Escolar Documentos

Profissional Documentos

Cultura Documentos

Fatigue Behaviour of A Structural Steel

Enviado por

Kamila LopesDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fatigue Behaviour of A Structural Steel

Enviado por

Kamila LopesDireitos autorais:

Formatos disponíveis

Fatigue Behaviour of 42CrMo4 STEEL Luís Reis et al.

FATIGUE BEHAVIOUR OF A STRUCTURAL STEEL

UNDER NON-PROPORTIONAL MULTIAXIAL LOADING

LUÍS REIS*, BIN LI, MANUEL de FREITAS

Department of Mechanical Engineering, Instituto Superior Técnico

Av. Rovisco Pais, 1049-001 Lisboa

E-mail: lreis@ist.utl.pt

ABSTRACT: This paper reports experimental studies on the fatigue behaviour of 42CrMo4 steel under non-proportional

loading conditions. Although the 42CrMo4 steel is widely used in complex stressed components such as shafts, etc, most

of the studies in the literature were on the uni-axial fatigue behaviour of this steel. The objective of this work is to study

the mechanical behaviour of the steel 42CrMo4 under specified multiaxial fatigue loading conditions, which will allow a

better understanding of the ratio between normal and shear stress, and validate the fatigue damage models. A series of tests

were carried out in load control for several multiaxial fatigue loading paths. Experimental results show that the ratio

between normal stress and shear stress components has a strong influence to fatigue damage and consequently to fatigue

life. Multiaxial fatigue damage models based on the shear stress amplitude are applied to correlate the test results,

improved correlation results are shown.

Keywords: Multiaxial fatigue, Non-proportional loading, Plasticity, Cyclic hardening, Multiaxial Fatigue models.

RESUMO: Este artigo apresenta um estudo sobre o comportamento em fadiga multiaxial do aço 42CrMo4, sob condições

de carregamento não proporcional. Embora o aço 42CrMo4 seja utilizado em muitos componentes mecânicos, a maioria

dos estudos referenciados na literatura apenas referem o seu comportamento em fadiga uniaxial. O objectivo deste trabalho

é estudar o comportamento mecânico do aço 42CrMo4 sob condições especificas de carregamento, as quais permitirão um

melhor entendimento do rácio entre a componente da tensão normal e da tensão de corte e consequentemente validar os

modelos de dano à fadiga. Foram realizados vários testes, em controlo de carga, para diferentes trajectórias de

carregamento. Os resultados experimentais mostram que o rácio entre a componente da tensão normal e da tensão de corte

tem uma forte influência no dano à fadiga e consequentemente na vida à fadiga. São utilizados modelos de dano à fadiga

multiaxial, baseados na amplitude da tensão de corte, para correlacionar com os resultados experimentais. Com o novo

rácio obtém-se uma melhor correlação dos resultados.

Palavras chave: Fadiga multiaxial, Carregamento não-proporcional, Plasticidade, Encruamento cíclico, Modelos fadiga

multiaxial.

1. INTRODUCTION multiaxial fatigue models and appropriate approaches for

shear stress evaluation under service loading conditions [1].

Engineering components in machines, vehicles and

structures are generally subjected to multiaxial stress states. For structural steels, the shear stress amplitude is one of the

Under service multiaxial loading, microscopic cracks can most important parameters in the formulations of multiaxial

initiate and grow until a macroscopic crack and fatigue damage models. Conventionally, the shear stress

consequently originates the damage of the component and/or amplitude was usually evaluated in the shear stress space

structure. The behaviour of crack initiation and propagation based on the von Mises equivalence (τ=σ/sqrt(3)) or the

until final fracture of materials under multiaxial stress states Tresca equivalence (τ=σ/2) for the multiaxial loading

is quite different from that under uniaxial stress state, conditions. However, the relationship of the equivalent shear

therefore, multiaxial fatigue has become a very active topic stress related to the axial stress component may vary

in the past 20 years, because of the great importance in significantly depending on the type of the material. For

mechanical design. example, the ratio of the torsion fatigue limit over the

bending fatigue limit τ-1/ff-1 varies from 0.5 for mild metals

There are many multiaxial fatigue models proposed in the to 1 for brittle metals [2].

literature, and many corresponding approaches have been

developed for evaluating the shear stress amplitude under In this paper, systematic fatigue experiments are presented

multiaxial fatigue loading conditions. For efficient for a structural steel, 42CrMo4, quenched and tempered

computational fatigue analysis of components and steel, under typical axial-torsional multiaxial loading paths

structures, it is required to carry out further validations of

Ciência e Tecnologia dos Materiais, Vol. 20, n.º 1/2, 2008 87

Luís Reis et al. Fatigue Behaviour of 42CrMo4 STEEL

(a lozenge, a rectangle and an ellipse). Tests were carried Tests of biaxial cyclic tension-compression with cyclic

out in high cycle fatigue regime, 105 – 107 cycles. torsion were performed on a biaxial servo-hydraulic

machine, shown in Fig. 2. Test conditions were as follows:

