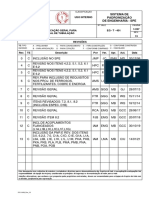

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 1 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

SAFETY DISTANCE CALCULATION NOTE

(Based on FEED document FALCAO-FE-SAF-7-01)

Páginas revistas: 14, 15 e 16

DIRECTOR DO PROJECTO: A. Freitas Ana Freitas

(nome & rúbrica)

2022.03.10

18:03:13 Z

S.Firmino Lígia Filipe S.Firmino

2022.03.10 16:07:58 2022.03.10 2022.03.10

Z 16:08:08 Z

16:01:29 Z

A2 10/03/2022 ISSUE FOR REVISION S.FIRMINO L. FILIPE S.FIRMINO

A1 30/11/2021 ISSUE FOR REVISION S.FIRMINO L. FILIPE S.FIRMINO

Data EMITIDO VERIFICADO APROVAÇÃO TÉCNICA

Rev DESCRIÇÃO

DD/MM/AA (nome & rúbrica) (nome & rúbrica) (nome & rúbrica)

REVISÕES DO DOCUMENTO

As secções modificadas na última revisão são identificadas por uma linha vertical na margem direita

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 2 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

CONTENTS

1. Introduction .................................................................................................................................. 3

2. Scope of document ...................................................................................................................... 3

3. References ................................................................................................................................... 4

3.1. Project Documents ......................................................................................................... 4

3.2. Codes and standards ...................................................................................................... 4

4. Abbreviations and definitions ........................................................................................................ 4

4.1. Abbreviations .................................................................................................................. 4

4.2. Definition......................................................................................................................... 4

5. Calculation methods ..................................................................................................................... 5

5.1. EFFECTS (TNO) ............................................................................................................ 5

5.2. Generalities about PHAST .............................................................................................. 5

5.3. Scenarios Criteria ........................................................................................................... 6

5.4. Gas composition ............................................................................................................. 8

5.5. Operation conditions ....................................................................................................... 9

6. Environmental conditions ............................................................................................................. 9

7. GRDU Process area safety distances ........................................................................................ 10

7.1. Fire zone safety distance .............................................................................................. 10

7.2. ESDV............................................................................................................................ 11

7.3. Restricted area safety distance ..................................................................................... 12

7.4. Impacted areas safety distance .................................................................................... 13

8. Safety distance inside GRDU process area ................................................................................ 13

9. GRDU cold vent safety distances ............................................................................................... 14

10. Domestic Gas Pipeline (DGP) inlet ........................................................................................ 15

11. Conclusions ........................................................................................................................... 15

Appendix A – Graphical representation of the safety distance......................................................... 17

Appendix B – Example safety distances of areas ............................................................................ 24

Appendix C – RESULTS (New Composition – EFFECTS) .............................................................. 25

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 3 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

1. INTRODUCTION

Angola LNG is operating a LNG plant in Northern Angola, near Soyo to liquefy and export gas

produced from offshore Angola fields.

Gas is taken from LNG plant to supply the domestic users located in the new industrial area near

Soyo.

A Distribution Gas Pipeline (DGP) will be laid between LNG plant and the Gas Receiving Distribution

Unit (GRDU).

This gas will be filtered in the GRDU and distributed to load users in particular the new power plant.

The FALCÃO PROJECT EPC consists in the review and updating of the DGP and GRDU FEED

UPDATE prepared in 2013. Since the composition of the inlet gas has changed, new calculations

were made to verify the required safety distances.

2. SCOPE OF DOCUMENT

To be able to reduce the consequence of hazardous events, safety distances are calculated for the

following hazardous events:

- Jet fire,

- Dispersion of flammable gas leak,

- Explosion,

- Ignited cold vent.

This means that by applying a safety distance between areas (equipment) a hazardous event in one

area will not impact other areas to an extent where their integrity and/or the safety of people working /

living in these areas could be put at risk.

The following safety distances will be calculated for both the GRDU process area and for the

Domestic Gas Pipeline (DGP) inlet:

- Fire zone,

- Restricted area,

- Impacted area,

- Location of ESDV.

For new gas composition the distances will be computed using TNO effects software (version 10.1.1).

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 4 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

3. REFERENCES

3.1. PROJECT DOCUMENTS

[1] GRDU-EG-SEG- 04-001 Safety concept

[2] FALCAO-FE-GEN-5-01 Equipment Design Conditions

[3] FALCAO-BP-PRO-7-03 Vent Network and Radiation Calculation Note

[4] GRDU-EG-SEG-07-002 Gas dispersion Calculation Note

[5] FALCAO-FE-PRO-6-02 Heat & Material Balance Report

[6] FALCAO-FE-GEN-4-01 Design Basis

[7] GRDU-EG-PRC-05-001 Process Design Basis

3.2. CODES AND STANDARDS

[8] API RP 14J Recommended Practice for Design and Hazards Analysis for Offshore

Production Facilities, 2nd Edition, May 1, 2001, Reafirmation notice,

January 2013.

4. ABBREVIATIONS AND DEFINITIONS

4.1. ABBREVIATIONS

ALNG Angola LNG

DGP Domestic Gas Pipeline

EDP Emergency De-Pressurisation

ESDV Emergency Shut-Down Valve

LFL Lower Flammable Limit

FEED Front End Engineering Design

GRDU Gas Reception and Distribution Unit

MMSCFD Million Standard Cubic Feet per Day

N/A Not applicable

NR Not Reachable

UDM Unified Dispersion Model

PFP Passive Fire Protection

4.2. DEFINITION

Outside the impacted area: People are not subject to any increased hazards than those inherent to

any other human activities

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 5 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Inside the impacted area (but outside the restricted area): People might be subject to irreversible

effects caused by a major failure of the installation. However, during normal plant operations,

permanent prejudice to human beings is not expected

Inside the restricted area: The consequences of an incident or from normal operation can be severe

enough to cause permanent prejudice to human beings and therefore the restricted area shall be off-

limits to public.

Fire zones are the areas within the installation where equipment are grouped by nature and/or

homogeneous level of risk attached to them.

The partition of an installation into fire zones results in a significant reduction of the level of risk.

An example of the area zoning is presented in appendix B.

5. CALCULATION METHODS

5.1. EFFECTS (TNO)

EFFECTS software (version 6.6) is used for modelling the new composition.

5.2. GENERALITIES ABOUT PHAST

DNV Technica PHAST software (version 6.6) is used for the modelling of gas cloud dispersion.

The hazard associated to the cloud depends on its size, location and concentration-profile. These

parameters all change with time, and the program must calculate and record these changes in order

to correctly describe the cloud and its hazards. The calculations have been performed using the

Unified Dispersion Model (or UDM), which produces a table giving the essential cloud data at various

time steps from the start of the release.

The UDM is an advanced similarity model capable of describing a wide range of types of accidental

releases. The main characteristic of similarity models is that profiles for concentration, velocity, and

temperature are assumed. The UDM uses a particularly flexible form for the concentration profile,

allowing for sharp-edged profiles which become more diffuse downwind. The vertical cross section is

in general an ellipse while elevated, and a truncated ellipse while touching the ground.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 6 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

For a Continuous release, the profile extend from the source downwind is shown below.

5.3. SCENARIOS CRITERIA

All the scenarios of safety distances have been calculated according to below defined criteria:

Fire Zones Restricted Area Impacted Area

ESDV location

Scenarios (FZ) Criteria (RA) Criteria (IA) Criteria

20 mm (2) 50 mm (2) 50 mm (2) 20 mm (2)

Un-ignited flammable gas/spray

100% LFL 100% LFL - -

cloud dispersion

Unconfined Vapour Cloud

200 mbar 140 mbar 50 mbar 300 mbar

Explosion (UVCE)

9.5 kW/m²

Jet fire 4.7 kW/m² (1) 3.2 kW/m² (1) 15.9 kW/m² (1)

(1)

Cold vent - emergency

- 4.7 kW/m² (1) 2 kW/m² (1) -

operation (ignited release) (3)

Cold vent - emergency

operation (un-ignited release) - 100% LFL - -

(4)

Cold vent - continuous

- 3.2 kW/m² (1) 1.6 kW/m² (1) -

operation (ignited release) (3)

(1) Including solar radiation

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 7 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

(2) Leak hole diameter

- For the fire zone and ESDV safety distance calculation a maximum leak hole size of 20 mm

is considered. It is generally recognized as corresponding to the full bore rupture of a 1” line /

tapping.

- For the restricted and impacted safety distance calculation the minimum leak hole size of 50

mm is considered. It is generally recognized as the minimum leak size to be considered for

“major failure” events, when the more stringent value of 20% of the largest pipe diameter is

deemed too conservative. As the GRDU process is very simple, with non-corrosive gas, mild

piping stress conditions and very low risk of damage to the pipes from handling or from vibrating

equipment, and as the lines will be buried as much as feasible, this “low end” value of 50mm is

considered acceptable.

(3) Cold vent radiations have been calculated in Ref [3].

(4) Cold vent dispersion (emergency operation) has been calculated in Ref [4].

This implies that consequences of a fire, flammable gas leak or an explosion corresponding to the

credible event likely to occur in the concerned fire zone, shall not impact other fire zones to an extent

where their integrity could be put at risk.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 8 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

5.4. GAS COMPOSITION

The gas composition is provided in % mol in Table 1 - Gas composition, as per the “Heat & Material

Balance Report”, Ref. [5] or Design Basis, Ref. [6].

In order to understand the need to change the safety distance calculations, the composition from the

“FEED phase” and the new composition considered in detail engineering are presented in Table 1.