It is proposed to evaluate the shear stress amplitude in the frequency 4-6 Hz at room temperature and laboratory air.

stress space appropriate to the material type. For the Tests ended up when the specimens were completely

42CrMo4 steel studied, the shear stress space with the broken.

equivalence (τ=0.65*σ) is used for the shear stress

amplitude evaluations under multiaxial loading conditions. To study the effects of the multiaxial loading paths and in

The MCE (Minimum Circumscribed Ellipse) approach, particular both the effect of axial component and the effect

developed by the authors [3], previously, is used for of torsional component on the fatigue life, a series of

evaluating the shear stress amplitude and correlating loading paths were applied in the experiments as shown in

experimental results. Improved correlations are shown. Tables 3 and 4.

Table 3 – Reference multiaxial fatigue loading paths.

2. MATERIAL DATA, SPECIMEN FORM AND TEST

PROCEDURE

3τ 3τ

The material studied in this paper is the 42CrMo4 quenched

and tempered high strength steel. The chemical composition σ σ

is shown in Table 1. In order to characterize the cyclic

stress-strain behaviour of the material studied, tension-

compression low cycle fatigue tests were carried out.

case I case II

Monotonic and cyclic mechanical properties are shown in

Table 2 (cyclic properties obtained by fitting the test 3τ 3τ

results). The geometry and dimensions of the specimen are

shown in Fig. 1.

σ σ

Table 1 – Chemical composition of the material studied

42CrMo4 (in wt%). case III case IV

C Si Mn P S Cr Ni Mo Cu

0.39 0.17 0.77 0.025 0.02 1.1 0.3 0.16 0.21

Table 4 – Variations of the reference multiaxial fatigue

loading paths.

3τ 3τ

σ σ

case II_A case II_B

Fig. 1. Specimen geometry for biaxial cyclic tension-

compression with cyclic torsion tests. 3τ

3τ

Table 2 – Monotonic and cyclic mechanical properties of

the material studied. σ σ

Tensile Strength, ı (MPa) 1100

Yield Strength, ı0.2 (MPa) 980 case III_A case III_B

Elongation, A (%) 16 3τ 3τ

Cyclic Yield Strength, ıp0.2,cyclic (MPa) 540

Strength coefficient, K´ [MPa] 1420

σ σ

Strain hardening exponent, n´ 0.12

Fatigue strength coefficient, σf´ (MPa) 1154

Fatigue strength exponent, b -0.061 case IV_A case IV_B

Fatigue ductility coefficient, εf´ 0.18

Fatigue ductility exponent, c -0,53

88 Ciência e Tecnologia dos Materiais, Vol. 20, n.º 1/2, 2008

Fatigue Behaviour of 42CrMo4 STEEL Luís Reis et al.

method MCE for evaluating the effective shear stress

amplitude of the non-proportional loading path.

The evaluation of shear stress amplitude is a key issue for

fatigue estimations using Eq. (1). The definition of the

square root of the second invariant of the stress deviator is:

J2 ≡

1

6

{( − ) +(

2

− ) + (σ

2

zz − σ xx )

2

} + {(σ xy ) + (σ ) + ( ) }

2

yz

2

zx

2

(2)

One direct way to calculate the amplitude of J 2 is:

J 2, ≡

1

6

{( , − yy , ) +(

2

yy , − , ) + (σ

2

, −σ , ) } + {(σ ) + (σ ) + (

2

y,

2

y ,

2

)}

2

(3)

Eq.(3) is applicable for proportional loading, where all the

stress components vary proportionally. However, when the

stress components vary non-proportionally (for example,

with phase shift between the stress components), Eq.(3)

Fig. 2. Biaxial testing machine (Instron 8874). gives the same result with that of proportional loading

condition. In fact, the non-proportionality has influence on

the shear stress amplitude generated by multiaxial loading.

3. THEORETICAL ANALYSIS: EVALUATION OF Therefore, a new methodology is needed.

THE SHEAR STRESS AMPLITUDE

Many multiaxial fatigue models have been proposed in the 3.1 Equivalent Stress Range of ASME Code

last decades [1]. Among several parameters and constants

the shear stress amplitude is one of the most important The ASME Boiler and Pressure Vessel code Procedure [6] is

parameters in the formulations of the multiaxial fatigue based on the von Mises hypothesis, but employs the stress

damage models, in high cycle fatigue regime. difference Δσi between to two arbitrary instants t1 and t2:

{( Δσ )}

1

− Δσ y ) + ( Δσ y − Δσ z ) + ( Δσ z − Δσ x ) + 6 (

1 2 2

Among many multiaxial models, the Sines [4] and the Δσ eq = x

2 2

2 2

Crossland [5] are two important criteria, which are

formulated by the amplitude of the second deviatoric stress (4)

invariant and the hydrostatic stress PH:

where the equivalent stress range Δσeq is maximized with

respect to time. Eq. (4) produces a lower equivalent stress

J 2, a + k ( N ) PH = λ ( N ) (1) range, for some conditions, in out-of-phase than the in-phase

loading, leading an increase of the fatigue life, which is in

contradiction with experimental results.

where k(N) and λ(N) denote material parameters for a given

life N.