PHAST Software directly calculates the LFL of the gas mixture. LFL are given in ppm in following

Table 2 - Gas chemical characteristics. For the new composition, the LFL is calculated with EFFECTS

software. The value is also presented in the same table.

(FEED phase) (New composition)

GAS COMPONENT

% MOLE % MOLE

Nitrogen 1.60 0.37

Methane 86.01 83.55

Ethane 5.07 7.13

Propane 1.17 5.58

i-Butane 0.73 1.02

n- Butane 1.44 1.53

i- Pentane 0.39 0.38

n-Pentane 2.34 0.30

n-Hexane and heavier 1.25 0.13

Water 0.00 0.00

Benzene 0.01

Table 1 - Gas composition

LFL (ppm) 37568 41895

Table 2 - Gas chemical characteristics

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 9 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

5.5. OPERATION CONDITIONS

As per the “Heat & Material Balance Report”, Ref. [5], the most conservative GRDU inlet operating

conditions, related to the Case 4 (Maximum pressure at DGP inlet, minimum pressure at Power Plant

and design flowrate at 150 MMSCFD), have been used for the safety distance calculations:

- Gas pressure at GRDU inlet = 40.0 barg

- Gas temperature at GRDU inlet = 44.8 °C.

For new lng composition the following operating conditions in GRDU inlet, as per “Process Design

Basis”, Ref. [7] were used for safety distance calculations:

- Gas pressure at GRDU inlet = 34,7 barg;

- Gas temperature at GRDU inlet = 29,6 ºC

6. ENVIRONMENTAL CONDITIONS

The following environmental conditions are issued from “Equipment Design Conditions”, Ref. [5]

- Atmospheric pressure: 1,010 bara

- Average ambient air temperature: 28°C

- Average relative humidity: 86%

- Solar radiation: 1,2 kW/m2

For new lng composition, the following environmental conditions are issued from “Vent Network and

Radiation Calculation Note”, Ref. [5]

- Atmospheric pressure: 1,010 bara

- Average ambient air temperature: 32°C

- Average relative humidity: 72%

- Solar radiation: 1,2 kW/m2

The following environmental conditions are the typical value for input data of DNV Technica PHAST

software

- Surface roughness parameter: 0.11 (flat terrain)

- Wind speed: 1, 2, 5, 10 m/s (general wind speed considered for

this project calculation) and 16 m/s (maximum wind

speed as per Ref. [3])

- Pasquill stability category: D (neutral atmosphere) and F (very stable) (Note 1)

Note 1: As an example 2/D means 2 m/s with a neutral atmosphere.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 10 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

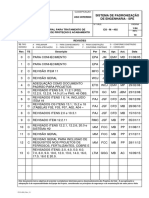

7. GRDU PROCESS AREA SAFETY DISTANCES

All the distances calculated below are distances from the process fire zone boundary (refer to

Appendix B).

7.1. FIRE ZONE SAFETY DISTANCE

The following fire zone safety distances are calculated for the process area:

Meteo 1/F 2/D 5/D 10/D 16/D

Maximum dispersion d at 100%

12.5 12 10 8 7

(horizontal release) LFL (m)

Maximum

dispersion

100% LFL 15

(horizontal release)

new composition

d at

Maximum radiation

FIRE ZONE 9.5kW/m² 21 21 22 22.5 23

due to Jet fire

safety distance (m)

from process Maximum radiation

FIRE ZONE due to Jet fire new 9,5 kW/m² 32 30 26 22 21

boundary (m) composition

Maximum d at

overpressure due to 200 mbar NR NR NR NR NR

an Explosion (m)

Maximum

overpressure due

200 mbar 17

to an Explosion

new composition

The fire zone safety distance from process fire zone boundary, due to jet fire, is 32 m.

This means that equipment located outside this area cannot be impacted.

See Figure 1 and Figure 2 in appendix A for graphical representation of the calculated results.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 11 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

7.2. ESDV

The following ESDV location safety distances are calculated for the process area:

Meteo 1/F 2/D 5/D 10/D 16/D

ESDV location

safety distance

Maximum radiation

from process 15.9 kW/m² 19 19 20 21 22

due to Jet fire

FIRE ZONE

boundary (m)

Maximum radiation

15.9

due to Jet fire new 31 28 24 21 20

kW/m²

composition

Maximum

overpressure due to 300 mbar NR NR NR NR NR

an Explosion

Maximum

overpressure due

300 mbar NR NR NR NR NR

to an Explosion

new composition

The ESDV location safety distance from process fire zone boundary, due to jet fire, is 31 m.

This means the inlet / outlet ESDVs shall be located at 31 m from process fire zone boundary.

If one of these ESDVs cannot be located at this calculated safety distance, this ESDV shall be fitted

with PFP.

See Figure 3 in appendix A for graphical representation of the calculated results.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 12 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

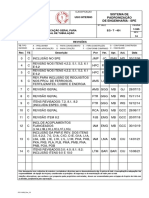

7.3. RESTRICTED AREA SAFETY DISTANCE

The following restricted area safety distances are calculated for the process area:

Meteo 1/F 2/D 5/D 10/D 16/D

Maximum dispersion

100% LFL 40 38 37 35 33

(horizontal release)

Maximum

dispersion

(horizontal 100% LFL 38

release) new

composition

RESTRICTED Maximum radiation

4.7 kW/m² 61 61 62 63 60

AREA safety due to Jet fire

distance from Maximum

process FIRE radiation due to

4.7 kW/m² 81 75 67 60 57

ZONE boundary Jet fire new

(m) composition

Maximum

overpressure due to 140 mbar NR NR NR NR NR

an Explosion

Maximum

overpressure due

140 mbar 46

to an Explosion

new composition

The restricted area safety distance from process fire zone boundary, due to jet fire, is 81 m.

This means that the fence and all buildings (not blast proofed) shall be located at 81 m from the fire

zone boundary.

It shall be noted that the restricted area of the whole plant is not defined only by this result. The

results of the restricted safety distance for the cold vent, provided in § 9, shall also be taken into

account to determine the overall footprint of the restricted area of the whole plant.

See Figure 4 and Figure 5 in appendix A for graphical representation of the calculated results.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 13 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

7.4. IMPACTED AREAS SAFETY DISTANCE

The following impacted area safety distances are calculated for the process area:

Meteo 1/F 2/D 5/D 10/D 16/D

Maximum radiation

3.2 kW/m² 68 68 68 67 63

due to Jet fire

Maximum radiation

IMPACTED due to Jet fire new 3.2 kW/m² 86 80 71 65 62

AREA safety composition

distance from Maximum

process FIRE overpressure due to 50 mbar 110 99 108 118 98

ZONE boundary an Explosion

(m) Maximum

overpressure due

50 mbar 59

to an Explosion

new composition

The impacted area safety distance from process fire zone boundary, due to explosion, is 118 m.

If the impacted area is not within the GRDU fence, and thus not under the control of COMPANY, it

shall be agreed with the local authorities that the limit of impacted area shall

be the limit for construction of buildings, in particular permanent settlement, or operation and

transportation means open to public.

See Figure 6 and Figure 7 in appendix A for graphical representation of the calculated results.

8. SAFETY DISTANCE INSIDE GRDU PROCESS AREA

According to API RP 14 J, Ref. [8], ignition sources shall be segregated from fuel sources by

separation of equipment. The incinerator package (fired process) is considered to be an ignition

source. The other unfired process equipment (gas pig receiver, scrubber and fiscal metering package)

are considered to be fuel sources.

Therefore the incinerator package shall be located at a sufficient safety distance from any other

unfired process equipment. According to good engineering practices, it shall be located at 30 m from

any unfired process equipment.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 14 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

9. GRDU COLD VENT SAFETY DISTANCES

The results (extracted from the radiation study provided in Ref. [3] and from the dispersion study

provided in Ref. [4]) of the GRDU cold vent safety distances are summarised in the following table:

Meteo 1/F 2/D 5/D 10/D 16/D

Maximum horizontal

dispersion of un-ignited 100% LFL 1.3 1.8 2.1 2.5 2.9

release of GRDU EDP

Maximum horizontal 35 (cold vent defined to comply

dispersion of un-ignited with this distance. Dispersion is

100% LFL

release of GRDU EDP dependent on the discharge

new composition diameter vs flowrate)

Maximum radiation due to

RESTRICTED ignited release of GRDU 4.7 kW/m² 30

AREA safety EDP

distance from the Maximum radiation due

cold vent tip (m) to ignited release of

4.7 kW/m² 35

GRDU EDP new

composition

Maximum radiation due to

ignited release of DGP 3.2 kW/m² 33

manual EDP

Maximum radiation due

to ignited release of

3.2 kW/m² N/A

DGP manual EDP new

composition

Maximum radiation due to

ignited release of GRDU 2.0 kW/m² 65

EDP

Maximum radiation due

to ignited release of

2.0 kW/m² 105

IMPACTED AREA GRDU EDP new

safety distance composition

from the cold vent Maximum radiation due to

tip (m) ignited release of DGP 1.6 kW/m² 70

manual EDP

Maximum radiation due

to ignited release of

1.6 kW/m² 60

DGP manual EDP new

composition

The restricted area safety distance from the cold vent tip, due to radiation, is 35 m.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 15 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

The impacted area safety distance from the cold vent tip, due to radiation, is 105 m.

These data determine the overall footprint of the GRDU plant. The fence shall be located at the limit

of the restricted area. As the impacted area is not within the GRDU fence, and thus not under the

control of COMPANY, it shall be agreed with the local authorities that the limit of impacted area shall

be the limit for construction of buildings, in particular permanent settlement, or operation and

transportation means open to public.