3.2. MCE Approach for evaluating shear stress amplitude

Crossland suggested using the maximum value of the

hydrostatic stress PH,max instead of the mean value of The longest chord (LC) approach is one of the well-known

hydrostatic stress PH,m used by Sines in the Eq.(1). A approaches as summarized by Papadopoulos [2], which

physical interpretation of the criterion expressed in Eq.(2) is defines the shear stress amplitude as half of the longest

the follow: for a given cyclic life N, the permissible chord of the loading path, denoted as D/2.

amplitude of the root-mean-square of the shear stress over

all planes is a linear function of the normal stress averaged The MCC approach [2] defines the shear stress amplitude as

over all planes. Besides, from the viewpoint of the radius of the minimum circle circumscribing to the

computational efficiency, the stress-invariant based loading path. On the basis of MCC approach, a new

approach such as Eq. (1) it is easy to use and approach, called the minimum circumscribed ellipse (MCE)

computationally efficient. approach [3], was proposed to compute the effective shear

stress amplitude taking into account the non-proportional

In practical engineering design, the Sines and Crossland loading effect.

criteria have found successful applications for proportional

multiaxial loading. For non-proportional multiaxial loading, The load traces are represented and analyzed in the

it has been shown that the Sines and Crossland criteria can transformed deviatoric stress space, where each point

also yield better prediction results by using improved

represents a value of J 2 and the variations of J 2 are

Ciência e Tecnologia dos Materiais, Vol. 20, n.º 1/2, 2008 89

Luís Reis et al. Fatigue Behaviour of 42CrMo4 STEEL

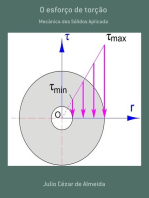

shown during a loading cycle. The schematic representation lozenge up and lozenge down loading paths, respectively

of the MCE approach and the relation with the minimum (see Tables 3 and 4). Fig.(s) 4 and 5 show the evolution of

circumscribed circle (MCC) approach are illustrated in Fig. experimental life with equivalent von Mises stress parameter

3: for cases I, II, II_A, II_B, III, III_A and III_B.

Minimum

Load Path 1 800

Circumscribed

Non-Proportional

Circle

700

von Mises [MPa]

Load Path 2

(Rectilinear) 600

Rb

500

400

τm

Minimum

Ra 300

Circumscribed

Case I Case II Case II_B Case II_A

Ellipse

O

200

1000 10000 100000 1000000 10000000

Experimental life (N)

Fig. 3. The MCC and MCE circumscribing to shear stress

traces, Ra and Rb are the major and minor radius of MCE, Fig. 4. Evolution of experimental life with equivalent von

respectively. Mises stress: cases I, II, II_A and II_B, respectively.

The idea of the MCE approach is to construct a minimum

circumscribed ellipse that can enclose the whole loading 800

path throughout a loading block in the transformed

deviatoric stress space. 700

600

J 2,a = Ra by the minimum

von Mises [MPa]

Rather than defining

circumscribed circle (MCC) approach, a new definition of 500

J 2, a was proposed [3], where Ra and Rb are the lengths 400

of the major semi-axis and the minor semi-axis of the

minimum circumscribed ellipse respectively. 300

Case I Case III Case III_B Case III_A

200

The ratio of Rb/Ra represents the non-proportionality of the 1000 10000 100000 1000000 10000000

shear stress path. The important advantage of this new MCE

Experimental life (N)

approach is that it can take into account the non-proportional

loading effects in an easy way. Fig. 5. Evolution of experimental life with equivalent von

Mises stress: cases I, III, III_A and III_B, respectively.

As shown in Fig. 3, for the non-proportional loading path 1,

the shear stress amplitude is defined as: From Fig.(s) 4 and 5 it is shown that the von Mises

parameter gives a big scatter when correlating the

2 2 experimental results. In both pictures, it seems that there’s

J 2,a = R a + Rb (5) two tendencies, one for proportional loading, case I, with

cases II_A and III_A (strong torsional component) and

For the proportional loading path 2, it is defined as another one with cases II, III, II_B and III_B (strong axial

component). Can also be observed that cases II_A and III_A

J 2,a = Ra since Rb is equal to zero (rectilinear loading are least severe together with the proportional case I. This

trace). means that a bigger torsional component, as compared with

the axial one, has not so strong influence in the fatigue life

strength.

4. RESULTS AND DISCUSSIONS

4.1. Experimental cyclic stress-strain behavior under 5.2. Experimental cyclic stress-strain behavior under

proportional and non-proportional loading with von Mises proportional and non-proportional loading with new fatigue

parameter parameter

Proportional and non-proportional cyclic tests were Fig.(s) 6 and 7 show the evolution of experimental life with

conducted in the plane (σ , √3τ). Non-proportional cyclic the new parameter for cases I, II, II_A, II_B, III, III_A and

tests were conducted with the square, rectangle up and III_B.

rectangle down, circle, ellipse down, ellipse up, lozenge,

90 Ciência e Tecnologia dos Materiais, Vol. 20, n.º 1/2, 2008

Fatigue Behaviour of 42CrMo4 STEEL Luís Reis et al.

800 800

700 700

Ta+Sig_h [MPa]

600 600

Ta+Sig_h [MPa]

500 500

400 400

300 300 Case II_A Case III_A Case IV_A

Case I Case II Case II_B Case II_A Case II_B Case III_B Case IV_B

200 200

1000 10000 100000 1000000 10000000 1000 10000 100000 1000000

Experimental life (N) Experimental life (N)

Fig. 6. Evolution of the new fatigue parameter with Fig. 8. Evolution of the new fatigue parameter with

experimental life: cases I, II, II_A and II_B, respectively. experimental life: cases II_A, II_B, III_A, III_B, IV_A and

IV_B, respectively.

800

5. CONCLUSIONS

700

Experimental results show that the ratio between normal

600 stress component and shear stress component has a strong

Ta+Sig_h [MPa]

influence to fatigue damage and consequently in fatigue life.

500

The shear stress space used for the evaluation of the shear

400 stress amplitude of multiaxial loading conditions should be

appropriate for this material type.

300

Case I Case III Case III_B Case III_A

200 ACKNOWLEDGEMENTS

1000 10000 100000 1000000 10000000

Experimental life (N) Financial support of this work by FCT - Fundação para

Ciência e Tecnología (Portuguese Foundation for Science

Fig. 7. Evolution of the new fatigue parameter with

and Technology) is gratefully acknowledged through the

experimental life: cases I, III, III_A and III_B, respectively.

project PPCDT/EME/59577/2004.

In order to get better correlations, the new shear stress space

parameter with the equivalence τ=0.65*σ is used for the REFERENCES

shear stress amplitude evaluations under multiaxial loading

conditions. The parameter (Ta+Sig_h) is obtained from Eq. [1] Socie D. F. and Marquis G. B. Multiaxial Fatigue,

(2) with the shear stress amplitude calculated from Eq. (5). SAE, Warrendale, PA 15096-0001, (2000).

Fig. (s) 6 and 7, show the improved correlations obtained

with the new parameter, presented in this paper. There’s a [2] Papadopoulos, I.V., Davoli, P., Gorla, C., Fillipini,

good correlation between the different cases, which can be M.and Bernasconi, A. A comparative study of

observed from the position of the data and corresponding to multiaxial high-cycle fatigue criteria for metals.

a unique tendencies. International Journal of Fatigue, Vol. 19, Nº3, pp. 219-

235, (1997).

Fig. 8 present all the results obtained from the variations of

the reference multiaxial fatigue loading paths (Table 4). It [3] M. de Freitas, B. Li and J.L.T. Santos, Multiaxial

can be observed that there’s a good correlation between the Fatigue and Deformation: Testing and Prediction,

data. The present work is part of continuous research in this ASTM STP 1387, S. Kaluri and P.J. Bonacuse, Eds.,

matter and these results give some confidence in the ASTM, West Consh, PA, pp.139-156. (2000).

upcoming work.

[4] Sines, G., Metal Fatigue, (edited by G. Sines and

J.L.Waisman), McGraw Hill, N.Y, pp.145-169,

(1959).

[5] Crossland, B., Proc. Int. Conf. on Fatigue of Metals,

Inst. of Mech. Eng, London, pp.138-149, (1956).

[6] ASME Code Case N-47-23 (1988) Case of ASME

Boiler and Pressure Vessel Code, ASME.

Ciência e Tecnologia dos Materiais, Vol. 20, n.º 1/2, 2008 91

Você também pode gostar

- Modulo Online de Engenharia MecânicaDocumento83 páginasModulo Online de Engenharia MecânicaBruno100% (1)

- Campos de Tensões em Zonas de DescontinuidadeDocumento8 páginasCampos de Tensões em Zonas de DescontinuidadeRodolfo ShamáAinda não há avaliações

- Fatigue Behaviour of A Structural SteelDocumento5 páginasFatigue Behaviour of A Structural SteelKamila LopesAinda não há avaliações

- Influence of Graphite Nodules On Fatigue Limit of Nodular Cast IronDocumento8 páginasInfluence of Graphite Nodules On Fatigue Limit of Nodular Cast IronLucas LimaAinda não há avaliações