10. DOMESTIC GAS PIPELINE (DGP) INLET

As the gas composition, process conditions and the maximum hole sizes are assumed to be the same

as for the GRDU facility, the safety distances calculated for the GRDU process area can be applied

for the DGP inlet.

11. CONCLUSIONS

The following minimum safety distances have been calculated for the GRDU process area:

- fire zone safety distance

- restricted area safety distance

- impacted area safety distance

- safety distance for ESDV location

- safety distance cold vent

The safety distances for the cold vent (restricted area and impacted area) are extracted from the Ref.

[3] and the Ref. [4].

The fire zone safety distance is 32 m from the process fire boundary (equipment located outside this

area cannot be impacted).

The safety distance for ESDV location is 31 m from the process fire zone boundary. If the inlet / outlet

ESDV cannot be located at this distance, the ESDV shall be fitted with PFP or be buried.

The incinerator package shall be located, within the process fire zone, at 30 m from any other unfired

process equipment.

The restricted area safety distance is 81 m from the process fire zone boundary (location of the fence;

buildings outside this area do not have to be additionally protected i.e no gas detection, fire proofing).

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 16 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

The impacted area safety distance is 118 m from the process fire zone boundary. As the impacted

area is not within the GRDU fence, and thus not under the control of COMPANY, it shall be agreed

with the local authorities that the limit of impacted area shall be the limit for construction of buildings,

in particular permanent settlement, or operation and transportation means open to public.

The different safety distances need to be interpreted as shown in Appendix B.

The restricted area safety distance from the cold vent tip is 35 m.

The impacted area safety distance from the cold vent tip is 105 m.

The safety distances calculated for the GRDU process area shall also be applied for the DGP inlet. In

this case, the DGP fence is not possible to comply with this distances. Nevertheless, as this fence is

inside an industrial area, the safety distances are complied by this other fence.

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 17 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

APPENDIX A – GRAPHICAL REPRESENTATION OF THE SAFETY DISTANCE

Figure 1 – Flammable gas dispersion (fire zone), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

10/D

2/D

16/D 5/D

1/F

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 18 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 2 –Radiation distance jet fire (fire zone), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

5/D

16/D

2/D

10/D

1/F

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 19 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 3 – Radiation distance jet fire (ESDV), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

5/D

16/D

2/D

1/F 10/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 20 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 4 – Flammable gas dispersion (Restricted area), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

1/F

2/D

10/D

5/D

16/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 21 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 5 –Radiation distance jet fire (Restricted area), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

5/D 16/D

2/D 10/D

1/F

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 22 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 6 –Radiation distance jet fire (Impacted area), weather conditions 1/F, 2/D, 5/D and 9/D

10/D

5/D

16/D

2/D

1/F

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 23 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 7 –Explosion distance (Impacted area), weather conditions 1/F, 2/D, 5/D and 9/D

2/D

5/D

16/D

1/F

10/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 24 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

APPENDIX B – EXAMPLE SAFETY DISTANCES OF AREAS

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 25 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

APPENDIX C – RESULTS (NEW COMPOSITION – EFFECTS)

Figure 8 – Flammable gas dispersion

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 26 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 9 –Radiation distance jet fire (fire zone), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 27 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 10 –Radiation distance jet fire (ESDVs), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 28 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 11 –Radiation distance jet fire (Restricted Area), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Projeto Falcão Fase 2 – Construção da GRDU

SAFETY DISTANCE CALCULATION NOTE

Âmbito Disciplina Tipo Número Rev. Página: 29 / 29

Contrato Nº 4600015710 EG SEG 07 001 A2 GRDU-EG-SEG-07-001-A2

Ref. TEE: 2831-CN-1900-01-A2

Figure 12 –Radiation distance jet fire (Impacted Area), weather conditions 1/F, 2/D, 5/D, 10/D and 16/D

TECHNOEDIF ENGENHARIA, SA IMPTECG01/Rev.1

Você também pode gostar

- Grdu Eg Seg 01 001 - A1Documento6 páginasGrdu Eg Seg 01 001 - A1cadilson.albertoAinda não há avaliações

- Q02-006 - Plano Gestão - EstoqueDocumento43 páginasQ02-006 - Plano Gestão - EstoqueSandro LuccianoAinda não há avaliações

- Almoxarifado SPDADocumento14 páginasAlmoxarifado SPDAPedro Vinicius Nascimento De LimaAinda não há avaliações

- Be8097-0-R2 - Manual Fabricante GGD CPTM - GcfoDocumento79 páginasBe8097-0-R2 - Manual Fabricante GGD CPTM - GcfoGregory De Souza Barreto100% (1)

- PlanoriggingDocumento23 páginasPlanoriggingHelioAinda não há avaliações

- Requisição - Correia, Lampada e CaboDocumento1 páginaRequisição - Correia, Lampada e CaboMarcio LuizAinda não há avaliações