- 6a Aula - Ciência Materiais - Propriedades Dos Materiais - M. I.Documento62 páginas6a Aula - Ciência Materiais - Propriedades Dos Materiais - M. I.Herbert Alves De SouzaAinda não há avaliações

- MaterialDocumento22 páginasMaterialOrochimaro2011Ainda não há avaliações

- Mecanica Dos Solidos - CisalhamentoDocumento18 páginasMecanica Dos Solidos - CisalhamentoGustavo CastroAinda não há avaliações

- RL Encurvadura EulerDocumento4 páginasRL Encurvadura EulerGilberto Laranja100% (1)

- Relatório PMTDocumento33 páginasRelatório PMTSerginho VieiraAinda não há avaliações

- Ensaios Mecânicos PDFDocumento78 páginasEnsaios Mecânicos PDFDaniele Souza PassosAinda não há avaliações

- Roteiro Relatorio Ensaio de Tracao Laboratorio 2013Documento4 páginasRoteiro Relatorio Ensaio de Tracao Laboratorio 2013Felipe Augusto De LimaAinda não há avaliações

- Ensaios de Fadiga Por Meio de Esforços de TorçãoDocumento1 páginaEnsaios de Fadiga Por Meio de Esforços de TorçãoKamila LopesAinda não há avaliações

- Ensaio de TraçãoDocumento52 páginasEnsaio de TraçãoMatheus AndradeAinda não há avaliações

- Ensaio de TracaoDocumento4 páginasEnsaio de TracaoAndre AbregoAinda não há avaliações

- TM Aula 01 - Ensaio de TraçãoDocumento95 páginasTM Aula 01 - Ensaio de TraçãoMaria Eduarda Quintanilha100% (1)

- Relatorio Tracao e DurezaDocumento9 páginasRelatorio Tracao e Durezachrisandrade07Ainda não há avaliações

- Relatorio CompressãoDocumento4 páginasRelatorio CompressãoRodrigo TecchioAinda não há avaliações

- 1986 Contribuicao Ao Estudo Das Microestacas Tubulares InjetadasDocumento14 páginas1986 Contribuicao Ao Estudo Das Microestacas Tubulares InjetadasGustavoAinda não há avaliações

- (20170908032627) Pré Aula - Propriedades Mecânicas 1Documento3 páginas(20170908032627) Pré Aula - Propriedades Mecânicas 1Allan Silva Dos SantosAinda não há avaliações

- Materiais RefratáriosDocumento21 páginasMateriais RefratáriosmarcaolacerdaAinda não há avaliações

- 1986-Viii Cbmsef Contribuicao Ao Estudo Microestacas Tubulares Injetadas PDFDocumento13 páginas1986-Viii Cbmsef Contribuicao Ao Estudo Microestacas Tubulares Injetadas PDFpressottiAinda não há avaliações

- FadigaDocumento9 páginasFadigaSandra PenhaAinda não há avaliações

- Relatório 1Documento6 páginasRelatório 1Débora BretasAinda não há avaliações

- Apostila CM2 - II Propriedades Mecânicas PDFDocumento22 páginasApostila CM2 - II Propriedades Mecânicas PDFThiarlle SdAinda não há avaliações

- Prática 01 - Ensaio de TraçãoDocumento3 páginasPrática 01 - Ensaio de TraçãoMilena MilanezAinda não há avaliações

- Critérios Von Misses e TrescaDocumento41 páginasCritérios Von Misses e Trescawesleyfc1Ainda não há avaliações

- Comportamento Mecânico Dos Materiais E Studo DirigidoOK 7Documento4 páginasComportamento Mecânico Dos Materiais E Studo DirigidoOK 7Zenaida Jorge100% (1)

- Proc Conf Capítulo 2Documento12 páginasProc Conf Capítulo 2José Eduardo Salgueiro LimaAinda não há avaliações

- Propriedades Mecânicas Dos MateriaisDocumento18 páginasPropriedades Mecânicas Dos MateriaisRaphael Valentim RodriguesAinda não há avaliações

- Trabalho Ensaio Tracao TCCDocumento23 páginasTrabalho Ensaio Tracao TCCOtávio S. B. SouzaAinda não há avaliações

- Análise de Ensaio Convencional de TraçãoDocumento3 páginasAnálise de Ensaio Convencional de TraçãoHigor BarbosaAinda não há avaliações

- Resistencia Dos Materiais Unidade 4Documento28 páginasResistencia Dos Materiais Unidade 4Franklin de Assis PereiraAinda não há avaliações

- Slide ViDocumento21 páginasSlide ViCleveston MoraisAinda não há avaliações

- Gabarito Da AtividadeDocumento3 páginasGabarito Da AtividadeGeovane GasparAinda não há avaliações

- Exercícios Resistência e Falha de MateriaisDocumento8 páginasExercícios Resistência e Falha de MateriaisCaio KuribayashiAinda não há avaliações

- Relatorio ESMAEL FinalDocumento11 páginasRelatorio ESMAEL FinalvirgilioAinda não há avaliações

- CTM - Roteiro de Prática EAETI - Ensaios MecânicosDocumento4 páginasCTM - Roteiro de Prática EAETI - Ensaios MecânicosFladimyAinda não há avaliações

- Fatigue Testing and Analysis-2Documento167 páginasFatigue Testing and Analysis-2Kamila LopesAinda não há avaliações

- 1494 7060 2 PBDocumento12 páginas1494 7060 2 PBFelipe Pisklevits LaubeAinda não há avaliações

- Exercícios RESMATDocumento6 páginasExercícios RESMATCaio KuribayashiAinda não há avaliações

- Elementos de Máquinas Prof Daniel - Aula 04Documento32 páginasElementos de Máquinas Prof Daniel - Aula 04Daniel Alves de AndradeAinda não há avaliações

- 8620 FadigaDocumento128 páginas8620 FadigaHelder KennedyAinda não há avaliações

- Estudo Aço 1020Documento27 páginasEstudo Aço 1020Heitor JoaoAinda não há avaliações

- Estudo Das Propriedades Mecânicas em Tração Dos Aços Sae 1020 e Sae 1045 em Diferentes Condições MetalúrgicasDocumento6 páginasEstudo Das Propriedades Mecânicas em Tração Dos Aços Sae 1020 e Sae 1045 em Diferentes Condições MetalúrgicasEduardo GaspariniAinda não há avaliações

- Introd Fadiga Mec Sol 2018 2Documento74 páginasIntrod Fadiga Mec Sol 2018 2Alex CapitaniAinda não há avaliações

- Aula 6 - Propriedades MecânicasDocumento29 páginasAula 6 - Propriedades MecânicasJhonatan RodriguesAinda não há avaliações

- Lista 1Documento3 páginasLista 1SenophoeAinda não há avaliações

- CAPÍTULO 2 Tensaodefrev03Documento11 páginasCAPÍTULO 2 Tensaodefrev03Marilia GoulartAinda não há avaliações

- Aula Pos Fadiga 3 v2Documento91 páginasAula Pos Fadiga 3 v2José Luciano Cerqueira CesarAinda não há avaliações

- Relatorio g8 (t1m1)Documento32 páginasRelatorio g8 (t1m1)Natalia FreitasAinda não há avaliações

- CM P1, P2 OnlineDocumento9 páginasCM P1, P2 OnlineRafaelSilvaChicoliAinda não há avaliações

- LRT (MPa) 3,45xHBDocumento4 páginasLRT (MPa) 3,45xHBHenrique SouzaAinda não há avaliações

- Auto-Teste para Exame de RecorrenciaDocumento3 páginasAuto-Teste para Exame de RecorrenciaRhamadanny OmarAinda não há avaliações

- BIM 04 - AtividadeDocumento7 páginasBIM 04 - AtividadeGustavo ArraisAinda não há avaliações

- Tensao e Deformação Verdadeira 3Documento18 páginasTensao e Deformação Verdadeira 3lamarckederAinda não há avaliações

- Tenacidade À Fratura PDFDocumento39 páginasTenacidade À Fratura PDFTéfo OliveiraAinda não há avaliações

- Análise Modal Operacional: a metodologia de análise de vibrações estruturais aplicada em um píerNo EverandAnálise Modal Operacional: a metodologia de análise de vibrações estruturais aplicada em um píerAinda não há avaliações

- ReferenciasDocumento21 páginasReferenciasKamila LopesAinda não há avaliações

- Silva, 2022Documento53 páginasSilva, 2022Kamila LopesAinda não há avaliações

- Análise de Fissuras em Uma Instituição de Ensino Da Cidade de Joca Claudino-PB (LOURENÇO, 2022)Documento86 páginasAnálise de Fissuras em Uma Instituição de Ensino Da Cidade de Joca Claudino-PB (LOURENÇO, 2022)Kamila LopesAinda não há avaliações

- Análise de Manifestações Patológicas em Edificações Públicas - Utilização Do Metodo Gut para Definição de Prioridades (SANTOS FILHO, 2021)Documento41 páginasAnálise de Manifestações Patológicas em Edificações Públicas - Utilização Do Metodo Gut para Definição de Prioridades (SANTOS FILHO, 2021)Kamila LopesAinda não há avaliações

- Dano A Vizinho - Modelo de Planejamento de VistoriaDocumento3 páginasDano A Vizinho - Modelo de Planejamento de VistoriaKamila LopesAinda não há avaliações

- Projeto de Maquina de Ensaio de Fadiga Por Flexão RotativaDocumento5 páginasProjeto de Maquina de Ensaio de Fadiga Por Flexão RotativaKamila LopesAinda não há avaliações

- TCC Gustavo Stallivieri CarraDocumento44 páginasTCC Gustavo Stallivieri CarraKamila LopesAinda não há avaliações