- 3362 e PBT 0004Documento123 páginas3362 e PBT 0004Wagner CarapinaAinda não há avaliações

- Relatório para TreliçaDocumento17 páginasRelatório para TreliçaJoão Pedro TorquatoAinda não há avaliações

- Ce DG02 TQ3 23 00Documento12 páginasCe DG02 TQ3 23 00JMC TVAinda não há avaliações

- Solicitação de Informação TécnicaDocumento30 páginasSolicitação de Informação TécnicaMARIOAinda não há avaliações

- CP-J-501 Automacao Industrial Rev 12Documento32 páginasCP-J-501 Automacao Industrial Rev 12Daiane IzaAinda não há avaliações

- EG-T-401 Material Tubulacao Rev 10Documento193 páginasEG-T-401 Material Tubulacao Rev 10MANOEL JUNIORAinda não há avaliações

- Relatório de Medição de Aterramento TEAGDocumento22 páginasRelatório de Medição de Aterramento TEAGFernando Casemiro100% (1)

- Documento Técnico: Ncee - Núcleo de Capacitação em Engenharia de Estruturas LtdaDocumento22 páginasDocumento Técnico: Ncee - Núcleo de Capacitação em Engenharia de Estruturas LtdaherendyAinda não há avaliações

- JjsjdujnsjiskDocumento2 páginasJjsjdujnsjiskAugusto OliverAinda não há avaliações

- Projeto de Iluminação de Rodovias: Especificação TécnicaDocumento32 páginasProjeto de Iluminação de Rodovias: Especificação TécnicaEmerson GranzottiAinda não há avaliações

- Book de Executivo Planejamento: CONTRATO: 5900.0114632.20.2Documento39 páginasBook de Executivo Planejamento: CONTRATO: 5900.0114632.20.2bruno paulaAinda não há avaliações

- ColeteDocumento8 páginasColeteEd NevesAinda não há avaliações

- Manual de Montagem PDFDocumento93 páginasManual de Montagem PDFGustavo Herrmann83% (6)

- EG-T-401 Material Tubulacao Rev 13Documento237 páginasEG-T-401 Material Tubulacao Rev 13Kauê Velho100% (1)

- Bel-0008b2-Qc-Man-Nxt-0008 - 02 RNCDocumento146 páginasBel-0008b2-Qc-Man-Nxt-0008 - 02 RNCSandoval SouzaAinda não há avaliações

- Folha de Especificação - Regularização Itens NR10 em BrancoDocumento9 páginasFolha de Especificação - Regularização Itens NR10 em BrancoHeitor ConstantinoAinda não há avaliações

- 6960 Sgad M VD 020 026Documento32 páginas6960 Sgad M VD 020 026muitodollarAinda não há avaliações

- AT02 Planejamento de 5 Anos para Execução de Manutenção.Documento50 páginasAT02 Planejamento de 5 Anos para Execução de Manutenção.Tadeu HumbertoAinda não há avaliações

- EG-M-402 Tratam Superf Pintura Protecao Acabamento Rev 14Documento54 páginasEG-M-402 Tratam Superf Pintura Protecao Acabamento Rev 14Filipe Mendes0% (2)

- Par 40 11 Vs SM Ies 003 2 Proce TráfegoDocumento13 páginasPar 40 11 Vs SM Ies 003 2 Proce Tráfegoicaro AssisAinda não há avaliações

- ASIPDocumento2 páginasASIPsabatrumpetAinda não há avaliações

- 373301370932022OC01075Edital Anexo24 - 01 - 2023 15 - 23 - 10Documento53 páginas373301370932022OC01075Edital Anexo24 - 01 - 2023 15 - 23 - 10Luciano PereiraAinda não há avaliações

- Em-9 86 00 34-700-001Documento14 páginasEm-9 86 00 34-700-001RC COMERCIOAinda não há avaliações

- EG-M-402 Tratam Superf Pintura Prot Acabamento Rev 17Documento62 páginasEG-M-402 Tratam Superf Pintura Prot Acabamento Rev 17RICARDO PATRICK RODRIGUES DA SILVA100% (1)

- MD - Memorial DescritivoDocumento37 páginasMD - Memorial Descritivosinalizacaobras1Ainda não há avaliações

- Germano Geral Barragem Germano Geral Bacia Do Chico Especificação Técnica Projeto DescaracterizaçãoDocumento65 páginasGermano Geral Barragem Germano Geral Bacia Do Chico Especificação Técnica Projeto DescaracterizaçãoNubia MaitanaAinda não há avaliações

- Implantação Da Barragem Dos Imigrantes Do Rio Jucu: Projeto GeralDocumento61 páginasImplantação Da Barragem Dos Imigrantes Do Rio Jucu: Projeto GeralGeologo EduardoAinda não há avaliações

- Normas ValeDocumento54 páginasNormas ValeDistintas100% (1)