- Henrique Catuzzo Ecf PRDocumento51 páginasHenrique Catuzzo Ecf PRKamila LopesAinda não há avaliações

- Contribuicao Elaboracao PraticasDocumento56 páginasContribuicao Elaboracao PraticasKamila LopesAinda não há avaliações

- Catálogo Pavplus 2022Documento12 páginasCatálogo Pavplus 2022Kamila LopesAinda não há avaliações

- Fadiga em Elementos Metalicos V20220613aDocumento24 páginasFadiga em Elementos Metalicos V20220613aKamila LopesAinda não há avaliações

- Fema 350Documento224 páginasFema 350Kamila LopesAinda não há avaliações

- Review On Fatigue Problems of Orthotropic Steel Bridge DeckDocumento17 páginasReview On Fatigue Problems of Orthotropic Steel Bridge DeckKamila LopesAinda não há avaliações

- Metodología Probabilística Weibull de Diseño de Vigas de AceroDocumento8 páginasMetodología Probabilística Weibull de Diseño de Vigas de AceroKamila LopesAinda não há avaliações

- Mechanical Behavior of Materials (Meyers 2009) (301-600)Documento300 páginasMechanical Behavior of Materials (Meyers 2009) (301-600)Kamila LopesAinda não há avaliações

- Mechanical Behavior of Materials (Meyers 2009) (001-300)Documento300 páginasMechanical Behavior of Materials (Meyers 2009) (001-300)Kamila LopesAinda não há avaliações

- Mechanical Behavior of Materials (Meyers 2009) (601-882)Documento282 páginasMechanical Behavior of Materials (Meyers 2009) (601-882)Kamila LopesAinda não há avaliações

- Mechanical Properties of Ausforged 27MnSiVS6 Microalloyed SteelDocumento8 páginasMechanical Properties of Ausforged 27MnSiVS6 Microalloyed SteelKamila LopesAinda não há avaliações

- Fatigue Safety Level Provided by Brazilian Design Standards ForDocumento24 páginasFatigue Safety Level Provided by Brazilian Design Standards ForKamila LopesAinda não há avaliações

- Fatigue Testing and Analysis-2Documento167 páginasFatigue Testing and Analysis-2Kamila LopesAinda não há avaliações

- Estudo Da Propagaçãode Trinca Por Fadiga No Aço 1045 LaminadoDocumento67 páginasEstudo Da Propagaçãode Trinca Por Fadiga No Aço 1045 LaminadoKamila LopesAinda não há avaliações

- Análise Do Comportamento em Fadiga Do Aço Sae 52100 SobDocumento135 páginasAnálise Do Comportamento em Fadiga Do Aço Sae 52100 SobKamila LopesAinda não há avaliações

- Congresso - Validação de Resultados Obtidos Através de Uma Máquina de Fadiga de Flexão Rotativa Utilizando Aço AISI SAE 1045Documento9 páginasCongresso - Validação de Resultados Obtidos Através de Uma Máquina de Fadiga de Flexão Rotativa Utilizando Aço AISI SAE 1045Kamila LopesAinda não há avaliações

- (Nussbaumer Et Al, 2011) LIVRO - Fatigue Design of Steel and Composite Structures (181-330)Documento150 páginas(Nussbaumer Et Al, 2011) LIVRO - Fatigue Design of Steel and Composite Structures (181-330)Kamila LopesAinda não há avaliações

- Análisis Del Diseño A Fatiga en Detalles de Refuerzo de Vigas de Acero Mediante Elementos FinitosDocumento136 páginasAnálisis Del Diseño A Fatiga en Detalles de Refuerzo de Vigas de Acero Mediante Elementos FinitosKamila LopesAinda não há avaliações

- (MANSUR, 2003) Avaliação e Desenvolvimento de Modelos de Determinação de Acúmulo de Danos Por Fadiga em Um Aço EstruturalDocumento215 páginas(MANSUR, 2003) Avaliação e Desenvolvimento de Modelos de Determinação de Acúmulo de Danos Por Fadiga em Um Aço EstruturalKamila LopesAinda não há avaliações

- Ensaios de Fadiga Por Meio de Esforços de TorçãoDocumento1 páginaEnsaios de Fadiga Por Meio de Esforços de TorçãoKamila LopesAinda não há avaliações

- (TONI, 2021) Desenvolvimento de Equipamento de Ensaio de Fadiga Por Flexão RotativaDocumento85 páginas(TONI, 2021) Desenvolvimento de Equipamento de Ensaio de Fadiga Por Flexão RotativaKamila LopesAinda não há avaliações

- (SDORFF, 2017) Jonathan Maciel Ziehlsdorf - TCCFAB - 2017Documento80 páginas(SDORFF, 2017) Jonathan Maciel Ziehlsdorf - TCCFAB - 2017Kamila LopesAinda não há avaliações

- Trabalho Filme-Réquiem para Um SonhoDocumento12 páginasTrabalho Filme-Réquiem para Um SonhoTatiane Micheli Okamoto Silva VicenteAinda não há avaliações

- Lenormand ClássicoDocumento26 páginasLenormand ClássicoClayton BritoAinda não há avaliações

- Proposta PCC IVDocumento20 páginasProposta PCC IVIngrid CostaAinda não há avaliações

- Psib12 dp5 Teste Genetica e Sistema NervosoDocumento2 páginasPsib12 dp5 Teste Genetica e Sistema NervosoPedro PintoAinda não há avaliações

- Resumo (Our Universe)Documento4 páginasResumo (Our Universe)Alinne LealAinda não há avaliações

- ED História Da Psicologia - ExercicioDocumento20 páginasED História Da Psicologia - Exerciciobethrosa133Ainda não há avaliações

- Imagem e Exercício Na Aprendeizagem Da LeituraDocumento14 páginasImagem e Exercício Na Aprendeizagem Da LeituraOrquídio Mimósio NhampossaAinda não há avaliações

- Lista de Metas e ObjetivosDocumento1 páginaLista de Metas e ObjetivosSabrina NavesAinda não há avaliações

- Slide Vídeo Aula - Avaliação, Progressão Das Aprendizagens e Definição de Metas Anuais em LP, de Acordo Com o SEAMADocumento21 páginasSlide Vídeo Aula - Avaliação, Progressão Das Aprendizagens e Definição de Metas Anuais em LP, de Acordo Com o SEAMAGilviane CostaAinda não há avaliações

- BiossegurançaDocumento6 páginasBiossegurançaNagila CabralAinda não há avaliações

- Curso de Questões Da Banca FGV: Prof. Fernando PestanaDocumento35 páginasCurso de Questões Da Banca FGV: Prof. Fernando PestanaErica MarinhoAinda não há avaliações

- Brglb14ab1 PDFDocumento48 páginasBrglb14ab1 PDFRita limaAinda não há avaliações

- Resolução - Teoria Do Texto PoeticoDocumento4 páginasResolução - Teoria Do Texto PoeticoanaAinda não há avaliações

- Teste de Inteligência EmocionalDocumento20 páginasTeste de Inteligência EmocionalBruno De SouzaAinda não há avaliações

- UFCDs Mais RecentesDocumento6 páginasUFCDs Mais Recentesbetybrito7199Ainda não há avaliações

- AtividadeDidatica 03Documento2 páginasAtividadeDidatica 03Eduardo MonteiroAinda não há avaliações

- Equação e Inequação ModularDocumento5 páginasEquação e Inequação ModularSilvio PereiraAinda não há avaliações

- Ef09er33mg - o Que É ReligiãoDocumento1 páginaEf09er33mg - o Que É ReligiãoMaria AparecidaAinda não há avaliações

- BAAL - Ficha RegistoDocumento12 páginasBAAL - Ficha RegistoDiana VeronicaAinda não há avaliações

- SuzyDocumento20 páginasSuzyNhawas Ernesto100% (2)

- PORTARIA SPA - MAPA #171, DE 23 DE MAIO DE 2022 - PORTARIA SPA - MAPA #171, DE 23 DE MAIO DE 2022 - DOU - Imprensa NacionalDocumento7 páginasPORTARIA SPA - MAPA #171, DE 23 DE MAIO DE 2022 - PORTARIA SPA - MAPA #171, DE 23 DE MAIO DE 2022 - DOU - Imprensa NacionalAntonioCutrimAinda não há avaliações

- Identificação Do Aluno/A: Só Após o Pagamento Da Inscrição, Quando Aplicável, A Mesma Será ValidadaDocumento3 páginasIdentificação Do Aluno/A: Só Após o Pagamento Da Inscrição, Quando Aplicável, A Mesma Será ValidadaJoana DaniAinda não há avaliações

- 086 EditalADocumento4 páginas086 EditalAJahyrzinho Silva SilvaAinda não há avaliações

- Auxiliar de LimpezaDocumento3 páginasAuxiliar de LimpezaDener SouzaAinda não há avaliações

- Apostila 19 - Eletrodomésticos RefrigeradoresDocumento34 páginasApostila 19 - Eletrodomésticos Refrigeradoresandre maia100% (1)

- Biomas EjaDocumento2 páginasBiomas EjaRogério Castro AlvesAinda não há avaliações

- Relatório Final de Estágio Administração EAD - Passei DiretoDocumento7 páginasRelatório Final de Estágio Administração EAD - Passei DiretoFilipe LimaAinda não há avaliações

- Caderno1 AbreviadoDocumento215 páginasCaderno1 AbreviadoSilvanio Mineiro100% (1)

- Case 1 e Case 2Documento8 páginasCase 1 e Case 2Thiago RaydanAinda não há avaliações

- Teste 2 de SociologiaDocumento4 páginasTeste 2 de SociologiaGilberto RodriguesAinda não há avaliações