- PPP Amaro AbilioDocumento4 páginasPPP Amaro AbilioBruno Hideki NonakaAinda não há avaliações

- PPP 16Documento2 páginasPPP 16ramonAinda não há avaliações

- Manual Da Peneira HaverDocumento31 páginasManual Da Peneira HaverLúcia OliveiraAinda não há avaliações

- ET D10 C38 0002 - RevaDocumento25 páginasET D10 C38 0002 - RevaFernando Da RosAinda não há avaliações

- C Rel 00273 0001Documento27 páginasC Rel 00273 0001Victor ChameletteAinda não há avaliações

- EG-T-401 Material Tubulacao Rev 14Documento245 páginasEG-T-401 Material Tubulacao Rev 14Delano MaurissoAinda não há avaliações

- Laudo NR-12 Prensa EnfardadeiraDocumento10 páginasLaudo NR-12 Prensa EnfardadeiraMarcos Freire100% (1)

- Vu-Pr147-14-Mc-11-201-1-20190710124451 - InterseçãoDocumento209 páginasVu-Pr147-14-Mc-11-201-1-20190710124451 - InterseçãoJordana FurmanAinda não há avaliações

- EG-M-402 Tratam Superf Pintura Protecao Acabamento Rev 15Documento99 páginasEG-M-402 Tratam Superf Pintura Protecao Acabamento Rev 15Gustavo MoreiraAinda não há avaliações

- F2a - Cert CTL Engenharia 01-22Documento1 páginaF2a - Cert CTL Engenharia 01-22Lucas SinoAinda não há avaliações

- ET D10 G12 0001 - RevaDocumento7 páginasET D10 G12 0001 - RevaFernando Da RosAinda não há avaliações

- Abnt NBR 15280-2 - Dutos TerrestresDocumento90 páginasAbnt NBR 15280-2 - Dutos TerrestresJosue SilvaAinda não há avaliações

- Circuito ElétricoDocumento20 páginasCircuito ElétricoEveraldo Silva100% (1)

- Das PN Seg Encaixotador - l01Documento155 páginasDas PN Seg Encaixotador - l01Nino DantasAinda não há avaliações

- Pro Seg Ea 0001 1 A SsmaDocumento16 páginasPro Seg Ea 0001 1 A SsmaglaubermaurinAinda não há avaliações

- Instalações at E MT: Sistemas de Alimentação de Corrente Contínua 110/48 VDocumento66 páginasInstalações at E MT: Sistemas de Alimentação de Corrente Contínua 110/48 VipradaAinda não há avaliações

- PGR. 1 Revisão (Nov 2023) - TCMA (Ponte Sobre Rio Meia Ponte, GOIASA - Goiatuba Álcool Ltda)Documento233 páginasPGR. 1 Revisão (Nov 2023) - TCMA (Ponte Sobre Rio Meia Ponte, GOIASA - Goiatuba Álcool Ltda)reengenhariadotrabalhoAinda não há avaliações

- Patente Tramontina NitretaçãoDocumento2 páginasPatente Tramontina NitretaçãoRodolfo M. PortoAinda não há avaliações

- Normam-30 Rev.1 Mod 3 PDFDocumento137 páginasNormam-30 Rev.1 Mod 3 PDFAdriano FreitasAinda não há avaliações

- Interpretação Da Rede de HidrogeologicaDocumento61 páginasInterpretação Da Rede de HidrogeologicaEdmilson S. CastroAinda não há avaliações

- PPP - Ex2Documento2 páginasPPP - Ex2willesrbanks50% (2)

- ENG 22 08 0002mcDocumento14 páginasENG 22 08 0002mcronaldo engenhariaAinda não há avaliações

- PVH-VIN-SSO-AD-0921-01 - TAV - Pipa RMW-9E00Documento1 páginaPVH-VIN-SSO-AD-0921-01 - TAV - Pipa RMW-9E00Jean Carlos de Lima ParreiraAinda não há avaliações

- Desenvolvendo Um Supervisório Em Vb Com Gauge Angular Para Monitoramento De Gaussímetro Programado No ArduinoNo EverandDesenvolvendo Um Supervisório Em Vb Com Gauge Angular Para Monitoramento De Gaussímetro Programado No ArduinoAinda não há avaliações

- Monitorando Co2 No Pic Com Sintetizador De Voz Programado No Visual BasicNo EverandMonitorando Co2 No Pic Com Sintetizador De Voz Programado No Visual BasicAinda não há avaliações

- Monitorando Co2 No Pic Com Sintetizador De Voz Programado No Visual C#No EverandMonitorando Co2 No Pic Com Sintetizador De Voz Programado No Visual C#Ainda não há avaliações

- Nissan - O Mês Do ÊxodoDocumento5 páginasNissan - O Mês Do ÊxodoJoão QuilomboAinda não há avaliações

- Revolução Cubana - Prof. AlbanirDocumento14 páginasRevolução Cubana - Prof. AlbanirAlbanir FaleirosAinda não há avaliações

- Anatomia Aplicada A AnestesioDocumento2 páginasAnatomia Aplicada A AnestesioBRUNA LARYSSA JUSTINIANO DE ALMEIDAAinda não há avaliações

- O Espaço Físico Nas Instituições de Educação InfantilDocumento13 páginasO Espaço Físico Nas Instituições de Educação InfantilAna KeliAinda não há avaliações

- Educação Infantil - BNCC de BolsoDocumento24 páginasEducação Infantil - BNCC de BolsoTalita BatistaAinda não há avaliações

- Investigação Digital - Top 7 Ferramentas para OSINTDocumento4 páginasInvestigação Digital - Top 7 Ferramentas para OSINTAuster PhisherAinda não há avaliações

- Sede PerfeitosDocumento31 páginasSede PerfeitosRoberta Montellato100% (1)

- Cópia de Receituário Especial para ImpressãoDocumento1 páginaCópia de Receituário Especial para ImpressãoLetícia MeloAinda não há avaliações

- Potenciação & Radiciação: Prof. Gilberto Santos JRDocumento12 páginasPotenciação & Radiciação: Prof. Gilberto Santos JRLeonardo FariaAinda não há avaliações

- TCC 1.1Documento36 páginasTCC 1.1Silas SambaAinda não há avaliações

- Avaliação de Ciências - 5º Ano - 2022 - 4º BimestreDocumento6 páginasAvaliação de Ciências - 5º Ano - 2022 - 4º Bimestrecmazzoni_3100% (10)

- Ficha BladesingerDocumento3 páginasFicha BladesingerLuis PalosoAinda não há avaliações

- UFCD 6557 FichTrab2 2018.2019Documento1 páginaUFCD 6557 FichTrab2 2018.2019João CaladoAinda não há avaliações

- Gaiolas e Asas - Rubem Alves 01 PDFDocumento2 páginasGaiolas e Asas - Rubem Alves 01 PDFJoãoSunahAinda não há avaliações

- Cartilha BandeiradeLutas 2019versaofinalDocumento18 páginasCartilha BandeiradeLutas 2019versaofinalbrenda cruzAinda não há avaliações

- Campo Harmonico e Transposição - EmanuelDocumento7 páginasCampo Harmonico e Transposição - EmanuelDarci Pinheiro MdfAinda não há avaliações

- O Congresso de Milão HQ LetrariaDocumento45 páginasO Congresso de Milão HQ LetrariaQueli Dornelles MoraisAinda não há avaliações

- Conheça Os Principais Tipos de Hidratação e Reconstrução Dos CabelosDocumento3 páginasConheça Os Principais Tipos de Hidratação e Reconstrução Dos CabelosCassia MacielAinda não há avaliações

- Comprovante Uber - 7658684 PDFDocumento4 páginasComprovante Uber - 7658684 PDFeng.victoreuclidesAinda não há avaliações

- Fonte Chaveaada Projeto PDFDocumento33 páginasFonte Chaveaada Projeto PDFSOSIGENES TAVARESAinda não há avaliações

- Redação 9º AnoDocumento6 páginasRedação 9º AnoCheysa AbdallaAinda não há avaliações

- 【ASSISTIR HD】▷ Boku no Hero Academia: World Heroes' Mission 【2021】 Dublado Filme Online Grátis em PortuguêseDocumento7 páginas【ASSISTIR HD】▷ Boku no Hero Academia: World Heroes' Mission 【2021】 Dublado Filme Online Grátis em Portuguêsetakbisa0% (1)

- Captura de Tela 2021-07-27 À(s) 14.36.53Documento64 páginasCaptura de Tela 2021-07-27 À(s) 14.36.53tamara carvalhoAinda não há avaliações

- Escritas Do SuporteDocumento262 páginasEscritas Do SuporteJh SkeikaAinda não há avaliações

- Cinco Ritos TibetanosDocumento5 páginasCinco Ritos Tibetanoscarros-120Ainda não há avaliações

- A Fina Lâmina Da Palavra PDFDocumento30 páginasA Fina Lâmina Da Palavra PDFJoão NetoAinda não há avaliações

- 2006 - Maria Lais de Oliveira Kutchenski - Parte2Documento25 páginas2006 - Maria Lais de Oliveira Kutchenski - Parte2fernandoAinda não há avaliações

- Curso Técnico em Refrigeração e Climatização 1200h - Cetec AraguaínaDocumento79 páginasCurso Técnico em Refrigeração e Climatização 1200h - Cetec AraguaínaJorge ChavesAinda não há avaliações

- V5 Ficha de CoterieDocumento1 páginaV5 Ficha de CoterieDavi GonçalvesAinda não há avaliações

- Lista de Análise MorfológicaDocumento2 páginasLista de Análise MorfológicaLilia Abrantes88% (8)